Halogenated Butyl Rubber Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433561 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Halogenated Butyl Rubber Market Size

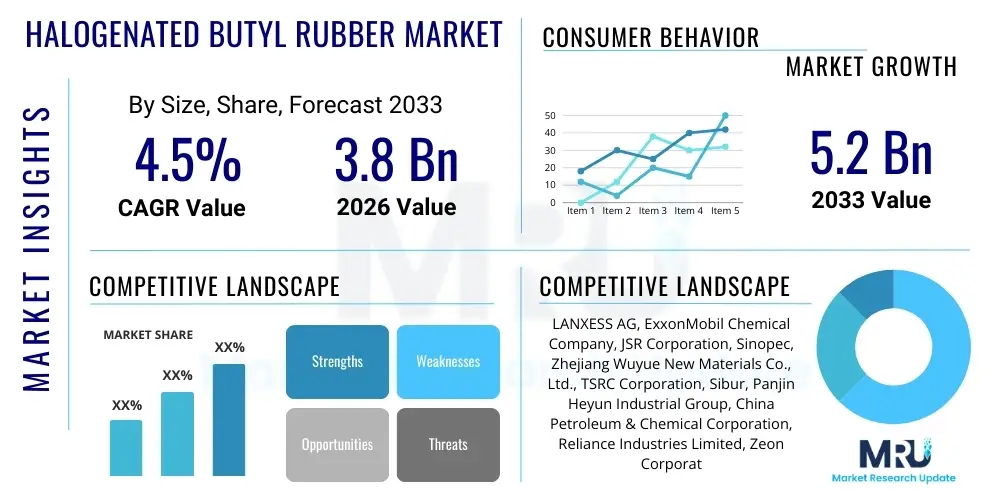

The Halogenated Butyl Rubber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at $3.8 Billion in 2026 and is projected to reach $5.2 Billion by the end of the forecast period in 2033.

Halogenated Butyl Rubber Market introduction

Halogenated Butyl Rubber (HIR), primarily encompassing Chlorinated Butyl Rubber (CIIR) and Brominated Butyl Rubber (BIIR), is a synthetic elastomer derived from the halogenation of Butyl Rubber (Isobutylene-Isoprene Rubber, IIR). This critical modification process introduces reactive halogen sites (chlorine or bromine) onto the polymer chain, which significantly enhances the material's curing capabilities, enabling co-vulcanization with general-purpose rubbers and improving overall performance attributes. These attributes include exceptional impermeability to gases, high resistance to heat, ozone, and weathering, and excellent dampening characteristics, making it indispensable in high-performance applications.

The primary and largest application area for Halogenated Butyl Rubber is the automotive sector, specifically in the manufacturing of tire inner liners. Its superior air retention properties are crucial for maintaining tire pressure, thereby improving fuel efficiency and safety, a factor heavily emphasized by global regulatory standards regarding vehicular emissions and performance. Beyond tires, HIR is vital in the healthcare industry, serving as the material of choice for pharmaceutical stoppers, vial seals, and syringe plungers due to its chemical inertness, low extractables profile, and seal integrity.

Market growth is predominantly driven by the surging global demand for high-performance and safety-critical components, particularly in the expanding automotive industry in Asia Pacific, coupled with increasingly stringent regulatory requirements regarding material quality in pharmaceutical packaging. Furthermore, the inherent benefits of HIR, such as dimensional stability and excellent flex-fatigue resistance, solidify its position as a premium material over traditional rubber alternatives, ensuring sustained demand across specialized industrial applications.

Halogenated Butyl Rubber Market Executive Summary

The Halogenated Butyl Rubber market is poised for steady expansion, fueled by robust demand from the tire industry, driven by the need for enhanced fuel efficiency in both internal combustion engine vehicles and Electric Vehicles (EVs), which also rely on low permeability tires. Key business trends involve significant investments by leading petrochemical companies in expanding production capacity, particularly for Brominated Butyl Rubber (BIIR) due to its superior processing characteristics and higher reactivity, making it preferable for high-speed curing in tire manufacturing. Additionally, there is an increasing focus on developing specialty grades tailored for specific medical applications, meeting the extremely high standards of regulatory bodies like the FDA and EMA concerning drug compatibility and integrity.

Regionally, the Asia Pacific (APAC) stands as the dominant market, simultaneously being the largest consumer and the fastest-growing region, primarily attributed to the massive scale of automotive production, especially in China, India, and Southeast Asia. North America and Europe maintain a mature but stable market, focusing heavily on premium and specialized applications, particularly high-end pharmaceutical closures and advanced industrial seals, driven by innovation and stringent environmental regulations favoring durable, long-lasting components. The geopolitical stability of raw material supply, specifically isobutylene and isoprene, remains a critical factor influencing regional production economics and pricing strategies.

Segmentation analysis highlights that Brominated Butyl Rubber (BIIR) dominates the market share due to its superior vulcanization speed and enhanced performance in tire inner liners. The tire and automotive application segment continues to hold the largest value share, anchoring the market's stability. However, the pharmaceutical closures segment is exhibiting the highest growth rate, reflecting the rapid expansion of global biopharma manufacturing and the increased focus on sterile and tamper-proof drug delivery systems. Innovation in processing technologies, such as developing halogenated butyl rubber with reduced nitrosamine formation potential, is also shaping segment trends, particularly within the medical grade market.

AI Impact Analysis on Halogenated Butyl Rubber Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Halogenated Butyl Rubber market often revolve around efficiency gains in manufacturing, optimization of polymerization processes, and enhanced quality control protocols. Common themes include how AI can reduce variability in halogenation reactions, predict material performance under extreme conditions (e.g., high heat in tires), and streamline supply chain logistics for essential raw materials like isobutylene. Users express expectations that AI-driven predictive maintenance will minimize costly downtime in large-scale polymerization plants, while advanced computer vision systems integrated into production lines will ensure defect-free output, especially for high-stakes products such as pharmaceutical stoppers, where zero defects are mandatory. The consensus suggests AI will primarily act as an optimization tool, enhancing capital efficiency rather than disrupting the fundamental chemistry or material science of HIR.

- AI-driven optimization of polymerization kinetics to ensure consistent molecular weight distribution and halogen content, reducing batch-to-batch variability.

- Implementation of Machine Learning (ML) models for predictive maintenance in complex reactors and processing equipment, enhancing operational uptime.

- Utilization of computer vision and deep learning algorithms for high-speed, automated quality inspection of finished rubber products (e.g., innerliners, medical seals).

- AI modeling for simulating material stress and fatigue performance, accelerating the development of next-generation high-durability halobutyl grades.

- Optimization of global supply chain and logistics, forecasting demand, and managing inventory for key precursors like isobutylene and halogens.

DRO & Impact Forces Of Halogenated Butyl Rubber Market

The Halogenated Butyl Rubber market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities. The core driver is the unrelenting global push for greater fuel efficiency in vehicles. As mandated by global emissions standards (e.g., CAFE standards in the US, Euro 6/7 in Europe), minimizing rolling resistance in tires is paramount, and the unparalleled air barrier properties of HIR inner liners directly contribute to this goal. This demand is further amplified by the rapid electrification of the automotive fleet, as EVs require highly reliable, low-permeability tires to maximize battery range. Simultaneously, the substantial growth in the global healthcare and pharmaceutical sector, especially for sterile injectable drug packaging, provides a high-value, recession-resistant application base for premium halobutyl grades.

However, the market faces significant restraints. Halogenated Butyl Rubber production is highly capital-intensive, requiring complex reaction processes and specialized infrastructure, which limits market entry for new players and concentrates production among a few global giants. Furthermore, the volatility in the prices of raw materials, particularly crude oil derivatives used to produce isobutylene and isoprene, poses a continuous challenge to profitability and stable pricing. Environmental concerns related to end-of-life tire management and the recyclability of halogenated elastomers also present potential regulatory hurdles in certain regions.

Opportunities for growth are abundant, centering on technological advancements and market diversification. The development of specialized, ultra-clean halobutyl grades specifically designed to prevent leachables or extractables in sensitive pharmaceutical formulations offers premium pricing potential. Another significant opportunity lies in expanding applications beyond tires and medical seals, into areas like high-temperature industrial hoses, protective membranes, and specialized adhesives and sealants for infrastructure projects. The industry is also exploring innovative cross-linking technologies to further enhance the material's mechanical properties without compromising its barrier characteristics, creating new tiers of performance.

Segmentation Analysis

The Halogenated Butyl Rubber market segmentation is fundamentally driven by the chemical composition, leading to distinct product performance profiles that cater to specific end-use requirements. The primary product segmentation differentiates between Brominated Butyl Rubber (BIIR) and Chlorinated Butyl Rubber (CIIR). BIIR typically holds a larger market share due to its higher reactivity, faster cure rates, and superior compatibility with other elastomers, making it the preferred choice for mass-produced tire inner liners and certain pharmaceutical applications requiring high-purity sealants. CIIR, while slightly less reactive, is valued for its specific characteristics in applications demanding higher stability and compatibility with certain chemical environments.

Application segmentation reveals that the tire industry is the undisputed dominant consumer, absorbing the majority of the global production volume. Within the tire segment, the shift towards larger, performance-oriented tires and the inherent requirements of EV tires ensure sustained high demand. However, the non-tire segments, including pharmaceutical closures, tank linings, protective clothing, and construction sealants, collectively represent a rapidly growing market, driven by the material's unique combination of chemical resistance, low permeability, and thermal stability. The demand profile across these segments is highly sensitive to regulatory changes—specifically, automotive safety standards and healthcare material certifications.

Geographically, production and consumption are highly concentrated. While manufacturing capacity is centralized in specific regions (often near major petrochemical hubs), consumption follows global automotive and pharmaceutical manufacturing trends. The increasing industrialization and automotive manufacturing base in Asia Pacific, particularly its shift towards producing export-quality, high-performance vehicles, dictates the global consumption patterns for both BIIR and CIIR grades.

- By Type:

- Brominated Butyl Rubber (BIIR)

- Chlorinated Butyl Rubber (CIIR)

- By Application:

- Tire Industry (Inner Liners, Sidewalls, Air Springs)

- Pharmaceutical Closures (Vial Stoppers, Syringe Plungers)

- Adhesives, Sealants & Waxes

- Protective Linings and Membranes (Chemical Tank Linings)

- Others (Hoses, Belts, Dampers)

- By End-Use Industry:

- Automotive and Transportation

- Healthcare and Pharmaceutical

- Building and Construction

- Consumer Goods

- Chemical and Industrial

Value Chain Analysis For Halogenated Butyl Rubber Market

The value chain for Halogenated Butyl Rubber begins with the upstream procurement and processing of petrochemical feedstock. The primary raw materials are isobutylene and a small amount of isoprene, which are derived from crude oil refining and cracking processes. This upstream segment is highly consolidated and susceptible to global oil price volatility, exerting significant pressure on the production costs of the core polymer, Butyl Rubber. Major chemical companies operating within this segment invest heavily in proprietary polymerization technologies, often utilizing specialized catalyst systems in a low-temperature cationic polymerization process to create the IIR precursor.

The core manufacturing stage involves the halogenation of the Butyl Rubber polymer using elemental bromine or chlorine. This specialized process is technically demanding and requires stringent control to ensure uniform halogen distribution, which is critical for the final product’s performance, reactivity, and stability. Producers in this stage must meet extremely high safety and environmental standards due to the handling of halogens. Successful differentiation at this stage relies on process efficiency, minimizing energy consumption, and achieving superior polymer consistency, which directly affects the downstream processing capabilities of clients.

The downstream distribution channels typically move the finished halobutyl bales from producers to highly specialized compounders, molders, and end-product manufacturers. Distribution is often global, utilizing specialized logistics due to the material's bulk nature. Direct distribution is common for large-volume tire manufacturers, while smaller, specialized end-users (like pharmaceutical closure producers) often rely on technical distributors who can provide localized support and smaller batch sizes. The final stage involves the conversion of the rubber into precision parts—such as injection-molded vial stoppers, compression-molded inner liners, or extruded seals—where quality control is paramount, especially when supplying the regulated automotive and healthcare industries.

Halogenated Butyl Rubber Market Potential Customers

The primary customer base for Halogenated Butyl Rubber is the global automotive industry, specifically major tire manufacturers who consume the vast majority of the produced material for inner liners and air retention components. These customers prioritize materials with exceptional gas impermeability, high-temperature resistance, and excellent adhesion to other tire compounds, seeking long-term supply contracts with stable pricing and consistent quality to maintain mass production volumes. The shift towards lightweighting and performance optimization in vehicles means tire makers are constantly seeking advanced halobutyl grades that offer even better dynamic performance and lower rolling resistance.

A rapidly growing segment of potential customers includes pharmaceutical and biopharmaceutical packaging companies. These manufacturers require ultra-clean, medical-grade halobutyl stoppers and seals for injectable drugs, vaccines, and biologics. These customers are driven by regulatory compliance (FDA, ISO standards), low extractables requirements, and the necessity for exceptional seal integrity to protect sensitive drug formulations. Price sensitivity is lower in this segment compared to the tire market, but the barrier to entry is high due to rigorous qualification and validation processes.

Other significant buyers include industrial rubber goods manufacturers specializing in protective equipment, hoses, and sealants for chemical processing environments. Customers in this category require halobutyl rubber for its superior chemical inertness and resistance to weathering and ozone. These products are often used in specialized applications such as tank linings, protective suits, and high-performance industrial belts, where failure of the material could lead to severe environmental or safety hazards, thus emphasizing durability and specialized resistance properties.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $3.8 Billion |

| Market Forecast in 2033 | $5.2 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LANXESS AG, ExxonMobil Chemical Company, JSR Corporation, Sinopec, Zhejiang Wuyue New Materials Co., Ltd., TSRC Corporation, Sibur, Panjin Heyun Industrial Group, China Petroleum & Chemical Corporation, Reliance Industries Limited, Zeon Corporation, Kumho Petrochemical Co., Ltd., Versalis S.p.A., Dow Chemical Company, Mitsui Chemicals Inc., LyondellBasell Industries, Formosa Plastics Corporation, LG Chem, Denka Company Limited, SK Global Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Halogenated Butyl Rubber Market Key Technology Landscape

The technological landscape of the Halogenated Butyl Rubber market is dominated by advancements in polymerization methods and subsequent halogenation techniques aimed at improving polymer uniformity, reducing energy consumption, and customizing material properties for specific high-value applications. A key ongoing development involves optimizing the continuous cationic polymerization process, which is necessary to produce the Butyl Rubber precursor, often conducted at extremely low temperatures (typically below -90°C). Innovations here focus on catalyst systems that enhance reaction efficiency and minimize environmental impact, ensuring the resulting polymer has a tightly controlled molecular weight distribution critical for consistent downstream processing.

In the halogenation stage, which transforms IIR into CIIR or BIIR, modern technology is concentrated on reactor design and mixing efficiency. Advanced reactive extrusion technologies are increasingly employed to ensure homogeneous incorporation of the halogen groups along the polymer chain, which is vital for achieving desired cure kinetics and physical properties. Manufacturers are also implementing real-time analytical tools, such as in-line spectroscopy, to monitor the degree of halogenation dynamically, ensuring product conformity and significantly reducing the likelihood of off-spec batches, a crucial factor given the strict quality requirements of the automotive and pharmaceutical sectors.

Furthermore, technology development is heavily focused on creating specialty grades with tailored functionalities. For the healthcare industry, this includes proprietary purification and finishing techniques designed to produce ultra-low extractables and leachables (E&L) halobutyl grades, minimizing the risk of drug contamination. For the automotive industry, research is centered on novel cross-linking systems that allow for faster curing cycles and enhanced synergy with silica fillers, resulting in lighter, more durable, and energy-efficient tire components. Intellectual property surrounding high-solids slurry polymerization and advanced reactor fouling minimization remains a significant competitive barrier.

Regional Highlights

The Asia Pacific (APAC) region constitutes the largest and most dynamic market for Halogenated Butyl Rubber, driven primarily by its position as the global hub for automotive manufacturing. Countries like China, India, and South Korea exhibit tremendous demand, fueled by expanding domestic vehicle ownership and large-scale tire production aimed at both internal consumption and export. Government policies supporting infrastructure development and a burgeoning middle class contribute to robust growth in the transportation sector. Furthermore, the region is rapidly expanding its pharmaceutical and healthcare manufacturing capabilities, increasing the local requirement for high-purity halobutyl stoppers and seals, underpinning APAC's continuous market leadership.

North America maintains a significant market share, characterized by high consumption of specialized, high-margin halobutyl grades. The market here is mature and emphasizes premium performance and regulatory compliance. Demand is stable, anchored by large domestic tire manufacturers focusing on high-performance and specialty off-road tires, and a substantial, highly regulated pharmaceutical industry that requires the highest specification elastomers for sterile packaging. Technological innovation, particularly in developing energy-efficient and durable elastomeric components for the rapidly expanding domestic EV market, is a key regional driver.

Europe represents a sophisticated market characterized by stringent environmental regulations and a strong focus on sustainable manufacturing practices. The implementation of strict regulations concerning vehicle emissions and tire labeling standards directly reinforces the demand for high-quality halobutyl rubber to improve tire performance and longevity. While the automotive production volume growth is slower compared to APAC, the high value of pharmaceutical manufacturing and the region's focus on advanced industrial sealants and protective equipment ensure steady consumption. The market here demands materials that comply with REACH regulations and contribute to the circular economy, driving research into bio-based or more sustainable synthetic rubber alternatives.

- Asia Pacific (APAC): Dominates consumption and manufacturing capacity, driven by high automotive production volumes in China and India, and expanding pharmaceutical packaging sector.

- North America: Mature market focused on premium specialty grades; high demand from the established automotive and highly regulated pharmaceutical industries, emphasizing EV component resilience.

- Europe: Characterized by stringent quality and environmental regulations (REACH), driving demand for high-performance elastomers for fuel-efficient tires and specialized medical applications.

- Latin America (LATAM): Emerging market showing steady growth due to increased infrastructure spending and developing domestic automotive manufacturing bases, particularly in Brazil and Mexico.

- Middle East and Africa (MEA): Growth is primarily linked to ongoing infrastructure projects, oil and gas sector demands for high-performance seals, and localized tire production facilities, driven by regional investment in petrochemical complexes.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Halogenated Butyl Rubber Market.- LANXESS AG

- ExxonMobil Chemical Company

- JSR Corporation

- Sinopec (China Petroleum & Chemical Corporation)

- Zhejiang Wuyue New Materials Co., Ltd.

- TSRC Corporation

- Sibur Holding

- Panjin Heyun Industrial Group

- Reliance Industries Limited

- Zeon Corporation

- Kumho Petrochemical Co., Ltd.

- Versalis S.p.A.

- Dow Chemical Company

- Mitsui Chemicals Inc.

- LyondellBasell Industries

- Formosa Plastics Corporation

- LG Chem

- Denka Company Limited

- SK Global Chemical Co., Ltd.

- Sumitomo Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Halogenated Butyl Rubber market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Halogenated Butyl Rubber?

The primary driver is the stringent global mandate for enhanced vehicle fuel efficiency. Halogenated Butyl Rubber (especially BIIR) is indispensable for manufacturing tire inner liners due to its exceptional air barrier properties, which maintain optimal tire pressure and significantly reduce rolling resistance and fuel consumption.

How do Brominated Butyl Rubber (BIIR) and Chlorinated Butyl Rubber (CIIR) differ in application?

BIIR is generally preferred over CIIR for high-volume tire production because it offers faster curing rates, better co-vulcanization compatibility with other tire compounds, and superior heat resistance. CIIR is often selected for specialized applications requiring specific chemical stability and compatibility.

Which end-use industry represents the fastest-growing application segment for halobutyl rubber?

The Pharmaceutical Closures segment (stoppers, seals, plungers) is the fastest-growing application. This growth is fueled by the expansion of global injectable drug and vaccine production, requiring ultra-clean, low-extractables halobutyl elastomers for drug integrity and patient safety.

What are the main constraints impacting the Halogenated Butyl Rubber market growth?

Major constraints include the high volatility of raw material costs, specifically petrochemical derivatives like isobutylene and isoprene. Additionally, the complex, capital-intensive nature of the polymerization and halogenation processes limits capacity expansion and market entry for new manufacturers.

Which geographical region dominates the consumption of Halogenated Butyl Rubber?

The Asia Pacific (APAC) region dominates the market consumption, driven by its massive scale of automotive manufacturing and tire production, particularly in economic powerhouses like China and India, alongside rapidly expanding healthcare sectors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager