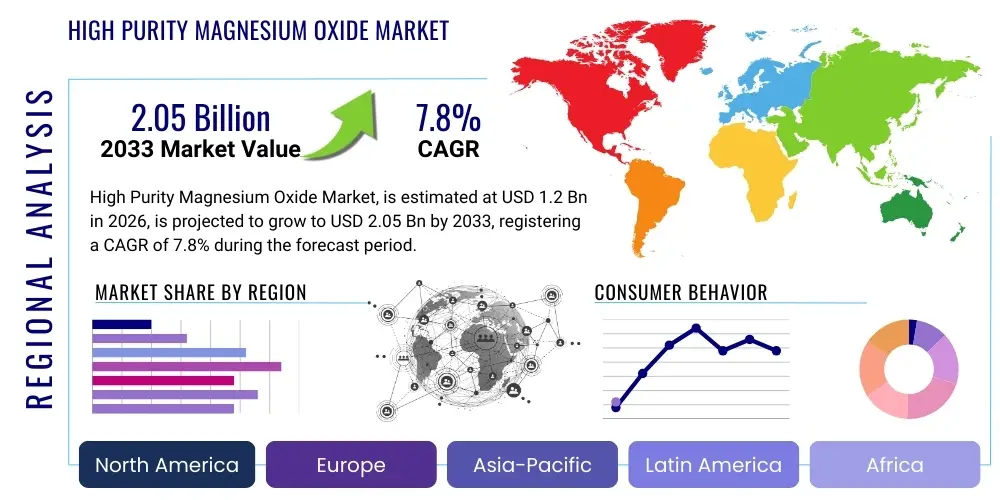

High Purity Magnesium Oxide Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435965 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

High Purity Magnesium Oxide Market Size

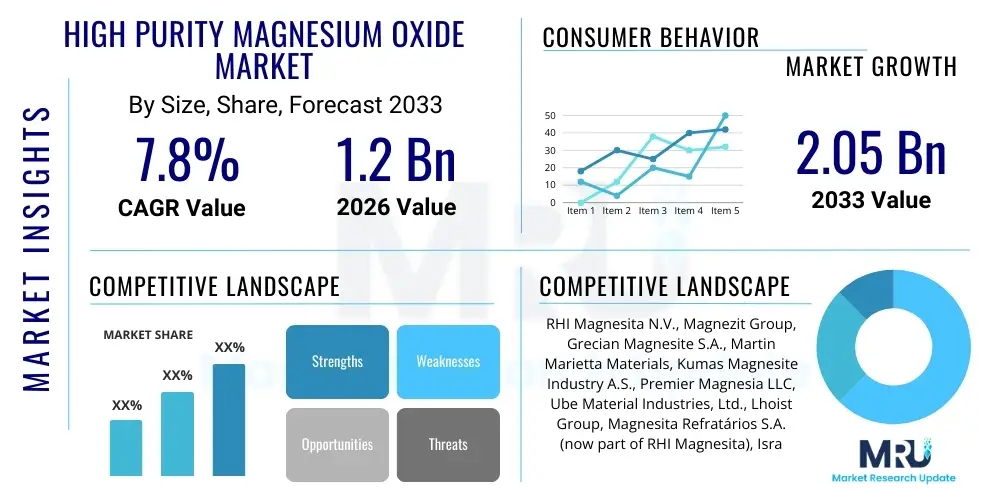

The High Purity Magnesium Oxide Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 2.05 Billion by the end of the forecast period in 2033.

High Purity Magnesium Oxide Market introduction

The High Purity Magnesium Oxide (HP MgO) Market encompasses specialized chemical products characterized by magnesia content exceeding 98.5%, often reaching 99.99% purity. HP MgO is a versatile compound known for its exceptional thermal stability, high melting point, high electrical resistivity, and chemical inertness, making it indispensable in demanding industrial applications. Key applications include specialty refractories, advanced ceramics, electronic components, rubber and plastic additives, and pharmaceutical excipients. The product’s superior properties allow it to outperform standard magnesia in areas requiring strict compositional control and performance under extreme conditions, driving demand from high-tech manufacturing sectors.

The primary benefits of utilizing High Purity Magnesium Oxide stem from its crystalline structure and resistance to chemical attack, crucial in applications such as crucibles for melting superalloys, or as a substrate in high-frequency electronic devices. Its role in environmental applications, particularly in flue gas desulfurization (FGD) and wastewater treatment, is also expanding due to its effectiveness as an alkaline agent. Market growth is fundamentally driven by the escalating global demand for advanced electronic materials, the rapid expansion of the semiconductor industry, and continuous infrastructure development requiring high-performance refractory linings in steel and cement industries.

Driving factors for this market include stringent quality requirements across end-user industries, necessitating materials with minimal impurities; technological advancements in material science leading to new uses for HP MgO ceramics; and the global shift towards high-value manufacturing. Furthermore, the increasing adoption of magnesium oxide nanopowders in medical and coating applications contributes significantly to market expansion. However, the market faces challenges related to the high energy intensity of calcination processes and volatility in raw material (magnesite) sourcing and pricing, which necessitate continuous optimization of processing technologies to maintain competitive costs and supply chain stability.

High Purity Magnesium Oxide Market Executive Summary

The High Purity Magnesium Oxide Market is characterized by robust growth, primarily fueled by rapid technological integration in the electronics and specialty ceramics sectors. Business trends indicate a strong focus on vertical integration among key producers, aiming to secure raw material supply and optimize purity levels through advanced processing techniques like seawater synthesis and controlled high-temperature decomposition. Strategic partnerships between raw material suppliers and end-product manufacturers are becoming common to meet the increasingly stringent specifications required by semiconductor and aerospace industries. Investment in sustainable production methods, including energy-efficient calcination, is a critical differentiating factor, addressing growing regulatory pressures and corporate sustainability mandates.

Segment trends reveal that the 99.5% purity grade segment dominates the market volume due to its optimal balance of performance and cost-effectiveness in refractory and structural ceramic applications. However, the Ultra-High Purity (>99.9%) segment is registering the fastest CAGR, driven by its essential use in advanced electronic insulation, piezoelectric components, and specialized optical materials. Application-wise, the ceramics and refractory segment holds the largest share, while the chemical intermediates and flame retardants application shows significant, consistent growth, reflecting increasing safety standards in construction and consumer goods.

Regionally, the Asia Pacific (APAC) stands out as the primary engine of market expansion, primarily due to the concentration of electronic manufacturing hubs (China, South Korea, Taiwan) and massive infrastructure projects driving demand for specialty refractories. North America and Europe demonstrate mature market characteristics, focusing primarily on high-value, niche applications such as aerospace components and medical materials, characterized by higher pricing and lower volume. Strategic market players are increasingly prioritizing expansion in developing APAC markets while focusing R&D efforts in established Western regions to capture future high-tech market opportunities and optimize global supply chains for HP MgO products.

AI Impact Analysis on High Purity Magnesium Oxide Market

User queries regarding AI in the HP MgO market frequently center on optimizing material synthesis, enhancing quality control for ultra-high purity grades, and predictive maintenance within energy-intensive calcination plants. Common themes include the application of machine learning (ML) in predicting yield based on magnesite ore characteristics, the use of computer vision for defect detection in ceramic fabrication, and the role of AI-driven supply chain management in mitigating geopolitical raw material risks. Stakeholders are keen to understand how AI can reduce the environmental footprint of production and accelerate the discovery of novel magnesium oxide composite materials. The overriding expectation is that AI will be the primary lever for achieving the next level of purity and operational efficiency, crucial for meeting the demands of sensitive end-use industries like semiconductors and advanced optics.

The integration of Artificial Intelligence and Machine Learning (ML) is fundamentally transforming the high-purity mineral processing industry, particularly affecting the yield and quality consistency of Magnesium Oxide production. AI models are deployed to analyze vast datasets generated during the synthesis phase, encompassing variables like furnace temperature gradients, reaction kinetics, particle size distribution, and impurity trace levels. By employing predictive algorithms, manufacturers can preemptively adjust processing parameters, minimizing batch variations and ensuring that the final HP MgO product consistently meets the stringent specifications, especially the >99.9% purity thresholds required for electronic applications. This optimization directly translates into reduced waste and significant energy consumption savings, tackling two major operational cost centers.

Furthermore, AI is significantly influencing the research and development (R&D) lifecycle for high-purity ceramics. Generative AI tools and ML-driven material informatics platforms are accelerating the simulation and discovery of novel HP MgO derived composites with tailored thermal or electrical properties. This acceleration is critical for industries like aerospace and 5G infrastructure, where material innovation is essential for next-generation performance. AI is also enhancing the automation of Quality Assurance (QA) through advanced sensor networks and image recognition systems that provide real-time contamination detection, moving beyond traditional laboratory sampling methods to continuous, high-precision monitoring of material purity throughout the refining process.

- AI-driven optimization of calcination furnace energy efficiency and throughput.

- Machine Learning models predicting final product purity based on initial raw material composition.

- Enhanced quality assurance through AI-powered vision systems for real-time defect and contamination detection.

- Predictive maintenance schedules for high-capital processing equipment, minimizing unplanned downtime.

- Accelerated R&D of novel HP MgO ceramic composites using material informatics and generative AI.

- Optimization of complex, global supply chains to mitigate risks associated with magnesite sourcing.

- Reduction in process waste and environmental impact through precise chemical reagent dosing control.

DRO & Impact Forces Of High Purity Magnesium Oxide Market

The High Purity Magnesium Oxide market dynamics are governed by a complex interplay of rapid technological demand (Driver), high production energy requirements (Restraint), and the emergence of new applications in sustainable technologies (Opportunity). The fundamental Impact Forces center around buyer bargaining power due to highly specific technical requirements, and the competitive rivalry driven by the need for advanced proprietary purification technologies. The market equilibrium is constantly challenged by the shift towards ultra-high purity grades, which significantly increases barriers to entry for new competitors who lack the necessary advanced processing infrastructure and expertise to reliably deliver consistency at the atomic level.

Drivers: Growing demand from the electronics and semiconductor industry for insulating materials and sputtering targets; increasing adoption of advanced ceramics in aerospace and automotive sectors due to superior thermal and mechanical properties; expansion of environmental remediation applications, particularly in flue gas treatment and heavy metal sequestration; and the intrinsic material advantages over competing oxides in high-temperature environments. Restraints: The high capital expenditure required for setting up high-purity production facilities; the extremely energy-intensive nature of the calcination and purification processes contributing to high operational costs; volatility and geopolitical concentration of natural magnesite raw material sources; and the challenging technical hurdles associated with consistently achieving ultra-high purity levels (>99.99%) at commercial scale.

Opportunities: Significant potential lies in developing HP MgO nanopowders for specialized battery components (e.g., solid-state electrolytes), advanced drug delivery systems, and enhanced UV-blocking coatings. Furthermore, the push towards developing cost-effective, environmentally friendly synthesis routes, such as optimizing seawater-based precipitation methods, presents a major strategic advantage. The continuous expansion of 5G infrastructure and data centers creates sustained, robust demand for HP MgO in passive electronic components and thermal management solutions, offering opportunities for specialized product differentiation and premium pricing strategies across the forecast period.

Segmentation Analysis

The High Purity Magnesium Oxide market is comprehensively segmented based on its origin (Source), the achieved purity level, and the specific application areas that leverage its unique properties. Understanding these segmentations is critical for market participants to tailor their product offerings, align production capabilities, and focus strategic investments on high-growth, high-margin niches, particularly those driven by stringent regulatory environments and technological convergence. Segmentation analysis reveals significant differences in pricing power and competitive intensity across the purity grades, with the ultra-high purity segment commanding substantial premiums due to the complexity of manufacturing and verification.

Segmentation by Source distinguishes between Natural Magnesite, where purity is achieved through intensive beneficiation and purification of mined ore, and Synthetic MgO, often derived from brine solutions or seawater. While natural sources offer volume, synthetic processes generally provide superior purity consistency essential for electronics. Purity grade segmentation is the most critical determinant of value, ranging from 98.5% (used in high-end refractories) up to 99.99% and above (crucial for optical and semiconductor applications). The application segmentation demonstrates the breadth of HP MgO utility, covering large industrial volume users like refractories and specialty chemical synthesis, alongside highly sensitive, low-volume consumers such as pharmaceuticals and advanced magnetic materials.

- By Source:

- Natural (Magnesite-derived)

- Synthetic (Brine, Seawater, Chemical routes)

- By Purity Grade:

- 98.5% – 99.0%

- 99.1% – 99.5% (Standard High Purity)

- 99.6% – 99.9% (Premium High Purity)

- >99.9% (Ultra-High Purity/Electronic Grade)

- By Application:

- Refractories and Construction

- Ceramics and Electronic Components (Substrates, Insulators)

- Chemical Intermediates and Synthesis (Pharmaceuticals, Catalysts)

- Rubber, Plastic, and Polymer Additives (Flame Retardants)

- Environmental Applications (Water Treatment, Flue Gas Desulfurization)

- Others (Cosmetics, Fertilizers, Advanced Magnetic Materials)

Value Chain Analysis For High Purity Magnesium Oxide Market

The value chain for High Purity Magnesium Oxide is intensive, starting with upstream raw material extraction and proceeding through highly technical purification and customization stages before reaching sophisticated downstream end-users. Upstream analysis focuses on the sourcing of high-quality raw magnesite ore or the reliable provision of brine/seawater feedstocks. Efficiency at this stage—including initial sorting, crushing, and flotation—significantly dictates the purification complexity and cost later in the chain. Geopolitical factors heavily influence the upstream segment, as primary magnesite reserves are geographically concentrated, creating potential supply bottlenecks and necessitating strong long-term sourcing agreements.

The midstream processing phase involves energy-intensive steps such as calcination, dead-burning, precipitation, and subsequent chemical or physical purification techniques (e.g., acid leaching, vacuum sintering) to achieve high purity grades. Key players differentiate themselves here through proprietary technological know-how that minimizes impurities like calcium, silicon, and iron oxides. Distribution channels for HP MgO are bifurcated: high-volume, lower-purity grades often utilize indirect distribution through specialized chemical distributors catering to refractory and bulk industrial customers. Conversely, ultra-high purity grades destined for electronics or pharmaceuticals frequently employ direct distribution models, characterized by complex technical agreements and strict Quality Control documentation, ensuring material integrity and traceability up to the point of use.

The downstream analysis focuses on the integration of HP MgO into final products. Direct sales dominate when serving major clients in electronics (e.g., ceramic capacitor manufacturers) and aerospace, where customized particle size and surface area specifications are critical. Indirect channels serve smaller or geographically dispersed end-users, relying on distributors with specialized handling capabilities. The profitability margins increase significantly as the product moves downstream into niche applications (electronic ceramics) compared to bulk industrial uses, reflecting the high value added during the purification and stringent quality verification processes conducted by the primary HP MgO producers.

High Purity Magnesium Oxide Market Potential Customers

The primary customers for High Purity Magnesium Oxide are large, global manufacturing conglomerates requiring materials with exceptional thermal, electrical, or chemical performance characteristics that standard grade materials cannot meet. End-users span the structural materials industry, the chemical synthesis sector, and increasingly, the advanced technology fabrication space. Key structural buyers include steel manufacturers (utilizing specialty HP MgO refractories for critical linings), cement producers, and foundries that require robust insulation for extreme temperature operations.

In the high-tech sphere, the most valuable potential customers are semiconductor manufacturers and producers of passive electronic components (capacitors, varistors, insulators) who rely on HP MgO for its superior dielectric properties and thermal dissipation capabilities. These customers mandate ultra-high purity grades (>99.9%) to prevent device failure and ensure consistency in miniaturized electronic circuits. Pharmaceutical and specialty chemical companies also represent a significant customer base, using HP MgO as a key chemical intermediate, antacid, or buffering agent, requiring strict compliance with pharmacopeia standards and ISO certifications for minimal heavy metal contamination.

Furthermore, emerging buyers include companies focused on developing next-generation energy storage solutions, such as solid-state battery component developers, where the purity and morphology of magnesium oxide nanopowders are critical for enhancing ionic conductivity and overall battery safety. Automotive manufacturers, particularly those in the electric vehicle (EV) sector, are increasing demand for HP MgO used in thermal management systems and high-performance structural ceramics, driven by the need for lightweight, heat-resistant components.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 2.05 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | RHI Magnesita N.V., Magnezit Group, Grecian Magnesite S.A., Martin Marietta Materials, Kumas Magnesite Industry A.S., Premier Magnesia LLC, Ube Material Industries, Ltd., Lhoist Group, Magnesita Refratários S.A. (now part of RHI Magnesita), Israel Chemicals Ltd. (ICL), Konoshima Chemical Co., Ltd., Baymag Inc., Imerys S.A., Kyowa Chemical Industry Co., Ltd., Hebei Meishen Technology Co., Ltd., Liaoning Xinghai Chemical Co., Ltd., JFE Mineral Company, Nagasawa Chemical Co., Ltd., Qinghai Salt Lake Industry Co., Ltd., Haicheng Huayu Magnesium Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Purity Magnesium Oxide Market Key Technology Landscape

The technological landscape of the High Purity Magnesium Oxide market is primarily defined by advancements in synthesis methods, thermal processing, and post-production refinement necessary to consistently achieve ultra-low trace impurity levels. Key technologies revolve around controlled precipitation from seawater or brine solutions (Synthetic Route), offering superior control over particle morphology and purity compared to natural ore processing. This synthetic route often employs advanced techniques such as controlled crystallization kinetics and hydrothermal processing to produce high-reactivity MgO suitable for chemical and pharmaceutical applications. Furthermore, the development of sophisticated de-metallization processes, utilizing selective leaching agents or specialized solvent extraction, is crucial for eliminating undesirable metal ions that could compromise the material's performance in electronic substrates.

In thermal processing, the shift from conventional rotary kilns to more energy-efficient shaft kilns and specialized plasma furnaces is critical, particularly for the dead-burning process required to create dense, thermally stable refractory grades. Innovations in sintering additives and ultra-high-temperature handling equipment allow manufacturers to achieve specific crystal structures and density profiles essential for advanced ceramic applications. The utilization of microwave heating and plasma technology offers paths toward significantly lower energy consumption and faster processing times, directly addressing one of the primary restraints in the HP MgO value chain—the high operational energy cost.

Another area of intense technological focus is nanoparticle synthesis. Technologies such as high-energy ball milling, sol-gel methods, and flame spray pyrolysis are utilized to produce highly uniform MgO nanopowders. These materials exhibit enhanced surface area and unique quantum size effects, making them ideal for integration into advanced functional materials, including specialized catalysts, high-performance polymer matrices, and biomedical applications. The market is increasingly seeing the adoption of continuous monitoring systems and sensor technology, integrating with AI platforms, to maintain real-time process control and guarantee batch-to-batch consistency, solidifying technological superiority over competitors relying on older, batch-based processing methods.

Regional Highlights

The geographical distribution of the High Purity Magnesium Oxide market reflects global industrial capacity, raw material availability, and demand from high-tech manufacturing sectors.

- Asia Pacific (APAC): Dominates the global market share and growth trajectory. This is driven by massive industrial infrastructure expansion, the concentration of the world’s leading electronics and semiconductor fabrication facilities (e.g., in China, South Korea, Japan, Taiwan), and the significant production capacity in magnesite mining and processing, particularly in China.

- North America: Represents a mature market characterized by demand for ultra-high purity grades focused on niche, high-value applications, including aerospace, advanced materials research, specialized medical devices, and high-performance defense systems. Innovation in synthetic MgO production techniques is prominent here, focusing on proprietary chemical routes.

- Europe: A key consumer in the specialty refractories and automotive catalyst sectors. Strict environmental regulations drive demand for HP MgO in pollution control (FGD). The region is a hub for R&D in ceramic materials and high-temperature insulation, maintaining a strong market share in high-specification industrial applications.

- Latin America (LATAM): Growth is tied heavily to infrastructure projects and the commodity sector (steel and cement production), creating steady, albeit lower-purity, HP MgO demand. Local production capacity often focuses on serving regional industrial requirements.

- Middle East and Africa (MEA): Emerging market characterized by significant investments in petrochemicals, infrastructure, and mining. HP MgO demand is rising, particularly for use in construction materials and specialized chemical intermediate production, though supply is largely dependent on imports or localized synthetic production from seawater/brine sources.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Purity Magnesium Oxide Market.- RHI Magnesita N.V.

- Magnezit Group

- Grecian Magnesite S.A.

- Martin Marietta Materials

- Kumas Magnesite Industry A.S.

- Premier Magnesia LLC

- Ube Material Industries, Ltd.

- Lhoist Group

- Magnesita Refratários S.A. (now part of RHI Magnesita)

- Israel Chemicals Ltd. (ICL)

- Konoshima Chemical Co., Ltd.

- Baymag Inc.

- Imerys S.A.

- Kyowa Chemical Industry Co., Ltd.

- Hebei Meishen Technology Co., Ltd.

- Liaoning Xinghai Chemical Co., Ltd.

- JFE Mineral Company

- Nagasawa Chemical Co., Ltd.

- Qinghai Salt Lake Industry Co., Ltd.

- Haicheng Huayu Magnesium Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the High Purity Magnesium Oxide market and generate a concise list of summarized FAQs reflecting key topics and concerns.What distinguishes High Purity Magnesium Oxide (HP MgO) from standard grade MgO?

HP MgO is defined by a minimum purity level, typically exceeding 98.5% and often reaching 99.99%. This high purity minimizes trace element contamination (such as CaO, Fe₂O₃, and SiO₂) which could compromise electrical or thermal performance. Standard grades are suitable for basic industrial use, while HP MgO is essential for advanced applications like electronic ceramics, optical components, and specialty refractory linings where minute impurities are detrimental to product performance and lifespan.

Which application segment drives the highest demand for Ultra-High Purity (UHP) MgO?

The Electronic Components and Advanced Ceramics segment drives the highest demand for Ultra-High Purity (>99.9%) MgO. UHP MgO is critical for manufacturing substrates, insulators, and thermal management materials used in semiconductors, multilayer ceramic capacitors (MLCCs), and aerospace components, where consistent dielectric strength and thermal shock resistance are non-negotiable requirements for highly sensitive, miniaturized devices.

How does the sourcing method impact the final quality and market price of HP MgO?

HP MgO sourced from synthetic routes (seawater or brine) generally offers superior purity consistency, finer particle size control, and higher reactivity compared to natural magnesite-derived materials, commanding a premium price. While natural sources offer bulk volume at lower cost, achieving ultra-high purity from ore requires intensive, expensive purification processes, which often makes synthetic methods the preferred choice for electronic and pharmaceutical grade materials.

What role do technological advancements play in mitigating the high production cost of HP MgO?

Technological advancements, particularly the integration of Artificial Intelligence for process optimization and the implementation of advanced energy-efficient thermal processing (like plasma or shaft kilns), are crucial for mitigating high production costs. These technologies reduce the energy footprint of calcination and minimize batch variability, leading to higher yields of specification-compliant material and decreasing overall operational expenditures per ton.

What are the primary geopolitical risks affecting the High Purity Magnesium Oxide supply chain?

The primary geopolitical risk stems from the heavy concentration of high-quality natural magnesite reserves and processing capacity, particularly in specific regions of Asia Pacific. Trade tariffs, export restrictions, and regional instability can lead to significant supply chain disruptions and price volatility for raw materials, compelling downstream manufacturers to focus on securing diversified synthetic supply routes or regional stockpiling strategies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager