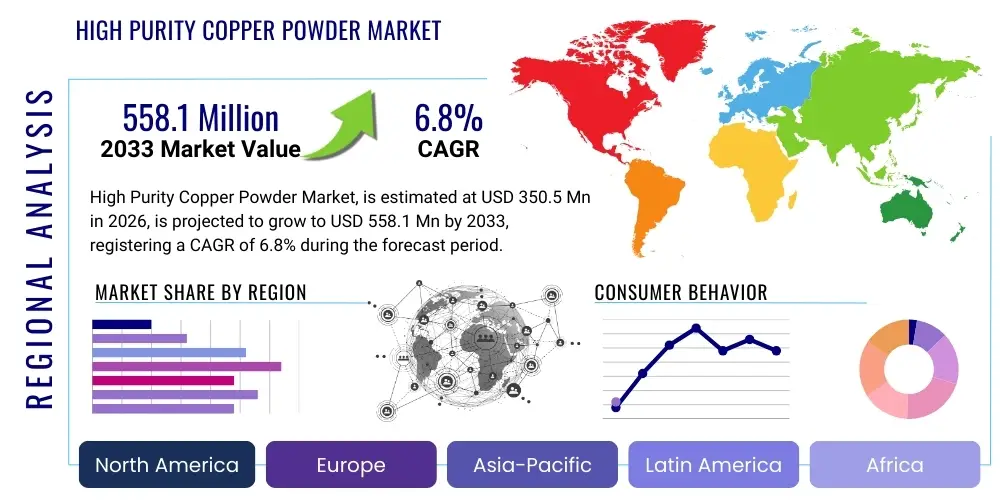

High Purity Copper Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436951 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

High Purity Copper Powder Market Size

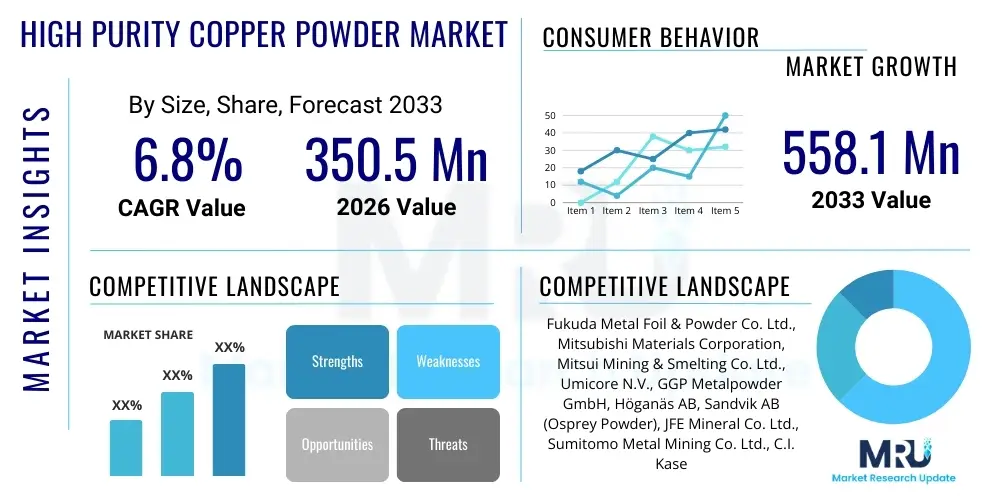

The High Purity Copper Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 350.5 million in 2026 and is projected to reach USD 558.1 million by the end of the forecast period in 2033.

High Purity Copper Powder Market introduction

The High Purity Copper Powder Market encompasses the production and distribution of copper powder characterized by exceptionally low levels of impurities, typically exceeding 99.9% copper content. This specialized material is critical for advanced technological applications where standard copper purity is insufficient, ensuring optimal electrical conductivity, thermal performance, and mechanical stability. Key production methodologies include electrolytic deposition, atomization (gas or water), and chemical reduction, each yielding specific particle sizes and morphologies tailored for distinct industrial requirements. The rising demand for miniaturization in electronics and the rapid adoption of Additive Manufacturing (AM) technologies are the primary catalysts driving market expansion globally.

High purity copper powder is indispensable across several high-growth industries. In electronics, it is utilized in conductive pastes, multilayer ceramic capacitors (MLCCs), and heat dissipation components due to its superior thermal and electrical properties. The automotive sector, particularly the electric vehicle (EV) segment, relies on high-purity copper for battery components, motor windings, and sophisticated thermal management systems, seeking efficiency gains and reduced weight. Furthermore, its role in metallurgy, specifically in powder metallurgy processes for creating intricate, high-strength parts, highlights its versatility as a foundational material for future industrial innovation.

The major driving factors fueling this market growth include significant government investments in semiconductor manufacturing infrastructure worldwide, the accelerating shift towards electric mobility, and the continuous innovation within 3D printing techniques. High Purity Copper Powder offers unparalleled benefits such as enhanced thermal conductivity (essential for high-performance computing), exceptional ductility, and consistent particle size distribution necessary for precision applications like selective laser melting (SLM) in AM. However, the market faces challenges related to the high energy costs associated with purification processes and the stringent quality control required to maintain ultra-high purity standards.

High Purity Copper Powder Market Executive Summary

The High Purity Copper Powder Market is characterized by robust growth, propelled by the convergence of the electronics, automotive, and additive manufacturing sectors. Business trends indicate a strong move towards finer particle sizes (nanopowders) to meet the demands of advanced conductive inks and paste formulations necessary for flexible electronics and advanced packaging technologies. Strategic collaborations between powder manufacturers and end-user technology developers, particularly those in the 3D printing space, are accelerating product innovation and customization, ensuring that materials meet precise application specifications, thereby reinforcing market value.

Regionally, the Asia Pacific (APAC) dominates the market, primarily due to its established and rapidly expanding electronics manufacturing base, coupled with significant investments in EV production, particularly in China, South Korea, and Japan. North America and Europe are also experiencing substantial growth, driven by increasing adoption of industrial-grade Additive Manufacturing for aerospace and medical device components, where material purity and reliability are paramount. Regulatory pressures emphasizing sustainable material sourcing and processing methods are increasingly influencing regional competitive dynamics, favoring manufacturers who can demonstrate environmental responsibility alongside high product quality.

Segment trends reveal that the Electronics application segment holds the largest market share, directly benefiting from the proliferation of 5G infrastructure, IoT devices, and high-density packaging. By production method, the electrolytic method remains highly significant due to its cost-effectiveness in producing high-purity material, while the chemical reduction method is gaining traction for producing ultra-fine nanopowders required for advanced chemical and catalytic uses. The market is witnessing increasing consolidation among major players seeking economies of scale and control over the highly technical production processes.

AI Impact Analysis on High Purity Copper Powder Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the High Purity Copper Powder Market predominantly focus on how AI can optimize production efficiency, enhance material quality control, and accelerate research and development (R&D) cycles, particularly for specialized particle morphologies. Common concerns revolve around the integration costs of AI-driven sensor systems and predictive maintenance tools within existing high-throughput facilities, and the potential for AI to optimize resource utilization in energy-intensive purification processes like electrolytic refinement. Users expect AI to stabilize production variability, which is critical for maintaining the ultra-high purity standards required by sensitive electronic and AM applications.

AI is beginning to revolutionize the manufacturing process of high purity copper powder by enabling predictive modeling of particle characteristics based on input parameters (temperature, current density, chemical composition). This capability allows manufacturers to fine-tune processes in real-time, significantly reducing batch failures and waste. Furthermore, in R&D, AI algorithms are used to screen millions of potential synthesis routes and optimize doping levels or surface treatments, drastically shortening the time needed to develop novel copper-based materials designed for specific emerging applications, such as high-efficiency catalysts or specialized conductive inks for printed electronics.

- AI-driven optimization of electrolytic deposition processes, leading to consistent purity levels (99.999%).

- Predictive maintenance schedules for high-wear atomization equipment, minimizing downtime and operational costs.

- Enhanced quality control through machine vision and deep learning models for rapid defect detection in powder morphology.

- Accelerated material discovery and formulation testing for new copper alloy powders used in additive manufacturing.

- Improved resource management, particularly energy consumption, in purification and annealing stages through smart process controls.

DRO & Impact Forces Of High Purity Copper Powder Market

The High Purity Copper Powder Market is subjected to a complex interplay of drivers, restraints, opportunities, and inherent impact forces that shape its growth trajectory. The primary driver is the pervasive demand for electrification and miniaturization across consumer, industrial, and automotive applications, which mandates materials with superior conductivity and thermal stability. Restraints include the volatility of raw copper prices, high capital expenditure required for establishing and maintaining high-purity production facilities, and the necessity for extremely precise quality assurance protocols. Opportunities are abundant, particularly in the burgeoning fields of flexible electronics, advanced batteries (solid-state), and high-resolution 3D printing, which continuously push the boundaries of required material performance and particle size distribution.

Impact forces currently dominating the market include technological advancements in competing materials, such as silver alternatives or specialized composites, though copper's cost efficiency and performance profile often maintain its edge. Economic stability directly affects capital investment decisions in end-user sectors like aerospace and heavy machinery, influencing the adoption rate of powder metallurgy components. Furthermore, environmental regulations concerning metal dust handling and solvent use in chemical reduction processes impose structural adjustments and compliance costs on manufacturers, acting as a moderate dampener on market expansion, especially in developed economies.

Overall, the demand for ultra-clean, consistent material for critical components is non-negotiable, positioning purity and reliability as the key impact forces governing supplier selection. The market exhibits high forward integration potential, where powder manufacturers seek to offer pre-mixed or surface-treated powders optimized for specific AM machines or conductive paste formulations. This move from basic commodity supply to value-added material solution provision increases profit margins and cements long-term strategic relationships with major industrial consumers.

Segmentation Analysis

The High Purity Copper Powder Market is comprehensively segmented based on its Purity Grade, Production Method, Particle Size, and Major Application, providing distinct insights into consumer preferences and technological requirements across various industrial verticals. Understanding these segments is crucial for manufacturers to tailor their production capabilities and marketing strategies, ensuring alignment with the rigorous performance standards demanded by sectors such as advanced electronics and aerospace. The complexity of end-use applications often necessitates customized material specifications, driving specialization within the market.

- By Purity Grade:

- 99.9% (Standard High Purity)

- 99.99% (Ultra-High Purity)

- 99.999% (5N Purity and above)

- By Production Method:

- Electrolytic Deposition

- Atomization (Gas Atomization, Water Atomization)

- Chemical Reduction (e.g., Reduction of Copper Oxide)

- Others (e.g., Plasma Spheroidization)

- By Particle Size:

- Micron Powder (>1 µm)

- Sub-Micron Powder (0.1 µm – 1 µm)

- Nanopowder (<0.1 µm or 100 nm)

- By Application:

- Electronics and Electrical Components (Conductive Pastes, MLCCs, Heat Sinks)

- Additive Manufacturing (3D Printing - SLM, EBM)

- Powder Metallurgy (Sintered Parts, Friction Materials)

- Chemical and Catalysts

- Automotive and Aerospace

Value Chain Analysis For High Purity Copper Powder Market

The value chain for High Purity Copper Powder begins with the upstream analysis, which involves the sourcing of high-grade copper feedstock (primary copper or high-quality copper scrap). The critical phase here is the initial refining process to achieve the necessary purity level before powder manufacturing begins. Key challenges in the upstream segment include ensuring sustainable sourcing practices and managing the volatile costs of raw materials, which directly impact the final production cost of the powder. Suppliers capable of providing consistent, low-impurity feedstock are essential to the specialized nature of this market.

The midstream section constitutes the core manufacturing processes: electrolytic deposition, atomization, and chemical reduction. This stage adds significant value through technical expertise, employing specialized equipment to control particle morphology, size distribution, and surface characteristics. Distribution channels are varied, including direct sales from manufacturers to large industrial end-users (especially in Additive Manufacturing and specialized electronics), and sales through indirect specialized metal powder distributors. These distributors often provide technical support and smaller, customized batch sizes, catering to R&D labs and niche component manufacturers.

Downstream analysis focuses on the integration of the copper powder into final products across major applications. For electronics, the powder is formulated into conductive pastes; for powder metallurgy, it is compacted and sintered; and for 3D printing, it is used directly in highly controlled atmospheric environments. The trend toward customized, application-specific powders means that collaboration between the powder producer (midstream) and the end-user (downstream) is intensifying. The effectiveness of the indirect channel is crucial for market penetration in geographically diverse and technically demanding markets, ensuring timely delivery and specialized handling.

High Purity Copper Powder Market Potential Customers

The end-users and buyers of High Purity Copper Powder are typically large-scale industrial manufacturers operating in highly regulated and technically demanding sectors where material failure is unacceptable. These customers prioritize consistency, certified purity levels, and precise particle size metrics over generalized pricing. A significant segment comprises Electronics Manufacturing Services (EMS) providers and component manufacturers (like producers of passive components and printed circuit boards) who rely on the powder for advanced thermal and conductive solutions in high-performance devices, including smartphones, servers, and telecommunications equipment.

Another major segment includes advanced manufacturing firms, specifically those involved in aerospace and medical device production utilizing metal Additive Manufacturing (3D printing). For these customers, high purity copper powder is essential for creating complex, lightweight parts that require high thermal or electrical conductivity. The aerospace industry uses it for heat exchangers and combustion chamber components, while the medical sector utilizes it for specialized surgical tools and customized implants where biocompatibility and precise metallurgy are non-negotiable requirements, thereby driving demand for the ultra-high purity grades.

Furthermore, the automotive industry, spearheaded by electric vehicle (EV) manufacturers and their supply chains, represents a rapidly expanding customer base. These buyers require substantial volumes of high purity copper powder for battery contacts, busbars, sophisticated cooling plates, and efficient motor magnets. The demand here is driven by the global imperative for improved EV range and charging speed, which necessitates maximizing the efficiency of every copper component. These customers often seek multi-year supply contracts to ensure material stability and pricing predictability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 million |

| Market Forecast in 2033 | USD 558.1 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fukuda Metal Foil & Powder Co. Ltd., Mitsubishi Materials Corporation, Mitsui Mining & Smelting Co. Ltd., Umicore N.V., GGP Metalpowder GmbH, Höganäs AB, Sandvik AB (Osprey Powder), JFE Mineral Co. Ltd., Sumitomo Metal Mining Co. Ltd., C.I. Kasei Co. Ltd., Ametek Inc., Alfa Aesar (Thermo Fisher Scientific), Pometon Powder, Atlantic Equipment Engineers, ECKA Granules GmbH, Uniformity Labs, Praxair Surface Technologies, Metal Powder Company (MEPCO), H.C. Starck Solutions, Nanostructured & Amorphous Materials Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Purity Copper Powder Market Key Technology Landscape

The technological landscape of the High Purity Copper Powder Market is dominated by refinement processes aimed at achieving ultra-low oxygen content and exceptional control over particle geometry. The primary technologies employed are advanced electrolytic methods, which offer the highest purity levels (up to 5N) by carefully controlling current density and electrolyte composition to precipitate fine copper particles directly. Recent innovations focus on reducing the high energy consumption of these processes while maintaining rigorous quality standards, often through the integration of sophisticated monitoring systems and optimized cell designs.

Atomization techniques, particularly gas atomization, are critical for producing spherical copper powders highly valued in Additive Manufacturing (AM). The technology involves melting high-purity copper and rapidly solidifying it by high-pressure gas jets (typically argon or nitrogen). The key technological development here involves optimizing the atomizer nozzle design and gas parameters to achieve extremely narrow particle size distribution (PSD) and high flowability, which are essential characteristics for successful Selective Laser Melting (SLM) and Electron Beam Melting (EBM) processes, minimizing wasted material and ensuring part density.

Furthermore, the growing demand for nanopowders has spurred advancements in chemical reduction and plasma techniques. Chemical reduction processes allow for the synthesis of copper particles in the 10-100 nm range, often coated or surface-treated for stability, making them ideal for high-resolution conductive inks and catalytic converters. Plasma spheroidization is another niche but growing technology used to transform irregular or porous particles into highly spherical, dense powders, improving the overall packing density and performance in high-end applications like electronics encapsulation and thermal interface materials.

Regional Highlights

The global distribution and consumption of High Purity Copper Powder are heavily influenced by the presence of advanced manufacturing hubs and regional strategic investments in electronics and clean energy technologies. Asia Pacific (APAC) stands as the undisputed leader in both production and consumption, primarily due to the concentration of major semiconductor manufacturers, vast consumer electronics assembly operations, and aggressive government policies supporting domestic electric vehicle manufacturing, particularly in countries like China, Taiwan, and South Korea. This region dictates global pricing trends and technological adoption rates.

North America and Europe represent mature markets with high demand for premium, ultra-high purity grades, largely driven by the aerospace, medical device, and specialized industrial Additive Manufacturing sectors. In North America, the reshoring of semiconductor production, supported by initiatives like the CHIPS Act, is creating a sustained surge in demand for high-purity materials used in advanced packaging and circuitry. European demand is bolstered by stringent environmental standards and a strong focus on high-performance automotive components and sustainable catalytic solutions, necessitating reliable local supply chains.

Latin America, the Middle East, and Africa (MEA) currently hold smaller market shares but are exhibiting promising growth, particularly in areas related to infrastructural development and localized electronics assembly. MEA is focusing on leveraging its resource wealth to establish local manufacturing capabilities, increasing demand for technical powders. The growth in these regions, while slower than in APAC, represents long-term opportunities for manufacturers focused on offering cost-competitive, standard high-purity grades for general powder metallurgy and electrical applications.

- Asia Pacific (APAC): Dominates the market due to robust electronics manufacturing (5G, IoT) and leading EV production; high adoption of electrolytic and nanopowders.

- North America: Strong demand from Additive Manufacturing (aerospace, medical) and new investments in semiconductor fabrication; focus on ultra-high purity grades (5N).

- Europe: Driven by specialized automotive (EV infrastructure), stringent environmental requirements, and advanced powder metallurgy for industrial machinery.

- Latin America: Emerging market characterized by increasing industrialization and localized electrical infrastructure projects; gradual adoption of standard high-purity powders.

- Middle East and Africa (MEA): Growth tied to infrastructure investment and diversification efforts away from oil; potential for catalytic applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Purity Copper Powder Market.- Fukuda Metal Foil & Powder Co. Ltd. - A key Japanese producer renowned for expertise in fine copper powder and flakes used extensively in advanced conductive pastes and printed electronics. Their focus is on highly specialized morphologies and surface treatments for high-end electronic applications, maintaining a strong presence in the APAC electronics supply chain.

- Mitsubishi Materials Corporation - A diversified materials group offering a wide range of metal powders, including high purity copper. They leverage proprietary refining and atomization technologies to supply large volumes of spherical powder for powder metallurgy and additive manufacturing, focusing on quality control and scalability for global industrial clients.

- Mitsui Mining & Smelting Co. Ltd. - Major player focusing on chemical products, including high-purity non-ferrous metal powders. They are critical suppliers to the electronics industry, providing materials essential for components like multilayer ceramic capacitors (MLCCs) where purity and consistency are vital.

- Umicore N.V. - A global materials technology and recycling group, offering high purity and ultra-fine copper powders, particularly emphasizing sustainable sourcing and advanced materials for battery technology and catalysts. Their commitment to closed-loop manufacturing appeals to environmentally conscious buyers.

- GGP Metalpowder GmbH - European specialist in high-quality metal powders, providing specific grades of copper and copper alloys optimized for powder metallurgy applications and friction materials in the automotive sector. Known for tailored particle size distributions and batch consistency.

- Höganäs AB - World leader in iron and metal powders, providing high purity copper powders through advanced atomization processes. Their strength lies in large-scale production capabilities and supply chain reliability for the traditional powder metallurgy sector and additive manufacturing materials.

- Sandvik AB (Osprey Powder) - Offers high-performance metal powders, including highly specialized copper alloys and pure copper powder produced via state-of-the-art atomization, targeting demanding applications in aerospace and industrial 3D printing where material integrity is paramount.

- JFE Mineral Co. Ltd. - Focuses on high-quality mineral and metal products, supplying copper powder primarily through advanced electrolytic methods, ensuring exceptional purity suitable for critical electronic contacts and sophisticated chemical applications.

- Sumitomo Metal Mining Co. Ltd. - A major Japanese producer involved from mining to final product, offering high-purity copper products, including powders and specialized materials for semiconductors and advanced battery electrodes.

- C.I. Kasei Co. Ltd. - Specializes in unique chemical products and fine materials, contributing to the market with chemically derived copper powders that achieve fine particle sizes necessary for specific ink and paste formulations.

- Ametek Inc. - Through its various divisions, Ametek supplies high-performance metal powders primarily through gas atomization, catering to aerospace, defense, and power generation sectors where reliability in complex components is key.

- Alfa Aesar (Thermo Fisher Scientific) - A provider of high-purity research chemicals and materials, supplying smaller, specialized quantities of high purity and nanopowders for academic research and high-tech R&D applications, ensuring broad market accessibility for innovation.

- Pometon Powder - European manufacturer of metal powders and flakes, offering competitive solutions for general industrial applications, friction materials, and certain electrical components, focusing on customized particle shapes.

- Atlantic Equipment Engineers - Specializes in high-purity metal powders and materials for R&D and small-scale production, often servicing niche markets requiring custom specifications and rapid turnaround.

- ECKA Granules GmbH - Focuses on metal powders and flakes, serving the powder metallurgy and chemical industries, providing standardized and specialized copper grades for large industrial users globally.

- Uniformity Labs - An emerging player focused on developing optimized powders specifically for Additive Manufacturing, utilizing unique processes to enhance powder density and flowability, crucial for improving 3D printing throughput and quality.

- Praxair Surface Technologies - Supplies specialized thermal spray powders and materials, including high purity copper, often used for coating applications requiring high electrical conductivity and corrosion resistance.

- Metal Powder Company (MEPCO) - Indian producer with extensive capabilities in electrolytic copper powder, targeting industrial applications, friction materials, and emerging markets with cost-effective, high-quality material.

- H.C. Starck Solutions - Known for advanced refractory metal materials, they also supply specialized high purity copper products, often integrated into complex composite materials for extreme environment applications.

- Nanostructured & Amorphous Materials Inc. - Focuses solely on nanopowders and ultra-fine materials, providing critical components of high purity copper nanopowder essential for next-generation conductive inks and flexible electronic substrates.

Frequently Asked Questions

Analyze common user questions about the High Purity Copper Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for High Purity Copper Powder in electronics?

The primary driver is the need for enhanced thermal management and superior electrical conductivity in increasingly miniaturized electronic devices, 5G components, and high-density integrated circuits. Ultra-high purity copper powder is essential for creating high-performance conductive pastes and heat dissipation solutions that minimize signal loss and prevent overheating, directly impacting device reliability and efficiency.

How does Additive Manufacturing (AM) influence the requirements for copper powder quality?

AM, particularly Selective Laser Melting (SLM), necessitates spherical copper powders with exceptional purity, high flowability, and narrow particle size distribution (typically 15-45 µm). Purity is critical to prevent laser absorption inconsistency and maintain part density, while high sphericity ensures uniform powder bed packing and efficient material transfer during the demanding layer-by-layer printing process.

Which production method yields the highest purity grade, and for which application is it used?

The Electrolytic Deposition method is typically favored for producing the highest purity grades, often achieving 99.999% (5N) purity. This material is primarily used in the most sensitive electronic applications, such as sputtering targets, advanced semiconductor packaging materials, and critical component manufacturing where trace impurities can severely compromise device performance.

What is the key regional growth engine for the High Purity Copper Powder market?

The Asia Pacific (APAC) region is the key growth engine, driven by the colossal manufacturing footprint of consumer electronics and the substantial governmental and private investment in electric vehicle (EV) production and battery technology, particularly in East and Southeast Asian countries. This sustained industrial expansion demands reliable, high-volume supplies of pure copper powders.

What role do copper nanopowders play in the future of conductive materials?

Copper nanopowders are crucial for the development of next-generation conductive inks and pastes used in printed electronics and flexible circuits. Their extremely small size allows for ultra-fine resolution printing and sintering at lower temperatures compared to micron-sized powders, facilitating the manufacturing of lightweight, flexible electronic components on various substrates.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager