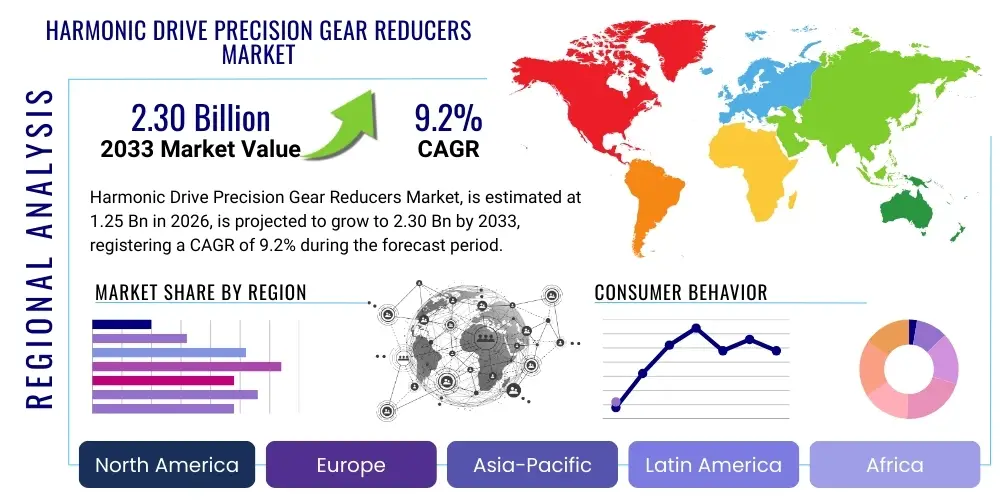

Harmonic Drive Precision Gear Reducers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439485 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Harmonic Drive Precision Gear Reducers Market Size

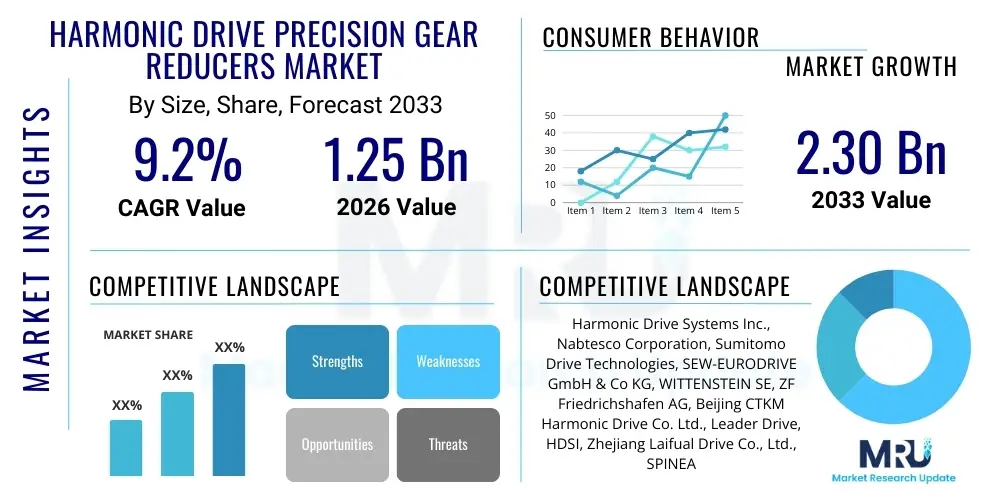

The Harmonic Drive Precision Gear Reducers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.2% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 2.30 billion by the end of the forecast period in 2033.

Harmonic Drive Precision Gear Reducers Market introduction

Harmonic Drive precision gear reducers represent a highly specialized segment within the broader power transmission industry, distinguished by their exceptional precision, high torque-to-weight ratio, zero backlash, and compact design. These mechanical components are engineered to achieve extremely accurate motion control and are primarily used in applications demanding superior positional accuracy and repeatability. The core technology, based on the principle of elastic deformation of metals, enables a single-stage reduction ratio that can exceed 100:1, making them indispensable in scenarios where space is limited and high gear ratios are required without sacrificing precision.

The product, often characterized by its three main components—a Wave Generator, a Flexspline, and a Circular Spline—operates by converting high-speed, low-torque input into low-speed, high-torque output with minimal energy loss. Major applications for Harmonic Drive precision gear reducers span across industrial robotics, aerospace and defense, medical equipment, semiconductor manufacturing, and advanced automation systems. Their ability to deliver smooth, accurate motion and withstand high radial and axial loads makes them ideal for articulated robot arms, surgical robots, satellite antenna positioning, and high-precision machine tools, among other demanding environments.

The benefits associated with these advanced gear reducers are numerous and crucial to their widespread adoption. These include unparalleled accuracy, typically measured in arc-seconds, which is critical for sensitive tasks; high efficiency, reducing energy consumption; a compact and lightweight form factor that aids in miniaturization and weight reduction of end products; and exceptional durability and reliability, ensuring long operational lifetimes even under continuous high-stress conditions. These intrinsic advantages, combined with the increasing global demand for automation, precision manufacturing, and advanced robotic solutions, are driving the market forward, fostering continuous innovation in design and material science to meet evolving industry needs.

Harmonic Drive Precision Gear Reducers Market Executive Summary

The Harmonic Drive Precision Gear Reducers Market is experiencing robust growth, primarily fueled by significant advancements in industrial automation, the proliferation of robotics across diverse sectors, and the escalating demand for high-precision motion control solutions in critical applications. Business trends indicate a strong focus on enhancing manufacturing efficiency, reducing operational costs, and achieving higher levels of product quality, all of which are directly supported by the capabilities of harmonic drive technology. Furthermore, strategic collaborations between gear manufacturers and robot integrators, alongside ongoing research and development into new materials and design methodologies, are accelerating market expansion and product innovation. The market's resilience is also attributed to its critical role in advanced sectors where alternative technologies often fall short in meeting stringent performance criteria, cementing its indispensable status.

Regionally, the Asia Pacific continues to dominate the market, propelled by rapid industrialization, extensive investments in automation and manufacturing capacities, particularly in countries like China, Japan, and South Korea, which are major hubs for robotics and electronics production. North America and Europe also represent significant markets, characterized by their mature industrial bases, high adoption rates of advanced robotics in automotive and aerospace, and substantial spending on research and development in medical and defense sectors. Emerging economies in Latin America and the Middle East & Africa are showing promising growth, albeit from a smaller base, driven by increasing foreign direct investment in manufacturing and a nascent but growing adoption of automation technologies to enhance industrial competitiveness. Each region's unique industrial landscape and technological priorities contribute to varying demand patterns and growth trajectories within the global market.

Segmentation trends highlight the increasing demand for smaller, more lightweight, and higher-precision units, reflecting the broader industry push towards miniaturization and enhanced dexterity in robotic systems. The "Industrial Robotics" application segment remains the largest and fastest-growing, as collaborative robots (cobots) and advanced manufacturing robots increasingly integrate harmonic drives for their critical joints. Moreover, the market for "Aerospace and Defense" applications is experiencing steady growth due to the imperative for reliable, high-performance components in aircraft control surfaces, satellite positioning, and defense systems. Technology advancements are also fostering diversification, with new harmonic drive variants catering to specific needs such as high-speed operation or extreme environmental resistance, further fragmenting and enriching the product landscape to meet highly specialized demands.

AI Impact Analysis on Harmonic Drive Precision Gear Reducers Market

The integration of Artificial Intelligence (AI) is set to profoundly influence the Harmonic Drive Precision Gear Reducers Market, primarily by optimizing design processes, enhancing predictive maintenance capabilities, and fostering the development of more autonomous and intelligent robotic systems. Users are keenly interested in how AI can lead to more efficient, durable, and cost-effective gear reducers, anticipating advancements in material science through AI-driven simulations and the creation of self-optimizing motion control systems. There is also a strong expectation that AI will streamline manufacturing, improve quality control, and enable more personalized product configurations, thereby reducing lead times and meeting highly specific application requirements with greater agility. The core themes revolve around leveraging AI for performance enhancement, operational efficiency, and extending the lifespan of these critical components, ultimately driving higher value for end-users and accelerating innovation within the industry.

- Design Optimization: AI algorithms can analyze vast datasets of material properties, stress points, and operational parameters to optimize the geometric design of harmonic drives, leading to lighter, stronger, and more efficient reducers with extended lifespans and reduced material usage. This includes generative design approaches that explore novel configurations impossible with traditional methods.

- Predictive Maintenance: AI-powered sensors and analytics can monitor the operational health of harmonic drives in real-time, predicting potential failures before they occur. This enables proactive maintenance, minimizes downtime, reduces repair costs, and significantly extends the service life of equipment in critical applications.

- Enhanced Manufacturing Processes: AI can optimize manufacturing parameters, such as machining speeds, tooling paths, and heat treatment processes, to improve production efficiency, reduce waste, and ensure consistent, high-quality output for precision components. This leads to tighter tolerances and superior performance.

- Robotics and Automation: AI integration within robotic control systems allows for more adaptive, precise, and autonomous robot movements. Harmonic drives, as fundamental components of robot joints, benefit from AI-driven path planning and force control, leading to improved performance in complex tasks and collaborative environments.

- Quality Control and Inspection: AI-driven vision systems and anomaly detection algorithms can automate and significantly enhance the accuracy of quality control inspections for harmonic drive components, identifying microscopic defects that human inspectors might miss, ensuring only the highest quality products reach the market.

- Customization and Rapid Prototyping: AI tools can facilitate rapid prototyping and mass customization by quickly generating and testing various design iterations based on specific customer requirements, dramatically shortening the product development cycle and enabling agile responses to market demands.

DRO & Impact Forces Of Harmonic Drive Precision Gear Reducers Market

The Harmonic Drive Precision Gear Reducers Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, alongside broader impact forces that shape its trajectory. Key drivers include the relentless expansion of the industrial robotics sector, particularly the surge in collaborative robots (cobots) and humanoid robots, which critically rely on the compact, precise, and backlash-free motion capabilities of harmonic drives. The increasing adoption of automation across diverse manufacturing industries, from automotive to electronics, further fuels demand. Moreover, the ongoing trend towards miniaturization in advanced medical devices, aerospace components, and semiconductor manufacturing equipment necessitates high-precision gear reducers that can deliver exceptional performance within confined spaces. Technological advancements leading to improved performance, higher torque densities, and cost efficiencies also act as strong market accelerators, attracting new applications and expanding existing ones.

Despite these robust drivers, the market faces several notable restraints. The high initial cost associated with Harmonic Drive precision gear reducers, compared to conventional gearing solutions, can be a barrier for cost-sensitive applications, particularly in emerging markets or for small and medium-sized enterprises (SMEs). The complexity of manufacturing these highly engineered components requires specialized expertise, advanced machinery, and rigorous quality control, which limits the number of potential manufacturers and can contribute to supply chain vulnerabilities. Furthermore, intense competition from alternative precision gearing technologies, such as cycloidal drives and planetary gears (though often not matching the zero-backlash characteristic), forces continuous innovation and price competitiveness. The perceived learning curve for integrating these specialized components into new designs can also pose a minor impediment for engineers unfamiliar with their unique operational characteristics.

Opportunities for market growth are abundant and strategically significant. The burgeoning market for surgical robotics and exoskeletons presents a high-growth avenue, given the critical need for precise, reliable, and smooth motion in human-centric applications. The expansion of space exploration and satellite technology, requiring extremely durable and accurate positioning systems, offers another lucrative niche. Furthermore, advancements in smart factories and Industry 4.0 initiatives create demand for integrated motion control solutions where harmonic drives can play a central role in achieving highly automated and data-driven production environments. Developing region-specific manufacturing capabilities and offering customized solutions tailored to local industry needs can unlock untapped potential. The continuous innovation in material science and manufacturing processes, including additive manufacturing, holds the promise of reducing production costs and expanding design possibilities, thereby making harmonic drives more accessible to a broader range of applications and market segments, reinforcing their long-term growth prospects and solidifying their position as essential components in the evolving landscape of precision motion control.

Segmentation Analysis

The Harmonic Drive Precision Gear Reducers Market is comprehensively segmented across various dimensions to provide a granular understanding of its dynamics, identifying specific growth areas and market opportunities. These segmentations typically include analyses by product type, application, and end-use industry, each offering unique insights into demand patterns and technological preferences. This detailed breakdown allows stakeholders to discern the most lucrative market niches, understand the competitive landscape within specific segments, and tailor their product development and marketing strategies to meet the diverse needs of end-users. The precision, compactness, and zero-backlash properties of harmonic drives make them adaptable across a wide spectrum of specialized uses, justifying the necessity for a multi-faceted segmentation approach to truly capture the market's complexity and potential.

- By Product Type:

- Cup Type

- Hat Type

- Shaft Type

- Modular Type (e.g., geared motor units, actuators)

- Custom/Specialty Types

- By Application:

- Industrial Robotics (e.g., articulated robots, SCARA robots, collaborative robots)

- Machine Tools (e.g., milling machines, lathes, grinding machines)

- Semiconductor Manufacturing Equipment (e.g., wafer processing, inspection systems)

- Medical Equipment (e.g., surgical robots, diagnostic imaging, prosthetic devices)

- Aerospace & Defense (e.g., satellite antenna drives, aircraft actuators, radar systems)

- Printing & Packaging Machinery

- Test & Measurement Equipment

- Other Automation Systems (e.g., logistics automation, material handling)

- By End-Use Industry:

- Automotive

- Electronics & Semiconductor

- Healthcare & Pharmaceutical

- Aerospace & Defense

- Food & Beverage

- Logistics & Warehousing

- General Manufacturing

- Energy

- By Reduction Ratio:

- Low Ratio (e.g., below 50:1)

- Medium Ratio (e.g., 50:1 to 100:1)

- High Ratio (e.g., above 100:1)

- By Torque Capacity:

- Low Torque

- Medium Torque

- High Torque

Value Chain Analysis For Harmonic Drive Precision Gear Reducers Market

The value chain for the Harmonic Drive Precision Gear Reducers Market is a highly specialized and intricate network, beginning with the upstream supply of advanced materials and culminating in the integration of these precision components into complex end-user systems. Upstream activities are critical, involving the sourcing of high-grade specialty steels, advanced alloys, and composite materials that possess the necessary elastic properties, durability, and fatigue resistance essential for the unique operational principles of harmonic drives. Precision machining, heat treatment, and surface finishing technologies are integral to the production of the Wave Generator, Flexspline, and Circular Spline components. Suppliers in this segment must adhere to extremely tight tolerances and possess sophisticated metallurgical expertise to meet the stringent quality and performance requirements of harmonic drive manufacturers, making this a highly concentrated and specialized part of the supply chain.

Midstream activities primarily encompass the design, engineering, and manufacturing of the harmonic drive units themselves. This stage involves sophisticated R&D capabilities to innovate new designs, optimize existing products for specific applications, and integrate advanced manufacturing techniques such as CNC machining, grinding, and specialized assembly processes in cleanroom environments. Manufacturers invest heavily in intellectual property and proprietary technologies to maintain their competitive edge, often developing custom solutions tailored for high-volume customers or niche applications. Quality assurance and rigorous testing are paramount at this stage to ensure the zero-backlash performance, positional accuracy, and long-term reliability that are the hallmarks of these precision gear reducers, distinguishing them from standard gearing solutions and justifying their premium pricing in the market.

Downstream analysis focuses on the distribution channels and the integration of harmonic drives into end-user products. Distribution typically occurs through both direct sales channels for major OEM customers and specialized industrial distributors who provide technical support and local inventory for smaller clients and system integrators. The critical final step involves the integration of these reducers into end applications such as industrial robots, medical devices, aerospace actuators, and semiconductor manufacturing equipment. End-users often require extensive technical support from manufacturers or distributors to correctly select, install, and optimize the performance of harmonic drives within their complex systems. The direct channel fosters close collaboration with key customers, enabling co-development and customization, while indirect channels provide market reach and specialized local support, ensuring broad market penetration and effective after-sales service for a highly technical product.

Harmonic Drive Precision Gear Reducers Market Potential Customers

Potential customers for Harmonic Drive Precision Gear Reducers are primarily industries and enterprises that demand exceptional precision, reliability, and compact motion control solutions for their advanced machinery and systems. These end-users are typically involved in high-stakes applications where the cost of failure is immense, and the need for superior accuracy is non-negotiable. The primary demographic includes original equipment manufacturers (OEMs) of industrial robots, where harmonic drives are essential for the accurate and repeatable movement of robot joints in articulated arms and collaborative robots. These OEMs seek components that can contribute to the overall performance, longevity, and competitiveness of their robotic products, making harmonic drive technology an indispensable choice for their next-generation automation solutions.

Beyond industrial robotics, the market extends to manufacturers of advanced machine tools, particularly those used in high-precision machining, grinding, and indexing applications. These customers require gear reducers that offer zero backlash and high stiffness to maintain cutting accuracy and surface finish quality, directly impacting the final product's precision. Another significant customer base lies within the medical device manufacturing sector, where harmonic drives are integrated into surgical robots, diagnostic imaging equipment, and prosthetics. In this segment, the critical need for smooth, precise, and reliable motion, often in close proximity to humans or within sterile environments, makes the unique attributes of harmonic drives invaluable for enhancing patient safety and surgical outcomes, driving continued demand from this high-growth sector.

Furthermore, aerospace and defense contractors represent a crucial segment of potential customers, utilizing harmonic drives in satellite antenna positioning systems, aircraft control actuators, and radar mechanisms where environmental robustness, minimal weight, and extreme positional accuracy are paramount for mission success. The semiconductor industry also relies heavily on these precision reducers for wafer handling systems, lithography equipment, and inspection machinery, where micron-level accuracy is essential for chip fabrication. Other growing customer segments include specialized manufacturers of printing and packaging machinery, test and measurement equipment, and advanced laboratory automation systems, all of whom seek to leverage the unique combination of high reduction ratios, compactness, and unparalleled precision that Harmonic Drive technology offers to achieve their demanding operational requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 billion |

| Market Forecast in 2033 | USD 2.30 billion |

| Growth Rate | 9.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Harmonic Drive Systems Inc., Nabtesco Corporation, Sumitomo Drive Technologies, SEW-EURODRIVE GmbH & Co KG, WITTENSTEIN SE, ZF Friedrichshafen AG, Beijing CTKM Harmonic Drive Co. Ltd., Leader Drive, HDSI, Zhejiang Laifual Drive Co., Ltd., SPINEA, GAM Gear LLC, Neugart GmbH, Apex Dynamics, Inc., S.T.M. S.p.A., Varvel S.p.A., Cone Drive Operations, Inc., Dayton Superior Corporation, Motovario S.p.A., Rossi S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Harmonic Drive Precision Gear Reducers Market Key Technology Landscape

The key technology landscape of the Harmonic Drive Precision Gear Reducers Market is characterized by continuous innovation aimed at enhancing performance, durability, and cost-effectiveness while adhering to increasingly stringent application requirements. At its core, the technology relies on the principle of elastic mechanics and the unique interaction between the Wave Generator, Flexspline, and Circular Spline. Ongoing research focuses on advanced material science, specifically developing new alloys and composites for the Flexspline that offer improved fatigue life, higher strength-to-weight ratios, and greater resistance to extreme temperatures and corrosive environments. These material advancements are crucial for extending the operational lifespan and expanding the application scope of harmonic drives in demanding sectors like aerospace and medical devices, pushing the boundaries of what is mechanically achievable.

Manufacturing process innovations are also pivotal in the technology landscape. Ultra-precision machining techniques, such as advanced grinding, honing, and superfinishing, are continuously being refined to achieve tighter tolerances and superior surface finishes on critical components, which directly translates to improved accuracy, reduced backlash, and smoother operation. Additive manufacturing (3D printing) is emerging as a disruptive technology, offering potential for rapid prototyping of complex gear geometries and the creation of lightweight, customized harmonic drive components with intricate internal structures that are difficult to produce through traditional methods. This allows for greater design freedom and potentially faster development cycles for specialized applications, enabling manufacturers to respond more agilely to specific customer needs and market opportunities.

Beyond core mechanical design and manufacturing, the technology landscape is increasingly integrating smart features and digital capabilities. The development of integrated sensors for monitoring torque, temperature, vibration, and position is becoming more common, allowing for real-time performance diagnostics and predictive maintenance capabilities. This trend aligns with Industry 4.0 initiatives, where data-driven insights are used to optimize operational efficiency and prevent unplanned downtime. Furthermore, advanced simulation and modeling tools, often augmented by AI, are being utilized for virtual prototyping and performance prediction, reducing the need for extensive physical testing and accelerating product development. These digital advancements are transforming harmonic drives from purely mechanical components into intelligent, networked devices capable of providing valuable operational data and contributing to the overall intelligence of automated systems.

Regional Highlights

- North America: This region is a significant market, driven by substantial investments in advanced manufacturing, aerospace and defense, and medical device sectors. The United States, in particular, leads in robotics R&D and adoption of automation in high-value industries. The demand is for high-performance, robust, and precision-engineered harmonic drives suitable for complex applications and harsh environments.

- Europe: Europe represents a mature market with strong industrial bases in Germany, France, and Italy. The region benefits from high levels of automation in automotive manufacturing, stringent quality standards in machine tools, and a growing emphasis on collaborative robotics. Innovation in energy-efficient and compact designs is a key regional focus to support sustainable manufacturing practices.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for harmonic drive precision gear reducers. Countries like China, Japan, and South Korea are global leaders in industrial robot production and adoption, as well as semiconductor manufacturing and consumer electronics. Rapid industrialization, government support for automation, and expanding manufacturing capacities are the primary growth drivers in this dynamic region.

- Latin America: This region is an emerging market, experiencing growth due to increasing industrialization and foreign direct investment in manufacturing sectors, particularly in countries like Brazil and Mexico. The adoption of automation is steadily rising, albeit from a lower base, as industries seek to improve efficiency and competitiveness, creating opportunities for entry-level and mid-range harmonic drive solutions.

- Middle East and Africa (MEA): The MEA market for harmonic drives is in its nascent stages but shows promising growth potential, particularly in countries investing in industrial diversification, advanced infrastructure projects, and developing their manufacturing capabilities. Investments in oil & gas, defense, and emerging automation projects are expected to drive demand for precision motion control components in the coming years.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Harmonic Drive Precision Gear Reducers Market.- Harmonic Drive Systems Inc.

- Nabtesco Corporation

- Sumitomo Drive Technologies

- SEW-EURODRIVE GmbH & Co KG

- WITTENSTEIN SE

- ZF Friedrichshafen AG

- Beijing CTKM Harmonic Drive Co. Ltd.

- Leader Drive

- HDSI

- Zhejiang Laifual Drive Co., Ltd.

- SPINEA

- GAM Gear LLC

- Neugart GmbH

- Apex Dynamics, Inc.

- S.T.M. S.p.A.

- Varvel S.p.A.

- Cone Drive Operations, Inc.

- Dayton Superior Corporation

- Motovario S.p.A.

- Rossi S.p.A.

Frequently Asked Questions

Analyze common user questions about the Harmonic Drive Precision Gear Reducers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Harmonic Drive gear reducers over conventional gearing?

Harmonic Drive gear reducers offer superior advantages including zero backlash, high positional accuracy (typically in arc-seconds), a compact and lightweight design, high torque-to-weight ratio, and excellent repeatability. These features are critical for applications demanding precise motion control and space efficiency, unlike conventional gears which often have inherent backlash and are bulkier.

Which industries are the largest consumers of Harmonic Drive technology?

The largest consumers are industries requiring high-precision motion control, predominantly industrial robotics (for articulated joints), semiconductor manufacturing equipment (for wafer handling), medical equipment (for surgical robots), and aerospace and defense (for satellite and antenna positioning systems). These sectors benefit immensely from the accuracy and reliability of harmonic drives.

How does the high cost of Harmonic Drive reducers impact market adoption?

While harmonic drives have a higher initial cost compared to conventional gears, their superior performance, extended lifespan, and zero backlash lead to lower total cost of ownership in high-precision applications. This makes them a preferred choice where accuracy and reliability are paramount, outweighing the initial investment in critical sectors despite the price barrier for cost-sensitive markets.

What role does Artificial Intelligence (AI) play in the future of Harmonic Drive technology?

AI is increasingly vital for optimizing harmonic drive design, enabling predictive maintenance through real-time data analysis, enhancing manufacturing efficiency, and improving the autonomous capabilities of robots that integrate these reducers. AI helps create lighter, stronger, and smarter harmonic drives, extending their utility and performance within advanced automation systems.

What are the main types of Harmonic Drive reducers available in the market?

The market primarily offers three main types: Cup Type, known for its compact size and hollow shaft for wiring; Hat Type, which is more robust and suitable for higher torque; and Shaft Type, featuring through-holes for easy mounting. Modular and custom types are also available, offering integrated solutions or specialized designs for unique application requirements, expanding their versatility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager