Heat Resistant ABS Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437082 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Heat Resistant ABS Market Size

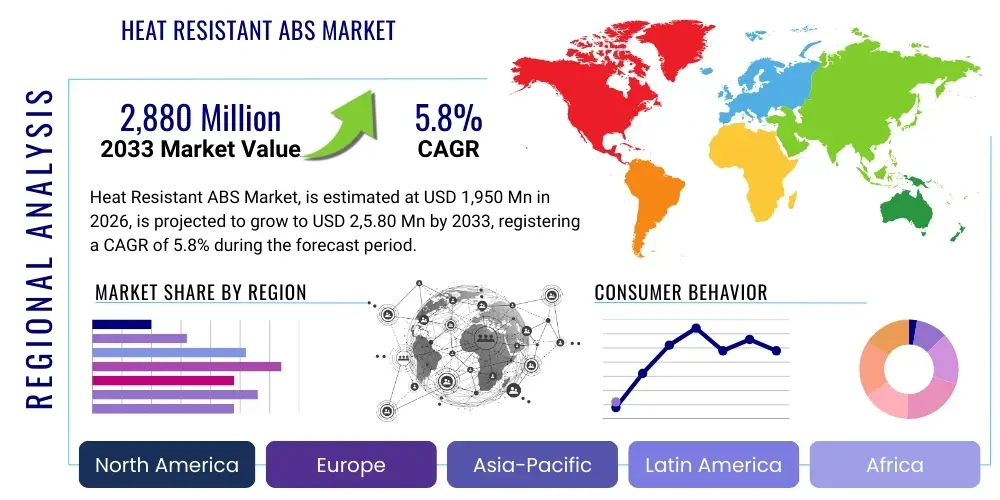

The Heat Resistant ABS Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1,950 Million in 2026 and is projected to reach $2,880 Million by the end of the forecast period in 2033.

Heat Resistant ABS Market introduction

Heat Resistant Acrylonitrile Butadiene Styrene (HR-ABS) is a specialized thermoplastic known for maintaining excellent mechanical properties and dimensional stability at elevated temperatures, significantly higher than standard ABS grades. This enhanced thermal performance is achieved through the modification of the base resin, typically by increasing the Acrylonitrile content or incorporating specialized comonomers like Alpha Methyl Styrene (AMS) or N-Phenyl Maleimide (NPMI). These modifications allow HR-ABS to withstand higher heat distortion temperatures (HDT), making it indispensable in applications exposed to operational heat or high ambient temperatures, such as automotive components, electrical enclosures, and high-performance consumer electronics.

The primary applications driving the HR-ABS market include automotive interior and exterior parts requiring resistance to sun load and engine heat (e.g., dashboards, mirror housings), and sophisticated electrical and electronic (E&E) equipment, including power supply components and charging stations, where operational heat buildup is a critical concern. Furthermore, HR-ABS offers the inherent benefits of standard ABS—ease of processing, superior impact strength, and excellent aesthetic capabilities—but without the thermal limitations, thus enabling cost-effective material substitution in applications traditionally reserved for more expensive engineering plastics like Polycarbonate (PC) or PC/ABS blends.

Major market growth is fueled by the stringent demands from the automotive sector for lightweighting solutions that meet stringent safety standards and withstand operational stresses, particularly in electric and hybrid vehicles where battery components require enhanced thermal management materials. The proliferation of complex electronic devices, coupled with the increasing trend towards miniaturization, which concentrates heat generation, further necessitates the adoption of materials with improved thermal resistance and fire retardancy capabilities. These driving factors position HR-ABS as a key enabling material across several high-growth industrial and consumer verticals globally.

Heat Resistant ABS Market Executive Summary

The Heat Resistant ABS market is characterized by robust growth, primarily driven by accelerated expansion in the automotive and electrical and electronics (E&E) industries, which prioritize materials offering thermal stability, impact resistance, and aesthetic appeal. Key business trends include the consolidation of manufacturing capabilities by major chemical companies focusing on customizing HR-ABS grades to meet specific vertical demands, particularly in flame retardant (FR) formulations necessary for compliance with stringent global safety standards like UL 94 V-0. Furthermore, there is a distinct shift towards sustainable manufacturing processes and the development of bio-based or recycled content HR-ABS to address increasing environmental regulations and corporate sustainability mandates.

Regionally, the Asia Pacific (APAC) dominates the market, largely owing to its status as the global manufacturing hub for automotive components and consumer electronics, coupled with rapid urbanization and industrialization in countries like China, India, and South Korea. North America and Europe demonstrate mature market demand, focusing heavily on specialized, high-performance grades used in premium vehicle segments and advanced industrial machinery, and are characterized by high regulatory hurdles requiring superior quality and traceability. Latin America and the Middle East & Africa (MEA) are emerging regions exhibiting significant potential due to increasing foreign direct investment in manufacturing and infrastructure development, boosting local demand for durable engineering plastics.

Segmentation trends indicate that the Application segment, particularly Automotive Interiors and E&E Housings, remains the largest revenue contributor due to the critical nature of thermal performance in these components. By Grade Type, the demand for High Flow Heat Resistant ABS is expanding rapidly as manufacturers seek materials that facilitate complex thin-walled designs and faster cycle times in injection molding processes. The convergence of safety regulations and thermal requirements ensures that specialized compounded grades, often blended with PC or tailored with glass fibers, will continue to command premium pricing and drive innovation within the broader market structure.

AI Impact Analysis on Heat Resistant ABS Market

Common user questions regarding AI’s impact on the Heat Resistant ABS market revolve around optimizing material formulation, predicting end-product performance under stress, and enhancing manufacturing efficiency. Users frequently inquire how AI and machine learning (ML) algorithms can accelerate the development cycle for new high-temperature grades, asking if predictive modeling can reduce the costly and time-consuming process of physical testing. There is significant interest in using AI for quality control, specifically in identifying defects during compounding and injection molding stages that might compromise thermal integrity. Furthermore, users seek to understand how AI can assist in raw material sourcing and volatility prediction, ensuring a stable supply chain crucial for this specialized polymer segment.

The integration of AI technologies, particularly predictive analytics and generative design, is poised to revolutionize the material science behind Heat Resistant ABS. AI models are capable of analyzing vast datasets comprising polymerization parameters, additive concentrations, and resulting thermal and mechanical properties. This data-driven approach allows researchers to rapidly iterate on formulations, precisely tailoring the glass transition temperature (Tg) and heat deflection temperature (HDT) of the resin. Consequently, the time required to develop a new grade of HR-ABS that meets specific OEM specifications—such as those required for high-wattage LED housings or battery enclosures—is drastically reduced, enhancing time-to-market for manufacturers.

In the manufacturing sector, AI-driven process optimization systems monitor variables in real-time during polymerization and compounding, including temperature profiles, screw speeds, and material feed rates. These systems use anomaly detection to predict and prevent batch variations, significantly improving product consistency and reducing scrap rates, which is critical given the high cost of specialty monomers used in HR-ABS production. Moreover, in end-user fabrication (e.g., injection molding), AI models are used to optimize tooling design and processing parameters, ensuring minimal internal stress and maximum dimensional stability of the final HR-ABS component, thereby mitigating thermal warpage and extending component longevity in demanding operating environments.

- AI optimizes polymer blend ratios, accelerating the discovery of new high-HDT HR-ABS grades.

- Machine Learning (ML) algorithms predict performance characteristics (HDT, tensile strength, melt flow index) based on formulation inputs, reducing physical prototyping costs.

- Predictive maintenance driven by AI minimizes downtime in compounding and extrusion lines, ensuring consistent specialty material output.

- Computer Vision systems utilize AI for real-time quality inspection of molded HR-ABS parts, detecting micro-cracks and surface imperfections critical for thermal performance.

- AI-enhanced supply chain management predicts price fluctuations and availability of key specialty monomers (e.g., AMS), securing the supply chain for manufacturers.

- Generative design tools leverage thermal simulation data to create complex, lightweight HR-ABS component geometries optimized for heat dissipation in E&E applications.

DRO & Impact Forces Of Heat Resistant ABS Market

The Heat Resistant ABS market dynamics are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively define the market's growth trajectory and inherent risks. Key drivers include the exponential increase in demand for thermally stable plastics from the rapidly evolving electric vehicle (EV) sector and the pervasive miniaturization trend in consumer electronics, both of which require materials capable of surviving high operational temperatures. Simultaneously, the inherent thermal limitations of even HR-ABS grades compared to super-engineering plastics, coupled with the frequent volatility in the price of raw materials like butadiene and styrene, pose significant restraints. Opportunities lie predominantly in sustainable innovation, specifically the development of bio-based HR-ABS variants and advanced compounding techniques to improve fire safety standards without compromising thermal performance.

Driving factors are heavily weighted towards technological advancements in application industries. The automotive industry’s shift toward stricter emission standards and EV adoption mandates the use of lightweight, thermally stable materials for battery enclosures, charging inlets, and sophisticated interior trims exposed to intense solar load. In the E&E sector, the demand for higher power density in chargers, adapters, and 5G infrastructure components requires superior heat resistance and often non-halogenated flame retardancy, making specialized HR-ABS blends an optimal material choice. Furthermore, the ease of processing and cost-effectiveness of HR-ABS compared to high-end polymers ensures its continuous substitution of traditional materials in various industrial applications.

However, the market faces significant headwinds. The most persistent restraint is the fluctuating cost and availability of key petrochemical feedstocks, directly impacting the final price and profitability margins for polymer producers. Another critical restraint is the continuous upward revision of temperature requirements in specific, high-stress applications; while HR-ABS offers improvements over standard ABS, highly specialized areas might still necessitate the use of much higher-priced polymers like PEEK or high-performance Polycarbonate blends. External impact forces, such as the increasing stringency of global chemical regulations (e.g., REACH in Europe) regarding certain flame retardants, force constant R&D investment to develop compliant, yet effective, new formulations, adding complexity and cost to the material manufacturing process.

Segmentation Analysis

The Heat Resistant ABS market is comprehensively segmented based on Grade Type, Application, and End-Use Industry, reflecting the diversity of product specifications required across different thermal and mechanical operating environments. Grade Type segmentation distinguishes between standard HR-ABS formulations and specialized compounded grades, such as high-flow or glass-fiber reinforced variants, tailored for specific manufacturing processes or enhanced structural integrity. The Application segment focuses on the component's function, ranging from automotive parts exposed to direct heat to non-critical internal electronic housings. Understanding these segments is crucial for manufacturers to target specific high-value niche markets that demand custom-engineered thermal solutions.

The Application segmentation, which includes Automotive Interiors, E&E Components, and Medical Devices, holds the highest relevance for revenue forecasting, as component performance requirements dictate the grade and price of the HR-ABS used. For instance, automotive parts often require high UV stability in addition to heat resistance, demanding a specialized product profile, whereas E&E enclosures prioritize thermal stability in conjunction with fire safety ratings. This deep application specificity drives the need for extensive collaboration between HR-ABS producers and tier-one component suppliers to develop optimized material solutions that satisfy both performance and regulatory criteria.

The End-Use Industry analysis confirms the dominance of the Automotive and Electrical & Electronics sectors, although the market is seeing burgeoning demand from the Industrial and Healthcare sectors. In healthcare, HR-ABS is utilized for durable equipment enclosures and components requiring resistance to sterilization heat cycles, provided the formulation meets strict biocompatibility standards. The continued evolution of these end-use sectors, particularly the accelerating electrification trends in transport and infrastructure, ensures sustained, high-quality demand for thermally advanced polymer solutions like Heat Resistant ABS.

- By Grade Type

- Standard Heat Resistant ABS (HDT 95°C - 105°C)

- High-Temperature Heat Resistant ABS (HDT 105°C - 120°C)

- High Flow HR-ABS (Optimized for thin-walled components and faster cycle times)

- Flame Retardant (FR) HR-ABS (Meeting UL 94 V-0 or V-1 standards)

- Glass Fiber Reinforced HR-ABS (Enhanced stiffness and dimensional stability)

- By Application

- Automotive Interior Components

- Dashboards and Instrument Panels

- Pillar Trims and Consoles

- Sunload-exposed parts

- Electrical and Electronic (E&E) Housings

- Power Supply Units (PSUs)

- Adapters and Chargers

- LED Lighting Housings (High Wattage)

- Home Appliances

- Hair Dryer Casings

- Coffee Maker Components

- Microwave Oven Bezels

- Industrial and Construction

- HVAC Components

- Circuit Breaker Housings

- Medical Devices

- Diagnostic Equipment Enclosures

- Sterilizable Handles and Casings

- Automotive Interior Components

- By End-Use Industry

- Automotive (Largest Share)

- Electrical and Electronics

- Consumer Goods

- Industrial Manufacturing

- Healthcare and Medical

Value Chain Analysis For Heat Resistant ABS Market

The value chain of the Heat Resistant ABS market begins with the procurement of essential petrochemical feedstocks, primarily butadiene, styrene, and acrylonitrile, which are synthesized into basic monomers by chemical manufacturers. This upstream segment is characterized by high capital intensity and vulnerability to oil price fluctuations, which directly influence the cost structure of the final polymer resin. Specialized additives, such as polymerization initiators, thermal stabilizers, and high-performance flame retardants, are also sourced at this stage. Effective management of this upstream segment is critical, as the quality and purity of monomers directly determine the thermal stability and processability of the resulting HR-ABS polymer.

The midstream segment involves the actual polymerization and subsequent compounding processes. HR-ABS manufacturers utilize advanced polymerization techniques, often incorporating high-heat resistant comonomers (e.g., AMS) during the reaction phase to elevate the heat deflection temperature beyond standard ABS limits. Compounding is a crucial step where the base resin is blended with impact modifiers, colorants, UV stabilizers, and necessary flame retardants to create specific commercial grades tailored for injection molding or extrusion. This manufacturing stage requires precision engineering and stringent quality control, as any variation can compromise the heat resistance properties essential for end-use applications.

The downstream distribution channel involves moving the finalized HR-ABS pellets to end-users. Distribution occurs through both direct sales (large volume contracts to major automotive OEMs or Tier 1 suppliers) and indirect channels (regional distributors and specialized plastic traders serving smaller processors and custom molders). Final fabrication is primarily done through injection molding, producing components used in automotive interiors, consumer electronics, and industrial enclosures. The success of the downstream segment relies on technical service support, offering advice on processing parameters and material selection to ensure optimal performance of the HR-ABS parts in their respective high-temperature operating environments.

Heat Resistant ABS Market Potential Customers

Potential customers for Heat Resistant ABS are entities involved in the design, manufacturing, and assembly of products that require plastics with superior thermal performance and robust mechanical properties. The largest volume buyers are Tier 1 and Tier 2 automotive suppliers who manufacture interior trim, dashboard components, and under-the-hood parts for major vehicle manufacturers, especially those focusing on electric vehicle components where thermal runaway protection and internal heat management are paramount. These customers demand high regulatory compliance, often requiring PPAP (Production Part Approval Process) validation and long-term supply agreements based on stringent thermal specifications.

A second major customer group includes manufacturers in the Electrical and Electronics sector, particularly those producing high-power density devices, lighting components (such as specialized LED light housings), and sophisticated IT and networking equipment. These customers prioritize materials that offer excellent dielectric properties, maintain dimensional stability under continuous operational heat, and comply with international fire safety standards like UL 94 V-0. Their purchasing decisions are heavily influenced by material traceability and certified adherence to non-halogenated flame retardant requirements, pushing the market towards advanced, specialized HR-ABS compounds.

Beyond the core automotive and E&E sectors, significant niche customer groups include appliance manufacturers needing materials for high-heat generating devices (e.g., high-performance blenders, heaters), and medical device companies requiring durable, heat-resistant casings capable of withstanding various sterilization techniques. These buyers often require smaller, customized batches and technical support for highly specific applications, driving demand for specialized HR-ABS distributors capable of providing localized technical expertise and fast lead times for specialized grades.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1,950 Million |

| Market Forecast in 2033 | $2,880 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SABIC, Trinseo, Chi Mei Corporation, INEOS Styrolution, LG Chem, Formosa Plastics Corporation, Kumho Petrochemical, Toray Industries Inc., LyondellBasell Industries Holdings B.V., Ravago Group, BASF SE, Lotte Chemical Corporation, Versalis S.p.A., Asahi Kasei Corporation, Daicel Corporation, Technyl (DOMO Chemicals), Sumitomo Chemical Co., Ltd., Japan Synthetic Rubber Co., Ltd. (JSR), Ampa Plastics International, Kingfa Sci.&Tech. Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Heat Resistant ABS Market Key Technology Landscape

The technological landscape of the Heat Resistant ABS market is dominated by advancements in polymerization chemistry, compounding techniques, and additive science aimed at elevating the heat deflection temperature (HDT) without sacrificing the inherent processability and impact strength of ABS. The primary technical innovation revolves around the incorporation of specialized high-temperature monomers, such as Alpha Methyl Styrene (AMS) or N-Phenyl Maleimide (NPMI), which increases the glass transition temperature (Tg) of the styrene-acrylonitrile (SAN) matrix. These monomer modifications require precise control over reaction conditions, including temperature, pressure, and residence time, to ensure uniform molecular weight distribution and optimal thermal performance across large production batches. This pursuit of higher Tg materials is critical for meeting the demanding specifications of modern automotive and high-power electronics applications.

Another crucial technological area is advanced reactive compounding and extrusion processes. HR-ABS often needs blending with other polymers, such as Polycarbonate (PC) or specialty polyesters, to achieve desired synergistic properties like enhanced toughness or chemical resistance at high heat. Manufacturers utilize sophisticated twin-screw extruders with optimized shear profiles to ensure complete and homogenous dispersion of the rubber phase (polybutadiene) and various additives, including thermal stabilizers, UV absorbers, and particularly, flame retardants. The transition towards non-halogenated flame retardant (NHFR) systems presents a significant technological challenge, requiring the development of highly effective phosphorus-based or inorganic compounds that do not compromise the mechanical properties or aesthetic quality of the final high-heat plastic component.

Furthermore, technology focusing on sustainability is gaining prominence, driven by regulatory pressure and consumer demand. This includes the development of chemical recycling methods that can effectively depolymerize post-consumer HR-ABS waste into reusable monomers (styrene, acrylonitrile, and butadiene), enabling a circular economy approach for these specialty plastics. Mechanical recycling, while simpler, is often constrained by the presence of high-heat additives and contaminants, necessitating advanced sorting and purification technologies to maintain the performance integrity required for new HR-ABS production. The integration of advanced simulation tools (e.g., Finite Element Analysis) for predicting material behavior under thermal stress also represents a key technology, allowing OEMs to rapidly validate HR-ABS grades for complex part designs before committing to expensive tooling.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing regional market for Heat Resistant ABS, primarily fueled by the region’s dominant position in global electronics manufacturing (China, South Korea, Taiwan) and its rapidly expanding automotive production base, particularly for electric and hybrid vehicles. The increasing demand for home appliances and consumer electronics, coupled with significant infrastructure investments requiring durable polymer solutions, sustains high consumption rates. Countries such as China and India are experiencing significant domestic demand, driving local capacity expansion among major regional and international HR-ABS producers.

- North America: North America represents a mature, high-value market characterized by a strong emphasis on high-performance, specialized HR-ABS grades used in premium automotive sectors and complex industrial equipment. Regulatory drivers, particularly rigorous safety standards for electric vehicle components and strict fire codes in construction and E&E applications, necessitate the use of advanced FR HR-ABS grades. Market growth here is steady, focusing on innovation in sustainable and bio-based high-heat plastics and replacing traditional metals in demanding applications for lightweighting purposes.

- Europe: Europe exhibits robust demand for HR-ABS, driven by stringent environmental regulations, particularly the European Union’s push toward circular economy policies and REACH compliance for chemical use. The regional market focuses on developing non-halogenated flame retardant HR-ABS grades for compliance-heavy sectors like construction and electrical infrastructure. Germany, France, and Italy are key consumers, driven by their established automotive industries and high standards for building and electronic safety. Innovation in compounding technology to achieve superior mechanical properties alongside high thermal resistance is a regional priority.

- Latin America (LATAM): The LATAM market is emerging, demonstrating moderate growth supported by industrialization and increasing foreign direct investment in manufacturing, particularly in Brazil and Mexico. The automotive manufacturing base in Mexico serves significant export markets, creating steady demand for HR-ABS in component production. However, market adoption can be volatile due to macroeconomic instabilities and reliance on imported specialty polymer grades. Focus areas include basic HR-ABS grades for consumer goods and automotive tier 2 components.

- Middle East and Africa (MEA): MEA is the smallest but potentially fastest-growing regional market, driven by large-scale infrastructure projects, rapid urbanization, and growing automotive assembly operations, particularly in countries like Turkey, South Africa, and the Gulf Cooperation Council (GCC) states. Demand is concentrated in construction-related E&E components and domestic appliance manufacturing. Challenges include developing local technical expertise and reliance on complex global supply chains for specialized HR-ABS formulations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Heat Resistant ABS Market.- SABIC (Saudi Basic Industries Corporation)

- Trinseo PLC

- Chi Mei Corporation

- INEOS Styrolution Group GmbH (now part of INEOS)

- LG Chem Ltd.

- Formosa Plastics Corporation

- Kumho Petrochemical Co., Ltd.

- Toray Industries Inc.

- LyondellBasell Industries Holdings B.V.

- Ravago Group

- BASF SE

- Lotte Chemical Corporation

- Versalis S.p.A. (Eni Group)

- Asahi Kasei Corporation

- Daicel Corporation

- Technyl (DOMO Chemicals)

- Sumitomo Chemical Co., Ltd.

- Japan Synthetic Rubber Co., Ltd. (JSR)

- Ampa Plastics International Pty Ltd.

- Kingfa Sci.&Tech. Co., Ltd.

- Mitsubishi Chemical Corporation

- Daelim Industrial Co., Ltd.

- Polykemi AB

- Plastics Engineering Company (PLENCO)

- Polyplastics Co., Ltd.

- TSRC Corporation

- DIC Corporation

- Kaneka Corporation

- PCL Industrial Plastics

- Shanghai Huajin Composite Materials Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Heat Resistant ABS market and generate a concise list of summarized FAQs reflecting key topics and concerns.What defines Heat Resistant ABS (HR-ABS) compared to standard ABS?

HR-ABS is defined by its significantly higher Heat Deflection Temperature (HDT), typically ranging from 95°C to over 120°C, achieved through chemical modification (e.g., AMS inclusion). This allows it to maintain mechanical strength and dimensional stability under thermal stress, unlike standard ABS which rapidly deforms above 85°C, making HR-ABS suitable for hot environments.

Which end-use industries drive the majority of demand for HR-ABS?

The primary drivers are the Automotive industry, particularly for interior and under-the-hood components requiring thermal stability against engine heat and solar load, and the Electrical and Electronics (E&E) sector for power supply enclosures, adapters, and LED lighting fixtures where operational heat is intense.

How is the volatility of raw material prices affecting the HR-ABS market?

Price volatility in key feedstocks such as styrene, butadiene, and acrylonitrile directly impacts the manufacturing cost of HR-ABS. Manufacturers must manage complex hedging strategies and supply chain risks, often leading to fluctuating pricing for specialized high-temperature grades, restraining overall market profitability.

What is the role of flame retardancy in the growth of the HR-ABS market?

Flame retardancy is critical, especially in E&E and construction applications, where HR-ABS must meet strict safety standards like UL 94 V-0. The market is increasingly shifting towards non-halogenated flame retardant (NHFR) HR-ABS grades to comply with global environmental regulations and enhance product safety profiles, driving specialized segment growth.

What are the primary technological challenges in developing ultra-high heat resistant ABS?

The main challenges involve increasing the material’s glass transition temperature (Tg) beyond 120°C without compromising its impact strength (toughness) or ease of processing (flowability). Achieving this balance requires complex polymerization control and the incorporation of specialized, often expensive, high-performance comonomers and blending agents.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager