High Purity Electronic Grade Ammonium Fluoride Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434826 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

High Purity Electronic Grade Ammonium Fluoride Market Size

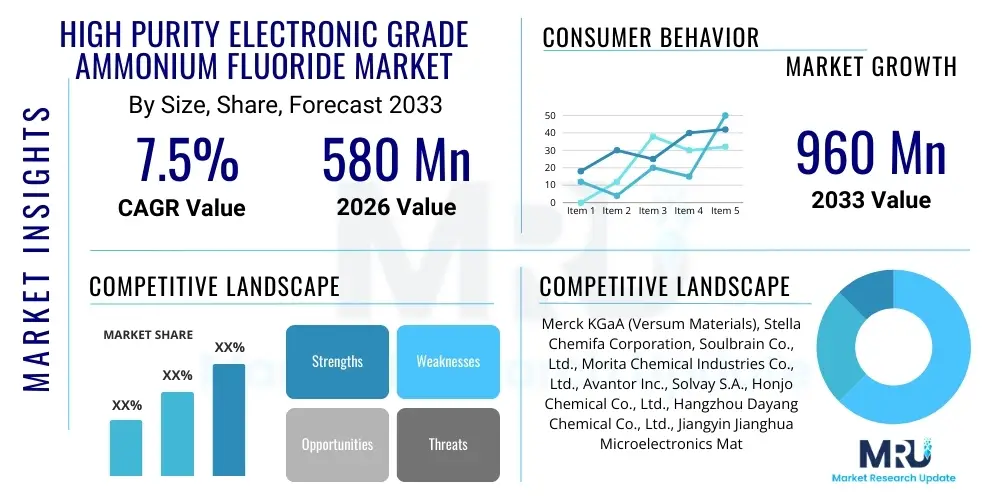

The High Purity Electronic Grade Ammonium Fluoride Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 580 Million in 2026 and is projected to reach USD 960 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the relentless miniaturization trend within the semiconductor industry, demanding ultra-clean processing agents for advanced etching and cleaning applications. The increasing complexity of 3D NAND and FinFET structures necessitates higher standards of chemical purity, solidifying the demand for electronic grade materials.

High Purity Electronic Grade Ammonium Fluoride Market introduction

The High Purity Electronic Grade Ammonium Fluoride (HP-EGAF) market encompasses the production, distribution, and consumption of ammonium fluoride solutions and crystal forms specifically engineered to meet the stringent purity requirements of the electronics and semiconductor manufacturing sectors. HP-EGAF serves as a critical component in the fabrication of integrated circuits, microelectromechanical systems (MEMS), and flat panel displays (FPDs), primarily functioning as an etchant, buffer oxide etchant (BOE) constituent, and cleaning agent. Its exceptional purity, typically measured in parts per billion (ppb) or parts per trillion (ppt) metallic impurity levels, ensures minimal defect generation during sensitive photolithography and deposition processes. The market growth is inherently tied to global capital expenditure in advanced fabrication facilities (Fabs) and the accelerating adoption of consumer electronics, 5G infrastructure, and sophisticated data center components. Key driving factors include technological advancements in wafer processing, the rising demand for higher memory capacity chips, and substantial investment in the Asian Pacific region, particularly in China and South Korea, which dominate global semiconductor output and require vast quantities of specialized electronic chemicals to sustain their advanced manufacturing ecosystems.

High Purity Electronic Grade Ammonium Fluoride Market Executive Summary

The High Purity Electronic Grade Ammonium Fluoride market is undergoing robust expansion, characterized by significant technological shifts favoring ultra-high purity materials. Business trends indicate a move toward regional supply chain localization, especially in response to geopolitical instability and the critical need for supply resilience within the semiconductor ecosystem. Major electronic chemical suppliers are increasing production capacity and investing heavily in advanced purification techniques to meet the evolving demands for sub-nanometer-scale etching precision required by leading-edge process nodes (e.g., 5nm and below). Regional trends reveal Asia Pacific as the undeniable epicenter of demand, driven by massive investments from TSMC, Samsung, SK Hynix, and SMIC, positioning this region as the fastest-growing and largest consumer globally. Conversely, North America and Europe are focusing on enhancing R&D and securing domestic supply lines for these critical materials. Segment trends highlight that the Semiconductor Grade sub-segment, particularly the ppb/ppt purity levels, commands the highest premium and exhibits the most rapid growth due to its indispensability in advanced logic and memory chip manufacturing, outpacing demand from FPD and solar photovoltaic applications.

AI Impact Analysis on High Purity Electronic Grade Ammonium Fluoride Market

User queries regarding the impact of Artificial Intelligence (AI) on the HP-EGAF market frequently center on how AI-driven optimization affects manufacturing efficiency, purity control, and ultimately, the demand trajectory for electronic chemicals. Key themes include the use of AI in predictive maintenance for chemical synthesis equipment, optimization of complex purification steps (such as ultrafiltration and crystallization) to achieve higher purity levels more consistently, and the role of AI in driving the demand for advanced semiconductors themselves. Users are keen to understand if AI-enhanced semiconductor fabrication will lead to more efficient chemical usage per wafer, potentially dampening volume growth, or if the sheer proliferation of AI-driven devices (data centers, edge computing) will overwhelmingly boost overall wafer production, thereby necessitating greater volumes of HP-EGAF. The consensus indicates that while AI can optimize production, its primary market impact is through drastically increased downstream demand for advanced, high-density chips, which rely heavily on high-purity etching agents like HP-EGAF during their complex manufacturing cycles.

- AI-driven fabrication optimization enhances chemical process control, ensuring consistent ultra-high purity (ppb/ppt levels) necessary for 5nm and below nodes.

- Predictive maintenance implemented via AI minimizes downtime in HP-EGAF manufacturing plants, improving overall supply chain reliability and yield.

- The exponential growth of AI and machine learning infrastructure (servers, specialized GPUs, NPUs) necessitates massive scaling of advanced semiconductor manufacturing, directly boosting HP-EGAF consumption.

- AI tools optimize chemical recycling and waste reduction within Fabs, slightly improving chemical utilization efficiency but offset by volume increases.

- AI algorithms assist in real-time quality assurance of chemical specifications, accelerating qualification processes for new HP-EGAF batches.

DRO & Impact Forces Of High Purity Electronic Grade Ammonium Fluoride Market

The market dynamics for High Purity Electronic Grade Ammonium Fluoride are dictated by strong underlying demand forces coupled with significant technological and regulatory constraints. Drivers include the accelerating global demand for advanced semiconductors, particularly in areas such as 5G, IoT, and high-performance computing, which require extremely precise etching processes enabled by high-purity chemicals. Restraints center on the high capital expenditure required for establishing ultra-purification facilities, stringent environmental regulations regarding fluorine waste disposal, and the high sensitivity of the supply chain to quality deviations. Opportunities arise from developing innovative solvent formulations that enhance etching selectivity and reduce defect rates, particularly in complex 3D structures like 3D NAND flash memory. Impact forces, such as the increasing global push for semiconductor independence and the subsequent construction of new Giga-Fabs outside of traditional Asian hubs, necessitate localized production and technical support for HP-EGAF suppliers, influencing investment decisions and market structure significantly over the forecast period. Furthermore, the constant requirement for higher purity levels acts as a continuous technological pressure, eliminating smaller players unable to invest in cutting-edge analysis and purification methods.

Segmentation Analysis

The High Purity Electronic Grade Ammonium Fluoride market is comprehensively segmented based on its Purity Level, Application, and End-User Industry, reflecting the diverse and highly specialized requirements across the electronics manufacturing ecosystem. Purity level segmentation is crucial, differentiating between standard Electronic Grade, often measured in parts per million (ppm), and Ultra High Purity grades, measured in parts per billion (ppb) or parts per trillion (ppt), which cater to the most advanced process nodes. Application segmentation primarily revolves around etching processes (silicon dioxide, silicon nitride) and cleaning steps. The complexity and performance requirements of the end-user device directly dictate the necessary purity standard and the specific form factor of the chemical utilized, driving distinct market dynamics within each segment. The semiconductor industry remains the dominant application segment, followed by the relatively steady demand from the Flat Panel Display and Photovoltaic cell manufacturing sectors.

- By Purity Level:

- Parts Per Million (PPM) Grade

- Parts Per Billion (PPB) Grade

- Parts Per Trillion (PPT) Grade (Ultra-High Purity)

- By Application:

- Etching Agent (Silicon Dioxide, Silicon Nitride)

- Cleaning Agent

- Buffer Oxide Etchant (BOE) Mixture Component

- By End-User Industry:

- Semiconductors (Logic, Memory, Foundry)

- Flat Panel Displays (FPDs)

- Photovoltaic (PV) Cells

- Others (MEMS, LEDs)

- By Form:

- Aqueous Solution

- Crystal/Powder Form

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For High Purity Electronic Grade Ammonium Fluoride Market

The value chain for High Purity Electronic Grade Ammonium Fluoride is complex, starting with the upstream sourcing of raw materials, primarily high-purity ammonia and hydrofluoric acid (HF). Upstream analysis reveals significant challenges in securing consistent, low-impurity HF, as the quality of the starting materials directly limits the achievable purity of the final EGAF product. Synthesis and subsequent purification are the most capital-intensive steps, requiring specialized materials (Teflon, PFA) and meticulous cleanroom environments to prevent contamination. The purification phase often involves multiple crystallization, filtration, and ion exchange stages to strip metallic impurities down to the required ppt level. Downstream, the product is packaged, typically in specialized, non-contaminating containers, and distributed directly to high-volume semiconductor fabrication plants (Fabs). The distribution channel relies heavily on specialized logistics providers capable of handling corrosive and regulated electronic chemicals, often bypassing conventional broad distributors to ensure supply chain integrity and minimal risk of contamination. Direct sales models dominate the relationship between major HP-EGAF manufacturers and tier-one semiconductor foundries, emphasizing strong technical support and customized chemical specifications.

High Purity Electronic Grade Ammonium Fluoride Market Potential Customers

Potential customers for High Purity Electronic Grade Ammonium Fluoride are almost exclusively situated within highly capitalized and technologically advanced manufacturing sectors requiring ultra-precise chemical processing. The primary buyers are large integrated device manufacturers (IDMs) and pure-play foundries specializing in the mass production of sophisticated logic and memory chips. These entities utilize HP-EGAF in processes such as pre-gate cleaning, native oxide removal, and precise silicon etching, especially critical for advanced node fabrication (7nm, 5nm, and 3nm). Secondary consumers include manufacturers of advanced flat panel displays, particularly those utilizing high-resolution OLED and QLED technologies, where etching precision is crucial for display uniformity. Furthermore, large-scale solar panel manufacturers consuming PV-grade EGAF constitute a significant volume buyer, although their purity requirements are generally less stringent than the semiconductor sector. Procurement decisions are heavily influenced by the chemical supplier's ability to consistently meet stringent specifications, provide extensive documentation, and offer just-in-time delivery to maintain continuous, high-volume manufacturing lines.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 580 Million |

| Market Forecast in 2033 | USD 960 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA (Versum Materials), Stella Chemifa Corporation, Soulbrain Co., Ltd., Morita Chemical Industries Co., Ltd., Avantor Inc., Solvay S.A., Honjo Chemical Co., Ltd., Hangzhou Dayang Chemical Co., Ltd., Jiangyin Jianghua Microelectronics Materials Co., Ltd., Suzhou Crystal Clear Chemical Co., Ltd., FujiFilm Wako Pure Chemical Corporation, Kanto Chemical Co., Inc., Chang Chun Group, Iwatani Corporation, Showa Denko K.K., BASF SE, Central Glass Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Purity Electronic Grade Ammonium Fluoride Market Key Technology Landscape

The technological landscape for High Purity Electronic Grade Ammonium Fluoride is characterized by continuous refinement of purification and analytical methodologies aimed at achieving progressively lower impurity thresholds. The manufacturing process heavily relies on advanced multi-stage crystallization techniques, coupled with sophisticated membrane filtration and ion-exchange resin systems, specifically designed to remove trace metallic ions (Fe, Ni, Cu, Na) and organic contaminants. Crucial technological advancements focus on the deployment of real-time monitoring systems using specialized analytical instruments such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Atomic Absorption Spectroscopy (AAS) capable of detecting impurities in the parts per trillion (ppt) range, ensuring compliance with leading-edge semiconductor specifications. Furthermore, innovations in packaging and delivery systems, utilizing ultra-clean PFA and PTFE materials and specialized drum types, are vital to maintain the chemical's integrity from the manufacturing site to the point of use in the Fab. The industry is also exploring alternative synthesis routes to improve yield and reduce the environmental footprint associated with traditional production methods, although the core purification technology remains the primary competitive differentiator among leading suppliers.

Regional Highlights

The consumption and production landscape of High Purity Electronic Grade Ammonium Fluoride is overwhelmingly dominated by the Asia Pacific (APAC) region, which accounts for the vast majority of global demand due to its status as the world’s leading hub for semiconductor and FPD manufacturing. Countries such as South Korea, Taiwan, and Mainland China host the largest fabrication facilities globally, driving insatiable demand for ultra-high purity process chemicals. The rapid expansion of domestic semiconductor manufacturing capabilities in China, supported by government initiatives aimed at self-sufficiency, has resulted in high double-digit growth rates for EGAF consumption within the region, necessitating substantial capacity additions by both local and multinational chemical suppliers. North America and Europe, while smaller consumers in terms of volume, play a critical role in innovation, primarily through the development of next-generation chemical formulations and advanced purification technologies. Recent geopolitical factors and supply chain shocks have spurred renewed governmental and corporate focus on establishing or strengthening local supply chains for critical electronic chemicals in these Western regions, diversifying the global manufacturing base away from its current concentration.

- Asia Pacific (APAC): Dominates the global market volume and growth, fueled by leading semiconductor manufacturers (TSMC, Samsung, SK Hynix) and extensive investment in new Giga-Fabs, particularly in advanced nodes requiring ppt-grade purity.

- North America: Focuses on securing domestic supply and technological innovation. Key demand stems from specialized foundries and R&D centers, with anticipated growth supported by government incentives (e.g., the CHIPS Act) promoting regional manufacturing expansion.

- Europe: Exhibits steady demand driven by established automotive electronics and industrial semiconductor sectors. Growth is moderate but stable, with increasing focus on environmental sustainability and closed-loop chemical management systems.

- South Korea and Taiwan: The core centers of ultra-high purity consumption, due to their concentration of 3D NAND and leading-edge logic chip production, requiring the highest specification EGAF available.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Purity Electronic Grade Ammonium Fluoride Market.- Merck KGaA (Versum Materials)

- Stella Chemifa Corporation

- Soulbrain Co., Ltd.

- Morita Chemical Industries Co., Ltd.

- Avantor Inc.

- Solvay S.A.

- Honjo Chemical Co., Ltd.

- Hangzhou Dayang Chemical Co., Ltd.

- Jiangyin Jianghua Microelectronics Materials Co., Ltd.

- Suzhou Crystal Clear Chemical Co., Ltd.

- FujiFilm Wako Pure Chemical Corporation

- Kanto Chemical Co., Inc.

- Chang Chun Group

- Iwatani Corporation

- Showa Denko K.K.

- BASF SE

- Central Glass Co., Ltd.

- JMC Co., Ltd.

- Dongjin Semichem Co., Ltd.

- Tokyo Ohka Kogyo Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the High Purity Electronic Grade Ammonium Fluoride market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is High Purity Electronic Grade Ammonium Fluoride (HP-EGAF) primarily used for?

HP-EGAF is primarily used as an ultra-clean etchant and component in Buffer Oxide Etchants (BOE) within the semiconductor manufacturing process. Its main function is the selective removal of silicon dioxide and silicon nitride layers during the fabrication of integrated circuits, memory chips, and high-resolution flat panel displays, where precise and defect-free etching is critical for device performance.

How does the purity level affect the market price and application?

Purity level is the dominant factor determining both price and application. Grades measured in Parts Per Trillion (PPT) command the highest price premium and are mandatory for advanced process nodes (e.g., 5nm and below) due to the necessity of minimizing metallic contaminants that cause catastrophic device failures. Lower purity grades (PPM) are used in less demanding applications like older display technologies or solar cells.

Which geographical region exhibits the highest demand for HP-EGAF?

The Asia Pacific (APAC) region, specifically countries hosting major semiconductor foundries such as Taiwan, South Korea, and Mainland China, accounts for the highest global consumption and fastest growth rate of HP-EGAF. This dominance is driven by high capital expenditure and concentration of advanced logic and memory chip manufacturing capacity.

What are the main alternatives or substitutes for Ammonium Fluoride in etching processes?

While complete substitution is difficult due to its unique chemical properties, alternatives include various fluorinated gases (like NF3 or CHF3) used in dry etching techniques, or specialized organic solvents used in cleaning. However, for wet chemical etching of silicon oxide, HP-EGAF and its derivative BOE solutions remain industry standards, especially for bulk removal and surface conditioning steps.

What key regulations impact the manufacturing and disposal of Electronic Grade Ammonium Fluoride?

Manufacturing is heavily regulated by quality standards such as SEMI specifications (ensuring chemical purity). Disposal is impacted by stringent environmental regulations concerning hazardous waste, particularly fluorine compounds. Manufacturers must invest significantly in specialized wastewater treatment facilities to neutralize and safely manage fluoride effluents before discharge, influencing operational costs and site selection.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager