High Pressure Reactors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432769 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

High Pressure Reactors Market Size

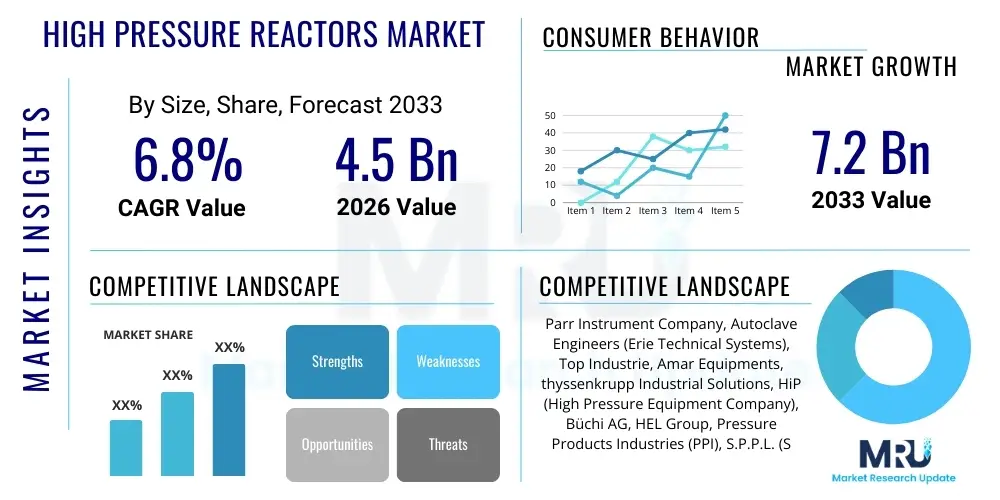

The High Pressure Reactors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 billion in 2026 and is projected to reach USD 7.2 billion by the end of the forecast period in 2033.

High Pressure Reactors Market introduction

High Pressure Reactors (HPRs) are specialized vessels designed to facilitate chemical reactions or physical processes under elevated pressure conditions, often combined with high temperatures. These critical components are indispensable in industrial and research settings where extreme operating conditions are required to drive specific reactions, synthesize novel materials, or simulate harsh geological environments. HPRs are typically constructed from high-grade stainless steel or specialty alloys to withstand substantial internal stress, ensuring safety and reliability during operations such as polymerization, hydrogenation, oxidation, and catalytic reforming. Their robust design allows for precise control over kinetic parameters, making them central to modern chemical engineering and sustainable material development.

The core function of High Pressure Reactors involves maximizing reaction yield and selectivity under conditions unattainable in atmospheric reactors. The product spectrum ranges from small, laboratory-scale autoclaves used for academic research and screening new catalysts, to large, industrial units employed in the production of bulk chemicals, fertilizers, and high-density polyethylene. Major applications span the chemical and petrochemical sectors, particularly in processes like the Fischer-Tropsch synthesis and ammonia synthesis, which rely fundamentally on high-pressure environments. Furthermore, the pharmaceutical and biotechnology industries utilize smaller, highly precise HPRs for advanced synthesis of complex drug intermediates and formulation studies, requiring sterile and controlled atmospheres.

The market growth is primarily driven by the escalating demand for high-performance, specialty chemicals, and advanced materials across various manufacturing sectors. The benefits derived from using HPRs include enhanced reaction kinetics, improved thermodynamic efficiency, and the ability to handle volatile or gaseous reactants safely. Key driving factors involve continuous technological advancements in metallurgy and reactor design, focusing on modularity, automation, and enhanced corrosion resistance. The push towards sustainable chemistry and the use of supercritical fluids (e.g., CO2) as green solvents further necessitate the adoption of reliable and safe high-pressure systems, cementing the market’s positive trajectory through the forecast period.

High Pressure Reactors Market Executive Summary

The High Pressure Reactors market is witnessing sustained momentum, characterized by significant investment in R&D infrastructure globally and a strong shift towards optimizing operational efficiency in capital-intensive industries. Current business trends indicate a growing preference for modular and automated reactor systems that allow for flexible batch sizes and continuous processing, reducing downtime and enhancing scalability, particularly in the pharmaceutical and fine chemical synthesis sectors. Strategic collaborations between reactor manufacturers and specialized engineering firms are becoming common, aimed at developing custom-engineered solutions that meet increasingly stringent regulatory and safety standards, especially concerning material compatibility and thermal management at extreme pressures.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, largely due to rapid industrialization, massive expansion of the petrochemical complexes in China and India, and surging governmental investment in advanced materials research. North America and Europe maintain a mature market status, focusing on technological refinement, safety upgrades, and the integration of smart monitoring systems into existing reactor fleets, driven by the shift towards high-value, niche chemical production and green chemistry initiatives. The regional disparity is noticeable in demand patterns; APAC primarily seeks large-volume industrial reactors, whereas Western markets prioritize smaller, highly instrumented reactors for specialized R&D applications and pilot production scale-ups.

Segment trends highlight the dominance of the Chemical and Petrochemical industry as the largest end-user segment, driven by the continuous global need for primary feedstocks and high-volume polymers. From a product perspective, Stirred Tank Reactors remain the most widely adopted design due to their versatility and ease of mixing complex, multi-phase systems under pressure. However, there is accelerating adoption of specialized reactors, such as Loop Reactors and Fixed Bed Reactors, particularly in catalyst testing and continuous flow processes where enhanced mass transfer efficiency and energy conservation are critical requirements. The trend toward digitalization is transforming the market, with segments increasingly adopting integrated sensor technologies and sophisticated control algorithms to maximize yield and ensure predictive maintenance.

AI Impact Analysis on High Pressure Reactors Market

User queries regarding the impact of Artificial Intelligence (AI) on the High Pressure Reactors market frequently center on themes such as predictive maintenance capabilities, autonomous reaction optimization, and the efficiency gains from high-throughput experimentation. Users are keen to understand how AI-driven analytics can mitigate the risks associated with operating complex, high-pressure equipment, which are inherently high-risk assets requiring meticulous monitoring. The primary concern revolves around the integration complexity and the reliability of AI models in predicting catastrophic equipment failures, alongside expectations for AI to drastically shorten the product development cycle by optimizing catalyst selection and process parameters in real-time within the reactor environment.

AI's role in the High Pressure Reactors sector is evolving beyond simple data logging, moving into sophisticated predictive modeling and control loop optimization. Machine learning algorithms are being trained on vast datasets encompassing historical operational metrics, sensor readings (temperature, pressure, flow), and material fatigue characteristics. This enables the development of robust predictive maintenance schedules, forecasting component degradation, such as gasket failures or vessel wall erosion, long before they lead to unexpected shutdowns. This proactive approach significantly increases the asset uptime and lifespan of high-capital equipment, offering substantial returns on investment for plant operators and enhancing overall process safety, which is paramount in high-pressure environments.

Furthermore, AI is fundamentally transforming R&D within high-pressure chemistry. AI-driven experimental design (Active Learning or Automated Experimentation) allows researchers to intelligently select optimal pressure, temperature, and concentration ranges for novel syntheses, minimizing the number of expensive and time-consuming physical experiments required. This acceleration is particularly critical in specialty chemical production and catalyst development, where exploring vast combinatorial spaces is necessary. By automating decision-making within the reactor control system, AI ensures that reactions operate closer to their optimal kinetic and thermodynamic limits, leading to higher conversion rates, improved product purity, and reduced energy consumption per batch.

- Enhanced Predictive Maintenance: AI analyzes stress, temperature, and vibration data to forecast component failure, minimizing unexpected downtime and improving operational safety.

- Autonomous Reaction Optimization: Machine learning models dynamically adjust reaction parameters (pressure, temperature, mixing) in real-time to maximize yield and selectivity.

- High-Throughput Experimentation Acceleration: AI algorithms guide automated experimental setups in R&D, efficiently screening catalyst libraries and novel synthesis routes under high pressure.

- Improved Process Safety: AI monitors operational envelopes and instantly detects anomalies indicative of impending critical safety breaches, triggering automated emergency shutdown protocols.

- Digital Twin Modeling: Creation of precise virtual models of HPRs, allowing operators to simulate various operating conditions and training scenarios without risking physical assets.

DRO & Impact Forces Of High Pressure Reactors Market

The High Pressure Reactors market is fundamentally shaped by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively forming the critical Impact Forces influencing market expansion and technology adoption. The primary driving forces stem from the relentless global demand for advanced chemicals, particularly specialty polymers and intermediates required for sectors like automotive, aerospace, and electronics, which necessitate high-pressure synthesis techniques. Concurrently, increasing governmental focus on stringent process safety regulations and mandates for clean energy production (such as the Power-to-X processes) necessitates investment in robust, compliant high-pressure infrastructure. These drivers compel industries to upgrade or replace older, less efficient reactor systems with modern, highly instrumented HPRs, ensuring market vitality.

Despite the strong drivers, the market faces significant restraints, chiefly related to the formidable capital expenditure required for acquiring and installing HPR systems. These reactors require specialized materials, complex sealing mechanisms, and custom safety enclosures, making the initial investment prohibitive for smaller enterprises or academic institutions. Furthermore, the operational complexity and the need for highly skilled technical personnel for maintenance and troubleshooting pose ongoing challenges. Specifically, issues related to material fatigue, hydrogen embrittlement in high-temperature hydrogenation processes, and ensuring leak-proof operations under extreme pressures contribute to high operational costs and represent inherent technical restraints that manufacturers must continuously address through innovative material science.

Opportunities for market expansion are substantial, primarily anchored in the burgeoning field of green chemistry and sustainable industrial processes. The use of supercritical CO2 (scCO2) as a non-toxic, recyclable solvent in high-pressure reactions is opening new avenues, especially in pharmaceutical purification and polymer foaming, thereby driving demand for reactors designed specifically for scCO2 handling. Moreover, the increasing adoption of continuous flow chemistry over traditional batch processing, even under high pressure, offers efficiency and safety gains, representing a key area for technological innovation and market penetration. The combination of strong industrial need (Driver) and the potential for technological differentiation (Opportunity) overrides the constraint of high capital cost, ensuring a net positive market trajectory.

Segmentation Analysis

The High Pressure Reactors market segmentation provides a granular view of diverse product capabilities and application landscapes, essential for understanding market structure and targeted investment. Segmentation is broadly categorized by Type, Volume, and End-Use Industry, reflecting the varied requirements of laboratory R&D versus large-scale industrial production. The distinct design characteristics, such as internal agitation mechanisms and heat exchange capabilities, drive the classification by Type, while Volume segmentation dictates the scale of operation—ranging from micro-reactors for academic testing to mammoth industrial units used in petrochemical complexes. This multi-faceted structure allows manufacturers to tailor solutions precisely to customer operational needs and regulatory environments.

Segmentation by End-Use Industry reveals the varying criticality of pressure capabilities across different sectors. The Chemical & Petrochemical segment, which constitutes the largest market share, requires reactors optimized for throughput and longevity under continuous operation. In contrast, the Pharmaceutical & Biotechnology sector demands highly sterile, smaller-volume reactors capable of precise temperature and pressure control for complex synthesis of Active Pharmaceutical Ingredients (APIs). The Research & Development segment acts as a precursor, driving demand for flexible, modular systems with extensive sensor integration for rapid process optimization and discovery, often featuring maximum operational pressures exceeding those found in standard industrial units. Understanding these segment-specific requirements is vital for strategic market positioning.

The technological sophistication inherent in each segment also influences market dynamics. For instance, Fixed Bed Reactors are critical in the Oil & Gas sector for hydrocracking processes due to their ability to efficiently handle catalysts and continuous flows, whereas Stirred Tank Reactors dominate polymerization due to superior mixing capabilities. As industries trend toward sustainability, segments focusing on biomass conversion and carbon capture utilization (CCU) are increasingly adopting specialized HPR designs, signaling a shift in segment growth rates favoring R&D and specialized chemical applications over mature bulk petrochemical segments. This evolving demand landscape dictates future product development and service offerings across the value chain.

- By Type:

- Stirred Tank Reactors (STRs)

- Fixed Bed Reactors (FBRs)

- Loop Reactors

- Bubble Column Reactors

- Micro Reactors/Continuous Flow Reactors

- By Volume:

- Below 10 Liters (Laboratory Scale)

- 10 to 100 Liters (Pilot Plant Scale)

- Above 100 Liters (Industrial Scale)

- By End-Use Industry:

- Chemical & Petrochemical

- Research & Development (R&D)

- Pharmaceuticals & Biotechnology

- Oil & Gas

- Materials Science

- Energy & Environmental (e.g., CCU, Biomass Conversion)

Value Chain Analysis For High Pressure Reactors Market

The Value Chain for the High Pressure Reactors market begins with upstream analysis, focusing heavily on specialized raw material suppliers. Due to the extreme operating conditions (high pressure, high temperature, corrosive media), the quality and metallurgy of materials are paramount. Key upstream suppliers provide specialty alloys (e.g., Inconel, Hastelloy, various grades of stainless steel, and titanium), high-integrity sealing components, and complex forged parts. The critical nature of these inputs means that supply chain stability and quality control among these specialized material providers directly dictate the cost and performance limits of the final reactor systems. Intense qualification processes and long lead times characterize this phase.

The midstream involves the core manufacturing and integration processes. Reactor manufacturers engage in highly technical activities, including precision machining, specialized welding (e.g., explosion welding for dissimilar materials), surface treatment, and integration of complex control systems, pumps, and safety interlocks. This phase is characterized by intense intellectual property related to vessel design, heat transfer mechanisms, and agitation technologies. Manufacturers often integrate advanced sensor technologies and software for data acquisition and process control. The distribution channel, bridging the gap between manufacturing and end-user deployment, typically involves a mix of direct sales channels for large, custom industrial projects and specialized technical distributors for standardized laboratory-scale systems.

Downstream analysis focuses on installation, commissioning, operation, and lifecycle services provided to end-users (Direct Buyers). Given the complexity and safety requirements of HPRs, ongoing technical support, specialized maintenance contracts, regulatory compliance consulting, and periodic re-certification (e.g., ASME certification renewals) are significant revenue streams. The relationship is often direct (manufacturer to large chemical plant) or through highly specialized engineering, procurement, and construction (EPC) firms, particularly for major industrial expansions. Indirect sales channels, such as specialized laboratory equipment suppliers, cater primarily to the academic and smaller R&D market segments, offering standard, off-the-shelf reactor models with limited customization.

High Pressure Reactors Market Potential Customers

The primary customers for High Pressure Reactors are large multinational corporations operating in the chemical and petrochemical domains, particularly those engaged in high-volume synthesis of primary feedstocks, polymers, and fertilizers. These entities require large, robust industrial-scale reactors (Above 100 Liters) capable of continuous operation under pressures often exceeding 200 bar. Examples include producers of polyethylene, ammonia, and methanol, who view HPRs as mission-critical infrastructure essential for maintaining competitive production costs and meeting global demand for basic chemicals. The purchasing decision for these customers is driven by reliability, scale, energy efficiency, and long-term service agreements.

A secondary, yet rapidly expanding, segment of potential customers includes research institutions, universities, and dedicated R&D divisions within pharmaceutical and specialty chemical companies. These buyers predominantly seek smaller, highly flexible, and instrumented reactors (Below 10 Liters or Pilot Plant Scale). Their objective is exploratory research, catalyst screening, process optimization, and the synthesis of high-value, low-volume materials like APIs or novel functional materials. For these customers, the critical factors are precision control, rapid experimentation capabilities, and the integration of sophisticated analytical tools, such as in-situ spectroscopy and sampling systems, rather than sheer throughput volume.

Additionally, emerging niche markets represent significant potential customer bases, including companies focused on environmental applications and new energy technologies. This encompasses firms developing carbon capture and utilization (CCU) systems that often rely on high-pressure supercritical fluid technology, bio-fuel producers utilizing high-pressure catalytic processes for biomass conversion, and advanced materials manufacturers focused on ceramics, composites, and nanofabrication under extreme conditions. These buyers are often early adopters, prioritizing specialized reactor designs that push the boundaries of current pressure and temperature tolerances, driven by the imperative to commercialize novel, sustainable technologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 billion |

| Market Forecast in 2033 | USD 7.2 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Parr Instrument Company, Autoclave Engineers (Erie Technical Systems), Top Industrie, Amar Equipments, thyssenkrupp Industrial Solutions, HiP (High Pressure Equipment Company), Büchi AG, HEL Group, Pressure Products Industries (PPI), S.P.P.L. (Supercritical Process Plants Pvt. Ltd.), G.E. Baker & Associates, Chemineer (NOV), Mettler Toledo, IKA Works, and Premex Solutions. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Pressure Reactors Market Key Technology Landscape

The technological landscape of the High Pressure Reactors market is characterized by continuous innovation aimed at enhancing safety, efficiency, and operational flexibility. A cornerstone technology involves advancements in specialized metallurgy, particularly the development and use of exotic corrosion-resistant alloys such as nickel-based superalloys (e.g., Hastelloy and Inconel). These materials are essential for reactors operating with highly corrosive reactants, mitigating risks associated with hydrogen attack and stress corrosion cracking at high temperatures. Furthermore, manufacturing techniques like hot isostatic pressing (HIP) and advanced cladding/lining technologies are increasingly used to create seamless, defect-free pressure vessels capable of reliably handling pressures up to 1,000 bar or more, thereby setting new standards for equipment longevity and safety compliance.

Another crucial technological advancement is the integration of sophisticated monitoring and control systems, capitalizing on the broader industry trend towards Industry 4.0. Modern HPR systems utilize high-resolution pressure transducers, fiber optic temperature sensors, and real-time process analytical technology (PAT), often coupled with advanced magnetic drives and agitator designs that eliminate the need for dynamic seals, minimizing leak points inherent in traditional sealing mechanisms. The deployment of Supervisory Control and Data Acquisition (SCADA) systems and Distributed Control Systems (DCS) provides operators with precise, remote control over reaction kinetics, ensuring optimized performance and enabling complex, multi-step high-pressure syntheses with unprecedented repeatability and safety margins.

The push toward sustainable chemistry has further accelerated the adoption of technologies like continuous flow high-pressure reactors. Unlike traditional batch reactors, continuous flow systems offer superior heat and mass transfer characteristics, reducing reaction times and enhancing inherent safety by minimizing the volume of hazardous material contained at any single point. These systems leverage micro- and milli-reactor designs to handle exothermic high-pressure reactions safely and efficiently. Furthermore, there is a growing focus on developing specialized reactors optimized for supercritical fluid applications, demanding specialized pump systems, sophisticated back-pressure regulators, and specialized viewport technology to observe phase behavior under extreme pressures, enabling cleaner and more energy-efficient chemical processes.

Regional Highlights

- North America: The North American HPR market is mature and technology-intensive, driven primarily by stringent safety standards and high R&D spending, particularly in the US. The market focuses heavily on small- to medium-scale, highly customized reactors for specialty chemical synthesis, pharmaceutical development, and advanced materials research (e.g., polymers for aerospace). Investments are concentrated on integrating AI-driven monitoring systems and upgrading existing petrochemical infrastructure to meet lower carbon footprint targets. Canada’s strong focus on oil sands processing and heavy oil upgrading also drives significant, albeit specialized, demand for high-pressure, high-temperature catalytic systems. The region is a pioneer in advanced metallurgy and digital process control for pressure systems.

- Europe: Europe represents a powerhouse for technological innovation in the HPR space, fueled by strong regulations promoting green chemistry and sustainable practices (e.g., REACH). Germany, Switzerland, and the UK are major hubs for manufacturing high-precision laboratory and pilot-scale reactors. The region shows robust demand for specialized equipment catering to the synthesis of fine chemicals, APIs, and the development of power-to-X technologies, including hydrogen production and storage under extreme pressures. European manufacturers often lead in developing reactors optimized for continuous flow processes and supercritical CO2 applications, driven by EU mandates for environmental protection and resource efficiency, favoring high-efficiency, small footprint designs.

- Asia Pacific (APAC): APAC is the fastest-growing region, dominating global demand for industrial-scale high pressure reactors. This growth is predominantly driven by massive infrastructure expansion in the petrochemical and chemical industries across China, India, and South Korea, aiming to satisfy rapidly growing domestic and export needs for bulk chemicals, plastics, and fertilizers. Government incentives and large-scale industrial projects fuel the demand for large-volume (>100 Liters) Fixed Bed and Loop Reactors required for essential processes like ammonia synthesis and olefin polymerization. While the focus remains on scale and cost-effectiveness, rising quality expectations and the entry of local players are beginning to drive investment into localized R&D and technological parity with Western standards.

- Latin America: The Latin American market exhibits moderate growth, primarily tied to investment cycles in the domestic oil and gas sector (especially Brazil and Mexico) and the regional production of fertilizers and petrochemicals. Demand is often characterized by the refurbishment or replacement of aging infrastructure. The market size is smaller compared to APAC, and purchasing decisions are highly sensitive to global commodity prices. There is emerging demand in countries like Chile for high-pressure systems related to mineral processing and novel battery material development, signifying potential diversification beyond traditional energy sectors.

- Middle East and Africa (MEA): The MEA market is heavily skewed toward the oil and gas processing sector, demanding large-scale, custom high-pressure reactors for hydrocracking, hydrotreating, and ammonia production, particularly in Saudi Arabia, UAE, and Qatar. Investment is highly volatile, correlating directly with global crude oil prices and national diversification efforts. The primary drivers are the expansion of refining capacity and the integration of downstream petrochemical production facilities. Safety compliance and material resistance to hydrogen sulfide and other harsh compounds are crucial purchasing criteria in this high-risk operational environment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Pressure Reactors Market.- Parr Instrument Company

- Autoclave Engineers (Erie Technical Systems)

- Top Industrie

- Amar Equipments

- thyssenkrupp Industrial Solutions

- HiP (High Pressure Equipment Company)

- Büchi AG

- HEL Group

- Pressure Products Industries (PPI)

- S.P.P.L. (Supercritical Process Plants Pvt. Ltd.)

- G.E. Baker & Associates

- Chemineer (NOV)

- Mettler Toledo

- IKA Works

- Premex Solutions

- Bio-Chem Equipment Co., Inc.

- Suzhou High Pressure Reactor Institute Co., Ltd.

- Zhejiang Sanmen Xinda Chemical Equipment Co., Ltd.

- Supercritical Technology (SCT)

- Optima Group

Frequently Asked Questions

Analyze common user questions about the High Pressure Reactors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary safety considerations in operating high pressure reactors?

The primary safety concerns include pressure vessel integrity, material compatibility with corrosive reactants, ensuring zero leaks through robust sealing mechanisms, and the accurate monitoring of temperature and pressure to prevent exothermic runaway reactions. Regular non-destructive testing and compliance with standards like ASME Boiler and Pressure Vessel Codes are essential.

How is the adoption of continuous flow chemistry impacting the high pressure reactors market?

Continuous flow chemistry drives demand for smaller, highly efficient micro- and milli-reactors capable of handling high pressures. This shift prioritizes safety, improved heat transfer, faster reaction times, and reduced equipment footprint compared to traditional large-volume batch processing systems.

Which end-use industry is expected to show the highest growth rate for high pressure reactors?

The Research & Development and the Pharmaceutical & Biotechnology segments are projected to exhibit the highest growth rate, driven by accelerating novel drug discovery, catalyst screening, and the necessity for highly precise, small-scale synthesis capabilities under extreme operating conditions.

What technological advancements are crucial for improving reactor efficiency and lifespan?

Crucial advancements include utilizing corrosion-resistant specialty alloys (e.g., Hastelloy), integrating advanced magnetic coupling drives for agitation (eliminating dynamic seals), and implementing AI-driven predictive maintenance and real-time process control (PAT) to optimize operational parameters and minimize component wear.

How does the High Pressure Reactors market contribute to the green chemistry movement?

HPRs are integral to green chemistry by enabling reactions using environmentally benign solvents, such as supercritical CO2, facilitating efficient biomass conversion processes, and supporting the development of cleaner catalytic routes that reduce waste and energy consumption compared to traditional chemical synthesis methods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager