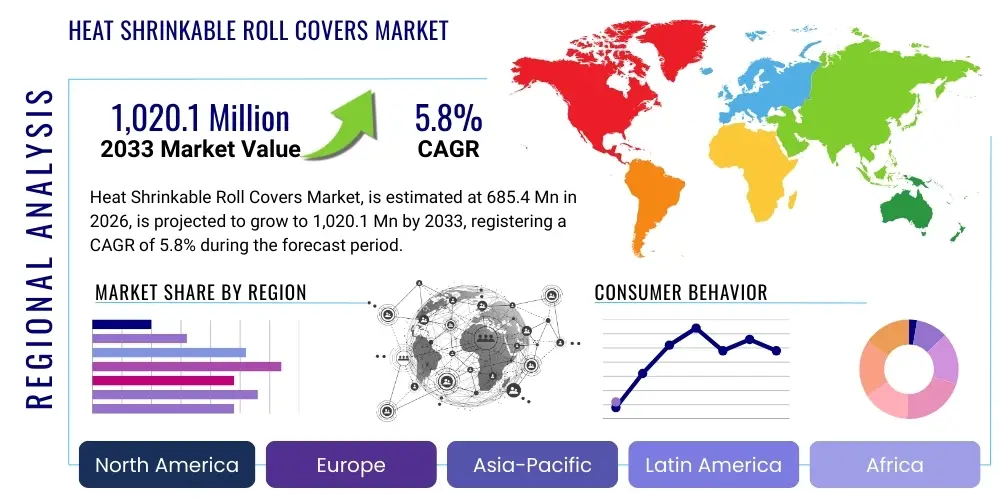

Heat Shrinkable Roll Covers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440479 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Heat Shrinkable Roll Covers Market Size

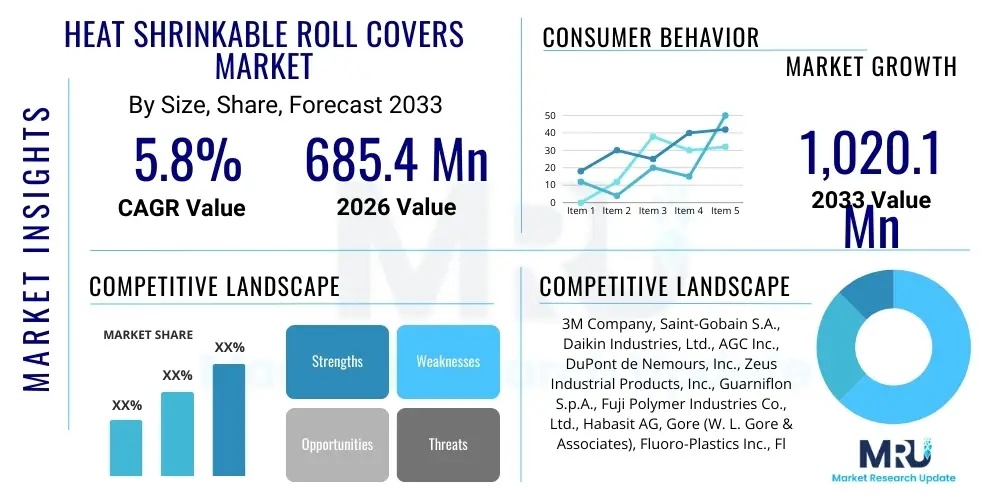

The Heat Shrinkable Roll Covers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 685.4 Million in 2026 and is projected to reach USD 1,020.1 Million by the end of the forecast period in 2033.

Heat Shrinkable Roll Covers Market introduction

Heat shrinkable roll covers are specialized tubular sleeves made from advanced fluoropolymers such as PTFE (Polytetrafluoroethylene) and FEP (Fluorinated Ethylene Propylene), designed to protect and enhance the performance of industrial rollers across various sectors. These covers, upon application of heat, conform tightly to the roller's surface, creating a seamless, non-stick, and chemically resistant protective layer. Their primary applications span industries like printing, packaging, textile, food processing, and chemical manufacturing, where rollers are critical components in conveying, pressing, and drying processes. The inherent benefits of these covers include significantly improved release properties, reduced material build-up, enhanced resistance to chemicals and abrasion, and extended roller lifespan, leading to reduced maintenance costs and minimized downtime. These advantages collectively drive the market growth by contributing to greater operational efficiency, superior product quality, and cost savings for end-users, making them indispensable in modern industrial settings.

The core technology behind heat shrinkable roll covers leverages the unique thermal properties of fluoropolymers. When exposed to heat, the pre-stressed polymer tubing shrinks uniformly, creating a tight, smooth, and robust fit over the roller. This creates a surface that is highly resistant to adhesion, corrosion, and extreme temperatures, crucial for processes involving sticky materials, aggressive chemicals, or high operational temperatures. Major applications include covering guide rollers in printing presses to prevent ink accumulation, enhancing release in laminating machines, protecting rollers in food contact applications to ensure hygiene, and safeguarding textile processing rollers from dyes and fibers. The superior performance characteristics, such as excellent dielectric strength, low friction coefficient, and broad chemical inertness, position these covers as an essential component in high-performance industrial machinery, facilitating smoother operations and mitigating potential production bottlenecks. The continuous advancements in polymer science further enhance their capabilities, expanding their utility into more demanding and niche applications.

Heat Shrinkable Roll Covers Market Executive Summary

The Heat Shrinkable Roll Covers Market is experiencing robust growth, primarily driven by the escalating demand for operational efficiency, enhanced product quality, and reduced maintenance in a multitude of industrial sectors. Key business trends indicate a strong focus on customization and the development of application-specific solutions, allowing manufacturers to cater to the precise needs of diverse end-user industries. There is a growing inclination towards advanced fluoropolymer compositions that offer superior chemical resistance, higher temperature tolerance, and enhanced durability, pushing the boundaries of material science. From a regional perspective, Asia Pacific emerges as a dominant and rapidly expanding market, fueled by burgeoning manufacturing industries and increasing automation investments, particularly in countries like China and India. North America and Europe, while mature, demonstrate steady growth driven by the need for process optimization in established industries and stringent regulatory demands for hygiene and safety. In terms of segment trends, the PTFE and FEP material types continue to hold significant market shares due to their proven performance, with thickness variations tailored to specific application requirements.

The market's trajectory is also significantly influenced by the global emphasis on sustainability and energy efficiency, prompting innovations in material science to develop more eco-friendly and long-lasting roll cover solutions. The widespread adoption of automation and advanced manufacturing techniques across industries necessitates high-performance roller surfaces that can withstand continuous operation and minimize downtime, directly boosting the demand for heat shrinkable roll covers. Furthermore, the expansion of the packaging and food processing industries, driven by global population growth and changing consumption patterns, creates a consistent need for anti-stick and hygienic roller surfaces. Challenges such as high initial investment costs and the need for specialized installation techniques are being addressed through product innovation and improved service offerings, leading to a more accessible and attractive market. Overall, the market remains dynamic, characterized by continuous technological advancements and strategic collaborations aimed at expanding product portfolios and geographic reach to capitalize on emerging opportunities and overcome existing restraints.

AI Impact Analysis on Heat Shrinkable Roll Covers Market

User inquiries about AI's impact on the Heat Shrinkable Roll Covers Market often revolve around how artificial intelligence can optimize the manufacturing processes, predict material performance, enhance quality control, and potentially personalize product offerings. Key themes include the use of AI in predictive maintenance for roller systems, thereby extending the lifespan of roll covers, and leveraging AI for material science breakthroughs to develop next-generation fluoropolymers with superior properties. There is also significant interest in how AI can streamline supply chain logistics and improve market forecasting for these specialized industrial components. Users expect AI to bring about efficiencies in production, greater precision in application, and a deeper understanding of market dynamics, ultimately leading to more robust, cost-effective, and tailor-made solutions for industrial clients.

- AI-driven optimization of fluoropolymer extrusion and shrinking processes, leading to reduced waste and improved material consistency.

- Predictive maintenance algorithms for industrial rollers, indicating optimal times for roll cover replacement, thus minimizing downtime.

- Enhanced quality control systems using AI-powered vision inspection for defect detection during manufacturing of roll covers.

- AI analytics for identifying novel material compositions and properties that could lead to more durable or specialized roll cover variants.

- Supply chain optimization through AI, predicting demand fluctuations and managing inventory levels for raw materials and finished products.

- Personalized product recommendations for specific industrial applications based on operational data and performance requirements.

- AI-enabled smart sensors embedded in rollers to monitor real-time performance and adhesion, guiding preventative maintenance for roll covers.

DRO & Impact Forces Of Heat Shrinkable Roll Covers Market

The Heat Shrinkable Roll Covers Market is propelled by several key drivers, primarily the escalating demand for enhanced operational efficiency and productivity across diverse manufacturing sectors. Industries are increasingly seeking solutions to minimize downtime, reduce maintenance costs, and improve the quality of their end-products, all of which are directly addressed by the superior performance of heat shrinkable roll covers in preventing material buildup and ensuring smooth operation. Furthermore, stringent regulatory standards, especially in the food processing and pharmaceutical industries, necessitate hygienic, non-contaminating, and easy-to-clean roller surfaces, which fluoropolymer covers inherently provide. The continuous expansion of manufacturing capacities, particularly in emerging economies, coupled with a global trend towards automation and sophisticated machinery, fuels the adoption of these advanced roll protection solutions. Technological advancements in material science, leading to the development of more durable and application-specific fluoropolymer compounds, also serve as a significant driver, broadening the scope of applications and reinforcing market growth.

However, the market also faces considerable restraints, including the relatively high initial cost associated with premium fluoropolymer materials and the specialized installation procedures required for heat shrinkable covers, which can deter smaller enterprises or those with limited capital budgets. The availability of substitute solutions, such as traditional roller coatings or conventional composite materials, though often less effective, poses a competitive challenge, particularly in cost-sensitive markets. Furthermore, the performance limitations of certain fluoropolymers under extremely high temperatures or in highly abrasive environments can restrict their application in niche industrial processes. Despite these restraints, opportunities abound for market expansion, particularly through the development of more cost-effective production methods, the introduction of user-friendly installation kits, and the exploration of new end-use industries. Innovations in sustainable and bio-based fluoropolymers also present a significant growth avenue, aligning with global environmental concerns and regulatory shifts. Strategic partnerships and increased investment in R&D to tailor products for specific, complex industrial challenges will be crucial for capitalizing on these opportunities.

The impact forces influencing this market are multifaceted. Competitive rivalry among manufacturers is moderate to high, driven by product differentiation, technological superiority, and geographical reach. Supplier power is relatively strong due to the specialized nature of fluoropolymer raw materials, often sourced from a limited number of high-tech chemical companies. Buyer power, particularly for large industrial clients, is also significant as they often demand customized solutions and competitive pricing for bulk orders. The threat of new entrants is moderate, as establishing the necessary expertise in fluoropolymer processing and heat shrink technology requires substantial capital investment and specialized knowledge. Lastly, the threat of substitutes, while present, is mitigated by the superior performance benefits and longevity offered by heat shrinkable roll covers, making them a preferred choice for critical applications where reliability and quality are paramount. These forces collectively shape the market's dynamics, influencing pricing strategies, product development, and competitive positioning.

Segmentation Analysis

The Heat Shrinkable Roll Covers Market is extensively segmented to reflect the diverse applications and material specifications demanded by various industrial sectors. This segmentation provides a granular view of market dynamics, allowing for a targeted analysis of growth opportunities, competitive landscapes, and evolving customer preferences. Key segmentation criteria include the type of material used, the specific application areas, the thickness of the cover, and the end-use industry. Understanding these distinctions is crucial for manufacturers to tailor their product offerings, optimize production processes, and develop effective market entry strategies. Each segment exhibits unique growth patterns influenced by technological advancements, regulatory environments, and regional industrial development, collectively shaping the overall market trajectory. The material type segment, for instance, highlights the dominance of fluoropolymers due to their superior properties, while the application and end-use segments underscore the critical role these covers play in enhancing operational efficiency across a broad spectrum of manufacturing processes.

- By Material Type:

- PTFE (Polytetrafluoroethylene)

- FEP (Fluorinated Ethylene Propylene)

- PFA (Perfluoroalkoxy Alkane)

- PVDF (Polyvinylidene Fluoride)

- Others (e.g., ETFE, ECTFE)

- By Thickness:

- Thin-Walled (<0.5 mm)

- Medium-Walled (0.5 mm - 1.5 mm)

- Thick-Walled (>1.5 mm)

- By Application:

- Printing & Graphics

- Packaging

- Textile Processing

- Food & Beverage Processing

- Paper & Pulp Industry

- Chemical Processing

- Roll Protection

- Anti-Stick Applications

- Corrosion Protection

- Other Industrial Applications

- By End-Use Industry:

- Printing Industry

- Packaging Industry

- Textile Industry

- Food Processing Industry

- Chemical Industry

- Pharmaceutical Industry

- Automotive Industry

- Electronics Industry

- General Manufacturing

- By Sales Channel:

- Direct Sales

- Distributors

- Online Retail

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Heat Shrinkable Roll Covers Market

The value chain for the Heat Shrinkable Roll Covers Market begins with the upstream sourcing of highly specialized raw materials, primarily fluoropolymers. Key suppliers in this segment include major chemical companies that synthesize and provide high-performance resins such as PTFE, FEP, PFA, and PVDF. These materials require advanced chemical engineering and are often proprietary, giving significant leverage to these raw material suppliers. The quality, purity, and specific properties of these polymers directly dictate the performance characteristics of the final roll cover. Following raw material procurement, the midstream activities involve the manufacturing and conversion processes, where these polymers are extruded into tubular forms, treated, and processed into heat shrinkable sleeves. This stage includes sophisticated manufacturing techniques like extrusion, calendering, stretching, and specific thermal treatments to impart the heat shrink properties. Manufacturers often specialize in precise wall thicknesses, diameters, and lengths to meet diverse customer specifications. The quality control at this stage is crucial to ensure dimensional stability, uniform shrinking characteristics, and the integrity of the non-stick and chemical-resistant surfaces.

Moving downstream, the distribution of heat shrinkable roll covers typically involves a combination of direct sales and indirect channels. Direct sales are common for large industrial customers who require highly customized solutions, technical support, and direct consultation with manufacturers. This approach allows for closer relationships, tailored product development, and efficient problem-solving. Indirect channels primarily involve specialized industrial distributors who maintain inventory, provide regional access, and offer value-added services such as cutting, slitting, and sometimes even installation support. These distributors play a crucial role in reaching a broader customer base, particularly small and medium-sized enterprises (SMEs) that may not have direct contact with manufacturers. The choice of distribution channel often depends on the customer's size, geographic location, and the complexity of their application requirements. Marketing and sales activities focus on highlighting the durability, performance benefits, and cost-saving aspects of these covers, often through technical datasheets, case studies, and industry trade shows.

The end-users, at the final stage of the value chain, integrate these roll covers into their machinery, such as printing presses, laminators, textile dryers, and food processing conveyors. The effectiveness of the roll cover directly impacts the end-user's operational efficiency, product quality, and maintenance costs. Post-purchase support, including installation guidance, troubleshooting, and replacement services, further adds value to the customer experience. The entire value chain is characterized by a strong emphasis on research and development, particularly in material science and processing technologies, to continuously innovate and meet evolving industrial demands. Collaboration between raw material suppliers, manufacturers, and end-users is vital for developing next-generation solutions that address emerging challenges, such as higher temperature resistance, improved chemical inertness, and enhanced durability in increasingly demanding industrial environments. This collaborative approach ensures that the products remain relevant and competitive, driving sustained growth within the market.

Heat Shrinkable Roll Covers Market Potential Customers

The Heat Shrinkable Roll Covers Market primarily serves a broad spectrum of industrial end-users who rely on efficient and well-maintained roller systems for their manufacturing and processing operations. Potential customers are entities that operate machinery incorporating various types of rollers, where issues such as material adhesion, chemical corrosion, abrasion, or frequent cleaning can impede productivity and compromise product quality. This includes, but is not limited to, manufacturers within the printing and graphics industry who seek to prevent ink buildup and improve print quality on guide rollers. The packaging industry represents a significant customer base, requiring non-stick surfaces on sealing and conveying rollers to handle a variety of film and adhesive materials efficiently. Textile mills utilize these covers to protect rollers from dyes, fibers, and processing chemicals, ensuring smooth fabric handling and reducing downtime. The food and beverage processing sector is a critical end-user, driven by stringent hygiene standards and the need for anti-stick surfaces on conveyor and press rollers to prevent food residue accumulation and facilitate easy cleaning, thus minimizing contamination risks and complying with regulatory requirements. Furthermore, chemical processing plants and pharmaceutical manufacturers also represent key segments, using these covers to protect rollers from corrosive substances and ensure clean room standards, maintaining the integrity of sensitive products. The automotive and electronics industries also leverage these covers in specific assembly and manufacturing processes, particularly where components need to be protected from static or surface contamination. Essentially, any industry utilizing rollers that benefit from enhanced surface properties, protection, or simplified maintenance is a potential customer for heat shrinkable roll covers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 685.4 Million |

| Market Forecast in 2033 | USD 1,020.1 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Saint-Gobain S.A., Daikin Industries, Ltd., AGC Inc., DuPont de Nemours, Inc., Zeus Industrial Products, Inc., Guarniflon S.p.A., Fuji Polymer Industries Co., Ltd., Habasit AG, Gore (W. L. Gore & Associates), Fluoro-Plastics Inc., Fluoron GmbH, PAR Group, Holscot Industrial Linings Ltd., Plastomer Technologies, Inc., Jiangsu Yunsheng Co., Ltd., Shanghai Kessen Co., Ltd., Changzhou Huaao Plastics Co., Ltd., Ningbo Tianlong Rubber & Plastic Co., Ltd., Jilin Ruixiang Plastic Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Heat Shrinkable Roll Covers Market Key Technology Landscape

The Heat Shrinkable Roll Covers Market is underpinned by a sophisticated array of technologies, primarily centered around advanced polymer science and specialized manufacturing processes. At the core is the development and processing of high-performance fluoropolymers such as PTFE, FEP, PFA, and PVDF. The manufacturing of these raw materials involves complex polymerization processes to achieve specific molecular weights, crystallinity, and purity levels that dictate their ultimate physical and chemical properties, including their non-stick characteristics, chemical inertness, and thermal stability. Technological advancements in fluoropolymer synthesis focus on enhancing these attributes, often by modifying polymer structures or developing novel copolymer formulations to meet ever more demanding industrial requirements. This includes improving processability, reducing cold flow, and increasing resistance to specific aggressive chemicals or extreme temperatures, which are critical for extending the lifespan and performance of the roll covers in harsh operating environments.

Beyond material synthesis, the key technologies involve the precise extrusion and shaping of these fluoropolymers into seamless tubular forms. This requires highly specialized extrusion equipment capable of handling the unique rheological properties of fluoropolymers, which often have high melt viscosities and require precise temperature control. The extrusion process is critical for achieving uniform wall thickness and consistent internal and external diameters, which are essential for proper heat shrinking and optimal performance. Subsequent to extrusion, the tubes undergo a post-processing stage where they are mechanically stretched or oriented and then quickly cooled to lock in the expanded state. This "memory effect" is what enables the material to shrink back to its original, smaller dimension when reheated, creating the tight, conformal fit on the roller. Advanced stretching and annealing techniques are employed to control the degree of shrinkage and ensure uniform radial and axial recovery, preventing wrinkles or uneven coverage on the roller surface. The precision of these manufacturing steps directly influences the final quality and effectiveness of the heat shrinkable roll covers.

Furthermore, surface modification technologies and adhesive bonding techniques also play a crucial role in the technological landscape. While fluoropolymers are inherently non-stick, some applications may benefit from surface treatments to further enhance release properties or to improve adhesion for specific bonding requirements at the ends of the roll covers. This can involve plasma treatment, chemical etching, or the application of specialized primers. The development of robust adhesive systems that can withstand the operational temperatures and chemical exposure is also vital for ensuring the long-term integrity of the installation. Continuous innovation in these areas focuses on improving material compatibility, enhancing bonding strength, and simplifying the installation process. Additionally, quality control technologies, including advanced optical inspection systems and non-destructive testing, are employed to ensure that each roll cover meets stringent performance specifications before reaching the end-user. The synergy of these material, processing, and application technologies is what drives the advancements and competitive edge within the Heat Shrinkable Roll Covers Market, enabling solutions that address the complex and evolving needs of industrial clients.

Regional Highlights

- North America: This region represents a mature yet robust market, driven by the presence of established manufacturing industries in printing, packaging, and food processing, coupled with a strong emphasis on automation and operational efficiency. The demand for high-performance, durable, and reliable components to minimize downtime and enhance productivity is a primary growth driver. Furthermore, stringent regulatory standards, particularly in the food and pharmaceutical sectors, necessitate the use of advanced, hygienic, and non-contaminating roll covers, boosting market adoption. Innovation in material science and processing technologies by regional players also contributes significantly to market expansion, with a focus on developing customized solutions for specialized applications.

- Europe: The European market is characterized by a strong industrial base, particularly in Germany, Italy, and the UK, with high-value manufacturing sectors like automotive, textiles, and specialized machinery. Strict environmental regulations and quality standards compel industries to adopt advanced materials and process optimization solutions, favoring heat shrinkable roll covers. There is a notable trend towards sustainable manufacturing practices and energy efficiency, driving demand for long-lasting and efficient roll cover solutions. R&D investments in fluoropolymer technology and a focus on precision engineering also contribute to the region's strong market position.

- Asia Pacific (APAC): APAC is the fastest-growing market for heat shrinkable roll covers, fueled by rapid industrialization, burgeoning manufacturing sectors, and increasing investments in automation across countries like China, India, Japan, and South Korea. The expansion of printing, packaging, textile, and food processing industries to cater to a large and growing population creates immense demand. The region benefits from lower manufacturing costs and a growing base of local manufacturers, although quality and technological advancements are rapidly catching up with Western counterparts. Government initiatives supporting manufacturing and infrastructure development further accelerate market growth.

- Latin America: This region exhibits emerging market potential, with gradual industrial growth and increasing adoption of modern manufacturing techniques. Countries like Brazil and Mexico are leading the demand, particularly in the packaging and food processing industries, driven by urbanization and changing consumer habits. The market growth is influenced by foreign direct investments in manufacturing and the upgrading of existing industrial infrastructure, leading to a greater need for efficient and protective roll cover solutions.

- Middle East & Africa (MEA): The MEA market is developing, primarily driven by investments in infrastructure, manufacturing, and food security initiatives. The expansion of packaging, food processing, and certain chemical industries contributes to the demand for heat shrinkable roll covers. While smaller in market size compared to other regions, opportunities exist for growth as industrialization progresses and awareness of advanced materials and their benefits increases, particularly in countries with growing manufacturing bases and processing facilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Heat Shrinkable Roll Covers Market.- 3M Company

- Saint-Gobain S.A.

- Daikin Industries, Ltd.

- AGC Inc.

- DuPont de Nemours, Inc.

- Zeus Industrial Products, Inc.

- Guarniflon S.p.A.

- Fuji Polymer Industries Co., Ltd.

- Habasit AG

- Gore (W. L. Gore & Associates)

- Fluoro-Plastics Inc.

- Fluoron GmbH

- PAR Group

- Holscot Industrial Linings Ltd.

- Plastomer Technologies, Inc.

- Jiangsu Yunsheng Co., Ltd.

- Shanghai Kessen Co., Ltd.

- Changzhou Huaao Plastics Co., Ltd.

- Ningbo Tianlong Rubber & Plastic Co., Ltd.

- Jilin Ruixiang Plastic Co., Ltd.

Frequently Asked Questions

What are the primary benefits of using heat shrinkable roll covers?

Heat shrinkable roll covers offer numerous advantages, including superior non-stick properties, enhanced chemical and abrasion resistance, protection against corrosion, extended roller lifespan, reduced material buildup, and minimized downtime for maintenance and cleaning. These benefits collectively lead to improved operational efficiency and higher product quality in various industrial processes.

In which industries are heat shrinkable roll covers most commonly utilized?

These covers find widespread application across diverse industries such as printing and graphics, packaging, textile processing, food and beverage processing, paper and pulp, and chemical manufacturing. They are crucial wherever rollers need protection and enhanced surface properties for optimal performance.

What materials are typically used to manufacture heat shrinkable roll covers?

The most common materials are high-performance fluoropolymers, primarily PTFE (Polytetrafluoroethylene), FEP (Fluorinated Ethylene Propylene), and PFA (Perfluoroalkoxy Alkane), due to their exceptional non-stick, chemical-resistant, and high-temperature properties.

How do heat shrinkable roll covers contribute to cost savings for businesses?

By protecting expensive industrial rollers from wear, corrosion, and material accumulation, these covers significantly extend roller lifespan, reduce the frequency of cleaning and maintenance, and minimize production downtime. These factors directly translate into substantial long-term cost savings for businesses.

What is the typical lifespan of a heat shrinkable roll cover?

The lifespan of a heat shrinkable roll cover varies significantly based on the application, operating conditions (e.g., temperature, chemical exposure, abrasion), and the type of fluoropolymer used. However, they are designed for extended durability, often lasting several years in typical industrial environments, outperforming many traditional roller coatings.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager