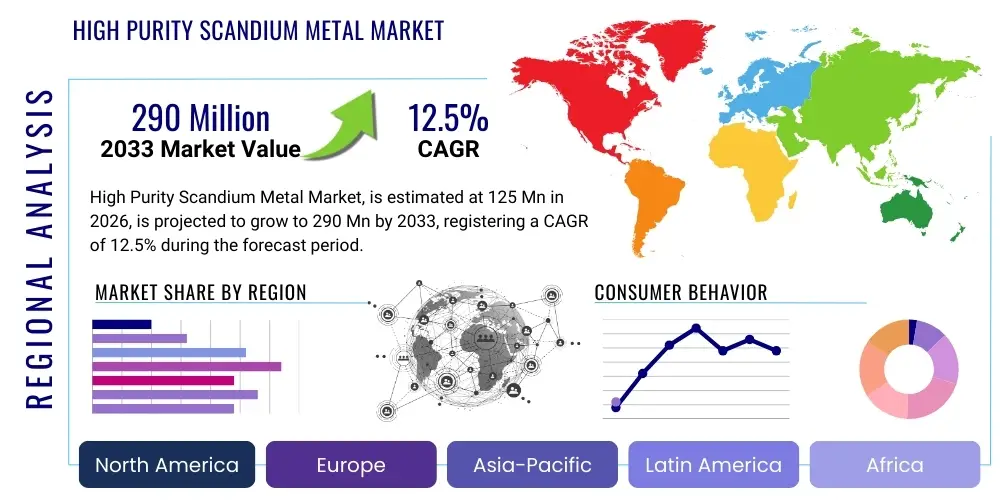

High Purity Scandium Metal Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440493 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

High Purity Scandium Metal Market Size

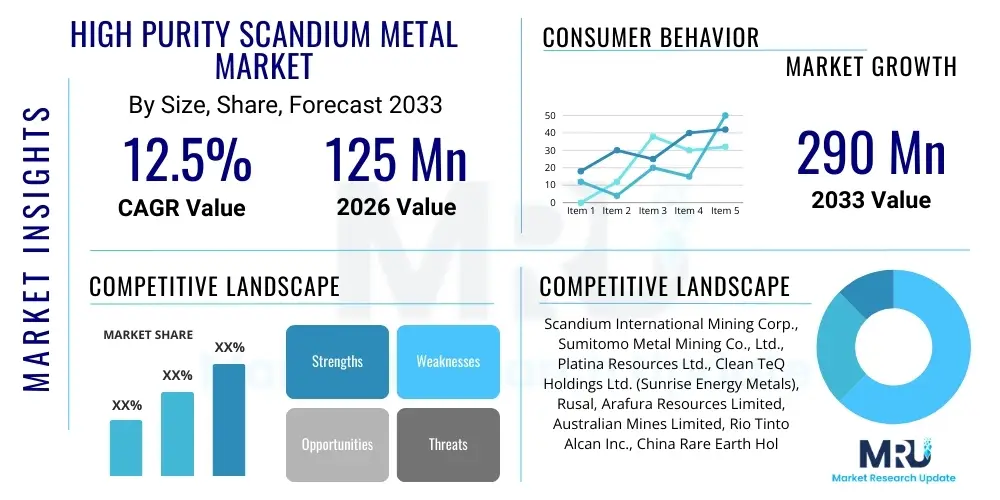

The High Purity Scandium Metal Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at USD 125 million in 2026 and is projected to reach USD 290 million by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by an increasing demand from advanced aerospace applications, a burgeoning solid oxide fuel cell (SOFC) sector, and continuous innovation in lightweight alloy formulations. The unique properties of high purity scandium metal, including its exceptional strength-to-weight ratio and high melting point, make it indispensable for critical, high-performance applications where material integrity and efficiency are paramount. As technological advancements accelerate across key industries, the strategic importance and market valuation of scandium metal are anticipated to climb significantly.

High Purity Scandium Metal Market introduction

The high purity scandium metal market encompasses the production, distribution, and application of scandium in its refined metallic form, typically with purities ranging from 99.9% to 99.999%. Scandium (Sc) is a rare earth element, though often classified as a transition metal, renowned for its lightweight properties and ability to significantly enhance the strength and corrosion resistance of aluminum alloys, even in trace amounts. These superior characteristics make high purity scandium metal a critical component in various high-performance applications, where material efficiency and durability are non-negotiable. Its primary applications span across the aerospace and defense sectors, where it is used in aircraft components and missile systems, and in the energy industry, particularly in the development of highly efficient Solid Oxide Fuel Cells (SOFCs) due to its unique oxygen ion conductivity when integrated into ceramic electrolytes. Furthermore, its benefits extend to the sporting goods industry for ultra-lightweight equipment, medical devices, and specialized high-performance lighting solutions.

The increasing adoption of high purity scandium metal is propelled by several key driving factors. Foremost among these is the global push for lightweighting in transportation sectors, aimed at improving fuel efficiency and reducing carbon emissions. The demand for advanced materials with superior performance characteristics in extreme environments also plays a crucial role, particularly in aerospace where material innovation directly translates to operational advantages and safety improvements. The escalating research and development efforts in alternative energy technologies, such as SOFCs, further bolster market growth, as scandium-stabilized zirconia offers enhanced efficiency and operational longevity compared to traditional materials. Additionally, ongoing technological advancements in extraction and refining processes are gradually improving supply chain stability and reducing production costs, making scandium more accessible for broader industrial integration. These combined factors underscore the expanding significance of high purity scandium metal as a vital strategic material for future technological progression.

High Purity Scandium Metal Market Executive Summary

The High Purity Scandium Metal Market is experiencing dynamic shifts, driven by escalating demand from critical sectors such as aerospace, defense, and clean energy. Business trends indicate a strategic focus on expanding mining and refining capacities, particularly as major economies prioritize material security and diversify supply chains away from single-source dependencies. There is a notable increase in collaborations between research institutions and industrial players to innovate new applications and improve extraction efficiencies. Furthermore, market players are actively investing in sustainable production methods to address environmental concerns and meet stringent regulatory requirements. This trend is fostering a competitive landscape where companies are differentiating themselves through product purity, reliable supply, and specialized application expertise, reflecting a mature yet rapidly evolving market structure. The emphasis on high-performance alloys and energy-efficient solutions is shaping procurement strategies and driving mergers and acquisitions aimed at consolidating market presence and technological know-how.

Regional trends reveal Asia Pacific as a dominant force in both production and consumption, primarily due to the presence of significant rare earth processing capabilities and robust manufacturing bases for electronics and automotive components. North America and Europe are witnessing substantial growth in application development, driven by strong aerospace industries and a concerted effort towards renewable energy adoption and advanced materials research. Governments in these regions are increasingly funding initiatives to secure domestic scandium supplies and foster innovation, reducing reliance on external markets. Emerging economies in Latin America and Africa are beginning to explore their own scandium reserves, signaling potential future shifts in global supply dynamics. Each region's unique industrial landscape and regulatory environment contribute to distinct growth patterns and market opportunities, necessitating a localized approach to market entry and expansion. The strategic importance of scandium for national defense and technological leadership is also influencing geopolitical considerations, further impacting regional market trajectories.

Segmentation trends highlight the increasing importance of purity levels, with ultra-high purity (99.999%) scandium commanding premium prices due to its critical role in highly sensitive electronic and medical applications. The application segment sees aerospace alloys maintaining a significant share, while solid oxide fuel cells are emerging as a high-growth area, driven by global decarbonization efforts. End-use industries are diversifying, moving beyond traditional defense applications to include significant demand from consumer electronics, automotive light-weighting, and advanced ceramics. By form, sputtering targets and specialized powders are gaining traction as manufacturing processes become more precise and require tailored material forms. These segmentation patterns illustrate a market undergoing specialization, where specific material attributes and forms are crucial for addressing distinct industrial requirements. The interplay of purity, application, and end-use is defining niche markets and fostering targeted product development strategies among leading market participants, ensuring continued innovation and expansion across the value chain.

AI Impact Analysis on High Purity Scandium Metal Market

User questions related to AI's impact on the High Purity Scandium Metal Market frequently revolve around how artificial intelligence can optimize the complex and energy-intensive processes of scandium extraction and refining, thereby reducing costs and environmental footprint. There is significant curiosity about AI's role in accelerating material discovery for new scandium alloys, predicting market demand fluctuations, and enhancing supply chain resilience through predictive analytics. Users also inquire about AI's potential to identify new, economically viable scandium deposits and streamline the recycling of scandium-containing products. The overarching themes reflect expectations for AI to bring greater efficiency, predictability, and sustainability to a market historically challenged by high production costs, supply volatility, and limited reserves.

- AI can optimize complex ore processing, improving scandium yield and reducing energy consumption through predictive modeling and real-time process adjustments.

- Predictive analytics powered by AI can enhance demand forecasting for scandium metal, enabling more efficient production planning and inventory management.

- AI algorithms can accelerate the discovery and design of novel scandium alloys by simulating material properties and performance characteristics, reducing R&D cycles.

- Machine learning can be applied to analyze geological data, identifying potential new scandium deposits with higher probability and lower exploration costs.

- AI-driven supply chain management tools can monitor global supply and demand dynamics, predict disruptions, and optimize logistics for improved resilience and stability.

- Robotics and automation, often integrated with AI, can improve safety and efficiency in mining and refining operations, especially in hazardous environments.

- AI can facilitate the development of advanced recycling techniques for scandium from end-of-life products, enhancing circular economy initiatives and resource sustainability.

DRO & Impact Forces Of High Purity Scandium Metal Market

The High Purity Scandium Metal Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities, all contributing to significant Impact Forces that shape its trajectory. Key drivers include the escalating demand for lightweight, high-strength materials in the aerospace and defense sectors, where scandium's ability to create superior aluminum alloys offers unparalleled performance advantages in terms of fuel efficiency and structural integrity. The rapid advancements in solid oxide fuel cell (SOFC) technology, which utilizes scandium-stabilized zirconia for enhanced efficiency and durability, also represent a powerful driver as the world transitions towards cleaner energy solutions. Additionally, growing interest in high-performance sporting goods and specialized lighting applications further contributes to market expansion. These drivers collectively create a robust demand pull, incentivizing investment and innovation across the value chain. The continuous push for material innovation in critical industries, coupled with stringent environmental regulations promoting lightweighting, sustains this positive momentum.

Conversely, significant restraints temper the market's growth potential. The primary challenge remains the high cost of scandium extraction and refining, which historically has made it one of the most expensive rare earth metals. This elevated cost restricts its widespread adoption, especially in price-sensitive applications, limiting market penetration. The scarcity of economically viable primary scandium deposits and the fact that it is often a byproduct of other mining operations (e.g., uranium, nickel, bauxite) lead to an inherently constrained and unstable supply chain. Geopolitical factors and trade policies, particularly concerning critical raw materials, further exacerbate supply vulnerabilities and market price volatility. Limited public awareness about scandium's unique properties and potential benefits outside of niche industrial applications also acts as a restraint, hindering broader market development. Overcoming these challenges requires substantial capital investment in new extraction technologies, diversification of supply sources, and sustained research into cost-effective production methods.

Opportunities for the High Purity Scandium Metal Market are substantial and multifaceted. The ongoing development of innovative extraction technologies, such as ion-exchange resin processes and solvent extraction, holds the promise of reducing production costs and increasing supply availability, thereby expanding market accessibility. The proliferation of electric vehicles and autonomous transportation systems presents a significant future opportunity, as scandium alloys can contribute to battery housing, structural components, and chassis lightweighting, enhancing range and performance. Furthermore, the growing global focus on renewable energy and energy storage solutions will continue to fuel demand from the SOFC sector. Strategic government investments in critical raw materials, coupled with increasing circular economy initiatives aimed at scandium recycling and recovery from industrial waste streams, offer pathways to secure supply and reduce environmental impact. Collaborative research and development efforts between industry and academia to explore new applications and material synergies will unlock previously untapped market segments. These opportunities, if effectively leveraged, could transform scandium from a niche material into a more widely utilized strategic resource, driving sustainable growth and technological advancement across diverse industries.

Segmentation Analysis

The High Purity Scandium Metal Market is meticulously segmented across various dimensions to provide a granular understanding of its complex dynamics and diverse applications. This comprehensive segmentation allows market participants to identify niche opportunities, tailor product offerings, and devise targeted strategies for market penetration and expansion. Key segmentations typically include purity levels, application areas, end-use industries, and product forms, each reflecting distinct value propositions and demand drivers within the market. Geographic segmentation further delineates regional consumption patterns and supply chain landscapes, highlighting disparities in industrial maturity and regulatory environments. Understanding these segments is crucial for accurate market forecasting, competitive analysis, and strategic decision-making in a rapidly evolving rare earth metal ecosystem. The interplay between these segments provides a holistic view of the market's current structure and future growth potential.

- By Purity:

- 99.9% Scandium Metal

- 99.99% Scandium Metal

- 99.999% Scandium Metal

- By Application:

- Aerospace Alloys (e.g., Al-Sc alloys for aircraft structures)

- Solid Oxide Fuel Cells (SOFC)

- Sporting Goods (e.g., bicycle frames, baseball bats)

- Medical Devices (e.g., prosthetics, surgical instruments)

- High-Performance Ceramics

- Specialized Lighting (e.g., metal halide lamps)

- Other Industrial Applications

- By End-Use Industry:

- Aerospace & Defense

- Energy (Fuel Cells, Nuclear)

- Electronics (Semiconductors, Sputtering Targets)

- Automotive (Lightweight Components)

- Healthcare (Implants, Diagnostic Equipment)

- Consumer Goods

- By Form:

- Scandium Powder

- Scandium Ingots

- Scandium Foils

- Scandium Sputtering Targets

- Scandium Oxide

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For High Purity Scandium Metal Market

The value chain for the High Purity Scandium Metal Market is intricate, spanning from raw material extraction to end-product manufacturing and distribution. Upstream analysis reveals that scandium is rarely found in concentrated deposits; instead, it is typically co-produced as a byproduct from the mining and processing of other primary metals like uranium, nickel, iron ore, and bauxite. This co-extraction often involves complex and energy-intensive hydrometallurgical or pyrometallurgical separation processes to isolate scandium compounds. Key upstream activities include geological exploration, mining, ore crushing, leaching, and initial chemical separation to produce scandium oxides or other intermediate compounds. The availability and economic viability of these primary mining operations significantly impact the overall supply of raw scandium materials, making the upstream segment a critical bottleneck and a focal point for technological innovation aimed at improving recovery rates and reducing environmental impact. The fragmented nature of these byproduct sources also contributes to supply chain complexities and price volatility, as scandium production is largely dependent on the economics and operational decisions of the larger primary metal industries.

Midstream activities involve the crucial refining and purification processes that transform scandium compounds into high purity scandium metal. This stage demands sophisticated metallurgical techniques, such as vacuum melting, electron beam refining, and various chemical purification steps, to achieve the desired purity levels (e.g., 99.9%, 99.99%, 99.999%). Specialized facilities and highly skilled personnel are essential for these operations, which often involve significant capital investment and proprietary technologies. After purification, the metal is typically fabricated into various forms such as powders, ingots, foils, or sputtering targets, depending on the specific application requirements of downstream industries. This transformation into usable forms adds significant value and enables its integration into advanced materials and components. The distribution channel in the midstream primarily involves specialized chemical and metal distributors who cater to niche industrial clients, ensuring that the high-value, sensitive material is handled and transported under appropriate conditions to maintain its integrity.

Downstream analysis focuses on the integration of high purity scandium metal into final products and its reach to end-users. Direct distribution often occurs for large industrial buyers in the aerospace and defense sectors, where direct procurement ensures quality control and security of supply. Indirect channels involve distributors or specialized material suppliers who provide scandium alloys or components to a broader range of manufacturers in industries such as sporting goods, medical devices, and high-performance lighting. These manufacturers incorporate scandium into their products, leveraging its unique properties to enhance performance, reduce weight, or improve durability. The market for downstream products is characterized by a strong emphasis on research and development, as end-users continuously seek innovative material solutions. The growth in end-user applications directly stimulates demand further upstream, making the downstream segment a key driver for market expansion. The effectiveness of both direct and indirect distribution channels is vital for ensuring market accessibility and supporting the widespread adoption of scandium-containing products across diverse high-tech industries.

High Purity Scandium Metal Market Potential Customers

The potential customers for high purity scandium metal are diverse, primarily comprising industries that demand advanced materials with exceptional strength-to-weight ratios, enhanced thermal stability, and superior electrical properties. The aerospace and defense sector represents a cornerstone of this customer base, with aircraft manufacturers and defense contractors seeking scandium-aluminum alloys for structural components, fuselage parts, and missile systems to achieve significant weight reduction, improve fuel efficiency, and extend operational lifespans. These customers prioritize material performance, reliability, and certifications above cost, making high purity scandium metal an attractive, albeit premium, solution. The stringent performance requirements and long design cycles in these industries often lead to stable, long-term demand relationships with scandium suppliers, further solidifying this customer segment's importance. The ongoing pursuit of next-generation aircraft and defense platforms ensures sustained innovation and integration of advanced materials, including scandium alloys, making this sector a perpetual growth driver for the market.

Another significant customer segment lies within the energy sector, particularly those involved in the development and manufacturing of Solid Oxide Fuel Cells (SOFCs). Companies producing SOFCs utilize scandium-stabilized zirconia (ScSZ) as an electrolyte material due to its superior oxygen ion conductivity and enhanced long-term stability at intermediate operating temperatures, which translates into higher energy conversion efficiency and greater durability compared to yttria-stabilized zirconia. As global efforts intensify towards decarbonization and the adoption of clean energy technologies, the demand from SOFC manufacturers is projected to surge. These customers are focused on improving the performance and longevity of their fuel cell stacks, where the marginal cost increase from scandium is justified by the substantial gains in efficiency and operational lifespan. The automotive industry, specifically in the electric vehicle (EV) segment, is also emerging as a potential customer, looking to scandium alloys for lightweight battery enclosures, structural components, and motor parts to extend range and enhance vehicle performance, aligning with the broader trend of vehicle lightweighting and efficiency improvements.

Beyond these primary sectors, the medical device industry, specialized lighting manufacturers, and high-end sporting goods companies constitute niche but valuable customer segments. Medical device manufacturers incorporate scandium into prosthetics and surgical instruments where biocompatibility, high strength, and corrosion resistance are paramount. In lighting, scandium iodide is used in metal halide lamps to improve luminous efficacy and color rendering, catering to specialized industrial and studio lighting applications. Sporting goods manufacturers, especially those producing high-performance equipment like bicycle frames, baseball bats, and lacrosse sticks, leverage scandium-aluminum alloys to achieve unparalleled lightness and strength, offering a competitive edge for athletes. Moreover, the electronics industry utilizes scandium in sputtering targets for thin-film applications in semiconductors and display technologies, where its unique material properties enable advanced device functionality. These diverse end-users collectively underscore the broad applicability and strategic value of high purity scandium metal, driving demand across a spectrum of advanced technological domains.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 125 million |

| Market Forecast in 2033 | USD 290 million |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Scandium International Mining Corp., Sumitomo Metal Mining Co., Ltd., Platina Resources Ltd., Clean TeQ Holdings Ltd. (Sunrise Energy Metals), Rusal, Arafura Resources Limited, Australian Mines Limited, Rio Tinto Alcan Inc., China Rare Earth Holdings Limited, Ganzhou Rare Earth Mineral Industry Co., Ltd., Inner Mongolia Baotou Steel Rare-Earth (Group) Hi-Tech Co., Ltd., Lynas Rare Earths Limited, Materion Corporation, AMG Advanced Metallurgical Group N.V., Tasman Resources Ltd., Scandium Australia Pty Ltd., ALS Limited, American Elements, Treibacher Industrie AG, Metalysis Limited |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Purity Scandium Metal Market Key Technology Landscape

The key technology landscape for the High Purity Scandium Metal market is dominated by advancements in extraction, purification, and alloying techniques, each critical for improving efficiency, reducing costs, and expanding application possibilities. In extraction, ongoing research is focused on developing more efficient and environmentally friendly methods to recover scandium from diverse primary and secondary sources. This includes refining solvent extraction processes, optimizing ion exchange resins, and exploring direct extraction from bauxite residue (red mud), which represents a significant untapped resource. Innovations in these areas aim to increase scandium yield from low-concentration ores and byproducts, making production more economically viable and less reliant on traditional, energy-intensive methods. Furthermore, pyrometallurgical techniques are being continuously improved to handle various ore compositions, while hydrometallurgical processes are becoming more selective and less wasteful, reducing the overall environmental footprint of scandium production. The drive for higher recovery rates from often complex feedstocks is a primary technological focus.

Purification technologies are equally vital, as the performance of scandium in high-tech applications is highly dependent on its purity. Electron beam melting (EBM) and vacuum induction melting (VIM) are critical for achieving ultra-high purity levels, removing trace impurities that can compromise material integrity. Researchers are also investigating advanced electrochemical methods and zone refining techniques to further enhance purity, especially for demanding electronic and medical applications where even minute contaminants can be detrimental. The ability to consistently produce 99.99% and 99.999% pure scandium metal is a significant technological differentiator in the market. These purification advancements are crucial not only for high-end applications but also for ensuring the consistent quality required for widespread industrial adoption, reducing potential batch variations and ensuring reliable performance across diverse manufacturing processes. The continuous refinement of these purification steps remains a core area of technological development.

Beyond extraction and purification, significant technological progress is observed in alloying and material science. The development of advanced aluminum-scandium (Al-Sc) master alloys, often with additional alloying elements like magnesium or zirconium, is crucial for tailoring specific properties such as increased strength, improved weldability, and enhanced corrosion resistance. Powder metallurgy techniques are gaining prominence for creating scandium-containing alloys with fine-grained microstructures and superior mechanical properties, particularly for additive manufacturing (3D printing) applications in aerospace. Furthermore, the synthesis of scandium-stabilized zirconia (ScSZ) for solid oxide fuel cells requires precise material engineering to optimize ionic conductivity and thermal stability. Research into new scandium compounds and their integration into superconductors, advanced catalysts, and thermoelectric materials also represents a growing frontier. These alloying and material science innovations are expanding the functional utility of high purity scandium metal, opening doors to novel applications and cementing its role as a strategic material in future technological advancements across multiple industries.

Regional Highlights

- Asia Pacific: This region is a major hub for both scandium production and consumption. Countries like China and Australia possess significant rare earth reserves and processing capabilities. China, in particular, dominates global supply, while the region's burgeoning aerospace, electronics, and automotive industries drive substantial demand for scandium alloys and SOFC components. Investment in sustainable mining practices and downstream processing is accelerating here.

- North America: Driven by a robust aerospace and defense industry and increasing investments in clean energy technologies, North America represents a critical demand center. The U.S. and Canada are actively exploring domestic scandium resources and promoting advanced materials research to reduce reliance on foreign supply chains, focusing on strategic self-sufficiency and innovation in high-performance applications.

- Europe: Europe is witnessing growing demand from its advanced manufacturing sectors, including aerospace, automotive, and energy. European initiatives like the European Raw Materials Alliance (ERMA) underscore a strategic commitment to securing critical raw materials like scandium. Investment in SOFC technology and lightweighting solutions for transportation are key drivers, along with efforts to establish local processing capabilities.

- Latin America: While not a primary producer or consumer currently, several countries in Latin America, such as Brazil, hold potential scandium resources. Emerging economies here are gradually developing their industrial bases, potentially fostering future demand for advanced materials, especially if regional aerospace or renewable energy sectors expand significantly.

- Middle East & Africa (MEA): This region is emerging as a potential source for scandium, with countries exploring their untapped rare earth deposits. Current demand is comparatively lower but is projected to increase with infrastructure development, defense spending, and nascent efforts in renewable energy, positioning MEA as a future player in the global scandium market supply chain.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Purity Scandium Metal Market.- Scandium International Mining Corp.

- Sumitomo Metal Mining Co., Ltd.

- Platina Resources Ltd.

- Clean TeQ Holdings Ltd. (Sunrise Energy Metals)

- Rusal

- Arafura Resources Limited

- Australian Mines Limited

- Rio Tinto Alcan Inc.

- China Rare Earth Holdings Limited

- Ganzhou Rare Earth Mineral Industry Co., Ltd.

- Inner Mongolia Baotou Steel Rare-Earth (Group) Hi-Tech Co., Ltd.

- Lynas Rare Earths Limited

- Materion Corporation

- AMG Advanced Metallurgical Group N.V.

- Tasman Resources Ltd.

- Scandium Australia Pty Ltd.

- ALS Limited

- American Elements

- Treibacher Industrie AG

- Metalysis Limited

Frequently Asked Questions

Analyze common user questions about the High Purity Scandium Metal market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications driving the High Purity Scandium Metal market?

The primary applications driving the high purity scandium metal market include lightweighting in aerospace and defense alloys for aircraft components and missile systems, and as a key electrolyte component in highly efficient Solid Oxide Fuel Cells (SOFCs). Its unique properties also find use in high-performance sporting goods and specialized lighting.

What are the main challenges hindering the growth of the Scandium Metal market?

The main challenges are the high cost of extraction and refining, which makes scandium an expensive material, and the limited and often unstable supply chain due to its nature as a byproduct of other mining operations. Geopolitical factors and lack of concentrated primary deposits also contribute to supply vulnerability.

How is AI impacting the High Purity Scandium Metal market?

AI is impacting the market by optimizing complex extraction and refining processes, improving scandium yield, and reducing energy consumption. It also aids in accelerating new material discovery, enhancing demand forecasting, and increasing supply chain resilience through predictive analytics and data-driven insights.

Which regions are key players in the High Purity Scandium Metal market, and why?

Asia Pacific, particularly China, is a key player due to significant rare earth reserves and processing capabilities, alongside robust industrial demand. North America and Europe are crucial due to strong aerospace industries, clean energy initiatives, and strategic investments in advanced materials research and domestic supply security.

What is the projected growth rate for the High Purity Scandium Metal market?

The High Purity Scandium Metal Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033, driven by increasing demand from advanced aerospace applications and the burgeoning solid oxide fuel cell (SOFC) sector.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager