High Purity Quartz Sand Sales Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439745 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

High Purity Quartz Sand Sales Market Size

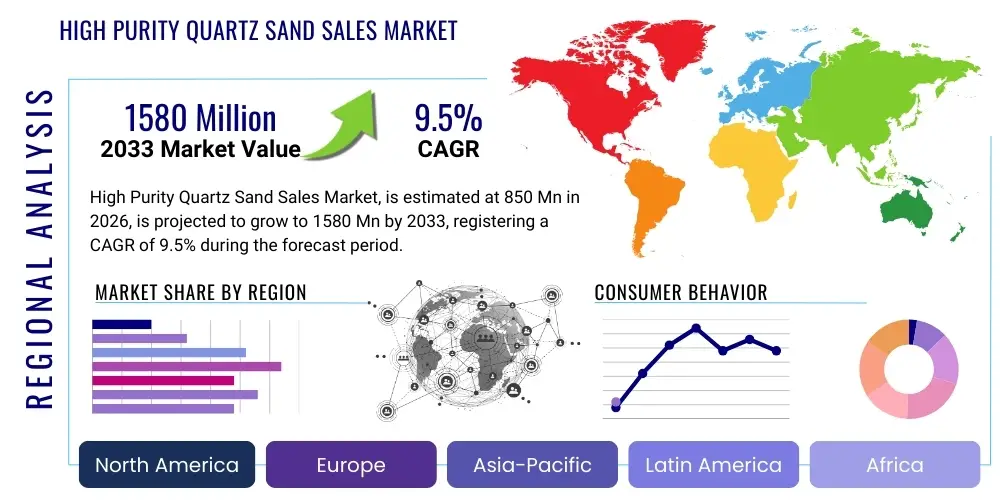

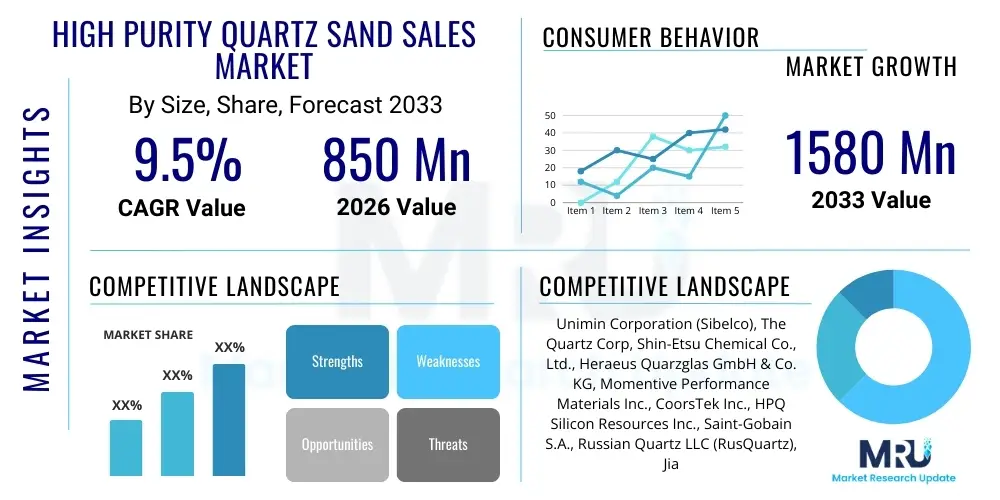

The High Purity Quartz Sand Sales Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1580 Million by the end of the forecast period in 2033.

High Purity Quartz Sand Sales Market introduction

The High Purity Quartz Sand Sales Market encompasses the global trade and consumption of quartz sand characterized by an exceptionally low concentration of impurities, typically exceeding 99.995% SiO2. This specialized material is indispensable in a multitude of advanced technological applications where even trace contaminants can severely impede performance and reliability. Its unique physical and chemical properties, including remarkable thermal stability, high chemical inertness, excellent electrical insulation, and superior optical transparency, make it a critical raw material for industries at the forefront of innovation. The production of high purity quartz sand involves rigorous beneficiation and purification processes to meet the stringent specifications demanded by its end-users, distinguishing it significantly from ordinary industrial quartz sands.

The primary applications of high purity quartz sand span across highly technical sectors, notably in the manufacturing of semiconductors, solar photovoltaic cells, advanced lighting solutions, and sophisticated optical components. In semiconductor fabrication, it forms the foundational material for crucibles, tubes, and other critical process equipment, directly influencing the quality and yield of microchips. For solar PV, it is essential for producing quartz glass components that encapsulate and protect solar cells, ensuring efficiency and longevity. The benefits of using high purity quartz sand are manifold, ranging from enabling the development of smaller, more powerful electronic devices to enhancing the durability and performance of renewable energy technologies. Its role in these industries underscores its strategic importance to global technological progress and economic development.

Driving factors for the sustained growth of this market include the relentless expansion of the global semiconductor industry, fueled by increasing demand for artificial intelligence, 5G technology, and high-performance computing. Furthermore, the accelerating adoption of solar energy worldwide, driven by environmental concerns and decreasing costs, continues to boost demand for high-quality quartz components. Technological advancements in purification techniques are also enabling the production of even higher grades of quartz sand, opening doors to new, more demanding applications and extending its utility. The critical role of this material in enabling next-generation technologies positions the High Purity Quartz Sand Sales Market as a vital and dynamic sector within the broader materials industry.

High Purity Quartz Sand Sales Market Executive Summary

The High Purity Quartz Sand Sales Market is experiencing robust growth, primarily propelled by burgeoning demand from the semiconductor and solar photovoltaic industries, which represent its core application segments. Business trends indicate a strong focus on vertical integration among key players to secure raw material supplies and optimize complex purification processes, alongside significant investments in research and development to achieve even higher purity levels. Strategic partnerships and mergers and acquisitions are also prevalent, aimed at expanding market reach, enhancing technological capabilities, and consolidating competitive positions. The market is characterized by a relatively concentrated supply base due to the scarcity of economically viable ultra-high purity quartz deposits and the capital-intensive nature of processing. Sustainability initiatives are increasingly influencing business operations, with companies exploring more environmentally friendly extraction and purification methods to meet evolving regulatory landscapes and consumer preferences.

Regionally, the Asia Pacific (APAC) continues to dominate the market, driven by the presence of major semiconductor manufacturing hubs in countries like China, Taiwan, South Korea, and Japan, as well as significant investments in solar energy projects across the region. North America and Europe also demonstrate substantial demand, particularly from advanced technology sectors requiring specialized quartz products, supported by strong research infrastructure and innovation ecosystems. Latin America and the Middle East & Africa (MEA) are emerging markets, showing potential for growth as industrialization and renewable energy adoption gain momentum, though currently representing smaller market shares. These regions are increasingly becoming targets for market expansion, with growing local manufacturing capabilities and infrastructure development contributing to future demand for high-purity materials.

In terms of segment trends, the semiconductor grade high purity quartz sand segment is anticipated to exhibit the fastest growth, primarily due to the ongoing miniaturization and increasing complexity of integrated circuits, which demand materials with almost zero defects and impurities. The solar photovoltaic segment also maintains a significant market share, driven by global renewable energy targets and continuous innovation in solar cell efficiency. Within the lighting segment, demand is stable for specialized lamps, while the optical and other specialty glass segments are growing steadily, benefiting from advancements in fiber optics, medical devices, and aerospace applications. The relentless pursuit of technological superiority across these sectors ensures a steady and increasing demand for the highest grades of quartz sand, pushing the boundaries of material science and manufacturing precision.

AI Impact Analysis on High Purity Quartz Sand Sales Market

User inquiries regarding AI's influence on the High Purity Quartz Sand Sales Market frequently revolve around how artificial intelligence and machine learning technologies will reshape demand for high-purity materials, optimize production processes, and potentially lead to the discovery of new applications or improvements in material quality. A significant concern among users is the direct correlation between AI advancements and the escalating requirements for high-performance semiconductor components, which are intrinsically reliant on ultra-high purity quartz sand. Users are keen to understand if AI can make the extraction and purification processes more efficient, thereby reducing costs or expanding the availability of this critical resource. There is also considerable interest in how AI could be leveraged for predictive analytics in supply chain management, ensuring stability and reducing lead times in a market often susceptible to geopolitical and logistical disruptions. Furthermore, the role of AI in quality control and defect detection within manufacturing processes for quartz-based products is a recurrent theme, as perfect material integrity is paramount for advanced electronic applications.

The overarching expectation is that AI will act as both a demand accelerator and an operational enhancer within the high purity quartz sand market. By fueling the development of more sophisticated AI chips and data centers, AI inherently drives the need for greater volumes and even higher grades of quartz sand. Simultaneously, AI tools offer transformative potential for optimizing every stage of the quartz sand value chain, from geological exploration and raw material sourcing to advanced purification and final product quality assurance. The adoption of AI-driven simulation and material design platforms could also potentially lead to the identification of novel processing techniques or the development of next-generation quartz-based materials with enhanced properties, thereby expanding the market's horizons beyond current applications. This dual impact positions AI as a pivotal force in the market's evolution, demanding strategic adaptation from all stakeholders.

- AI drives increased demand for high-performance semiconductors, directly boosting the need for ultra-high purity quartz sand in chip manufacturing.

- Predictive maintenance and process optimization in quartz mining and purification leverage AI to improve efficiency and reduce operational costs.

- AI-powered quality control systems enhance impurity detection and material sorting, ensuring consistent ultra-high purity levels.

- Supply chain management benefits from AI-driven forecasting and logistics optimization, improving resilience and reducing lead times for high purity quartz sand.

- Material discovery and innovation, supported by AI algorithms, could identify new sources or develop advanced purification techniques for quartz.

- Automation and robotics integrated with AI in processing plants lead to higher throughput and reduced human error in handling sensitive materials.

- AI's role in developing quantum computing and advanced display technologies creates new, ultra-demanding applications for high purity quartz sand.

DRO & Impact Forces Of High Purity Quartz Sand Sales Market

The High Purity Quartz Sand Sales Market is significantly influenced by a confluence of drivers, restraints, and opportunities, alongside various impact forces that shape its dynamics. Key drivers include the exponential growth of the semiconductor industry, propelled by global digitalization, the proliferation of 5G networks, and the rapid advancements in artificial intelligence and machine learning, all of which require increasingly pure quartz components for advanced chip fabrication. Simultaneously, the accelerating transition to renewable energy sources worldwide continues to bolster demand from the solar photovoltaic sector, where high purity quartz is essential for solar cell encapsulation and furnace components. Further impetus comes from the ongoing innovations in display technologies, optical fibers, and specialized lighting, which also rely heavily on the unique properties of high purity quartz. These macroscopic trends collectively create a robust and sustained demand environment for this critical material, underpinning market expansion.

However, the market also faces considerable restraints. The most prominent challenges involve the inherently high costs associated with the extraction, beneficiation, and meticulous purification processes required to achieve ultra-high purity levels, which can make the end product expensive. The scarcity of economically viable natural deposits of ultra-high purity quartz is another significant constraint, limiting the number of potential suppliers and leading to supply concentration risks. Furthermore, stringent environmental regulations pertaining to mining, waste management, and energy consumption during processing pose operational challenges and can increase compliance costs. Geopolitical instabilities and global supply chain vulnerabilities, as evidenced by recent disruptions, also present risks to the consistent supply and pricing of high purity quartz sand, impacting overall market stability and customer planning.

Despite these challenges, substantial opportunities exist for market growth and innovation. The emergence of new, high-value applications in nascent fields such as quantum computing, advanced biomedical devices, and specialized aerospace components presents avenues for market diversification and premium product development. Ongoing research into more efficient and sustainable purification technologies, including novel chemical and physical separation methods, could help mitigate production costs and environmental impacts. Moreover, initiatives focused on recycling quartz components from end-of-life electronics and solar panels could open up new supply streams and enhance resource sustainability. The strategic importance of high purity quartz in enabling future technological breakthroughs ensures continued investment in overcoming current limitations, fostering a dynamic environment for innovation and market expansion in the long term, pushing the boundaries of material science and application.

Segmentation Analysis

The High Purity Quartz Sand Sales Market is meticulously segmented to provide a granular understanding of its diverse applications, varying purity requirements, and end-user industries. This segmentation is crucial for market participants to identify niche opportunities, tailor product offerings, and develop targeted marketing strategies. The primary segmentation criteria typically include the purity level of the quartz sand, its specific application in various industries, and the end-use industry that procures the material. Each segment exhibits unique growth drivers, competitive landscapes, and price sensitivities, reflecting the specialized nature of high purity quartz sand and its critical role in advanced manufacturing processes. Analyzing these segments helps stakeholders understand the intricate demand patterns and technological requirements across the market value chain, enabling more informed decision-making and strategic resource allocation.

- By Purity:

- 99.995% SiO2

- 99.997% SiO2

- 99.998% SiO2

- 99.999% SiO2

- 99.9995% SiO2 (and higher, e.g., 6N, 7N)

- By Application:

- Semiconductor Devices (Crucibles, Tubes, Wafers, Etching Equipment)

- Solar Photovoltaics (Quartz Glass, Ingots, Cells)

- Lighting (Halogen Lamps, UV Lamps, High-Intensity Discharge Lamps)

- Optical Fibers and Components (Telecom, Medical Endoscopy)

- Specialty Glass (Laboratory Glassware, Precision Optics)

- Others (Medical, Aerospace, Advanced Ceramics, Thin Films)

- By End-Use Industry:

- Electronics (Semiconductors, Displays, Printed Circuit Boards)

- Solar Energy

- Lighting & Illumination

- Telecommunications

- Medical & Healthcare

- Aerospace & Defense

- Chemical & Petrochemical

- Research & Development

Value Chain Analysis For High Purity Quartz Sand Sales Market

The value chain for the High Purity Quartz Sand Sales Market is intricate and capital-intensive, starting from the exploration and extraction of raw materials through highly specialized processing steps to reach the end-users. Upstream analysis begins with the identification and mining of quartz deposits that inherently possess a low impurity profile, typically from specific geological formations. This initial stage involves geological surveys, mineral resource assessment, and extraction techniques designed to minimize contamination. Following extraction, the raw quartz undergoes preliminary beneficiation, which includes crushing, grinding, washing, and gravity separation to remove larger impurities and prepare the material for more advanced purification. This foundational step is critical in ensuring the subsequent high-purity processing is economically viable and effective in removing trace elements that are detrimental to advanced applications.

Further downstream, the beneficiated quartz is subjected to highly sophisticated purification processes. These can involve acid leaching, flotation, magnetic separation, high-temperature treatments, and various chemical purification methods, all aimed at reducing impurities to parts per million (ppm) or even parts per billion (ppb) levels. This stage represents a significant value-add, transforming common quartz into a high-value strategic material. Once purified to the required specifications, the high purity quartz sand may undergo further processing, such as fine grinding and particle size classification, to meet specific customer requirements for applications like semiconductor crucibles or solar cell components. The stringent quality control measures at every stage are paramount, as even minute impurities can compromise the performance of advanced electronic and optical devices, underscoring the technical complexity of this market's value chain.

The distribution channel for high purity quartz sand is often characterized by a blend of direct and indirect sales. Given the specialized nature and high value of the product, many major producers engage in direct sales to large-scale, critical end-users in the semiconductor and solar industries, fostering strong technical partnerships and long-term supply agreements. This direct model allows for customized product specifications, technical support, and close collaboration on R&D. Indirect channels typically involve specialized distributors and agents who possess deep market knowledge and logistics capabilities, serving smaller clients or those with less complex requirements across diverse geographical regions. These distributors play a crucial role in market penetration and providing local support. Both direct and indirect models emphasize efficient logistics, secure packaging to prevent contamination, and robust customer service, reflecting the product's high sensitivity and strategic importance to its global customer base.

High Purity Quartz Sand Sales Market Potential Customers

The potential customers for High Purity Quartz Sand are predominantly concentrated within highly technical and advanced manufacturing industries that demand materials with exceptional purity, thermal stability, and optical properties. The largest segment of end-users comprises semiconductor manufacturers, who utilize high purity quartz for a myriad of critical components in chip fabrication, including crucibles for silicon ingot growth, process tubes for diffusion and oxidation, and various carriers and furnace elements. These manufacturers require quartz with impurity levels often in the parts per billion range, as even trace contaminants can lead to defects in integrated circuits, severely impacting performance and yield. As the semiconductor industry continues to push the boundaries of miniaturization and processing power, the demand for increasingly pure quartz sand from these customers remains insatiable and strategically vital for global technological advancement.

Another significant group of potential customers includes companies in the solar photovoltaic (PV) industry. These manufacturers employ high purity quartz for the production of quartz glass components that are essential for solar cell encapsulation, furnace liners, and other critical process equipment used in the manufacturing of silicon ingots and wafers for solar panels. The integrity and optical properties of quartz directly affect the efficiency and longevity of solar cells, making high purity a non-negotiable requirement. With the global push towards renewable energy, investments in solar power generation continue to expand, driving consistent and growing demand for high purity quartz sand from this sector. The need for materials that can withstand high temperatures and harsh chemical environments without degradation further solidifies the solar industry's position as a core customer segment for this specialized material.

Beyond semiconductors and solar, other crucial potential customers include manufacturers of specialty lighting (such as halogen, UV, and high-intensity discharge lamps), where quartz glass is essential for its thermal shock resistance and UV transparency. The optical industry also represents a key customer segment, utilizing high purity quartz for fiber optics, lenses, prisms, and other precision optical components that demand superior transmission characteristics and minimal absorption. Furthermore, advanced material science companies developing laboratory glassware, medical devices, and components for aerospace and defense applications also form a segment of potential customers, each requiring specific grades of high purity quartz tailored to their unique performance criteria. The diversity and criticality of these applications underscore the broad and indispensable role that high purity quartz sand plays across multiple high-tech industrial ecosystems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1580 Million |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Unimin Corporation (Sibelco), The Quartz Corp, Shin-Etsu Chemical Co., Ltd., Heraeus Quarzglas GmbH & Co. KG, Momentive Performance Materials Inc., CoorsTek Inc., HPQ Silicon Resources Inc., Saint-Gobain S.A., Russian Quartz LLC (RusQuartz), Jiangsu Pacific Quartz Co., Ltd., Donghai Colourful Quartz Products Co., Ltd., Kyshtym Mining, Washington Mills, High Purity Materials (HPM), Minerali Industriali S.p.A., Nordic Mining ASA, Quarzwerke GmbH, US Silica Holdings Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Purity Quartz Sand Sales Market Key Technology Landscape

The technological landscape of the High Purity Quartz Sand Sales Market is characterized by continuous innovation aimed at enhancing purity, optimizing production efficiency, and ensuring sustainable sourcing. Core to this landscape are advanced beneficiation and purification techniques that are meticulously developed to remove even trace amounts of impurities such as iron, aluminum, titanium, and alkalis, which can severely compromise the performance of end-products in critical applications. These techniques often involve a multi-stage approach, combining physical methods like magnetic separation, flotation, and gravity concentration with sophisticated chemical treatments such as acid leaching, which employs strong acids to dissolve mineral impurities from the quartz surface. The precision required for these processes is immense, necessitating specialized equipment and highly controlled environments to prevent re-contamination and achieve the desired ultra-high purity levels, pushing the boundaries of material science and chemical engineering.

Beyond fundamental purification, significant technological advancements are also evident in particle size reduction and classification, critical for tailoring the quartz sand to specific application requirements. Technologies such as jet milling, ball milling, and air classification are employed to achieve precise particle size distributions, which directly impact the flowability, packing density, and reactivity of the quartz sand in subsequent manufacturing steps for semiconductors or optics. Furthermore, the development of advanced analytical instrumentation, including ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and XRF (X-ray Fluorescence), is paramount for rigorous quality control throughout the production process. These technologies enable rapid and accurate detection of impurities at parts per billion (ppb) levels, ensuring that the final product consistently meets the stringent specifications of demanding end-users and maintains product integrity from raw material to delivery.

The emerging technological trends also include the integration of automation and artificial intelligence (AI) into processing plants. AI and machine learning algorithms are increasingly being deployed for process optimization, predictive maintenance of complex machinery, and real-time quality monitoring, leading to improved operational efficiency, reduced waste, and enhanced product consistency. Additionally, research into sustainable mining practices and circular economy initiatives, such as the recycling of quartz from electronic waste, is gaining traction, driven by environmental concerns and resource scarcity. Innovations in synthetic quartz production, while currently more costly, represent a long-term technological frontier that could offer an alternative supply source for ultra-high purity material. These ongoing technological developments collectively shape a dynamic and evolving landscape, continuously striving for higher purity, greater efficiency, and more sustainable production methods to meet the ever-increasing demands of high-tech industries.

Regional Highlights

- North America: This region stands as a significant market for High Purity Quartz Sand, driven primarily by its robust semiconductor industry and strong innovation ecosystem. The presence of major technology companies and ongoing investments in R&D for advanced electronics, aerospace, and medical devices fuel consistent demand for ultra-high purity quartz. Countries like the United States lead in semiconductor manufacturing and high-tech research, creating a steady requirement for materials that meet the highest purity standards. Furthermore, growing initiatives in solar energy and specialized optics contribute to the market's expansion, with a focus on cutting-edge applications and sustainable sourcing practices.

- Europe: Europe is a key player in the High Purity Quartz Sand market, characterized by stringent quality requirements and a focus on advanced manufacturing. Countries such as Germany, France, and the UK have well-established industries in specialty glass, optics, and high-performance electronics, necessitating a reliable supply of high-purity quartz. The region also exhibits a strong emphasis on environmental regulations, pushing manufacturers towards sustainable and efficient production methods. Investments in renewable energy and advanced research facilities further contribute to the demand, particularly for specialized grades used in scientific instrumentation and industrial processes.

- Asia Pacific (APAC): The APAC region is undeniably the largest and fastest-growing market for High Purity Quartz Sand globally. This dominance is attributed to the colossal manufacturing base for semiconductors, solar photovoltaic cells, and consumer electronics in countries like China, Taiwan, South Korea, and Japan. Rapid industrialization, increasing disposable income, and massive government support for technological advancement and renewable energy projects are primary growth drivers. The region not only consumes the majority of high purity quartz sand but also houses a significant portion of its production and processing capabilities, establishing it as the epicenter of the market.

- Latin America: While a nascent market compared to other regions, Latin America shows potential for growth in the High Purity Quartz Sand sector. Expanding industrialization, particularly in countries like Brazil and Mexico, coupled with increasing investments in renewable energy infrastructure, is slowly driving demand. The region's rich mineral resources could also position it as a future source of raw quartz, although significant investments in advanced purification technologies would be required to meet high-purity specifications. Current demand is largely met through imports, but local manufacturing capacity is expected to gradually increase over the forecast period.

- Middle East and Africa (MEA): The MEA region is currently a smaller contributor to the global High Purity Quartz Sand market, yet it offers emerging opportunities. Growth drivers include diversifying economies away from oil, increasing investments in infrastructure development, and nascent efforts in renewable energy projects, particularly solar power in the Middle East. Countries like Saudi Arabia and the UAE are exploring high-tech manufacturing, which could stimulate demand for specialized materials. However, challenges such as limited local production facilities for high-purity grades mean the region remains largely reliant on imports, with gradual market maturation anticipated.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Purity Quartz Sand Sales Market.- Unimin Corporation (Sibelco)

- The Quartz Corp

- Shin-Etsu Chemical Co., Ltd.

- Heraeus Quarzglas GmbH & Co. KG

- Momentive Performance Materials Inc.

- CoorsTek Inc.

- HPQ Silicon Resources Inc.

- Saint-Gobain S.A.

- Russian Quartz LLC (RusQuartz)

- Jiangsu Pacific Quartz Co., Ltd.

- Donghai Colourful Quartz Products Co., Ltd.

- Kyshtym Mining

- Washington Mills

- High Purity Materials (HPM)

- Minerali Industriali S.p.A.

- Nordic Mining ASA

- Quarzwerke GmbH

- US Silica Holdings Inc.

- Guangdong Fenghua Advanced Technology Holding Co., Ltd.

- Pingxiang Sanrui Quartz Crystal Material Co., Ltd.

Frequently Asked Questions

What is high purity quartz sand and why is it important?

High purity quartz sand is a specialized form of silica (SiO2) characterized by exceptionally low levels of impurities, typically exceeding 99.995% SiO2. Its importance stems from its unique properties—high thermal stability, chemical inertness, excellent electrical insulation, and optical transparency—making it indispensable for critical applications in high-tech industries. It serves as a foundational material for components in semiconductors, solar photovoltaic cells, advanced lighting, and sophisticated optical devices, where even trace contaminants can compromise performance and reliability. Its role is pivotal in enabling the functionality and longevity of next-generation technologies, directly impacting global technological advancements and economic growth across diverse sectors.

Which industries are the primary consumers of high purity quartz sand?

The primary consumers of high purity quartz sand are the semiconductor and solar photovoltaic industries. Semiconductor manufacturers utilize it extensively for crucibles, tubes, and other process equipment critical to microchip fabrication, directly influencing chip quality and yield. The solar PV sector employs it for quartz glass components that encapsulate and protect solar cells, enhancing their efficiency and lifespan. Additionally, manufacturers of advanced lighting solutions (e.g., halogen, UV lamps), optical fibers, and specialized optics also represent significant consumer segments, requiring its superior optical and thermal properties for their products. The demand from these industries is driven by continuous technological innovation and global market expansion.

What are the key drivers for the growth of the high purity quartz sand market?

The key drivers for market growth are multifaceted and primarily revolve around the escalating demand from technology-intensive sectors. The rapid expansion of the global semiconductor industry, fueled by advancements in AI, 5G, and high-performance computing, is a significant catalyst. The increasing global adoption of solar energy, driven by environmental concerns and decreasing costs, further propels demand for high-quality quartz components in solar PV applications. Additionally, continuous innovations in display technologies, optical communications, and other specialized applications requiring highly pure and stable materials contribute substantially to the market's sustained growth. These macro-level trends underscore the material's strategic importance.

What are the main challenges facing the high purity quartz sand market?

The high purity quartz sand market faces several significant challenges. Foremost among these are the inherently high production and purification costs required to achieve ultra-high purity levels, making the final product expensive. The scarcity of economically viable natural deposits of ultra-high purity quartz is another major constraint, leading to a concentrated supply base and potential supply chain vulnerabilities. Furthermore, stringent environmental regulations governing mining and processing activities add to operational complexities and costs. Geopolitical instabilities and global trade dynamics also pose risks to consistent supply and pricing, impacting overall market stability and strategic planning for both producers and consumers in this critical materials sector.

How is AI impacting the high purity quartz sand market?

AI is impacting the high purity quartz sand market in a dual capacity: as a demand accelerator and an operational enhancer. Firstly, AI's rapid development directly fuels the demand for more advanced, high-performance semiconductor chips, which critically depend on ultra-high purity quartz sand for their fabrication. Secondly, AI and machine learning technologies are increasingly being applied to optimize various stages of the quartz value chain. This includes improving efficiency in raw material extraction, enhancing precision in purification processes, optimizing quality control for impurity detection, and streamlining supply chain management through predictive analytics, leading to reduced costs and improved product consistency. AI also holds potential for discovering new materials and processing techniques, thereby expanding future market opportunities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager