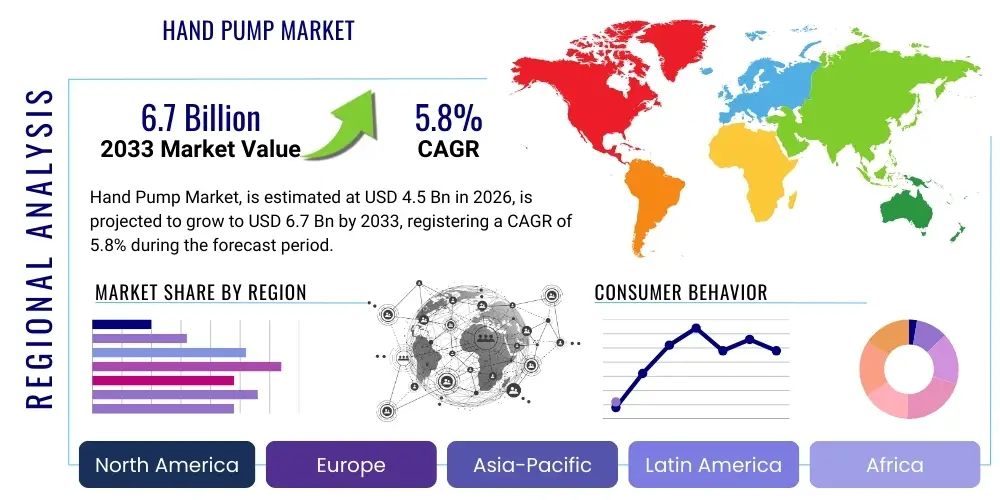

Hand Pump Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436164 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Hand Pump Market Size

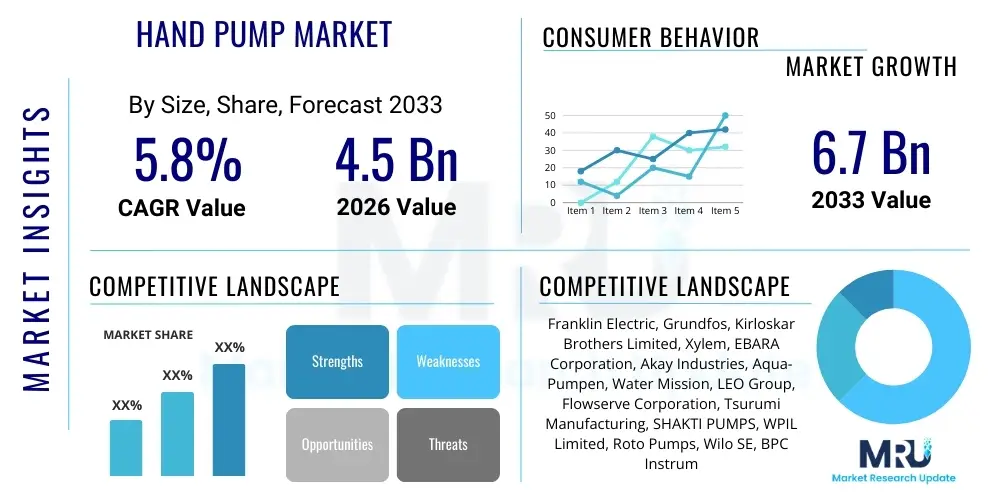

The Hand Pump Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by the persistent demand for reliable, low-cost, and energy-independent water extraction solutions, particularly in developing economies where electrification remains challenging.

The valuation reflects increased investments in rural infrastructure and sanitation initiatives globally. Furthermore, the market benefits from the necessity of these devices in emergency preparedness and disaster relief efforts, ensuring a baseline demand irrespective of economic cycles. Adoption rates are stabilizing in industrial and agricultural sectors where hand pumps serve as critical backups or specialized low-flow tools, driving the modernization and durability improvements across various product categories.

Hand Pump Market introduction

The Hand Pump Market encompasses a wide range of manually operated devices designed for moving fluids, predominantly water, from a low elevation to a higher one. These devices operate on mechanical principles, utilizing human power to create a vacuum or pressure difference, classifying them generally into categories such as reciprocating (piston) pumps, diaphragm pumps, and specialized borehole pumps (e.g., India Mark II, Afridev). Historically, hand pumps have been indispensable tools for rural water supply, agriculture, and sanitation, offering a sustainable and accessible solution in areas lacking motorized infrastructure or reliable electricity grids.

Major applications of hand pumps span critical sectors including municipal water provision in remote communities, irrigation for small-scale farming, industrial fluid transfer (like chemical dosing or oil drum emptying), and residential use for shallow well water access. Their inherent simplicity in design translates to minimal maintenance requirements, zero operational electricity costs, and robust reliability, making them a preferred choice for developmental projects focused on water security and public health improvement.

The primary driving factors sustaining market expansion include the global push toward achieving Sustainable Development Goal (SDG) 6 (Clean Water and Sanitation), increasing population growth in water-stressed regions, and the escalating demand for resilient, climate-independent infrastructure. Although competition from electric and solar pumps exists, the low initial capital outlay and the ease of local repair associated with traditional hand pumps secure their enduring relevance, especially across sub-Saharan Africa and South Asia.

Hand Pump Market Executive Summary

The Hand Pump Market is currently characterized by a robust focus on material science innovation aimed at enhancing longevity and corrosion resistance, particularly through the increased use of engineered plastics and composite materials replacing traditional cast iron components. Key business trends indicate a consolidation among manufacturers focusing on standardized, internationally recognized designs (such as those endorsed by UNICEF or the World Bank) to streamline global distribution via humanitarian organizations and governmental procurement tenders. Furthermore, manufacturers are increasingly integrating modular designs that facilitate easier field maintenance and reduce downtime, directly addressing user concerns regarding long-term operational viability.

Regionally, the Asia Pacific (APAC) continues to dominate the market share, driven by extensive agricultural needs and large-scale government initiatives in countries like India and China to provide potable water to rural populations. However, Sub-Saharan Africa is projected to register the fastest growth, fueled by rapid urbanization coupled with significant foreign aid and developmental funding directed towards water, sanitation, and hygiene (WASH) programs. North America and Europe maintain niche segments focused primarily on industrial barrel pumps, emergency water preparedness kits, and specific high-lift agricultural applications where manual operation is mandated or preferred.

Segment trends reveal that the Reciprocating Pump type holds the largest revenue share due to its established efficacy in deep well applications, while the Diaphragm Pump segment is experiencing significant growth owing to its superior handling capabilities for viscous fluids and effectiveness in lower-lift, less demanding environments. The segmentation by application highlights that the community water supply category remains the primary end-user, but the industrial sector is exhibiting increased adoption of specialized hand pumps for precise chemical handling and safety compliance, demonstrating market diversification beyond purely developmental needs.

AI Impact Analysis on Hand Pump Market

Common user questions regarding AI's influence on the Hand Pump Market typically revolve around whether such a low-tech, manually operated product can benefit from advanced computational capabilities, specifically questioning AI's role in supply chain efficiency, predictive maintenance for large installed bases, and optimizing pump design parameters. Users express concerns about the cost-benefit ratio of integrating smart components into traditionally inexpensive mechanical devices. Key themes emerging from this analysis confirm that while AI does not directly operate the pump, it plays a vital, indirect role in enhancing the lifecycle and service delivery model. AI algorithms are being leveraged to analyze usage patterns derived from remotely monitored pilots (often using integrated IoT sensors in smart monitoring solutions), predicting component failure rates, optimizing the logistics of spare parts distribution in remote areas, and dynamically adjusting manufacturing schedules based on forecasted regional needs, thereby reducing the total cost of ownership and improving sustainability outcomes for large-scale deployments.

- AI optimizes global logistics networks, ensuring timely delivery of spare parts and components to remote installation sites, minimizing inventory holding costs.

- Predictive analytics models utilize historic failure data and environmental inputs (water quality, usage frequency) to forecast potential mechanical failures in community pumps, enabling proactive maintenance scheduling.

- Machine learning algorithms inform ergonomic design improvements by analyzing user interaction data, enhancing efficiency and reducing the physical effort required for operation.

- AI-driven demand forecasting improves manufacturing precision, aligning production volumes with projected governmental and non-governmental organization (NGO) tender requirements, thereby mitigating overstocking or shortages.

- Computer vision systems accelerate quality control on assembly lines, rapidly identifying defects in molded plastic or cast metal components, ensuring higher product reliability before deployment.

DRO & Impact Forces Of Hand Pump Market

The Hand Pump Market dynamics are fundamentally shaped by a balanced interplay of drivers promoting growth, restraints limiting broader adoption, and opportunities paving the way for future innovations, all filtered through significant internal and external impact forces. A primary driver is the widespread lack of access to grid electricity in rural and underdeveloped regions, making manual pumping the only reliable, off-grid solution. Simultaneously, global water scarcity issues, exacerbated by climate change, necessitate diversified and resilient water access methods, positioning hand pumps as essential infrastructure. However, the market faces significant restraint from the proliferation of low-cost, subsidized solar-powered electric pumps, which offer higher volume output with reduced labor, posing a direct threat to high-volume hand pump sales in specific agricultural segments. Furthermore, the lack of universal standardization across different pump models often complicates the supply chain and local repair infrastructure, acting as a frictional force slowing mass deployment efficiency.

Opportunities for market expansion are centered on the integration of hand pumps with modern technologies, such as incorporating simplified water quality testing mechanisms and basic IoT monitoring sensors that track usage and water table levels, providing valuable data for resource management without compromising the manual core functionality. Another significant opportunity lies in specialized applications, including disaster relief operations where rapid deployment and operational simplicity are paramount, and in industrial settings requiring intrinsically safe, non-electric methods for fluid transfer. The market benefits substantially from external impact forces, particularly robust funding from international aid bodies (e.g., WHO, UNICEF) and national governments dedicated to achieving universal water access goals.

The overall impact forces influencing the market are high, driven by demographic pressures and climate resilience demands. Political initiatives prioritizing public health infrastructure and sanitation projects globally provide a stable, long-term demand foundation. Economic forces dictate the need for low-maintenance, cost-effective solutions, favoring the hand pump's capital expenditure profile. The primary challenge remains the technological impact force exerted by rapid advancements in decentralized solar power, compelling traditional hand pump manufacturers to pivot toward extreme durability and superior efficiency to maintain competitive advantage in the deep well segment.

Segmentation Analysis

The Hand Pump Market segmentation is critical for understanding varied demands across different geographical and application landscapes. The market is primarily dissected based on the mechanism type (Reciprocating, Diaphragm, Screw), the application category (Community Water Supply, Agriculture, Industrial), and the construction material used (Cast Iron, Stainless Steel, Plastics/Composites). This multifaceted segmentation allows stakeholders, including manufacturers, NGOs, and governmental procurement agencies, to accurately target products designed for specific lift requirements, fluid compatibility, longevity expectations, and budgetary constraints. The inherent simplicity of the technology dictates that material science and structural design optimizations are the key differentiators within these segments, focusing heavily on reducing friction losses and preventing corrosion to maximize operational life in harsh environments.

- By Mechanism Type:

- Reciprocating Pumps (Piston Pumps)

- Diaphragm Pumps

- Screw Pumps

- Bucket Pumps

- By Construction Material:

- Cast Iron

- Stainless Steel

- Plastics and Composites (e.g., PVC, HDPE)

- By Application:

- Community Water Supply (Potable Water Extraction)

- Agriculture and Irrigation

- Industrial (Barrel and Container Transfer, Chemical Dosing)

- Residential (Shallow Wells)

- By End-Use Depth:

- Shallow Well Hand Pumps (Surface to 7 meters)

- Deep Well Hand Pumps (7 meters and deeper)

Value Chain Analysis For Hand Pump Market

The value chain for the Hand Pump Market begins upstream with the procurement of critical raw materials, primarily focusing on metal foundries for cast iron and stainless steel components (cylinder, pump head, handle) and chemical suppliers for high-density polymers and engineered plastics used in seals, plungers, and piping. This upstream segment is highly sensitive to fluctuations in global commodity prices, particularly iron ore and plastic resin costs. Quality control at this stage, particularly ensuring materials meet anti-corrosion and tensile strength specifications, is vital as these factors directly dictate the pump's operational lifespan in adverse conditions, which is a major concern for end-users.

The manufacturing stage involves specialized processes like casting, molding, machining, and assembly. Manufacturers often operate highly automated facilities for components but require skilled labor for final assembly and crucial testing, especially for deep well models requiring precise component alignment. Downstream activities are dominated by complex distribution networks tailored to humanitarian needs. The distribution channel is bifurcated: direct distribution often involves large government tenders or direct procurement by international NGOs (like Oxfam or UNICEF) that purchase thousands of units for specific long-term deployment projects. Indirect distribution relies on regional distributors, local hardware stores, and specialized agricultural suppliers serving decentralized or retail customers.

A key characteristic of this value chain is the emphasis on after-market support. Since hand pumps are often deployed in remote areas, the availability of spare parts and local maintenance training is critical for market success and acceptance. Companies that establish robust local service partnerships and ensure accessibility to modular replacement kits gain a significant competitive advantage, transforming the product from a one-time sale into a long-term service relationship centered on sustainability and local empowerment.

Hand Pump Market Potential Customers

Potential customers for the Hand Pump Market span a diverse range of entities, driven largely by necessity, regulatory compliance, and economic constraints. The most substantial customer segment comprises government bodies and national water ministries in developing nations, procuring vast quantities of pumps through tenders to fulfill public mandates related to rural water supply and sanitation programs. These customers prioritize durability, adherence to national or international quality standards (e.g., BIS or international standards for VLOM – Village Level Operation and Maintenance), and low total lifecycle costs, often favoring robust deep well models like the India Mark III.

Another crucial customer segment includes international and local Non-Governmental Organizations (NGOs) and humanitarian aid agencies. These organizations purchase pumps for rapid disaster response, long-term refugee settlements, and community development projects. Their procurement decisions are heavily influenced by ease of installation, portability, rapid deployment capability, and the ability of the pump to be maintained using locally available tools and skills. This focus often drives demand for pumps built with high-impact plastic components that resist contamination and simplify transport logistics.

Furthermore, the agricultural and industrial sectors constitute specialized customer bases. Farmers, especially those engaged in small-scale, subsistence farming, utilize shallow well and irrigation hand pumps to manage water resources independent of costly electrical infrastructure. In the industrial sector, potential customers include chemical plants, manufacturing facilities, and storage depots that require hand-operated barrel pumps for safely transferring hazardous or non-hazardous chemicals, oils, and solvents, where regulatory requirements often mandate non-electric pumping for explosion safety or chemical segregation purposes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Franklin Electric, Grundfos, Kirloskar Brothers Limited, Xylem, EBARA Corporation, Akay Industries, Aqua-Pumpen, Water Mission, LEO Group, Flowserve Corporation, Tsurumi Manufacturing, SHAKTI PUMPS, WPIL Limited, Roto Pumps, Wilo SE, BPC Instruments, A.P. Industries, V-Guard Industries, Usha International, National Pump Company. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hand Pump Market Key Technology Landscape

The core technology landscape of the Hand Pump Market, while fundamentally mechanical, is evolving primarily through advancements in material science and engineering design aimed at longevity and efficiency. A crucial technological focus is on developing advanced composite plastics, such as high-density polyethylene (HDPE) and PVC derivatives, which offer superior resistance to corrosion caused by aggressive groundwater chemistry, a primary cause of failure in traditional metal pumps. These new materials are being used extensively for riser pipes, plungers, and pump heads, significantly extending the mean time between failures (MTBF) and reducing reliance on heavy, rust-prone cast iron components. Furthermore, the use of specialized, self-lubricating polymer bearings and sealing technologies minimizes frictional losses, reducing the physical effort required by the user, thereby enhancing the hydraulic efficiency of the pump system, particularly in deep well installations.

A second major technological trend involves the integration of monitoring and data collection features, moving the market toward the "Smart Hand Pump" concept. Although manually operated, certain models are now being equipped with simplified Internet of Things (IoT) devices, often powered by small, long-life batteries or low-power solar cells. These sensors track critical performance indicators such as stroke frequency, daily water yield, and potential water table drawdown. This remote monitoring capability is transformative for large governmental and NGO projects, providing real-time data crucial for water resource management, identifying maintenance needs proactively, and verifying pump functionality and usage rates in remote locations without requiring physical inspection.

Ergonomics and modular design constitute a third critical area of technological improvement. Modern hand pumps are engineered using computational fluid dynamics (CFD) and structural analysis to optimize the leverage ratio of the handle mechanism, ensuring maximal water output relative to user effort, making them accessible to a wider demographic, including women and children. The standardization of components across product lines facilitates interchangeability, which is vital for Village Level Operation and Maintenance (VLOM) models. This focus on simplifying field repair, utilizing standardized tools, and minimizing the number of specialized components represents a key technological advancement in operational sustainability.

Regional Highlights

The Hand Pump Market exhibits pronounced regional variances, driven by differing levels of infrastructure development, governmental water policies, and climate conditions, making regional analysis pivotal for market strategy.

- Asia Pacific (APAC): APAC is the global stronghold for the hand pump market, primarily due to the vast rural populations in India, Bangladesh, and Indonesia. Market demand is dominated by the requirement for deep well systems (like the India Mark II and III) used for both community potable water and extensive localized irrigation. Government subsidies and large-scale public health schemes focusing on rural water security are the primary market drivers. The challenge in APAC lies in managing the high arsenic and fluoride contamination in certain groundwater basins, necessitating pumps with robust internal materials and often requiring ancillary filtration technologies. This region demands cost-effectiveness coupled with extreme durability.

- Middle East and Africa (MEA): This region is characterized by the fastest growth rate, fueled by substantial international aid and developmental spending focused on water access in water-scarce zones and conflict-affected areas. Sub-Saharan Africa is a critical growth hub where hand pumps, particularly the Afridev and similar low-cost polymer designs, are essential for decentralized community water points. The regional emphasis is on VLOM principles, where pump designs must be repairable by local mechanics with minimal training. The market here is highly dependent on institutional purchasing power rather than retail sales.

- Latin America (LATAM): The LATAM market holds a moderate but consistent share, driven by decentralized agricultural needs in remote areas and niche industrial applications in mining and resource extraction. While electrification rates are generally higher than in MEA or certain parts of APAC, hand pumps serve as reliable backups and primary water sources in geographically challenging or indigenous communities. The focus in LATAM often shifts toward high-quality, corrosion-resistant materials due to varied water chemistry and often stricter national environmental standards.

- North America: The market in North America is highly specialized and mature. Demand is largely concentrated in industrial applications (barrel pumps for oil, chemicals, and hazardous waste transfer) and the residential sector for emergency preparedness, cabin/off-grid properties, and supplementary shallow well use. Manufacturers here focus on premium quality, regulatory compliance, and high ergonomic design, commanding higher average selling prices than their counterparts in developing regions.

- Europe: Similar to North America, the European market is niche, with strong demand for high-specification industrial hand pumps utilized in manufacturing, pharmaceuticals, and environmental clean-up operations where the use of electrical equipment might be hazardous or impractical. Consumer demand is minor, mainly tied to rural properties, gardens, and specialized fluid management in small businesses. Regulatory adherence to chemical resistance and safety standards dictates product innovation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hand Pump Market.- Franklin Electric

- Grundfos

- Kirloskar Brothers Limited

- Xylem

- EBARA Corporation

- Akay Industries

- Aqua-Pumpen

- Water Mission

- LEO Group

- Flowserve Corporation

- Tsurumi Manufacturing

- SHAKTI PUMPS

- WPIL Limited

- Roto Pumps

- Wilo SE

- BPC Instruments

- A.P. Industries

- V-Guard Industries

- Usha International

- National Pump Company

- M P Pumps

- Monarch Pumps

- Trafalgar Water Pumps

- Fluid-O-Tech

- Pentair

Frequently Asked Questions

Analyze common user questions about the Hand Pump market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for deep well hand pumps globally?

The primary factor driving demand for deep well hand pumps is the critical necessity for accessing reliable, non-contaminated water sources located far below the surface, particularly in developing economies where municipal infrastructure is non-existent and groundwater tables are dropping due to climatic changes or over-extraction. The low capital cost and independence from electrical grids make them essential tools for water security.

How do Hand Pumps achieve sustainability in remote rural settings?

Sustainability is achieved through the implementation of Village Level Operation and Maintenance (VLOM) principles, which prioritize simple, robust designs built with standardized, locally repairable components. This approach ensures that maintenance can be managed by community members with minimal training and resources, reducing reliance on external, costly expertise and supply chains.

What impact is the rise of solar-powered pumps having on the Hand Pump Market?

The rise of solar-powered pumps poses a significant competitive restraint, especially in agricultural segments requiring high-volume water extraction. However, hand pumps maintain a competitive edge in applications requiring zero electricity consumption, disaster relief efforts, and communities where the initial investment for solar infrastructure is prohibitively high or security for solar panels is a concern.

Which construction material offers the best balance of longevity and cost for hand pump manufacturing?

While traditional cast iron provides structural integrity, modern engineered plastics and composite materials (such as HDPE and PVC) offer the best balance. These materials provide superior corrosion resistance against aggressive groundwater chemistry, are lighter for transport and installation, and offer a comparable lifecycle cost when considering maintenance and replacement frequency in remote, harsh environments.

Where does the industrial application of hand pumps offer the highest value?

The highest value industrial application lies in the handling of hazardous or volatile fluids (like chemicals, fuels, and solvents) where safety regulations or specialized operational requirements mandate non-electric fluid transfer. Hand pumps used for industrial barrel and container transfer ensure intrinsic safety by eliminating the risk of electrical sparking near flammable substances.

What is the significance of the India Mark II and III pump designs in the global market?

The India Mark II and Mark III designs are internationally standardized, heavy-duty deep well pumps developed for challenging hydrological conditions. Their significance lies in their robust construction, standardized parts list, and adoption by numerous international aid organizations and national governments, making them the benchmark for community water supply projects across Asia and Africa.

How is climate change influencing the design requirements for new hand pump models?

Climate change is influencing design by demanding deeper well capabilities due to falling water tables and requiring superior resistance to highly corrosive water resulting from increased mineral concentration in depleted aquifers. Manufacturers are therefore focusing on high-lift mechanisms and advanced non-metallic components to cope with these increasingly severe operating conditions.

What role do NGOs play in the hand pump market's distribution channel?

NGOs (Non-Governmental Organizations) are crucial indirect distribution channels, often acting as the largest centralized buyers of hand pumps globally. They facilitate large-scale deployment to disaster zones and long-term development projects, heavily influencing demand for products that meet strict international quality, longevity, and ease-of-maintenance standards.

What are the typical maintenance challenges associated with widespread hand pump usage?

Common maintenance challenges include the rapid wear and tear of leather or rubber seals and plungers, corrosion of metal components (rods, cylinders), and the difficulty of transporting spare parts and skilled labor to remote operational sites. This necessitates the VLOM strategy and the shift toward more durable, low-friction plastic components.

Does the Hand Pump Market incorporate advanced manufacturing techniques like 3D printing?

Yes, 3D printing is beginning to impact the market, primarily in the rapid prototyping phase for new component designs and potentially in decentralized repair scenarios where custom, non-standard spare parts for older pump models need to be manufactured quickly in local maintenance hubs, optimizing supply chain agility.

How are environmental regulations affecting the materials used in hand pump manufacturing?

Environmental regulations are increasingly stringent regarding the use of materials that could leach contaminants into the water supply, such as certain plasticizers or heavy metal coatings. This forces manufacturers to use certified, food-grade polymers and corrosion-resistant alloys, adding to the initial production cost but improving the overall safety profile of the deployed pumps.

What is the competitive landscape like for hand pump manufacturers in developing regions?

The competitive landscape in developing regions is highly fragmented, featuring a mix of large international pump corporations and numerous small-to-medium-sized local manufacturers. Competition centers primarily on tender pricing, compliance with local specifications, and the ability to provide reliable after-sales support and spare parts availability.

What types of hand pumps are typically used for high-viscosity fluid transfer in industrial settings?

Diaphragm pumps and specialized screw pumps are most commonly utilized for high-viscosity fluid transfer in industrial settings. Diaphragm pumps are favored for their ability to handle slurries and chemicals without mechanical seals contacting the fluid, minimizing wear and contamination risk.

Why is hydraulic efficiency a critical design parameter for deep well hand pumps?

Hydraulic efficiency is critical because it dictates how much human energy is converted into water lift. Poor efficiency leads to increased user fatigue and reduced yield, severely limiting the pump's utility, especially when lifting water from depths exceeding 30 meters, where force multiplication must be maximized.

How does government standardization affect market entry for new manufacturers?

Government standardization, such as required adherence to specific national standards (e.g., ISI in India), creates a significant barrier to entry. New manufacturers must invest substantially in R&D and testing to ensure their designs meet these rigorous specifications, which often dictate specific material compositions, handle loads, and minimum operational lifespan requirements.

What defines the 'Shallow Well' segment of the hand pump market?

The Shallow Well segment typically includes pumps designed for suction lifts where the water source is less than 7 meters below the pump cylinder. These pumps, often simpler and cheaper (like pitcher pumps), rely on atmospheric pressure to lift water and are prevalent in areas with high water tables or for residential/garden use.

Is there a trend towards integrating filtration technology directly with hand pumps?

Yes, there is an emerging trend, particularly in areas with known contamination issues, to integrate basic filtration or chlorination mechanisms at the point of extraction. While full-scale purification is challenging, simple ceramic filters or chlorine dosing devices are sometimes attached to the spout to ensure better public health outcomes.

What are the key differences between reciprocating and diaphragm hand pumps?

Reciprocating (piston) pumps use a back-and-forth motion to displace water, excelling at high-lift, deep well applications. Diaphragm pumps use a flexible membrane to move fluid, making them better suited for lower-lift tasks, handling viscous fluids, and resisting damage from solids/sediment.

How do manufacturers ensure adequate spare parts inventory for global operations?

Manufacturers often employ regional warehousing and utilize inventory management software, increasingly incorporating AI-driven predictive analytics, to forecast regional demand for specific parts based on the installed base, environment (corrosion rates), and historical failure data, optimizing distribution networks to remote locations.

What is the forecasted role of Latin America in the future expansion of the hand pump market?

Latin America is expected to experience steady, specialized growth, driven primarily by continued necessity in remote agricultural and rural communities where connecting to the electrical grid is not feasible. The demand will be focused on high-quality, corrosion-resistant models suitable for handling diverse local fluid types, including certain chemicals used in farming and mining.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager