Harmonic Reducer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433286 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Harmonic Reducer Market Size

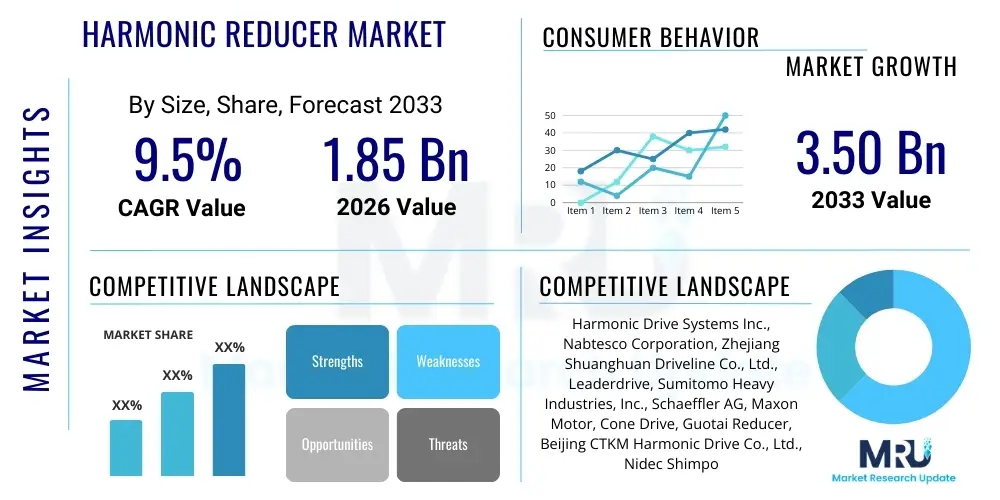

The Harmonic Reducer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.50 Billion by the end of the forecast period in 2033. This substantial growth is fundamentally driven by the accelerating global adoption of industrial automation technologies, particularly in advanced manufacturing and robotics. Harmonic reducers, known for their high precision, zero backlash, and compact design, are indispensable components in multi-axis robotic arms and high-accuracy positioning systems, cementing their vital role in the Industry 4.0 paradigm.

Harmonic Reducer Market introduction

The Harmonic Reducer Market encompasses the manufacturing, distribution, and utilization of high-precision gear reduction mechanisms based on the strain wave gearing principle. These devices convert high-speed, low-torque input from motors into low-speed, high-torque output with unparalleled accuracy, making them critical elements in demanding applications where precision and repeatability are paramount. The core product uses three main components—a wave generator, a flexspline, and a circular spline—to achieve a large reduction ratio in a small envelope size, offering advantages over traditional gearboxes in terms of size, weight, and motion control fidelity.

Major applications for harmonic reducers span across industrial automation, aerospace, medical devices, and semiconductor manufacturing. Industrial robots, especially articulated and collaborative robots (cobots), represent the largest consumer base, utilizing harmonic drives for wrist, elbow, and joint movements that require smooth operation and minimal accumulated error. Their intrinsic benefits, including high torque density, extremely low or zero backlash, and excellent positional accuracy, differentiate them from cycloidal and planetary reducers, justifying their premium pricing in high-end machinery.

The primary driving factors for market expansion include escalating labor costs prompting manufacturers to invest in automation, government initiatives supporting smart manufacturing infrastructure globally, and the continuous technological evolution leading to lighter, faster, and more robust robotic systems. Furthermore, the expansion of electric vehicle (EV) production, which relies on automated assembly lines, and the increasing complexity of semiconductor fabrication equipment necessitate the superior control provided by harmonic reducers, ensuring sustained market momentum through the forecast period.

Harmonic Reducer Market Executive Summary

The Harmonic Reducer Market is poised for robust expansion, primarily fueled by global investments in advanced robotics and the necessity for high-precision motion control across diverse industries. Business trends indicate a shift towards customization and the development of specialized harmonic drives featuring integrated sensors and smaller footprints to meet the stringent demands of collaborative robots (cobots) and micro-robotics. Key manufacturers are focusing on enhancing durability, thermal management, and reducing manufacturing costs through optimizing material science and production techniques, aiming to broaden application scope beyond traditional heavy industrial sectors into logistics automation and medical diagnostics.

Regionally, the Asia Pacific (APAC) dominates the market, largely driven by the colossal manufacturing bases in China, South Korea, and Japan, which are the leading adopters and developers of industrial robotics technology. Government support in countries like China (Made in China 2025) strongly encourages factory automation, creating immense demand for core components like harmonic reducers. Europe and North America also maintain significant shares, characterized by demand from high-value sectors such as aerospace, defense, and advanced medical imaging, emphasizing quality and performance over cost efficiency.

Segment trends reveal that the Industrial Robotics application segment will continue its supremacy, though the demand from the Semiconductor Manufacturing Equipment segment is exhibiting the fastest growth rate due to massive global investments in advanced chip fabrication capacity (e.g., 5G, AI chips). By Type, the Cup Type harmonic reducers remain the most widely used due to their simplicity and reliability, but the Hollow Shaft Type is gaining traction, particularly in applications requiring complex cable routing or integrated fluid lines, offering streamlined system integration and reduced installation complexity for next-generation robotic designs.

AI Impact Analysis on Harmonic Reducer Market

User queries regarding the impact of Artificial Intelligence (AI) on the Harmonic Reducer Market primarily revolve around how AI-driven optimization affects reducer design, maintenance, and system integration within smart factories. Common questions address whether AI-powered predictive maintenance will extend the lifespan of harmonic reducers, how AI optimizes the motor control algorithms reliant on reducer precision, and if generative design tools are being used to create lighter, more efficient reducer geometries. Users are keen to understand if AI can reduce the current reliance on high mechanical tolerances by compensating for minor variations through software, thereby potentially lowering manufacturing costs without sacrificing performance.

The integration of AI fundamentally transforms the operational life cycle of harmonic reducers, moving the focus from purely mechanical reliability to system-level intelligence. AI algorithms are crucial in analyzing vast datasets generated by sensors embedded near the reducer, such as vibration, temperature, and torque load, enabling highly accurate predictive maintenance schedules. This predictive capacity minimizes unexpected downtime, a major concern for highly automated production lines, directly improving the overall equipment effectiveness (OEE) of robotic systems that depend on the sustained, zero-backlash operation of harmonic drives. By optimizing lubrication cycles and detecting incipient faults before catastrophic failure, AI extends the effective mean time between failures (MTBF) of these critical components.

Furthermore, AI plays a role in enhancing the performance characteristics of harmonic drives when utilized within complex robotic kinematics. Machine learning models can fine-tune the motor control inputs based on real-time feedback from the reducer, compensating for thermal expansion, minor component wear, and load variations. This adaptive control capability ensures that the high theoretical precision of the harmonic reducer is maintained under dynamic operating conditions, which is particularly vital for highly sensitive applications like micro-assembly or surgical robotics. Generative AI tools are also accelerating the design process, allowing engineers to quickly iterate on complex flexspline designs for optimal stress distribution and minimal weight, pushing the boundaries of torque density achievable in smaller volumes.

- AI-driven Predictive Maintenance: Extends reducer lifespan and minimizes unplanned downtime by forecasting mechanical failures based on real-time sensor data analysis (vibration, temperature).

- Adaptive Motion Control: AI algorithms optimize motor commands to compensate for dynamic mechanical variations (wear, thermal effects), preserving the precision of the harmonic drive under operational stress.

- Generative Design Optimization: Utilizes AI to explore novel, optimized geometries for components like the flexspline, resulting in lighter, higher torque-density reducers.

- Enhanced Quality Control: Machine vision and AI systems perform rapid, high-accuracy inspection of reducer components during manufacturing, ensuring zero-defect output essential for zero-backlash performance.

- Improved System Integration: AI assists in the kinematic modeling and simulation of robotic arms, selecting the optimal size and configuration of harmonic reducers for specific payload and speed requirements.

DRO & Impact Forces Of Harmonic Reducer Market

The Harmonic Reducer Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape its growth trajectory and competitive landscape. The primary Driver is the unwavering global mandate for automation across manufacturing sectors, driven by escalating wage inflation and the quest for consistent, high-quality production, making highly accurate motion control indispensable. Conversely, the market faces significant Restraints, mainly stemming from the high initial cost of harmonic reducers compared to conventional gearing systems and the inherent technical complexity associated with their maintenance and precise installation, limiting their adoption in cost-sensitive or less-sophisticated applications. These forces are further modulated by critical Opportunities, particularly the emergence of new high-growth segments like medical robotics and the mass production of affordable collaborative robots, which require compact, efficient, and precise gear systems.

Impact forces within the market are predominantly high, reflecting the non-negotiable requirement for precision in end-use applications. Supplier power is moderate to high, concentrated among a few established global players (e.g., Harmonic Drive Systems, Nabtesco) who possess proprietary technology and deep expertise in strain wave gearing manufacturing, making it difficult for new entrants to compete solely on technical performance. Buyer power is also moderate, as large industrial robot manufacturers have significant leverage, but they remain locked into high-performance suppliers due to the critical nature of the reducer in overall robot performance and warranty adherence. The threat of substitutes, while present (e.g., high-precision planetary gears), is mitigated by the superior zero-backlash characteristic and high reduction ratios intrinsic to harmonic reducers, features substitutes often struggle to match in the same footprint.

The intensity of competitive rivalry remains high. Leading players are engaged in continuous R&D to improve torque density, reduce size, and enhance overall efficiency (reducing friction loss and heat generation). Innovation in material science, especially the use of specialized steels and advanced lubrication techniques, is a key battlefield. The need for precise machining and tight tolerance control acts as a natural barrier to entry. Furthermore, geopolitical shifts influencing supply chains, coupled with fluctuating raw material prices (especially high-grade steel), exert pressure on manufacturing costs and pricing strategies, requiring constant optimization of production processes to maintain profitability in a demanding technological environment.

Segmentation Analysis

The Harmonic Reducer Market is comprehensively segmented based on Type, Reduction Ratio, and Application, providing a detailed view of demand dynamics across various technological and industrial verticals. This segmentation is crucial for understanding specific product requirements, regional consumption patterns, and competitive positioning strategies. The Type segmentation distinguishes between design structures, affecting installation flexibility and torque handling, while the Reduction Ratio segment directly addresses the speed requirements and torque needs of the end machinery. Application analysis determines the volume and technological specifications required by major consuming industries, notably industrial robotics, which forms the bedrock of market demand, alongside rapidly evolving sectors like medical and aerospace technologies that demand the highest levels of accuracy and reliability.

- By Type: Cup Type, Hat Type, Hollow Shaft Type.

- By Reduction Ratio: 50:1 to 100:1, 100:1 to 150:1, Above 150:1.

- By Application: Industrial Robots (Articulated Robots, Collaborative Robots), Semiconductor Manufacturing Equipment, Machine Tools, Aerospace & Defense, Medical Equipment (Surgical Robots, Scanners), Others (Solar Tracking, Precision Actuators).

- By Region: North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA).

Value Chain Analysis For Harmonic Reducer Market

The value chain for the Harmonic Reducer Market is fundamentally complex, starting with the sourcing of specialized, high-grade raw materials and culminating in distribution to high-precision machinery manufacturers. Upstream analysis highlights the critical reliance on suppliers of high-purity, wear-resistant steel alloys and proprietary bearing components. Manufacturing harmonic drives requires extremely high-precision machining, heat treatment, and surface finishing capabilities, necessitating significant capital investment in specialized fabrication equipment. This reliance on exacting manufacturing standards means that the primary value accrues at the processing and assembly stages, where intellectual property relating to flexspline design and gearing geometry is concentrated.

Downstream analysis focuses on the integration of the reducer into the final product, predominantly industrial robotic arms and semiconductor wafer handling systems. Original Equipment Manufacturers (OEMs) in these sectors are the primary direct customers. The performance of the harmonic reducer dictates the overall precision and reliability of the final machine, making technical support, reliability documentation, and long-term supply agreements crucial aspects of the downstream value proposition. As robotic technology advances, OEMs demand continuous improvements in torque-to-weight ratio and dynamic stiffness, pushing manufacturers to innovate constantly.

Distribution channels for harmonic reducers are typically bifurcated into direct sales and indirect sales through specialized technical distributors. Direct channels are preferred for major robot manufacturers and large-volume contracts, allowing for detailed customization and technical consultation. Indirect channels, utilizing specialized distributors with expertise in motion control components, serve smaller volume buyers, machine tool manufacturers, and regional integrators. The distribution channel must offer robust pre-sales engineering support and rapid spares delivery, as the failure of a reducer can halt high-cost automated production lines, underscoring the necessity of a highly efficient and knowledgeable supply chain network.

Harmonic Reducer Market Potential Customers

The primary consumers and end-users of harmonic reducers are organizations operating in high-precision, automated manufacturing, and critical infrastructure sectors where accurate motion control is non-negotiable. Industrial robot manufacturers (such as Fanuc, ABB, KUKA, Yaskawa) constitute the largest segment of buyers, purchasing harmonic drives as essential joint components for their articulated robotic arms and increasingly, collaborative robots (cobots). These customers prioritize zero backlash, high rigidity, and longevity, often entering into long-term supply agreements for customized units that meet specific payload and cycle life criteria.

Another major segment consists of manufacturers of Semiconductor Manufacturing Equipment, including tools for deposition, etching, and precise wafer handling (e.g., ASML, Applied Materials). In this context, harmonic reducers ensure the micron-level accuracy required for positioning silicon wafers, where even minor errors can lead to astronomical production losses. These buyers demand extreme reliability in vacuum environments and minimal particulate generation, pushing the technological envelope for material cleanliness and operational precision.

Beyond these industrial heavyweights, significant purchasing power lies with manufacturers in the aerospace and defense sectors, where reducers are utilized in flight control surfaces, satellite deployment mechanisms, and radar positioning systems, demanding compliance with strict performance and quality certifications. Furthermore, the burgeoning medical equipment market, including manufacturers of robotic surgical systems and advanced medical imaging devices, constitutes a high-growth customer base, prioritizing compactness, smooth operation, and sterilizability alongside mechanical precision for delicate procedures.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.50 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Harmonic Drive Systems Inc., Nabtesco Corporation, Zhejiang Shuanghuan Driveline Co., Ltd., Leaderdrive, Sumitomo Heavy Industries, Inc., Schaeffler AG, Maxon Motor, Cone Drive, Guotai Reducer, Beijing CTKM Harmonic Drive Co., Ltd., Nidec Shimpo, SEJIN IG Co., Ltd., Reiner Reducer, Qinchuan Machine Tool Group, Dings Motion |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Harmonic Reducer Market Key Technology Landscape

The technological landscape of the Harmonic Reducer Market is characterized by continuous refinement aimed at improving torque density, reducing physical size and weight, and enhancing operational life. The core strain wave gearing principle remains constant, but innovation centers around material science, manufacturing precision, and integration capabilities. A significant technological focus is placed on developing superior steel alloys for the flexspline, which must endure extreme cyclical stress. These materials must offer high fatigue strength and resistance to wear, directly influencing the gearbox's lifetime and reliability, particularly in high-duty cycle robotic applications. Advanced manufacturing techniques, such as precision CNC machining and proprietary heat treatment processes, are essential for achieving the required micron-level tolerances that ensure zero backlash performance.

Integration technologies are also paramount. There is a growing trend towards developing frameless or component sets, allowing robot manufacturers greater flexibility in integrating the reducer directly into the structure of the robotic joint, thereby saving space and weight. Furthermore, the incorporation of advanced lubrication and sealing mechanisms is crucial for maintaining performance across varying operational temperatures and environments, ranging from clean rooms (semiconductor) to harsh industrial settings. Recent innovations include optimizing tooth profiles and wave generator design to minimize internal friction and heat generation, which improves efficiency and prevents thermal drift, thus maintaining positional accuracy during prolonged operation.

The future technology trajectory involves deeper integration with electronics and sensing technologies. Reducers are increasingly being equipped with integrated encoders, allowing for extremely high-resolution feedback loops necessary for sophisticated motion control in cobots and surgical robots. The push for smarter, more connected components also includes the adoption of condition monitoring sensors, providing real-time data for predictive maintenance and operational optimization (as detailed in the AI analysis). These technological advancements collectively aim to solidify the harmonic reducer's position as the gold standard for applications demanding the highest combination of precision, compactness, and high reduction ratio.

Regional Highlights

The Asia Pacific (APAC) region stands as the undisputed leader in the Harmonic Reducer Market, driven primarily by its immense manufacturing capacity and robust government policies prioritizing industrial automation. Countries like China, Japan, and South Korea host the world's largest robot manufacturers and end-user industries (automotive, electronics), creating massive internal demand. China’s strategic focus on upgrading its industrial base through initiatives like "Made in China 2025" guarantees sustained, high investment in robotics, making it the fastest-growing sub-region globally. Japan, home to market giants like Harmonic Drive Systems and Nabtesco, is a hub for innovation and high-quality production, catering to both local consumption and global export markets.

Europe represents the second-largest market, characterized by demand from high-value, sophisticated industries. Germany, Italy, and Switzerland are key consumers, particularly in the machine tool, specialized automation, and aerospace sectors. European demand is often focused on customized, high-reliability reducers that comply with stringent quality and safety standards. The adoption of collaborative robots (cobots) in small and medium-sized enterprises (SMEs) across Europe further stimulates demand for compact and precise harmonic drive solutions.

North America maintains a significant market presence, driven by substantial investments in aerospace and defense, medical robotics, and advanced semiconductor manufacturing facilities (following recent legislation promoting domestic chip production). The focus here is less on sheer volume and more on cutting-edge technology, particularly for applications requiring superior torque density and extreme accuracy, such as surgical robots and specialized space exploration mechanisms. Growth in Latin America and MEA remains nascent but is expected to accelerate as these regions increase automation adoption in mining, oil and gas, and foundational manufacturing processes.

- Asia Pacific (APAC): Dominates the market share due to large-scale robotic deployment in China, South Korea, and Japan; serves as both a major producer and consumer of harmonic drives.

- North America: Strong demand from high-tech, precision sectors including aerospace, defense, and medical robotics; focuses on highest performance and integration technology.

- Europe: Characterized by high-quality manufacturing and significant adoption in machine tools and collaborative automation; highly sensitive to technical specifications and reliability.

- Japan: A primary global technology and manufacturing hub for proprietary harmonic drive systems.

- China: Fastest-growing market, driven by national policies encouraging rapid industrial automation expansion and localization of component supply.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Harmonic Reducer Market.- Harmonic Drive Systems Inc.

- Nabtesco Corporation

- Leaderdrive (Sichuan Leader Harmonious Drive Technology Co., Ltd.)

- Zhejiang Shuanghuan Driveline Co., Ltd.

- Sumitomo Heavy Industries, Inc.

- Schaeffler AG

- Maxon Motor AG

- Cone Drive (Regal Rexnord Corporation)

- Nidec Shimpo Corporation

- Beijing CTKM Harmonic Drive Co., Ltd.

- Qinchuan Machine Tool Group

- Guotai Reducer (Jiangsu Guotai Reducer Co., Ltd.)

- SEJIN IG Co., Ltd.

- Reiner Reducer Co., Ltd.

- Dings Motion

- KHK Co., Ltd.

- Electromate Inc.

- WITTENSTEIN SE

- Bonfiglioli S.p.A.

- SDP/SI (Stock Drive Products/Sterling Instrument)

Frequently Asked Questions

Analyze common user questions about the Harmonic Reducer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What defines a harmonic reducer and why is it preferred in robotics?

A harmonic reducer, or strain wave gearing, is a high-precision mechanical gear system characterized by its use of an elliptical wave generator to deform a flexible spline, achieving high reduction ratios in a compact form. It is preferred in robotics due to its inherent zero or near-zero backlash, high torque capacity relative to its size, and exceptional positional accuracy, crucial for complex, multi-axis motion control.

How does the high cost of harmonic reducers impact market adoption?

The high unit cost of harmonic reducers, primarily due to the stringent manufacturing tolerances and specialized materials required, acts as a restraint, particularly in cost-sensitive applications. However, this impact is mitigated in high-end automation (like surgical or semiconductor robots) where precision is non-negotiable and the total cost of ownership justifies the premium price for superior performance and reduced maintenance risk.

Which application segment drives the highest demand for harmonic reducers globally?

The Industrial Robots segment, encompassing articulated, SCARA, and collaborative robots (cobots), generates the highest demand for harmonic reducers. These drives are vital components in every robotic joint where precise, repetitive motion and high torque density are essential for efficient operation on automated assembly lines.

What are the primary differences between Cup Type, Hat Type, and Hollow Shaft Type harmonic reducers?

The primary difference lies in their structural configuration and integration capacity. Cup Type is the standard, most rigid design. Hat Type offers a shorter length profile. Hollow Shaft Type is preferred for systems requiring routing of cables, wires, or pneumatic lines directly through the center of the reducer, simplifying complex robotic arm integration and reducing overall complexity.

How does AI contribute to improving the reliability and lifespan of harmonic drives?

AI improves reliability and lifespan through advanced predictive maintenance. By analyzing real-time data from embedded sensors (vibration, temperature, current), AI models accurately forecast potential failures, allowing for proactive servicing, optimal lubrication scheduling, and early detection of mechanical wear, thereby maximizing the mean time between failures (MTBF).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager