High Frequency Wood Board Jointing Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440057 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

High Frequency Wood Board Jointing Machines Market Size

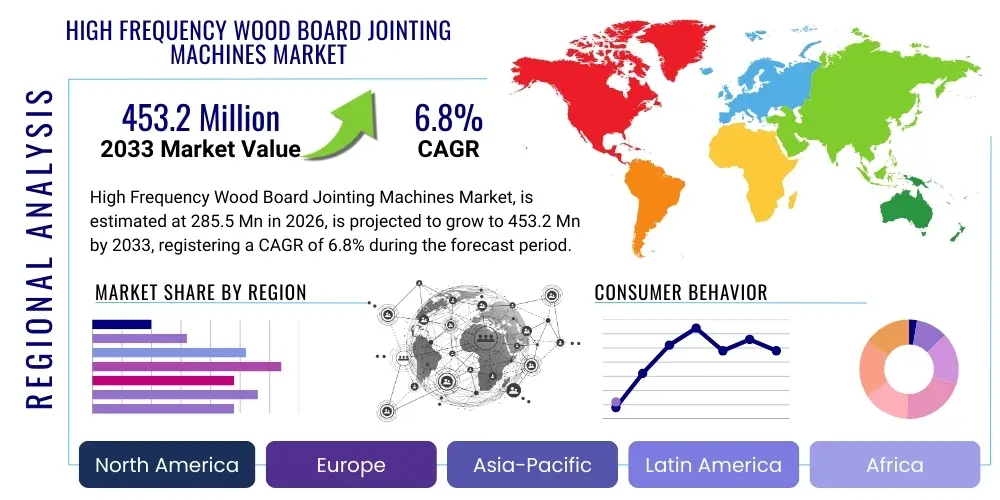

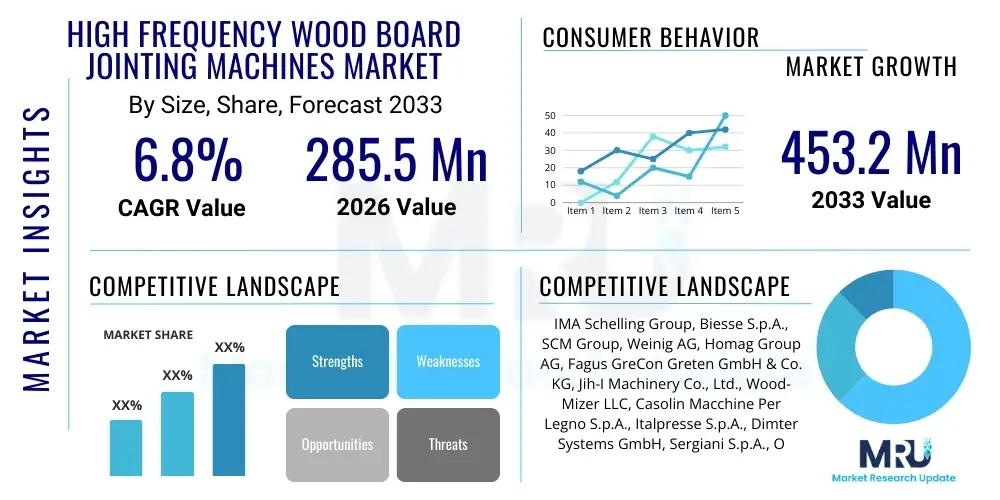

The High Frequency Wood Board Jointing Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 285.5 Million in 2026 and is projected to reach USD 453.2 Million by the end of the forecast period in 2033.

High Frequency Wood Board Jointing Machines Market introduction

The High Frequency Wood Board Jointing Machines Market encompasses specialized industrial equipment designed for efficient and robust bonding of various wood pieces, creating larger, more stable panels. These machines utilize high-frequency electromagnetic fields to rapidly heat and cure adhesive lines, resulting in stronger, more uniform joints compared to traditional cold pressing methods. The technology significantly reduces clamping time and increases production throughput, making it indispensable in modern woodworking industries where speed, precision, and joint integrity are paramount. Its application spans across diverse sectors, driven by a growing demand for high-quality wood products and sustainable manufacturing processes.

The core product in this market is the high-frequency generator coupled with a hydraulic press, forming a complete jointing system. These machines are engineered for precision, capable of handling a wide range of wood species, from softwoods to hardwoods, and various panel thicknesses. They are particularly adept at producing solid wood panels for furniture components, door and window frames, engineered flooring, and laminated beams. The key benefits include faster production cycles, reduced adhesive consumption due to targeted heating, superior joint strength and aesthetics, and significantly lower energy consumption compared to conventional heating methods, contributing to more environmentally friendly operations. The rapid curing capabilities minimize the need for extensive clamping times, freeing up valuable floor space and accelerating subsequent processing steps.

Major applications of high frequency wood board jointing machines are predominantly found in the furniture manufacturing industry, where they are crucial for producing tabletops, cabinet panels, and chair components. The construction sector also represents a significant end-user, utilizing these machines for manufacturing laminated timber for structural applications, such as glulam beams and cross-laminated timber (CLT). Other notable applications include the production of interior and exterior doors, stair parts, musical instruments, and custom millwork. The market growth is primarily driven by the increasing global demand for wooden furniture, the expansion of the construction industry, particularly in developing economies, and the growing preference for engineered wood products due to their enhanced stability and environmental benefits.

High Frequency Wood Board Jointing Machines Market Executive Summary

The High Frequency Wood Board Jointing Machines Market is experiencing robust growth, propelled by the escalating demand for high-quality engineered wood products and the continuous drive for manufacturing efficiency across global woodworking industries. Business trends indicate a strong emphasis on automation and smart factory integration, with manufacturers increasingly investing in advanced systems that offer enhanced precision, reduced labor costs, and higher throughput. The competitive landscape is characterized by innovation, with key players focusing on developing machines that can handle a broader range of wood types, incorporate IoT capabilities for predictive maintenance, and offer greater energy efficiency. Customization options for specific production needs are also becoming a significant differentiator, allowing manufacturers to tailor solutions for diverse end-user applications. The market is witnessing consolidation through strategic partnerships and acquisitions, as companies seek to expand their technological portfolios and regional footprints.

Regional trends highlight Asia Pacific as the leading and fastest-growing market, driven by booming construction activities, rapid urbanization, and a flourishing furniture manufacturing sector in countries like China, India, and Vietnam. This region benefits from lower manufacturing costs and a large consumer base, attracting significant investments in woodworking machinery. North America and Europe also maintain substantial market shares, characterized by a demand for premium, high-automation machines, and a strong focus on sustainable and eco-friendly production methods. The adoption of advanced machinery in these regions is spurred by stringent quality standards and a skilled labor shortage, necessitating automated solutions. Latin America, the Middle East, and Africa are emerging markets, showing gradual but steady growth as their industrial bases expand and local demand for wood products increases.

Segmentation trends reveal that machines categorized by power output (e.g., up to 30KW, 30-60KW, above 60KW) are experiencing varying demand, with higher power machines gaining traction for heavy-duty and continuous industrial operations. By application, the furniture manufacturing segment continues to dominate, followed closely by the construction and building materials sector. The increasing sophistication of engineered wood products, such as glulam and laminated veneer lumber (LVL), is driving demand for jointing machines capable of processing larger dimensions and higher volumes. Furthermore, a growing preference for fully automatic machines over semi-automatic and manual versions is observed across all segments, as industries strive for optimal operational efficiency and minimal human intervention, thereby enhancing productivity and reducing potential errors.

AI Impact Analysis on High Frequency Wood Board Jointing Machines Market

The integration of Artificial Intelligence (AI) is set to revolutionize the High Frequency Wood Board Jointing Machines Market by introducing unprecedented levels of automation, precision, and predictive capabilities. Users are increasingly concerned with how AI can optimize production processes, reduce material waste, and enhance the overall quality of bonded wood products. Common user questions revolve around the potential for AI-driven systems to identify and compensate for wood defects, fine-tune heating parameters for different wood species and adhesive types, and autonomously manage production schedules. There is also significant interest in AI's role in predictive maintenance, minimizing downtime, and improving the operational lifespan of these complex machines. Expectations are high that AI will lead to more intelligent, self-optimizing machines that can learn from operational data to continuously improve performance and adapt to changing production demands, ultimately driving down costs and increasing competitive advantage for manufacturers.

AI's influence extends to enhancing the decision-making process within high-frequency jointing operations. By leveraging machine learning algorithms, systems can analyze vast amounts of data related to wood moisture content, adhesive properties, ambient temperature, and machine performance. This analysis allows for real-time adjustments to power output, pressure, and curing cycles, ensuring optimal joint strength and minimizing energy consumption. For instance, AI could predict the ideal curing time for a specific batch of wood based on its density and grain patterns, a level of precision unattainable through traditional manual or fixed parameter controls. This predictive optimization capability not only improves product quality but also significantly reduces the likelihood of costly errors and rework, enhancing overall operational efficiency.

Furthermore, AI is poised to transform the maintenance and service aspects of high-frequency wood board jointing machines. Through sensor data analysis, AI algorithms can detect subtle anomalies in machine operation that might indicate impending component failure. This enables proactive maintenance scheduling, shifting from reactive repairs to predictive interventions, thereby drastically reducing unplanned downtime and associated production losses. Users anticipate that AI-powered diagnostics will provide clearer insights into machine health, suggesting specific maintenance tasks or part replacements before critical failures occur. Such capabilities contribute to a more reliable production environment and extend the lifespan of high-value machinery, offering a substantial return on investment for woodworking manufacturers.

- AI-driven optimization of heating and pressing parameters for superior joint strength and reduced energy consumption.

- Predictive maintenance analytics, identifying potential machine failures before they occur, minimizing downtime and extending equipment lifespan.

- Automated quality control systems using computer vision and AI to detect defects in wood and joints in real-time.

- Enhanced material utilization through AI algorithms that optimize cutting and jointing patterns, reducing waste.

- Intelligent production scheduling and adaptive process control, learning from past performance to improve efficiency and throughput.

- Remote monitoring and diagnostics capabilities, allowing manufacturers to troubleshoot and service machines from afar.

- Personalized machine settings and learning capabilities that adapt to specific wood species and adhesive characteristics over time.

DRO & Impact Forces Of High Frequency Wood Board Jointing Machines Market

The High Frequency Wood Board Jointing Machines Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the critical Impact Forces influencing its trajectory. A primary driver is the surging global demand for high-quality, stable, and aesthetically pleasing engineered wood products, spanning from furniture and cabinetry to structural building components. The efficiency and superior joint quality offered by HF technology are unmatched, making it the preferred method for modern woodworking. Simultaneously, the imperative for increased production efficiency, reduced labor costs, and faster cycle times across manufacturing sectors pushes industries towards automation, with HF jointing machines offering significant advantages in these areas. Growing environmental consciousness also acts as a driver, as HF technology often allows for more efficient use of wood resources and reduced adhesive waste compared to traditional methods.

However, the market also faces notable restraints. The initial capital investment required for high frequency wood board jointing machines is substantial, posing a barrier to entry for smaller enterprises or those with limited access to financing. This high cost can deter adoption, especially in price-sensitive emerging markets. Additionally, the operation and maintenance of these sophisticated machines require skilled technicians, and a shortage of such specialized labor in many regions can impede market growth. Furthermore, the energy consumption of high-frequency generators, although efficient in terms of heating speed, can still be a concern for industries in regions with high electricity costs, leading to operational cost challenges despite the overall efficiency gains.

Despite these challenges, significant opportunities exist for market expansion. The continuous innovation in adhesive technologies, particularly the development of more sustainable and rapidly curing glues, complements the advantages of HF jointing, opening new application possibilities. Emerging markets, with their burgeoning construction and furniture industries, represent vast untapped potential for market penetration and growth. Moreover, the increasing adoption of Industry 4.0 principles, including IoT integration, AI, and advanced automation, presents an opportunity for manufacturers to develop smarter, more connected, and highly efficient machines. This evolution can enhance machine performance, facilitate remote diagnostics, and offer predictive maintenance, thereby adding significant value for end-users and expanding the market's overall appeal and competitive edge.

Segmentation Analysis

The High Frequency Wood Board Jointing Machines Market is comprehensively segmented across various parameters to provide a detailed understanding of its dynamics and target customer groups. These segmentations typically include classifications based on product type or power output, operational mode (manual, semi-automatic, automatic), application (end-user industries), and geographical regions. Such granular segmentation allows for a nuanced analysis of market demand patterns, technological preferences, and regional adoption rates, enabling manufacturers to tailor their product offerings and market strategies effectively. Understanding these segments is crucial for identifying key growth drivers, competitive landscapes, and emerging trends within specific market niches, ultimately guiding investment decisions and strategic planning for stakeholders across the value chain.

- By Type:

- Up to 30KW

- 30KW - 60KW

- Above 60KW

- By Operation Mode:

- Manual

- Semi-Automatic

- Automatic

- By Application:

- Furniture Manufacturing

- Construction and Building Materials

- Door and Window Manufacturing

- Flooring Production

- Musical Instruments

- Others (e.g., custom millwork, sports equipment)

- By End-User:

- Large-Scale Industrial Enterprises

- Small and Medium-Sized Enterprises (SMEs)

- Custom Woodworking Shops

Value Chain Analysis For High Frequency Wood Board Jointing Machines Market

The value chain for the High Frequency Wood Board Jointing Machines Market is complex, beginning with the upstream suppliers of raw materials and specialized components crucial for manufacturing these technologically advanced machines. This includes manufacturers of high-frequency generators, hydraulic systems, control systems (PLCs, HMI interfaces), electrical components, and precision mechanical parts. The quality and availability of these components directly impact the performance, reliability, and cost-effectiveness of the final jointing machine. Strong relationships with reliable upstream suppliers are critical for machine manufacturers to ensure consistent quality, manage costs, and facilitate innovation in component design, enabling the integration of cutting-edge technology into their products.

Further along the value chain, machine manufacturers engage in the design, assembly, testing, and distribution of the finished high frequency wood board jointing machines. Distribution channels are varied, encompassing both direct sales and indirect channels. Direct sales are often preferred for large industrial clients requiring custom solutions, allowing manufacturers to provide personalized service, installation, training, and ongoing technical support. This direct engagement fosters stronger customer relationships and facilitates real-time feedback for product improvement. Indirect channels involve a network of distributors, agents, and resellers, particularly effective for reaching a broader market, including small and medium-sized enterprises (SMEs) and international customers, leveraging the local market knowledge and established networks of these partners.

The downstream segment of the value chain focuses on the end-users who integrate these machines into their production processes. Major end-users include furniture manufacturers, construction companies producing engineered wood products, door and window fabricators, and flooring manufacturers. Post-sales services, including installation, commissioning, operator training, maintenance, and spare parts supply, constitute a critical part of the downstream value chain, ensuring optimal machine performance and customer satisfaction. The efficiency and reliability of these services directly influence customer loyalty and repeat business. The interplay between upstream innovation, efficient manufacturing, robust distribution, and comprehensive downstream support defines the overall competitiveness and success of participants in the High Frequency Wood Board Jointing Machines Market.

High Frequency Wood Board Jointing Machines Market Potential Customers

The primary potential customers for High Frequency Wood Board Jointing Machines are enterprises engaged in various stages of wood processing and product manufacturing that require strong, reliable, and aesthetically pleasing wood joints for large panels or components. These machines cater to industries that demand high production volumes, precision, and efficiency in bonding wood. The versatility of high-frequency technology makes it appealing to a broad spectrum of manufacturers, from those producing standard wooden items to specialists creating custom, high-value products, all seeking to improve product quality, reduce manufacturing time, and optimize material utilization. The growing trend towards pre-fabricated and engineered wood solutions in construction further expands the customer base.

Key end-user segments include the expansive furniture manufacturing industry, where high-frequency jointing machines are indispensable for creating solid wood panels for tabletops, cabinet doors, bed frames, and other structural components. Manufacturers of kitchen and bathroom cabinets, office furniture, and upholstered furniture frames frequently invest in this technology to enhance the structural integrity and finish quality of their products. Another significant customer base is found within the construction and building materials sector, specifically companies involved in producing laminated timber products such as glulam beams, cross-laminated timber (CLT), and laminated veneer lumber (LVL). These engineered wood products are increasingly favored in modern construction for their strength, sustainability, and design flexibility, driving consistent demand for efficient jointing solutions.

Beyond these major segments, other potential customers include manufacturers of doors and windows, where the machines are used to create durable frames and panels; producers of wood flooring, especially for engineered wood flooring layers; and specialized woodworking shops that craft musical instruments, stair parts, or undertake custom architectural millwork. These diverse applications underscore the broad utility and market reach of high frequency wood board jointing machines. As consumer preferences shift towards more durable, sustainable, and custom-designed wood products, the customer base for this advanced machinery is expected to continue its expansion, particularly among enterprises keen on adopting automation and optimizing their production capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 285.5 Million |

| Market Forecast in 2033 | USD 453.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | IMA Schelling Group, Biesse S.p.A., SCM Group, Weinig AG, Homag Group AG, Fagus GreCon Greten GmbH & Co. KG, Jih-I Machinery Co., Ltd., Wood-Mizer LLC, Casolin Macchine Per Legno S.p.A., Italpresse S.p.A., Dimter Systems GmbH, Sergiani S.p.A., OMAG S.R.L., Heesemann Maschinenbau GmbH, KDT Machinery Co., Ltd., Cefla Finishing S.p.A., Panel Machinery & Automation, Inc., Doucet Machineries Inc., Altendorf GmbH, Minda Industrieanlagen GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Frequency Wood Board Jointing Machines Market Key Technology Landscape

The technology landscape of the High Frequency Wood Board Jointing Machines Market is characterized by a blend of established principles and continuous innovation aimed at enhancing efficiency, precision, and automation. At its core, the technology relies on a high-frequency (HF) generator that produces electromagnetic waves, typically in the radio frequency range, to rapidly heat the adhesive line between wood pieces. This dielectric heating process is significantly faster and more energy-efficient than traditional conductive heating methods, allowing for quick curing of glues and robust joint formation. Modern machines incorporate advanced solid-state HF generators, offering superior reliability, precise power control, and reduced maintenance compared to older vacuum tube-based systems, enabling consistent performance across various wood types and production requirements.

Beyond the core HF generation, the machines integrate sophisticated control systems, most commonly Programmable Logic Controllers (PLCs) coupled with Human-Machine Interface (HMI) touchscreens. These systems provide intuitive control over pressing parameters, heating cycles, and operational sequences, allowing operators to easily set and adjust specifications for different jobs. Automation plays a critical role, with features such as automatic feeding systems, precise alignment mechanisms, and robotic handling solutions becoming increasingly prevalent. These advancements not only reduce labor requirements and improve throughput but also enhance safety by minimizing direct human interaction with the high-frequency field and heavy machinery components, contributing significantly to improved factory floor safety standards and operational continuity.

Further technological advancements include the integration of sensor technology and data analytics, moving towards Industry 4.0 principles. Advanced sensors monitor parameters like wood moisture content, temperature, and pressure in real-time, feeding data to the control system for dynamic adjustments, ensuring optimal bonding conditions and preventing material waste. The adoption of Internet of Things (IoT) capabilities enables remote monitoring, predictive maintenance, and data logging, allowing manufacturers to optimize machine performance, plan maintenance proactively, and analyze production trends for continuous improvement. The evolution of adhesive chemistry also plays a crucial role, with new fast-curing, low-VOC (Volatile Organic Compound) glues being developed that are specifically optimized for HF curing, further boosting efficiency and environmental sustainability within the market.

Regional Highlights

- Asia Pacific: Dominates the market due to robust growth in the furniture and construction sectors, particularly in China, India, and Vietnam. Rapid industrialization, urbanization, and increasing consumer spending on wooden products fuel demand. Local manufacturing hubs for woodworking machinery also contribute to accessibility and competitive pricing.

- Europe: A mature market characterized by demand for high-quality, precise, and energy-efficient machines. Germany, Italy, and Poland are key players in both manufacturing and adoption, driven by strong woodworking traditions, stringent quality standards, and a focus on sustainable production practices. Innovation in automation and smart factory solutions is a significant trend.

- North America: Exhibits steady growth, propelled by the demand for engineered wood products in residential and commercial construction, alongside a resilient furniture industry. The market is characterized by investments in advanced automation and technologies to counter skilled labor shortages and enhance productivity. Focus on robust and high-capacity machines is prevalent.

- Latin America: An emerging market with increasing adoption rates, primarily driven by the expansion of its construction and furniture industries. Countries like Brazil and Mexico are witnessing gradual modernization of their woodworking sectors, creating opportunities for manufacturers of high frequency jointing machines. Growth is influenced by economic stability and industrial investments.

- Middle East and Africa (MEA): A nascent but promising market. Construction boom in the Middle East and growing manufacturing capabilities in parts of Africa are stimulating demand for woodworking machinery. Investments in infrastructure and diversification away from oil economies are driving industrial development, leading to increased adoption of advanced wood processing equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Frequency Wood Board Jointing Machines Market.- IMA Schelling Group

- Biesse S.p.A.

- SCM Group

- Weinig AG

- Homag Group AG

- Fagus GreCon Greten GmbH & Co. KG

- Jih-I Machinery Co., Ltd.

- Wood-Mizer LLC

- Casolin Macchine Per Legno S.p.A.

- Italpresse S.p.A.

- Dimter Systems GmbH

- Sergiani S.p.A.

- OMAG S.R.L.

- Heesemann Maschinenbau GmbH

- KDT Machinery Co., Ltd.

- Cefla Finishing S.p.A.

- Panel Machinery & Automation, Inc.

- Doucet Machineries Inc.

- Altendorf GmbH

- Minda Industrieanlagen GmbH

Frequently Asked Questions

Analyze common user questions about the High Frequency Wood Board Jointing Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using High Frequency Wood Board Jointing Machines?

High Frequency Wood Board Jointing Machines offer significant advantages including rapid curing of adhesives, resulting in significantly faster production cycles and increased throughput. They provide superior joint strength and aesthetic quality, reduce adhesive consumption through targeted heating, and generally consume less energy compared to traditional heating methods, leading to cost savings and higher operational efficiency.

How does high-frequency technology improve joint strength and quality?

High-frequency technology works by inducing heat directly within the glue line through electromagnetic fields, leading to uniform and rapid curing of the adhesive from the inside out. This process minimizes stress on the wood, prevents premature drying of the adhesive surface, and ensures a complete and strong bond throughout the joint, resulting in superior mechanical properties and a flawless finish.

What types of wood products are typically manufactured using these machines?

These machines are primarily used to manufacture a wide range of engineered wood products such as solid wood panels for furniture (tabletops, cabinet doors), laminated timber for construction (glulam beams, CLT), door and window frames, wood flooring components, and specialized millwork. They are crucial for creating larger, stable wood components from smaller pieces.

What is the typical return on investment for high frequency wood board jointing machines?

The return on investment (ROI) for High Frequency Wood Board Jointing Machines can be substantial, driven by increased production efficiency, reduced labor costs, lower adhesive consumption, and improved product quality leading to fewer defects and customer returns. While initial capital outlay is high, the long-term operational savings and capacity enhancements typically ensure a favorable ROI, often within a few years, depending on production volume and efficiency gains.

Are High Frequency Wood Board Jointing Machines suitable for small to medium-sized businesses (SMEs)?

Yes, while often associated with large industrial operations, many manufacturers offer high-frequency jointing machines tailored for SMEs. These models provide the same core benefits of speed and quality but in more compact and cost-effective configurations. The efficiency gains and enhanced product quality offered by HF technology can significantly boost the competitiveness of smaller woodworking businesses by enabling them to produce higher-value products more quickly.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager