Heatproof Sticker Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433474 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Heatproof Sticker Market Size

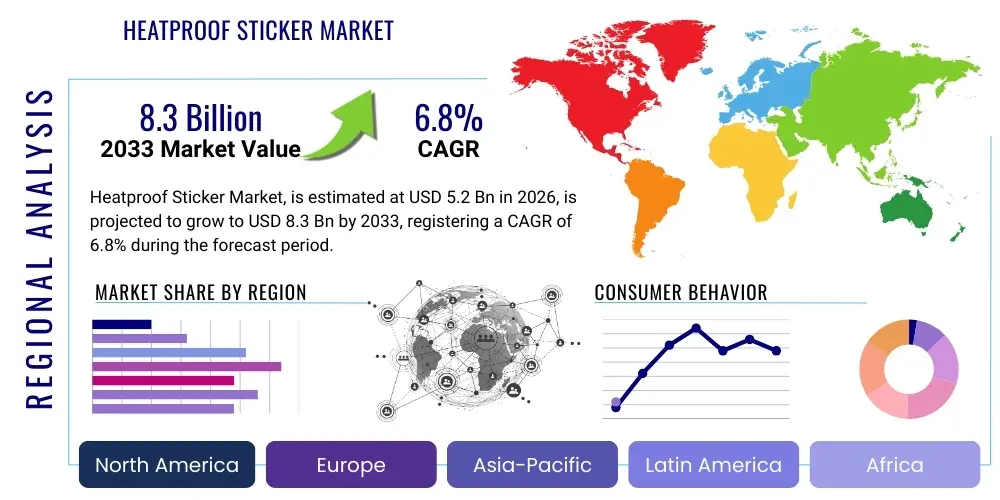

The Heatproof Sticker Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. This robust expansion is fueled by the increasing miniaturization of electronic components, stringent safety regulations across multiple industrial sectors, and the sustained demand for reliable identification and traceability solutions in high-temperature environments. The market is estimated at USD 5.2 Billion in 2026 and is projected to reach USD 8.3 Billion by the end of the forecast period in 2033, demonstrating significant resilience and technological maturity necessary to serve mission-critical applications.

Heatproof Sticker Market introduction

The Heatproof Sticker Market encompasses the production and distribution of specialized adhesive labels and decals designed to withstand extreme thermal conditions, chemical exposure, and mechanical abrasion without degradation in legibility or adhesive performance. These labels, often constructed from advanced materials like polyimide (Kapton), specialized polyesters, and ceramic-based films, utilize high-performance acrylic, silicone, or thermosetting adhesives to maintain structural integrity under continuous operating temperatures ranging from 150°C to over 500°C. Major applications span critical sectors, including the identification of circuit boards in consumer electronics, tracking components in automotive engines and exhaust systems, asset management in aerospace manufacturing, and labeling hot equipment in heavy industrial processes.

The primary benefits of utilizing heatproof stickers include ensuring regulatory compliance, facilitating quality control, enabling long-term asset traceability, and providing essential warning or safety instructions that must remain visible despite harsh environmental stresses. Their durability is crucial in industries where component failure due to overheating is a significant concern, thus guaranteeing operational efficiency and safety. The market is driven by global trends toward higher operational speeds and temperatures in manufacturing, coupled with the proliferation of complex electronic systems requiring permanent, heat-resistant identification.

Heatproof Sticker Market Executive Summary

The Heatproof Sticker Market is characterized by intense technological innovation focused on material science, particularly in developing thinner, more flexible films with enhanced thermal stability and improved resistance to fluxes and solvents used in manufacturing processes. Key business trends include the consolidation among major raw material suppliers and label converters, alongside an escalating focus on sustainable, non-hazardous adhesive formulations. Regional trends indicate that Asia Pacific (APAC) holds the largest market share, driven by robust growth in the electronics and electric vehicle (EV) manufacturing sectors in countries like China, South Korea, and Japan, which require extensive heat-resistant labeling for batteries and PCBs. North America and Europe, however, maintain leadership in high-value segments such as aerospace and defense, demanding highly specialized, certified heatproof labeling solutions.

Segment trends reveal that the Polyimide material segment dominates due to its superior thermal endurance and dimensional stability, making it the preferred choice for electronics applications. Furthermore, the Automotive segment is experiencing the fastest growth, primarily due to the mandated requirements for component traceability within high-heat areas of internal combustion engines and the thermal management needs of emerging EV battery packs. End-user trends show a strong shift toward integrated smart labeling solutions, including heatproof labels embedded with RFID or near-field communication (NFC) capabilities, facilitating real-time tracking and inventory management in harsh industrial environments, thereby elevating the value proposition of these specialized identification products.

AI Impact Analysis on Heatproof Sticker Market

User queries regarding the impact of Artificial Intelligence (AI) on the Heatproof Sticker Market often revolve around optimizing the supply chain, enhancing quality control during manufacturing, and developing predictive maintenance applications enabled by smart labeling. Key concerns include how AI algorithms can predict adhesive degradation under various thermal stress profiles, leading to the development of more robust material combinations. Users also inquire about the role of machine learning in automating the complex printing and die-cutting processes required for high-volume, highly precise labels, thereby reducing material waste and improving throughput. The overall expectation is that AI will primarily influence the efficiency and personalization aspects of heatproof sticker production and deployment, rather than disrupting the core material science, which remains physics-bound.

AI's primary influence will be seen in factory floor automation, where sophisticated vision systems coupled with deep learning are used for defect detection on printed heatproof labels at extremely high speeds, ensuring zero-defect output for critical applications like medical devices and aerospace components. Furthermore, AI-driven predictive analytics can assist raw material procurement by forecasting demand fluctuations for specialized high-performance materials such as polyether ether ketone (PEEK) or PTFE, thereby optimizing inventory levels and mitigating supply chain risks associated with niche chemicals. This integration of intelligent systems is leading to a significant reduction in operational costs and an improvement in the overall reliability and traceability capabilities offered by heatproof labeling solutions to end-users.

- AI-powered predictive maintenance: Analyzing temperature data collected via smart, heatproof labels embedded with thermal sensors to forecast equipment failure.

- Optimized manufacturing processes: Machine learning algorithms fine-tuning coating thickness and curing times for high-performance adhesives to ensure optimal heat resistance.

- Enhanced quality assurance: AI vision systems detecting micro-defects and registration errors on labels utilized in extreme heat applications.

- Demand forecasting: Utilizing AI to predict cyclical demand patterns for specific heat-resistant materials (e.g., polyimide films for microelectronics).

- Supply Chain Efficiency: Automated sourcing of specialized, thermally stable raw materials based on real-time global inventory and pricing fluctuations.

DRO & Impact Forces Of Heatproof Sticker Market

The market dynamics for Heatproof Stickers are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively forming the Impact Forces. Key drivers include the exponential growth in the global electronics sector, particularly high-density PCB manufacturing and power component identification, coupled with increasingly stringent regulatory requirements, such as those imposed by the FAA and FDA, mandating durable and long-lasting traceability markings. Opportunities arise from the rapid adoption of electric vehicles (EVs), which require robust, flame-retardant, and heat-resistant labels for battery modules and powertrain components, creating entirely new, high-volume application areas.

However, the market faces significant restraints, notably the high cost associated with advanced raw materials (like specialized polyimide films and silicone adhesives) compared to conventional labeling materials. Furthermore, the requirement for highly specialized printing and application equipment acts as a barrier to entry for smaller manufacturers. The Impact Forces influencing market direction are dominated by technological innovation, where companies investing heavily in R&D for next-generation material science and smart labeling integration are poised to gain substantial competitive advantage, dictating market standards and price points, particularly in mission-critical industrial and automotive applications.

The thermal stability requirement is paramount, necessitating continuous material science breakthroughs. Regulatory pressure concerning material safety and environmental impact (e.g., transition away from solvent-based adhesives) also forces manufacturers to innovate, often at a substantial cost. This focus on premium, certified solutions underscores the low price elasticity of demand in critical segments, ensuring that quality and performance trump cost considerations. Overall, the structural shift toward automated industrial processes demanding reliable component identification under harsh conditions guarantees sustained demand, overcoming the primary hurdle of high input material costs.

Drivers:

- Expansion of High-Density Electronics: Increased demand for heatproof labels in PCBs, microprocessors, and power supplies due to miniaturization and increased heat generation.

- Growth in Electric Vehicle (EV) Manufacturing: Mandatory labeling for high-heat components such as battery management systems (BMS) and power inverters requiring fire-retardant and high-temperature resistance.

- Stringent Regulatory Compliance: Adherence to industry standards (e.g., UL 969, RoHS, REACH) and traceability mandates in aerospace, medical, and automotive sectors.

- Industrial Automation and Asset Tracking: Need for durable identification tags on hot industrial machinery, furnaces, and manufacturing assets for optimized maintenance and inventory control.

- Advancements in High-Performance Materials: Continuous development of thin-film substrates and high-tack, thermally conductive adhesives offering superior performance.

Restraints:

- High Cost of Raw Materials: Elevated pricing associated with specialized polymers (e.g., polyimide, ceramic foils) and high-temperature silicone or acrylic adhesives.

- Complex Manufacturing Requirements: Need for sophisticated coating, curing, and printing technologies (e.g., laser marking) to ensure durability and legibility in extreme environments.

- Competition from Direct Marking Technologies: Increasing adoption of alternative identification methods like laser etching, dot peening, and direct thermal transfer printing in some industrial applications.

- Environmental and Disposal Concerns: Challenges in developing fully recyclable or biodegradable high-performance heatproof materials without compromising thermal stability.

Opportunities:

- Integration of Smart Technology: Development and commercialization of RFID and NFC-enabled heatproof labels for real-time temperature monitoring and asset tracking.

- Renewable Energy Sector Demand: Utilization of specialized thermal labels in solar panels, concentrated solar power (CSP) components, and high-heat elements of wind turbines.

- Emerging Medical Device Applications: Demand for sterile, heat-resistant labels used on surgical instruments requiring autoclave sterilization and high-temperature processes.

- Customization and Small-Batch Orders: Leveraging digital printing technologies to meet the growing need for personalized, low-volume, high-specification labels for niche industrial use.

Segmentation Analysis

The Heatproof Sticker Market is comprehensively segmented based on material type, application, printing technology, and end-use industry, reflecting the diverse and highly specialized needs of various high-temperature environments. Material type segmentation, which is the most critical differentiator, determines the maximum temperature threshold and chemical resistance of the final product, directly influencing adoption across sensitive sectors such as defense and electronics. The application matrix, covering everything from internal engine parts to industrial chemical processing, dictates the required adhesive strength, flexural properties, and overall durability.

The dominance of Polyimide stickers underscores the market’s reliance on extremely stable, high-performance materials capable of operating continuously at 260°C or higher, essential for wave soldering processes in electronics. Furthermore, the segmentation by end-user highlights the structural demand differences: automotive and electronics sectors drive volume and cost-efficiency requirements, while aerospace and heavy industry demand smaller volumes of ultra-premium, certified labels where performance is non-negotiable. This complex segmentation structure allows manufacturers to tailor solutions precisely to the specific thermal and chemical challenges encountered by different industries globally.

- By Material Type:

- Polyimide (PI)

- Polyester (PET)

- Fiberglass/Ceramic

- Vinyl (Specialty formulations)

- Polyethylene Naphthalate (PEN)

- Others (e.g., PEEK, PTFE derivatives)

- By Application:

- Printed Circuit Boards (PCBs) and Electronic Components

- Automotive Engine Parts and Exhaust Systems

- Aerospace and Defense Component Tracking

- Industrial Machinery and Equipment

- Metal Processing and Smelting

- Laboratory and Medical Sterilization

- Wire and Cable Identification (High-Temperature)

- By Printing Technology:

- Thermal Transfer Printing (TTP)

- Laser Marking

- Flexographic Printing

- Digital Printing

- By End-Use Industry:

- Electronics and Semiconductor

- Automotive and Transportation

- Aerospace and Defense

- Industrial Manufacturing

- Healthcare and Medical Devices

- Telecommunication

Value Chain Analysis For Heatproof Sticker Market

The value chain for the Heatproof Sticker Market begins significantly upstream, where raw material manufacturers specialize in producing high-performance polymers, films, and specialized adhesive chemistries critical for thermal resistance. Upstream activities involve complex chemical synthesis, particularly for materials like polyimide or silicone-based pressure-sensitive adhesives (PSAs) that must endure high temperatures without delamination or outgassing. The cost and quality of these input materials heavily influence the downstream product performance and profitability margins.

Midstream processing involves specialized label converters who perform critical tasks such as precision coating (applying adhesive to the substrate), printing (using heat-stable inks or thermal transfer ribbons), and advanced die-cutting techniques to produce precise label formats required by OEMs. Quality control at this stage is crucial, focusing on thermal stability testing, adhesion strength under high heat, and solvent resistance. Downstream distribution is multifaceted, encompassing direct sales channels to large Original Equipment Manufacturers (OEMs) in the automotive and electronics sectors, and specialized industrial distributors catering to the fragmented aftermarket and smaller industrial clients. The increasing utilization of e-commerce platforms is also streamlining the distribution of standardized heatproof labels.

Direct distribution often dominates high-specification orders, particularly in aerospace, where technical consultation and certification verification are necessary, fostering strong, long-term partnerships between converters and end-users. Conversely, indirect channels, relying on global distributors, handle the high-volume, standardized thermal transfer labels used widely in logistics and general manufacturing. The efficacy of the value chain is highly dependent on effective collaboration between material scientists and label application engineers to ensure that the final product meets the extreme environmental demands of the end-use application, particularly concerning thermal conductivity and dielectric properties.

Heatproof Sticker Market Potential Customers

The potential customer base for the Heatproof Sticker Market is broad, but intensely concentrated within sectors characterized by high operational temperatures, stringent quality control needs, and regulatory requirements for component traceability. The primary buyers are large-scale Original Equipment Manufacturers (OEMs) in the electronics and automotive industries who utilize these stickers directly on their products before they leave the factory floor. These include semiconductor manufacturers needing to label wafers and PCBs for processing traceability, and automotive manufacturers requiring durable labels for engine blocks, exhaust system components, and increasingly, EV battery modules.

Secondary high-value customers include specialized firms within the aerospace and defense sectors, such as aircraft component suppliers and military equipment contractors, where failure tolerance is near zero and material certification is mandatory. These buyers often require custom formulations capable of resisting extreme temperature cycles, radiation, and chemical exposure inherent to aviation or space applications. Additionally, large industrial processing plants (e.g., refineries, chemical manufacturers, and metal foundries) serve as crucial end-users, applying these labels to pipes, valves, and heavy machinery that operate continuously at elevated temperatures for safety and asset identification purposes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.2 Billion |

| Market Forecast in 2033 | USD 8.3 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Avery Dennison Corporation, Tesa SE, Brady Corporation, DuPont, Henkel AG & Co. KGaA, Nitto Denko Corporation, Schreiner Group, CCL Industries Inc., Fuji Seal International, Honeywell International Inc., SATO Holdings Corporation, Konica Minolta Inc., Lintec Corporation, UPM Raflatac, Etimark, Intertronics, Identco, OMNI Systems, Polyonics. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Heatproof Sticker Market Key Technology Landscape

The technological landscape of the Heatproof Sticker Market is dominated by advancements in material science, focusing on creating substrates and adhesives that offer higher sustained temperature resistance and chemical inertness. A pivotal technology is the refinement of polyimide film manufacturing, enabling the production of thinner, more flexible films that can still withstand the extreme heat cycles of reflow and wave soldering processes without cracking or shrinking. Furthermore, there is significant investment in developing next-generation pressure-sensitive adhesives (PSAs), specifically advanced silicone and thermoset acrylic formulations, designed to maintain high tack and shear strength even when operating near their glass transition temperatures (Tg), ensuring permanent adhesion to challenging surfaces like powder coatings or low-surface-energy plastics.

Beyond core materials, printing and marking technologies are undergoing critical evolution. Thermal Transfer Printing (TTP) remains standard, but manufacturers are increasingly utilizing high-resolution laser marking systems to etch indelible identification marks (such as 2D barcodes or serialized text) directly onto specialized heatproof materials. This method provides superior resistance to abrasion and industrial cleaning solvents that might otherwise degrade traditional ink prints. A significant emerging technology involves the integration of functional elements; this includes embedding micro-sensors, RFID chips, or NFC tags within the multilayer structure of the heatproof sticker, turning a passive identification tag into an active component for supply chain monitoring, telemetry, and condition-based maintenance applications, particularly valuable in aerospace and EV battery tracking.

The industry is also leveraging advanced coating technologies, such as plasma surface treatment and specialized corona discharge processes, to enhance the printability and adhesive receptive properties of inherently low-energy substrates like PTFE and high-density polyethylene. This ensures that the printed image or etched information remains legible and durable throughout the component's operational life. Furthermore, sustainability is driving innovation in water-based and UV-curable ink and adhesive systems, moving away from solvent-based formulations to meet stricter environmental regulations while maintaining the necessary thermal performance and resistance to industrial chemicals, a non-trivial challenge that demands complex chemical engineering solutions.

- Advanced Substrate Technology: Focus on ultra-thin polyimide (Kapton) films, fiberglass reinforced composites, and ceramic-based foils offering resistance up to 500°C.

- High-Performance Adhesives: Development of silicone, thermoset acrylic, and high-temperature epoxy-based PSAs with enhanced shear strength and chemical resistance to fluxes and oils.

- Laser Marking Integration: Utilizing CO2 and fiber lasers for high-contrast, permanent etching of data matrix codes and serial numbers directly onto thermal substrates.

- Smart Labeling Technology: Embedding micro-RFID inlays or temperature sensors within the label structure to facilitate active, real-time monitoring under harsh conditions.

- Precision Coating and Curing: Implementation of highly controlled, automated coating lines to ensure uniform adhesive thickness and optimized UV/thermal curing for superior bond strength.

- Sustainable Formulations: Research into non-solvent, water-based, and UV-curable thermal inks and adhesives that maintain performance standards while meeting environmental compliance targets.

Regional Highlights

The regional analysis of the Heatproof Sticker Market reveals distinct patterns of demand driven by localized industrial concentration and regulatory frameworks. Asia Pacific (APAC) commands the leading share, primarily due to its central role as the global manufacturing hub for electronics, semiconductors, and automotive components. Countries like China, Taiwan, and South Korea exhibit massive consumption volumes for high-heat polyimide labels used in PCB identification, driven by continuous expansion and adoption of high-speed manufacturing processes requiring robust component tracking. The accelerating electric vehicle (EV) manufacturing sector across APAC further strengthens this position, necessitating highly specialized, certified heatproof and flame-retardant labels for complex battery assemblies.

North America and Europe represent mature, high-value markets characterized by a demand for specialized, low-volume, high-margin solutions, particularly in aerospace, defense, and high-end industrial machinery. Regulatory bodies such as the Federal Aviation Administration (FAA) and European Union (EU) directives impose stringent requirements for material durability and traceability, driving innovation towards ultra-performance ceramic-based and specialized PTFE labels. In these regions, the focus is heavily skewed towards custom engineering solutions and certified materials rather than high volume, thus yielding higher Average Selling Prices (ASPs). Furthermore, the growth of advanced medical device manufacturing in these regions, requiring labels that survive autoclave sterilization cycles, contributes significantly to market value.

The Middle East and Africa (MEA) and Latin America (LATAM) are emerging markets experiencing moderate growth, linked to increasing investment in oil and gas infrastructure, power generation, and developing local manufacturing capabilities. In MEA, the demand is primarily concentrated in industrial process control and asset identification in extreme climatic conditions, requiring labels resistant not only to high heat but also to UV exposure and harsh chemicals commonly found in the petrochemical industry. While the volumes are lower than in APAC, the need for robust industrial-grade solutions provides niche opportunities for specialized global providers who can meet regional regulatory and environmental requirements effectively.

- Asia Pacific (APAC): Dominates the market due to concentrated electronics manufacturing (PCBs, semiconductors), massive automotive production, and rapid growth in the Electric Vehicle (EV) battery sector. High demand for volume, standardized polyimide labels.

- North America: Significant market share in high-value segments like Aerospace and Defense, and specialized Industrial Manufacturing. Emphasis on high-performance, certified materials and smart labeling (RFID integration).

- Europe: Strong growth driven by stringent EU regulations (e.g., REACH, RoHS), promoting demand for environmentally compliant, solvent-free adhesives and high-durability labels for automotive and medical sterilization applications.

- Latin America (LATAM): Emerging demand fueled by industrial modernization, particularly in Brazil and Mexico, focusing on asset tracking in manufacturing and energy sectors, requiring resistance to heat and humidity.

- Middle East and Africa (MEA): Growth tied to investments in petrochemicals, oil and gas, and power generation. Demand is centered on extremely durable, chemical and heat-resistant labels for infrastructure and pipeline identification in desert climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Heatproof Sticker Market. These companies are profiled based on their technological capabilities, strategic acquisitions, product portfolio breadth, and regional market penetration, focusing particularly on their high-performance material science expertise and certifications in critical industries such as automotive and aerospace.- 3M Company

- Avery Dennison Corporation

- Tesa SE

- Brady Corporation

- DuPont (Material Science Division)

- Henkel AG & Co. KGaA (Adhesive Technologies)

- Nitto Denko Corporation

- Schreiner Group GmbH & Co. KG

- CCL Industries Inc.

- Fuji Seal International, Inc.

- Honeywell International Inc.

- SATO Holdings Corporation

- Konica Minolta Inc.

- Lintec Corporation

- UPM Raflatac

- Etimark AG

- Intertronics

- Identco

- OMNI Systems, Inc.

- Polyonics, Inc.

Frequently Asked Questions

Analyze common user questions about the Heatproof Sticker market and generate a concise list of summarized FAQs reflecting key topics and concerns.What materials provide the highest temperature resistance for heatproof stickers?

Polyimide (Kapton) films offer the highest continuous operating temperatures, typically up to 260°C (500°F). For extreme conditions, specialized materials like ceramic-based foils or glass-reinforced films are used, which can withstand temperatures exceeding 500°C for short durations, essential for metallurgical or specific aerospace applications.

How do heatproof stickers ensure long-term legibility in harsh industrial environments?

Legibility is maintained through a combination of durable substrates and specialized printing techniques. Laser marking or thermal transfer printing utilizing high-performance resin ribbons ensures that text and barcodes resist solvents, abrasion, high heat, and UV exposure without fading or smearing, guaranteeing compliance and traceability.

What is the primary driver for the increased demand for heatproof stickers in the automotive sector?

The transition to Electric Vehicles (EVs) is the primary driver. Heatproof and flame-retardant labels are critically required for identifying and tracking individual battery cells and modules, which operate at elevated temperatures and require robust identification for safety compliance and recall management throughout the vehicle's lifecycle.

Are heatproof stickers compatible with modern smart labeling technologies like RFID?

Yes, integration is a key technological trend. Manufacturers embed miniature, high-temperature tolerant RFID or NFC inlays within the label structure, allowing the sticker to provide both visual identification and active, electronic data transmission for advanced asset tracking and real-time temperature monitoring in industrial settings.

What are the key certification standards required for heatproof stickers in critical industries?

Critical industries require certification for performance and safety. Key standards include UL 969 (Labeling and Marking Systems), military specifications (e.g., MIL-STD), automotive standards (e.g., ISO/TS 16949 for component traceability), and regulatory compliance checks for restricted substances such as RoHS and REACH, especially relevant for electronic components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager