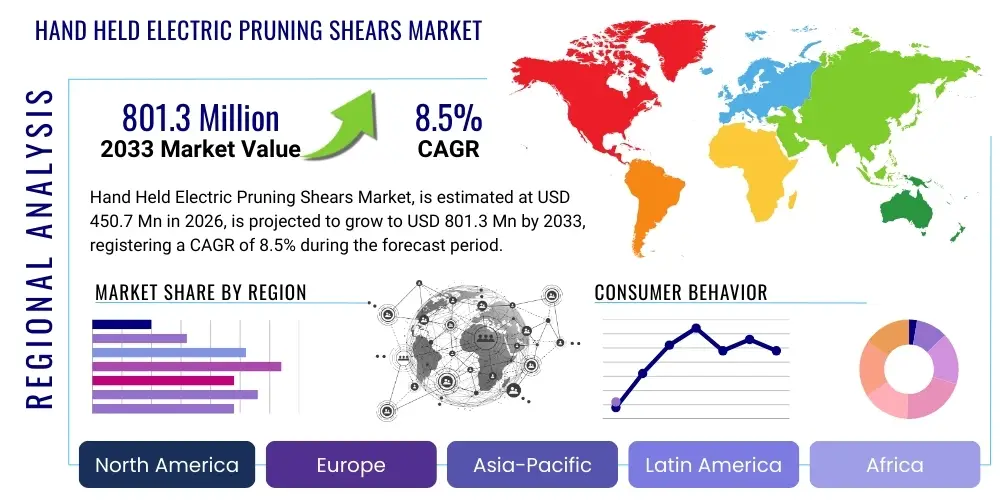

Hand Held Electric Pruning Shears Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439057 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Hand Held Electric Pruning Shears Market Size

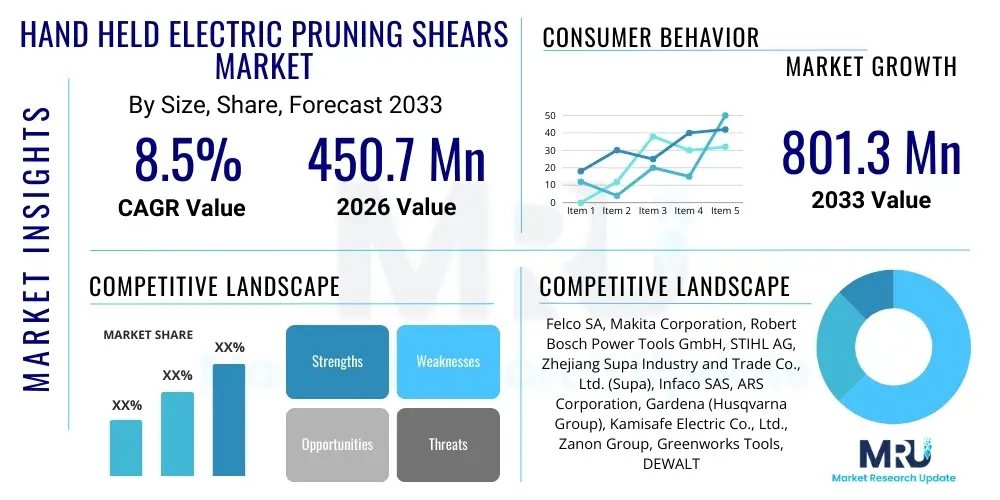

The Hand Held Electric Pruning Shears Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450.7 Million in 2026 and is projected to reach USD 801.3 Million by the end of the forecast period in 2033.

Hand Held Electric Pruning Shears Market introduction

The Hand Held Electric Pruning Shears Market encompasses advanced battery-powered tools designed for cutting and trimming branches, vines, and shrubs across various horticultural and agricultural settings. These devices replace traditional manual shears, offering significant advantages in terms of efficiency, reduced physical strain, and increased precision, thereby catering to the rising demands for ergonomic and productive farming practices. The core product is typically composed of a high-efficiency brushless motor, rechargeable lithium-ion battery packs, and specialized cutting blades, often featuring progressive cutting technology and safety locks to prevent accidents. These tools are witnessing rapid adoption driven by the increasing professionalization of agriculture, particularly in high-value crops like vineyards and orchards, where rapid, repetitive pruning tasks are essential for yield optimization and crop health management.

Major applications of electric pruning shears span commercial agriculture, professional landscaping, arboriculture, and intensive home gardening. The operational benefits, which include consistent cutting power, reduced operator fatigue during extended use, and enhanced speed compared to manual alternatives, are key market drivers. Furthermore, the global shift towards environmentally conscious tools favors electric models over pneumatic or gasoline-powered equipment due to zero direct emissions and lower noise pollution. The technological advancements focusing on extended battery life, lightweight design, and improved cutting capacity are continually enhancing the value proposition of these specialized hand tools, positioning them as essential equipment for modern horticultural management.

Hand Held Electric Pruning Shears Market Executive Summary

The Hand Held Electric Pruning Shears Market is characterized by robust growth, primarily fueled by significant business trends such as the integration of advanced battery technology and increasing automation in agricultural practices. Market players are heavily investing in research and development to enhance motor efficiency and introduce intelligent features like IoT connectivity for tracking usage and maintenance. A crucial segment trend involves the rapid adoption of cordless, high-voltage shears (e.g., 36V and above) by professional users in viticulture and intensive fruit cultivation, prioritizing durability and sustained power output over affordability. Conversely, the DIY and small-scale gardening segment drives demand for lightweight, lower-voltage models, emphasizing ease of use and ergonomic design. Competition is centered on product differentiation through battery longevity, blade quality, and comprehensive safety features, establishing distinct tiers of performance targeting diverse end-user requirements.

Regional trends indicate that mature markets, particularly North America and Europe, exhibit high penetration rates due to widespread labor shortages and well-established precision agriculture practices. Europe, with its vast vineyards and orchards, remains a pivotal consumer base, driving demand for specialized, high-performance tools compliant with stringent EU safety regulations. In contrast, the Asia Pacific (APAC) region is emerging as the fastest-growing market, driven by the mechanization of small and medium-sized farms in countries like China and India, facilitated by government subsidies supporting agricultural modernization. Manufacturers are adapting their distribution strategies, leveraging e-commerce platforms and specialized agricultural equipment dealerships to cater to both professional and consumer segments globally, reinforcing the market’s resilience and expansion potential across diverse geographical landscapes.

AI Impact Analysis on Hand Held Electric Pruning Shears Market

User inquiries regarding AI's influence on the Hand Held Electric Pruning Shears Market primarily revolve around optimizing operational efficiency, enhancing safety, and integrating these tools within broader smart farming ecosystems. Users frequently ask if AI can predict the optimal cutting force required for different wood densities, thus saving battery power, and if machine learning algorithms can analyze usage patterns to alert users about impending mechanical failures, transforming reactive maintenance into predictive maintenance. Key concerns also address the potential integration of pruning shears into semi-autonomous or fully robotic harvesting/pruning systems, where AI-driven vision systems guide precision cutting, minimizing human error and maximizing throughput. The overarching expectation is that AI will move these tools beyond simple mechanical devices into intelligent, networked components of modern agriculture.

The direct application of AI in handheld tools is focusing on real-time data processing and decision support. Embedded microcontrollers can use machine learning models trained on millions of cutting cycles to dynamically adjust motor torque based on the immediate feedback from the blade, optimizing both battery consumption and blade sharpness longevity. Furthermore, AI algorithms integrated into accompanying applications can analyze pruning data (e.g., location, time spent, number of cuts) to provide agronomical insights to farmers, helping them standardize pruning techniques across large labor forces and ensuring consistency, which directly impacts future yields. This shift ensures the shears are not just executing tasks but are actively contributing to data capture and intelligent operational feedback loops, significantly improving overall field management efficiency and reducing the cost per cut over the lifecycle of the tool.

- AI-Powered Predictive Maintenance: Algorithms analyze motor vibration, current draw, and temperature data to forecast potential component failure, minimizing downtime.

- Optimized Energy Management: Machine learning adjusts cutting speed and force based on real-time resistance analysis, extending battery life per charge cycle.

- Safety Enhancement: AI recognition systems, potentially integrated with proximity sensors, can identify proximity to non-target objects (e.g., hands) and instantly halt operation.

- Precision Pruning Guidance: Integration with external AI vision systems (via IoT) for autonomous or semi-autonomous pruning robots utilizing the shears as end-effectors.

- Data Logging and Agronomic Insights: AI processes aggregated cutting data to generate reports on labor productivity, crop health patterns, and optimal pruning density.

DRO & Impact Forces Of Hand Held Electric Pruning Shears Market

The market dynamics are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), significantly influencing adoption rates and technological trajectory. A primary driver is the accelerating trend of agricultural labor shortages worldwide, necessitating mechanized solutions to maintain productivity. Simultaneously, advancements in lithium-ion battery technology, offering higher energy density and faster charging cycles, have made electric tools practical for professional, all-day use. However, the market faces significant restraints, including the high initial capital investment required for professional-grade electric shears compared to manual alternatives, which can deter adoption among budget-conscious small farmers. The perceived reliability and lifespan of complex electronic components versus simple mechanical tools also pose a psychological barrier for some traditional users, impacting market penetration in less developed agricultural sectors.

Opportunities are abundant, particularly in integrating these tools into the burgeoning smart agriculture and IoT ecosystem, allowing for real-time monitoring and data collection. The expansion into niche markets, such as professional arborist work and municipal park maintenance, also presents avenues for specialized product development. The impact forces are predominantly technological, driving innovation in brushless motor design and ergonomic safety features (such as anti-rebound systems). Regulatory pressures promoting workplace safety and reducing manual strain, especially in developed economies, act as external forces accelerating the replacement cycle of older, less efficient equipment. The market's resilience will depend heavily on manufacturers’ ability to reduce unit costs through scale while continuously enhancing battery performance and tool longevity.

Segmentation Analysis

The Hand Held Electric Pruning Shears Market is comprehensively segmented based on various technical specifications and end-user applications to address the diverse needs of the global horticultural and agricultural industries. Key segmentation categories include the power source (typically defined by voltage), the end-user group, and the specific application area. This categorization allows manufacturers to tailor product features, such as maximum cutting diameter, tool weight, and battery capacity, to specific market requirements, ensuring optimal performance whether the shears are used in dense orchards requiring heavy-duty power or in delicate vineyards demanding high precision and lightweight design. Analyzing these segments is crucial for market stakeholders to identify high-growth niches and prioritize R&D efforts.

Segmentation by battery voltage, for example, often divides the market into 7.2V–12V (Consumer/DIY), 16V–24V (Prosumer/Landscaping), and 30V–48V+ (Professional/Heavy Agriculture). The growth rate of the high-voltage segment is significantly faster due to the increasing demand for tools capable of sustained, high-torque operation over long working hours without frequent recharging. Furthermore, application-based segmentation clearly delineates the specific design requirements, where vineyard shears prioritize narrow blades and speed, while orchard shears focus on robust capacity and shear strength to handle thicker wood. Understanding these distinct segments is vital for developing targeted marketing strategies and efficient distribution channels, ensuring product alignment with user expectations and operational demands across different agricultural environments.

- By Voltage/Power Source:

- Low Voltage (7.2V – 12V)

- Medium Voltage (16V – 24V)

- High Voltage (30V and Above)

- By Application:

- Viticulture (Vineyards)

- Orchards and Fruit Cultivation

- Arboriculture and Forestry Management

- Landscaping and Municipal Gardening

- Home Gardening (DIY)

- By End User:

- Professional Farmers and Growers (Commercial Agriculture)

- Landscaping and Gardening Service Providers

- Horticultural Research Institutions

- Individual Consumers (Hobbyists)

- By Motor Type:

- Brushed Motors

- Brushless Motors

Value Chain Analysis For Hand Held Electric Pruning Shears Market

The value chain for Hand Held Electric Pruning Shears begins with upstream suppliers, primarily providing specialized raw materials and critical components. This phase includes sourcing high-grade steel alloys for blades (requiring exceptional durability and edge retention), lithium-ion battery cells (a high-cost component dominated by specialized manufacturers), and precision mechanical components like gears, transmission systems, and brushless motors. Manufacturers rely heavily on established component suppliers to ensure quality and consistency, particularly for proprietary technologies related to motor control electronics and battery management systems (BMS). Efficient procurement and stringent quality control at the upstream stage directly influence the final product’s performance, reliability, and cost structure.

The midstream phase involves the design, assembly, and testing of the final product. Key activities here include ergonomic design optimization, integration of safety mechanisms, and rigorous performance testing under simulated field conditions. Manufacturers often focus on minimizing tool weight and maximizing balance, which are critical factors for user comfort during long work periods. The downstream element involves the distribution channels, which are segmented into direct sales, specialized agricultural machinery dealers, and mass-market retail/e-commerce platforms. Professional users typically prefer purchasing through specialized dealers who offer maintenance services, warranty support, and professional advice. Conversely, the DIY segment is heavily reliant on indirect channels, such as large home improvement stores and online marketplaces, valuing accessibility and competitive pricing.

The efficiency of the distribution network is crucial, especially for ensuring timely delivery of replacement parts and technical support. Direct distribution models are often utilized for large commercial clients or institutional buyers seeking customized solutions or bulk orders, allowing manufacturers greater control over branding and pricing. The growing dominance of e-commerce has streamlined the indirect distribution channel, enabling broader geographical reach and providing detailed product comparisons and user reviews, which significantly impact purchasing decisions for both professional and consumer segments. Effective management of the entire value chain, from component sourcing to post-sale support, dictates market share and long-term customer loyalty in this specialized tool sector.

Hand Held Electric Pruning Shears Market Potential Customers

The primary customer base for Hand Held Electric Pruning Shears consists of professional agriculturalists and commercial landscaping service providers who require durable, high-performance tools for sustained daily operation. Within commercial agriculture, key buyers include owners and managers of vineyards, orchards (apple, citrus, cherry), and intensive horticulture operations, where pruning is a critical, labor-intensive annual task. These professional users prioritize attributes such as high cutting capacity (up to 45mm diameter), extended battery run-time (often requiring backpack battery systems for 8+ hours of continuous use), and tools backed by extensive warranties and quick maintenance services, justifying the higher purchase price for long-term operational savings.

A secondary, rapidly expanding customer segment is composed of independent landscaping contractors, grounds maintenance staff for corporate campuses and public parks, and arborists. These users require versatile tools that balance power with maneuverability and lower noise output for urban environments. Their demand often focuses on mid-to-high voltage models that offer flexibility across various plant materials. The third significant segment encompasses hobbyist gardeners and homeowners who seek ergonomic efficiency for lighter pruning tasks around residential properties. This consumer segment, which drives significant volume, values ease of use, lighter weight, and competitive pricing, often opting for lower-voltage, integrated battery models. Manufacturers must therefore differentiate their offerings across these tiers, recognizing that professional buyers are driven by return on investment and productivity metrics, while consumers prioritize convenience and simplicity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.7 Million |

| Market Forecast in 2033 | USD 801.3 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Felco SA, Makita Corporation, Robert Bosch Power Tools GmbH, STIHL AG, Zhejiang Supa Industry and Trade Co., Ltd. (Supa), Infaco SAS, ARS Corporation, Gardena (Husqvarna Group), Kamisafe Electric Co., Ltd., Zanon Group, Greenworks Tools, DEWALT (Stanley Black & Decker), RYOBI (Techtronic Industries Co. Ltd.), EGO Power+, Pellenc S.A.S., KUKER S.L., T-Mech, Vesco S.r.l., Volpi Originale. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hand Held Electric Pruning Shears Market Key Technology Landscape

The technological landscape of the Hand Held Electric Pruning Shears Market is defined by continuous innovation focused on enhancing power, durability, safety, and connectivity. The most critical technological advancement is the widespread adoption of brushless DC (BLDC) motors, which offer significantly higher efficiency, longer lifespan, and reduced maintenance compared to traditional brushed motors. BLDC motors allow for precise electronic control of torque and speed, directly translating into optimized battery utilization and superior cutting performance, especially in heavy-duty applications. Furthermore, battery technology, specifically high-density Lithium-Ion cells (e.g., 18650 or 21700 formats), coupled with sophisticated Battery Management Systems (BMS), ensures safe operation, rapid charging capabilities, and maximization of cycle life, addressing the critical requirement for all-day operational power in commercial settings.

Safety technology represents another major area of innovation. Modern shears increasingly incorporate progressive cutting mechanisms, where the blade closing speed is proportional to the trigger pressure, providing the user with fine control. Advanced anti-cut protection systems, utilizing complex algorithms and sensors, immediately retract the blade upon detecting contact with non-organic materials or resistance levels inconsistent with wood cutting, significantly reducing the risk of accidental injury. Ergonomics and material science also play a key role, with manufacturers utilizing lightweight, high-strength composites and materials to reduce the overall weight and vibration, minimizing user fatigue during repetitive tasks, which is paramount for professional users performing thousands of cuts daily.

The emerging trend involves the integration of smart features and IoT connectivity. Certain premium models now incorporate Bluetooth or Wi-Fi connectivity, allowing the shears to interface with smartphone applications. These applications track usage statistics, monitor battery health, facilitate diagnostic checks, and even allow for firmware updates. This data-centric approach supports precision agriculture by providing granular insights into pruning intensity and labor productivity across different sections of a vineyard or orchard. This technological confluence of efficient motors, smart batteries, advanced safety features, and connectivity is transforming electric pruning shears from simple tools into sophisticated, data-generating instruments integral to modern horticultural management systems.

Regional Highlights

The market for Hand Held Electric Pruning Shears displays significant regional variation in adoption rates, application focus, and growth drivers, heavily influenced by local agricultural practices and economic maturity. North America, characterized by its focus on high-efficiency, large-scale commercial farming and professional landscaping services, represents a mature market demanding high-voltage, durable, and technologically advanced shears. The high cost of agricultural labor in the US and Canada strongly favors mechanization, leading to rapid replacement of manual tools with high-end electric models. The demand here is driven by the need for minimizing downtime and maximizing productivity across large tracts of high-value crops like table grapes and nut orchards.

Europe holds a commanding position, particularly due to its deep-rooted viticulture industry spanning countries like France, Italy, and Spain. These regions require specialized, high-precision tools for vine pruning, where the health and structure of the plant are paramount. Stringent worker safety standards within the EU further drive the adoption of shears featuring advanced electronic safety systems and ergonomic designs. European manufacturers, often pioneers in this field, maintain a strong competitive edge by focusing on quality, specialized accessories, and long-term service support. The European market exhibits stability and continuous incremental growth, emphasizing quality and sustainability.

The Asia Pacific (APAC) region is projected to be the fastest-growing market, primarily fueled by the accelerating modernization of agriculture in countries such as China, India, and Australia. While Australia and New Zealand align with the North American trend of large-scale commercial farming, populous nations like China and India are transitioning millions of smallholder farms from manual to mechanized operations, often supported by government initiatives and subsidies. This segment drives high volume, often demanding reliable, mid-range priced products. Growth is spurred by increased disposable income among farmers and rising awareness of the ergonomic benefits, signaling a massive untapped potential for both manufacturers and distributors in the coming decade, despite challenges related to diverse climatic conditions and fragmented distribution networks.

- North America: High demand for premium, heavy-duty shears (40V+), driven by high labor costs and extensive commercial orchards (nuts, fruits). Focus on IoT integration for fleet management.

- Europe: Dominated by specialized viticulture and professional arboriculture sectors. Strong emphasis on ergonomic design, advanced safety certification, and adherence to specific EU regulations.

- Asia Pacific (APAC): Highest projected growth, driven by agricultural modernization and mechanization in China and India. High volume demand for affordable and mid-range electric tools for small and medium farms.

- Latin America (LATAM): Emerging market characterized by strong growth potential in coffee and tropical fruit cultivation. Adoption sensitive to initial investment costs; preference for tools with robust local dealer support.

- Middle East & Africa (MEA): Niche market focused on specific high-value crops (e.g., date palms, olive groves). Growth is dependent on government investments in modern irrigation and farming infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hand Held Electric Pruning Shears Market.- Felco SA

- Makita Corporation

- Robert Bosch Power Tools GmbH

- STIHL AG

- Zhejiang Supa Industry and Trade Co., Ltd. (Supa)

- Infaco SAS

- ARS Corporation

- Gardena (Husqvarna Group)

- Kamisafe Electric Co., Ltd.

- Zanon Group

- Greenworks Tools

- DEWALT (Stanley Black & Decker)

- RYOBI (Techtronic Industries Co. Ltd.)

- EGO Power+

- Pellenc S.A.S.

- KUKER S.L.

- Vesco S.r.l.

- Volpi Originale

- LISAM Systems

- Echo Incorporated

Frequently Asked Questions

Analyze common user questions about the Hand Held Electric Pruning Shears market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the electric pruning shears market?

The primary factor driving market growth is the global shortage of skilled agricultural labor combined with the imperative for increasing operational efficiency in high-value crop cultivation, such as vineyards and orchards. Electric shears significantly reduce manual fatigue, increase cutting speed, and lower the long-term operational costs compared to traditional labor-intensive pruning methods, offering a strong return on investment (ROI) for professional users.

How long do the batteries of professional electric pruning shears typically last?

Professional-grade electric pruning shears, particularly those utilizing high-capacity Lithium-Ion backpack batteries (36V to 48V+), are designed to provide between 8 to 12 hours of continuous operation on a single charge. Tool run-time varies based on the cutting diameter, wood density, and frequency of cuts; manufacturers prioritize extended battery life to meet the demands of a full commercial workday.

What are the key safety features to look for in modern electric pruning shears?

Key safety features include progressive cutting control (blade closure speed controlled by trigger pressure), integrated electronic anti-cut or anti-kickback systems that immediately stop the blade upon contact with soft resistance, and mandatory safety switches requiring dual action to prevent accidental activation. These features are critical for protecting the operator during intensive use.

Is the use of brushless motors important for these tools?

Yes, the use of brushless DC (BLDC) motors is highly important. Brushless technology offers superior benefits, including higher energy efficiency (extending battery life), significantly longer motor lifespan due to reduced wear and tear (no carbon brushes), higher torque output, and quieter operation, making them the standard choice for all premium and professional electric pruning shears.

Which regional market holds the strongest demand for high-end professional shears?

Europe, particularly Western and Southern Europe (France, Italy, Spain), exhibits the strongest demand for high-end, specialized professional shears. This is driven by the region's massive, quality-focused viticulture sector and strict ergonomic and safety regulations that necessitate investments in premium tools offering precision, durability, and certified safety mechanisms.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager