Helium Compressors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439859 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Helium Compressors Market Size

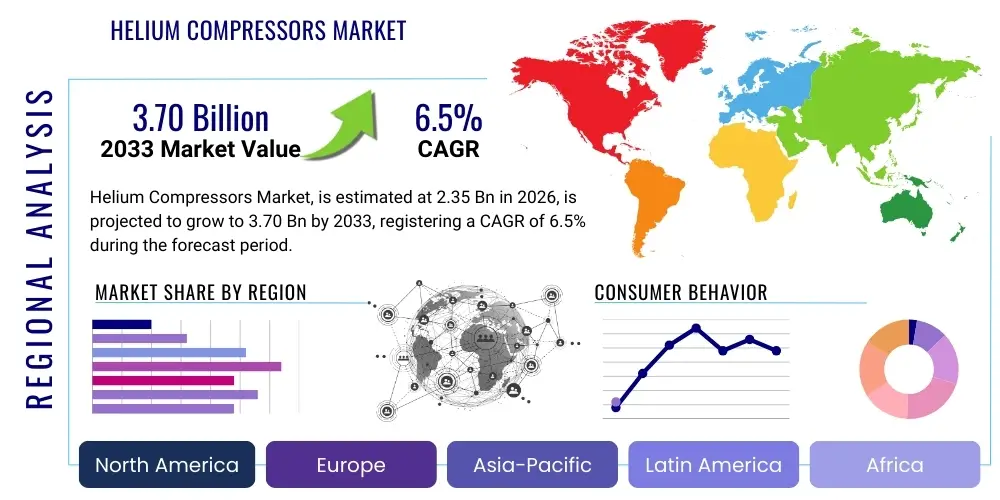

The Helium Compressors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 2.35 billion in 2026 and is projected to reach USD 3.70 billion by the end of the forecast period in 2033.

Helium Compressors Market introduction

The Helium Compressors Market encompasses the global industry involved in the manufacturing, distribution, and utilization of specialized compressor systems designed to handle helium gas. These compressors are crucial for a multitude of advanced applications requiring the unique properties of helium, particularly its extremely low boiling point and non-reactivity. The market primarily serves sectors demanding cryogenic temperatures, such as medical imaging, semiconductor fabrication, and high-energy physics research, where efficient and reliable helium re-liquefaction and gas recovery are paramount. The inherent challenges of compressing helium, including its small atomic size, high thermal conductivity, and low molecular weight, necessitate highly engineered solutions that minimize leakage and ensure operational integrity.

Helium compressors are vital components in closed-loop cryogenic systems, facilitating the continuous cooling of superconducting magnets in Magnetic Resonance Imaging (MRI) machines, Nuclear Magnetic Resonance (NMR) spectrometers, and particle accelerators. They also play an indispensable role in the aerospace and defense industries for various cooling applications, as well as in the precise manufacturing environments of the electronics sector for processes requiring inert atmospheres or extreme cooling. These systems are engineered to offer high efficiency, often employing advanced sealing technologies and precise control mechanisms to manage helium's unique characteristics, thereby ensuring long-term operational stability and cost-effectiveness for end-users.

The primary benefits of modern helium compressors include enhanced operational efficiency, reduced helium consumption through advanced recovery and re-liquefaction capabilities, and extended service life of cryogenic equipment. Driving factors for market growth are strongly linked to the increasing global demand for sophisticated medical diagnostics, the rapid expansion of the semiconductor industry, significant investments in scientific research, and the growing adoption of cryogenic technologies in emerging fields like quantum computing. These forces collectively underscore the critical and evolving role of helium compressors in facilitating high-tech advancements across diverse industrial and scientific landscapes, necessitating continuous innovation in compressor design and materials.

Helium Compressors Market Executive Summary

The Helium Compressors Market is experiencing robust expansion driven by burgeoning demand from critical high-technology sectors globally. Key business trends include a pronounced focus on developing more energy-efficient and compact compressor designs, spurred by rising operational costs and the need for reduced environmental footprints. Manufacturers are increasingly integrating smart monitoring systems and predictive maintenance capabilities, leveraging IoT and advanced sensor technologies to enhance reliability and minimize downtime for mission-critical applications. Furthermore, there is a strategic emphasis on expanding service networks and offering comprehensive after-sales support to cater to the complex maintenance requirements of specialized helium compression systems, reinforcing customer loyalty and extending product lifecycles within a competitive landscape.

Regional trends indicate significant market momentum in the Asia Pacific region, fueled by rapid industrialization, substantial government investments in scientific research, and the burgeoning growth of the semiconductor and electronics manufacturing industries, particularly in countries like China, South Korea, and Japan. North America and Europe continue to be pivotal markets, primarily driven by established healthcare infrastructures, advanced R&D initiatives, and a strong presence of aerospace and defense organizations. These regions are characterized by a high adoption rate of sophisticated medical imaging equipment and a continuous push towards innovation in cryogenics and superconductivity, maintaining their leadership in high-value applications for helium compressors.

Segmentation trends highlight the dominance of oil-free compressor types due to their critical requirement for maintaining helium purity in sensitive applications such as MRI and semiconductor fabrication, where even minute oil contamination can lead to significant operational failures. The cryogenic application segment remains the largest and fastest-growing, reflecting the increasing deployment of superconducting technologies across medical, scientific, and industrial domains. Furthermore, there is a growing interest in high-pressure range compressors to support emerging applications requiring greater helium density and storage solutions, indicating a diversified demand across various operational parameters within the market.

AI Impact Analysis on Helium Compressors Market

User questions regarding AI's impact on the Helium Compressors Market frequently center on how artificial intelligence can enhance operational efficiency, reduce maintenance costs, improve system reliability, and optimize energy consumption. Users are keen to understand if AI can predict component failures, streamline helium recovery processes, and aid in the design of more compact and intelligent compressor systems. There is also significant interest in AI's potential to integrate with existing cryogenic infrastructure, providing real-time analytics for performance optimization and contributing to more sustainable helium management practices. Users anticipate AI to usher in an era of smarter, self-optimizing helium compression solutions, addressing challenges like helium scarcity and the complexity of maintaining high-purity systems in critical applications.

- AI-driven predictive maintenance: Algorithms analyze operational data from sensors to forecast potential failures, enabling proactive servicing and minimizing unexpected downtime of helium compressors, crucial for continuous cryogenic processes.

- Optimized energy consumption: AI systems can dynamically adjust compressor parameters based on real-time demand and environmental conditions, leading to significant reductions in power consumption and operational costs.

- Enhanced helium recovery efficiency: Machine learning models can optimize gas flow management and purification cycles, maximizing the recovery rate of helium and mitigating the impact of its increasing scarcity and cost.

- Automated fault detection and diagnostics: AI can rapidly identify anomalies in compressor performance, pinpointing the root cause of issues faster than manual diagnostics, thereby accelerating repair times.

- Advanced design optimization: AI-powered simulation and generative design tools assist engineers in creating more efficient, compact, and robust helium compressor architectures, considering material stress, thermal management, and flow dynamics.

- Supply chain optimization: AI can analyze demand patterns and logistics, improving the efficiency of spare parts inventory management and ensuring timely availability of critical components for maintenance and repair of helium compressors.

- Remote monitoring and control: AI integrates with IoT platforms to provide comprehensive remote oversight, allowing operators to monitor compressor health and make adjustments from any location, improving flexibility and responsiveness.

DRO & Impact Forces Of Helium Compressors Market

The Helium Compressors Market is significantly driven by the escalating demand for advanced medical imaging technologies, particularly MRI scanners, which rely heavily on superconducting magnets cooled by liquid helium. The continuous expansion of the healthcare sector globally, coupled with a rising prevalence of chronic diseases requiring sophisticated diagnostic tools, directly fuels the need for efficient helium re-liquefaction and compression systems. Furthermore, the burgeoning semiconductor industry, with its rigorous requirements for ultra-low temperatures in fabrication processes and inert atmospheres, acts as a pivotal driver. Technological advancements in compressor design, focusing on energy efficiency, reduced maintenance, and improved helium recovery rates, further stimulate market growth by offering more cost-effective and reliable solutions to end-users across various high-tech industries.

Despite robust growth drivers, the market faces notable restraints. The high initial capital investment required for advanced helium compressor systems, coupled with the specialized infrastructure necessary for installation and maintenance, can be a significant barrier to adoption for smaller enterprises or emerging economies. Moreover, the inherent scarcity and volatile pricing of helium, a non-renewable resource, present a substantial challenge, impacting operational costs and long-term planning for businesses reliant on cryogenic applications. The complexity associated with operating and maintaining these intricate systems, requiring skilled technicians and specialized knowledge, also contributes to operational overheads and can deter potential market entrants, limiting broader market penetration.

Opportunities within the Helium Compressors Market are emerging from the rapid advancements in nascent fields such as quantum computing and space exploration, both of which necessitate cutting-edge cryogenic cooling solutions. The development of more compact and portable helium compressor units capable of operating in diverse environments opens up new application avenues, particularly for on-site research and remote industrial uses. Furthermore, ongoing research and development efforts aimed at integrating renewable energy sources into compressor operations and exploring alternative cooling technologies present avenues for sustainable market expansion. The strategic focus on improving helium recycling and purification technologies also offers a significant opportunity to mitigate supply chain risks and enhance the economic viability of helium-dependent applications, fostering long-term market resilience.

Segmentation Analysis

The Helium Compressors Market is comprehensively segmented across various critical dimensions, including type, pressure range, cooling method, application, and end-use industry, providing a granular view of market dynamics and consumer preferences. This detailed segmentation enables a thorough analysis of specific market niches, allowing stakeholders to identify key growth areas, understand competitive landscapes, and tailor product development strategies to meet the diverse and evolving needs of different sectors. Each segment reflects unique technological requirements, operational considerations, and market drivers, influencing purchasing decisions and fostering specialized innovations within the helium compression ecosystem.

- By Type:

- Oil-free Compressors: Essential for applications requiring absolute helium purity, such as in medical imaging and semiconductor manufacturing, where oil contamination is unacceptable.

- Oil-lubricated Compressors: Generally used in less sensitive industrial applications where slight oil presence does not compromise the process, offering potentially higher compression ratios and durability.

- By Pressure Range:

- Low Pressure Compressors: Typically used for applications requiring mild compression or initial stages of helium recovery.

- Medium Pressure Compressors: Common in various industrial and scientific applications, balancing efficiency and compression capability.

- High Pressure Compressors: Critical for helium storage, re-liquefaction, and applications demanding significant gas densification, often found in large-scale cryogenic systems.

- By Cooling Method:

- Air Cooled Compressors: Favored for their simplicity, lower installation costs, and suitability for environments where water cooling is impractical or unavailable.

- Water Cooled Compressors: Offers superior cooling efficiency, better temperature stability, and suitability for continuous, heavy-duty operations, particularly in industrial settings.

- By Application:

- Cryogenics: The largest application segment, encompassing superconducting magnets (MRI, NMR, particle accelerators) and various low-temperature research.

- Semiconductors & Electronics: Utilized for creating inert environments, cooling sensitive components, and specific fabrication processes.

- Medical & Healthcare (MRI, NMR): Direct application in diagnostic imaging and analytical instrumentation, ensuring the efficient operation of superconducting magnets.

- Aerospace & Defense: Essential for cooling infrared detectors, propulsion systems, and various space-based scientific instruments.

- Research & Development: Broad application across academic and industrial research labs for material science, physics experiments, and innovative cryogenic projects.

- Others: Includes niche applications in fiber optics manufacturing, welding, leak detection, and specialized industrial processes requiring inert gas or cooling.

- By End-Use Industry:

- Industrial Gas Producers: Companies that produce, purify, and supply helium to various industries, relying on compressors for efficient storage and distribution.

- Healthcare Facilities: Hospitals and diagnostic centers that operate MRI and other medical cryogenic equipment.

- Semiconductor Manufacturing: Facilities involved in the production of microchips and electronic components, where helium compressors are integral to various stages.

- Research Institutions: Universities, government labs, and private research organizations utilizing helium for scientific experiments and development.

- Aerospace & Defense Organizations: Entities involved in space programs, military applications, and defense technology development.

Value Chain Analysis For Helium Compressors Market

The value chain for the Helium Compressors Market initiates with upstream activities, focusing on the sourcing and processing of highly specialized raw materials and components. This stage involves suppliers of high-grade metals such as stainless steel and aluminum alloys, which are critical for manufacturing durable and leak-resistant compressor parts. It also includes providers of precision-engineered components like seals, bearings, electric motors, and advanced control systems, all of which must meet stringent quality and performance standards due to helium's unique properties and the demanding operational environments of these compressors. Expertise in material science, precision machining, and advanced manufacturing techniques is paramount at this stage to ensure the reliability and efficiency of the final product, directly impacting the compressor's longevity and performance in sensitive cryogenic applications.

Midstream activities involve the design, manufacturing, assembly, and testing of the helium compressor units. This phase requires significant investment in research and development to innovate compressor technologies that enhance energy efficiency, reduce noise, minimize vibration, and improve helium recovery rates. Manufacturers integrate various subsystems, including the compression stage, heat exchangers, purification units, and control electronics, ensuring seamless operation and adherence to specific industry standards. Rigorous quality control and extensive testing are performed to ensure each unit meets performance specifications and reliability benchmarks before it proceeds to distribution. This stage is characterized by high levels of technical expertise and advanced production capabilities, distinguishing key market players through their ability to deliver cutting-edge, high-performance systems.

Downstream activities encompass the distribution, sales, installation, and after-sales services for helium compressors. Products reach end-users through various distribution channels, including direct sales from manufacturers, through authorized distributors, or as part of Original Equipment Manufacturer (OEM) solutions, where compressors are integrated into larger cryogenic systems like MRI machines. Post-sales support, including installation, commissioning, maintenance, repair, and helium management services, forms a critical part of the value chain, directly impacting customer satisfaction and operational efficiency. The effectiveness of these downstream channels, particularly the provision of rapid and skilled technical support, is crucial for maintaining the uptime of helium-dependent systems in critical applications, thereby strengthening brand reputation and fostering long-term client relationships within the specialized market.

Helium Compressors Market Potential Customers

The primary potential customers for helium compressors span a diverse range of high-technology and scientific industries, all requiring precise and reliable cryogenic or inert gas management. Hospitals and diagnostic centers represent a significant segment, being the end-users of Magnetic Resonance Imaging (MRI) and Nuclear Magnetic Resonance (NMR) equipment. These institutions rely on helium compressors to re-liquefy helium gas used in superconducting magnets, ensuring continuous operation of vital diagnostic tools essential for patient care and advanced medical research. The demand from this sector is consistently high due to the increasing global healthcare expenditure, the expanding geriatric population, and the rising prevalence of diseases necessitating advanced imaging techniques for accurate diagnosis and treatment planning, making hospitals a core customer base for the market.

Another crucial customer group comprises semiconductor manufacturers and electronics companies. In the highly demanding environment of microchip fabrication, helium is utilized for its inert properties in various processes, and its excellent heat transfer capabilities for cooling sensitive components during manufacturing. Helium compressors are indispensable here for maintaining a continuous supply of purified helium, reducing operational costs through efficient recycling, and ensuring the integrity of ultra-clean manufacturing environments. The rapid global growth of the electronics industry, driven by advancements in artificial intelligence, 5G technology, and the Internet of Things, directly translates into sustained demand for high-performance helium compression systems from semiconductor giants and their expansive supply chains worldwide.

Furthermore, research institutions, universities, and government laboratories engaged in high-energy physics, material science, and quantum computing form a substantial segment of potential customers. These entities employ helium compressors to support advanced scientific experiments requiring extremely low temperatures, often for superconducting magnets in particle accelerators, fusion reactors, and novel quantum device development. Aerospace and defense organizations also represent a key customer base, utilizing helium compressors for cooling infrared detectors, advanced optical systems, and specialized components in satellites and defense applications. These diverse end-use sectors underscore the critical role of helium compressors in facilitating cutting-edge technological advancements and scientific discoveries across a broad spectrum of industries globally, requiring robust, reliable, and highly specialized compression solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.35 Billion |

| Market Forecast in 2033 | USD 3.70 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Gardner Denver (Ingersoll Rand), Linde, Chart Industries, Leybold GmbH (Pfeiffer Vacuum), BOC (Linde), Air Liquide, Cryostar, Sumitomo Heavy Industries, Inc., Ebara Corporation, Kaeser Kompressoren, Hitachi Industrial Equipment Systems Co., Ltd., PDC Machines, Quantum Design, Beijing Zhongye Shengde Technology Co., Ltd., Shanghai Jialong Compressor Co., Ltd., Suzhou Jinhong Gas Co., Ltd., Zhejiang Kaishan Compressor Co., Ltd., SIAD Macchine Impianti, Cryomech Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Helium Compressors Market Key Technology Landscape

The Helium Compressors Market is characterized by a dynamic technology landscape driven by the continuous pursuit of enhanced efficiency, reliability, and precision in handling helium gas. A fundamental technological trend involves the advancement of oil-free compression technologies, which are critical for applications demanding ultra-high helium purity, such as MRI systems and semiconductor manufacturing. These systems often employ scroll, diaphragm, or magnetic bearing compressors to eliminate any risk of oil contamination, ensuring the integrity and longevity of sensitive cryogenic equipment. Innovations in material science are also pivotal, focusing on developing new alloys and coatings that offer superior wear resistance, reduced friction, and improved thermal management, which are essential for the prolonged lifespan and consistent performance of compressor components under demanding conditions.

Another significant aspect of the technology landscape is the integration of advanced control systems and digitalization. Modern helium compressors are increasingly equipped with sophisticated Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and embedded software that allow for precise regulation of pressure, flow rates, and temperature. The adoption of Internet of Things (IoT) sensors and data analytics platforms is enabling real-time performance monitoring, predictive maintenance, and remote diagnostics, thereby minimizing downtime and optimizing operational efficiency. These digital advancements not only facilitate proactive problem-solving but also contribute to more accurate helium inventory management and energy consumption tracking, aligning with industry trends towards smart manufacturing and sustainable operations.

Furthermore, research and development efforts are concentrated on improving the overall energy efficiency of helium compression cycles and enhancing helium recovery rates. This includes the development of more efficient motor drives, variable speed technology, and optimized heat exchange designs to reduce power consumption and heat dissipation. Innovations in closed-loop systems, coupled with advanced purification techniques, are crucial for minimizing helium loss, which is economically and environmentally beneficial given helium's scarcity. Emerging technologies like active magnetic bearings offer frictionless operation, contributing to higher speeds, reduced maintenance, and improved reliability. These combined technological advancements are shaping the next generation of helium compressors, making them more environmentally friendly, cost-effective, and adaptable to an expanding array of high-tech applications.

Regional Highlights

- North America: This region holds a significant share in the Helium Compressors Market, primarily driven by a robust healthcare sector with high adoption rates of advanced medical imaging equipment like MRI scanners. Strong government and private investments in scientific research and development, particularly in high-energy physics and aerospace, further contribute to market growth. The presence of numerous leading technology companies and research institutions demanding advanced cryogenic solutions also underpins North America's market dominance.

- Europe: Europe represents another key market, characterized by its well-established industrial base, significant research funding, and stringent regulatory standards promoting energy efficiency. Countries like Germany, France, and the UK are at the forefront of industrial cryogenics, medical technology, and scientific research. The region's focus on technological innovation and sustainable practices drives the adoption of advanced, high-efficiency helium compressor systems for a wide array of applications, including industrial gas production and scientific laboratories.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market for helium compressors, propelled by rapid industrialization, massive investments in semiconductor manufacturing, and an expanding healthcare infrastructure, particularly in countries such as China, Japan, South Korea, and India. The increasing number of hospitals, growing R&D activities, and the surge in electronics production are creating unprecedented demand for efficient helium management solutions, making APAC a critical growth engine for the global market.

- Latin America: This region exhibits emerging growth opportunities, driven by increasing healthcare expenditure, expanding industrial sectors, and growing investments in scientific research infrastructure. While currently smaller than mature markets, countries like Brazil and Mexico are witnessing gradual adoption of advanced medical technologies and industrial gas solutions, leading to a steady demand for helium compressors. Economic development and infrastructure projects are expected to further stimulate market expansion in the coming years.

- Middle East and Africa (MEA): The MEA region is experiencing gradual market penetration, primarily influenced by growing investments in healthcare facilities, industrial projects, and oil and gas processing activities. The increasing focus on diversifying economies and developing scientific and research capabilities in several countries is creating new avenues for the adoption of helium compressors. While adoption is slower compared to other regions, the long-term growth potential remains promising as industrialization and infrastructure development continue to advance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Helium Compressors Market.- Atlas Copco

- Gardner Denver (Ingersoll Rand)

- Linde

- Chart Industries

- Leybold GmbH (Pfeiffer Vacuum)

- BOC (Linde)

- Air Liquide

- Cryostar

- Sumitomo Heavy Industries, Inc.

- Ebara Corporation

- Kaeser Kompressoren

- Hitachi Industrial Equipment Systems Co., Ltd.

- PDC Machines

- Quantum Design

- Beijing Zhongye Shengde Technology Co., Ltd.

- Shanghai Jialong Compressor Co., Ltd.

- Suzhou Jinhong Gas Co., Ltd.

- Zhejiang Kaishan Compressor Co., Ltd.

- SIAD Macchine Impianti

- Cryomech Inc.

Frequently Asked Questions

What are the primary applications driving the Helium Compressors Market growth?

The primary applications fueling market growth are medical imaging (MRI/NMR), semiconductor manufacturing for cooling and inert atmospheres, advanced cryogenics in scientific research (e.g., particle accelerators, quantum computing), and specialized aerospace and defense cooling systems. These sectors rely on helium's unique properties, driving demand for efficient compression and recovery systems.

How do oil-free helium compressors differ from oil-lubricated types, and why is this important?

Oil-free helium compressors operate without oil in the compression chamber, ensuring the delivered helium remains absolutely pure, which is critical for sensitive applications like MRI magnets and semiconductor fabrication where oil contamination would cause significant equipment damage or process failure. Oil-lubricated compressors, while potentially more robust for certain industrial uses, cannot guarantee this level of purity.

What are the main challenges facing the Helium Compressors Market?

Key challenges include the high initial capital investment required for these specialized systems, the volatile supply and pricing of helium as a finite resource, the technical complexity of operation and maintenance demanding skilled personnel, and the ongoing need for energy efficiency improvements to reduce operational costs and environmental impact.

How is AI impacting the future of helium compressors?

AI is set to revolutionize helium compressors through predictive maintenance, optimizing energy consumption by dynamically adjusting parameters, enhancing helium recovery efficiency via smart gas management, and enabling advanced design optimization. AI-driven remote monitoring and fault detection will also significantly improve reliability and reduce downtime across critical applications.

Which geographical region is expected to lead market growth for helium compressors?

The Asia Pacific (APAC) region is anticipated to lead market growth. This is driven by rapid expansion in semiconductor manufacturing, burgeoning healthcare infrastructure, and substantial investments in scientific research and development, particularly in countries like China, South Korea, and Japan, which are rapidly adopting advanced cryogenic technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager