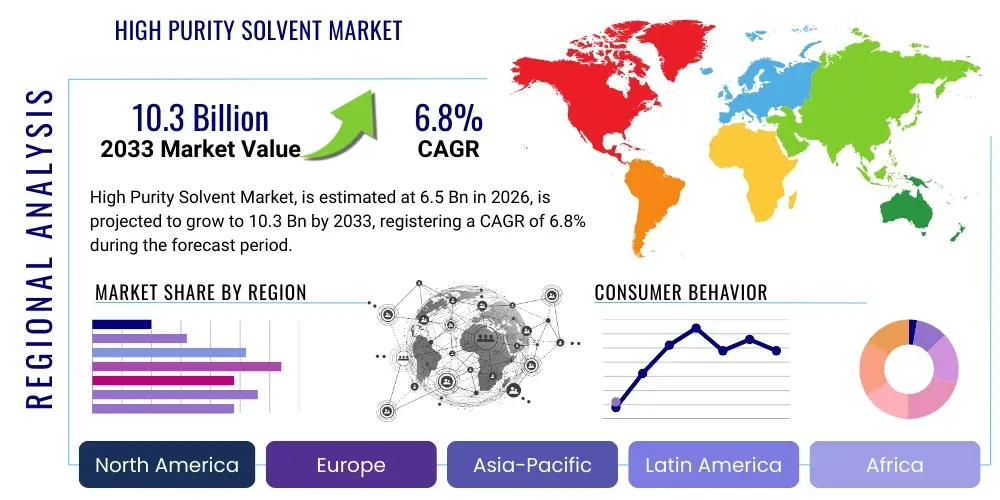

High Purity Solvent Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439882 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

High Purity Solvent Market Size

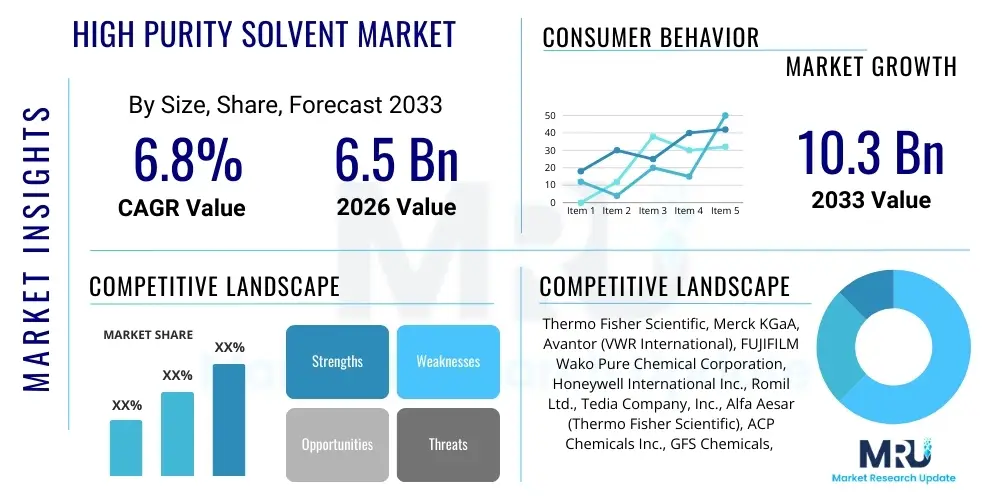

The High Purity Solvent Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 6.5 billion in 2026 and is projected to reach USD 10.3 billion by the end of the forecast period in 2033.

High Purity Solvent Market introduction

The High Purity Solvent Market encompasses the production and distribution of solvents meticulously purified to meet stringent quality specifications, often exceeding 99.9% purity. These specialized chemical compounds are essential for applications where the presence of impurities, even in trace amounts, could compromise product integrity, process efficiency, or analytical accuracy. Defined by their exceptional cleanliness, these solvents are free from contaminants such as water, heavy metals, particulates, and other organic or inorganic substances, ensuring optimal performance in sensitive environments.

Key applications for high purity solvents span across highly regulated and technology-intensive industries. Pharmaceuticals rely on them for drug synthesis, purification, and quality control, while biotechnology leverages them in DNA/RNA synthesis, protein purification, and cell culture. The electronics sector utilizes these solvents for cleaning semiconductor wafers and manufacturing intricate electronic components, where even microscopic impurities can lead to device failure. Furthermore, they are indispensable in chemical synthesis, advanced material science, and various research and academic laboratories for precise experimentation and analytical testing. The primary benefits of using high purity solvents include enhanced product yield, improved process reliability, extended shelf life of sensitive materials, and significantly reduced risk of contamination, which is paramount in critical manufacturing and research processes.

The growth of this market is predominantly driven by the escalating demand from these high-tech end-use industries, which are continually pushing the boundaries of miniaturization, precision, and efficacy. Stricter regulatory frameworks across sectors like pharmaceuticals and electronics necessitate the use of higher-grade input materials, including solvents, to ensure product safety and compliance. Additionally, continuous advancements in analytical techniques and scientific research further fuel the need for solvents with unparalleled purity, as these tools require immaculate conditions to deliver accurate and reproducible results, thereby solidifying the market's trajectory towards sustained expansion.

High Purity Solvent Market Executive Summary

The High Purity Solvent Market is experiencing robust expansion, characterized by dynamic business trends, significant regional shifts, and evolving segment demands. Globally, business trends indicate a strong emphasis on supply chain resilience, driven by recent disruptions, leading to increased investment in localized production and diversification of sourcing strategies. There is a growing trend towards strategic partnerships and mergers & acquisitions among key players to consolidate market share, enhance technological capabilities, and expand geographic reach. Furthermore, sustainability initiatives are influencing product development, with a heightened focus on green chemistry principles and the production of bio-based or recycled high purity solvents to meet environmental compliance and consumer preferences.

Regionally, Asia Pacific is poised for significant growth, largely attributed to rapid industrialization, the booming electronics manufacturing sector, and the expanding pharmaceutical and biotechnology industries in countries like China, India, and South Korea. North America and Europe continue to be mature but stable markets, driven by robust R&D activities, stringent regulatory standards, and well-established pharmaceutical and life sciences industries. Emerging economies in Latin America and the Middle East & Africa are demonstrating nascent but promising growth, fueled by increasing foreign investments in manufacturing and healthcare infrastructure. These regional dynamics highlight a diversified global market landscape with varying growth accelerators.

Segment-wise, the market is witnessing distinct trends across solvent types, grades, and applications. The demand for highly specialized grades such as LC-MS and electronic-grade solvents is accelerating due to their critical role in advanced analytical techniques and semiconductor manufacturing. Methanol, acetonitrile, and isopropanol remain dominant solvent types, but interest in specialized derivatives and mixtures for niche applications is growing. In terms of application, pharmaceuticals and biotechnology are consistently leading segments, propelled by increasing drug discovery initiatives and biopharmaceutical production. The electronics segment is also a major growth driver, particularly with the proliferation of complex microelectronics, underscoring the market's reliance on technological innovation and stringent quality requirements.

AI Impact Analysis on High Purity Solvent Market

The integration of Artificial Intelligence (AI) within the High Purity Solvent Market is generating considerable interest, with common user questions often revolving around how AI can enhance efficiency, improve quality control, and optimize supply chains. Users are keenly interested in AI's potential to streamline complex purification processes, predict market demands more accurately, and reduce operational costs. Concerns frequently arise regarding the initial investment required for AI infrastructure, the need for specialized skillsets to implement and manage AI systems, and data privacy issues. Expectations are high that AI will lead to more sustainable manufacturing practices, faster innovation cycles for new solvent formulations, and superior product consistency, ultimately transforming how high purity solvents are produced, tested, and distributed.

AI's influence is anticipated across multiple facets of the high purity solvent value chain. In research and development, AI can accelerate the discovery of novel solvent chemistries and optimize existing purification protocols by simulating molecular interactions and predicting performance characteristics. This capability significantly reduces the time and resources traditionally required for experimental trials. For manufacturing, AI-powered predictive analytics can monitor real-time process parameters, detect anomalies, and suggest adjustments to maintain optimal purity levels, thereby minimizing waste and energy consumption. This leads to higher batch consistency and reduces the likelihood of costly reprocessing or product rejection.

Furthermore, AI is expected to revolutionize supply chain management by providing advanced forecasting models that account for fluctuating raw material prices, geopolitical events, and changing customer demands, ensuring more efficient inventory management and timely delivery. In quality assurance, AI algorithms can rapidly analyze large datasets from chromatography and spectroscopy, identifying subtle impurities or deviations from specifications with greater accuracy than human inspection. This not only enhances product reliability but also frees up human experts to focus on more complex problem-solving. Overall, AI's role is seen as a catalyst for greater precision, efficiency, and sustainability within the high purity solvent industry, addressing both operational challenges and evolving market demands.

- Enhanced process optimization for purification and distillation, leading to higher yields and reduced energy consumption.

- Predictive maintenance for manufacturing equipment, minimizing downtime and extending asset lifespan.

- Accelerated R&D for novel solvent formulations and purification techniques through computational chemistry and data analysis.

- Improved quality control and impurity detection using AI-driven analytical data interpretation.

- Optimized supply chain and logistics, including demand forecasting and inventory management, for better resource allocation.

- Development of smart sensors and IoT integration for real-time monitoring of purity and process conditions.

- Facilitation of greener solvent alternatives by predicting biodegradability and toxicity profiles.

- Automated compliance checks and regulatory reporting to meet stringent industry standards.

DRO & Impact Forces Of High Purity Solvent Market

The High Purity Solvent Market is shaped by a confluence of driving forces, inherent restraints, promising opportunities, and overarching impact forces that collectively dictate its growth trajectory and operational landscape. A primary driver is the relentless expansion of end-use industries, particularly pharmaceuticals, biotechnology, and electronics, all of which exhibit an insatiable demand for ultra-pure materials due to their stringent quality requirements and complex manufacturing processes. The global push for miniaturization in electronics and the intricate synthesis of biologics and advanced pharmaceuticals necessitate solvents free from even trace contaminants, propelling market growth. Furthermore, increasingly stringent regulatory standards imposed by health and environmental agencies worldwide mandate the use of higher-grade solvents, compelling manufacturers to invest in advanced purification technologies and quality control measures to ensure compliance and product safety.

Despite these strong drivers, the market faces significant restraints. The high cost associated with the purification processes required to achieve exceptional purity levels often translates into premium pricing for high purity solvents, which can be a barrier for some end-users or smaller enterprises. Additionally, environmental concerns regarding the handling, storage, and disposal of certain conventional solvents, coupled with their potential toxicity, create pressure for manufacturers to develop and adopt greener alternatives, which often come with their own set of production challenges and higher initial costs. The complex logistical requirements for maintaining solvent purity during transport and storage further add to operational complexities and costs, posing a continuous challenge for supply chain management within the industry.

However, the market is rich with opportunities that promise future expansion and innovation. The growing emphasis on green chemistry is fostering the development and adoption of bio-based and environmentally benign high purity solvents, presenting a lucrative avenue for sustainable market growth. Emerging applications in fields like advanced material science, nanotechnology, and specialized diagnostics are opening new frontiers for solvent utilization, demanding tailored solutions that the industry can innovate to provide. Moreover, the rapid industrialization and burgeoning research and development activities in developing economies offer untapped potential, with increasing investments in pharmaceutical manufacturing and electronic production creating new demand hubs. These opportunities, combined with the impact forces of technological shifts in purification, evolving regulatory landscapes, and global economic fluctuations, dictate a market that is both challenging and ripe for strategic advancement.

Segmentation Analysis

The High Purity Solvent Market is comprehensively segmented based on various critical parameters including Type, Grade, Application, and End-Use Industry. Each segment offers unique insights into market dynamics, demand patterns, and growth opportunities. Understanding these segmentations is crucial for stakeholders to identify niche markets, develop targeted strategies, and forecast future trends, providing a granular view of where value is being created and consumed across the industry. This detailed breakdown allows for a more precise analysis of competitive landscapes and market positioning.

- By Type

- Acetone

- Acetonitrile

- Methanol

- Isopropanol

- Hexane

- Toluene

- Chloroform

- Dimethylformamide (DMF)

- Dimethyl Sulfoxide (DMSO)

- Tetrahydrofuran (THF)

- Ethyl Acetate

- n-Heptane

- Dichloromethane (DCM)

- Ethanol

- Other Types (e.g., Benzene, Xylene, Cyclohexane)

- By Grade

- HPLC Grade

- LC-MS Grade

- GC Grade

- Electronic Grade

- Reagent Grade

- Spectrophotometric Grade

- ACS Grade

- DNA/RNA Synthesis Grade

- Biotech Grade

- Other Grades (e.g., Ultra-Pure, Semiconductor Grade)

- By Application

- Chromatography

- Synthesis

- Extraction

- Cleaning

- Quality Control

- Sample Preparation

- Cell Culture

- Bioprocessing

- Residue Analysis

- Other Applications

- By End-Use Industry

- Pharmaceuticals

- Biotechnology

- Electronics and Semiconductor

- Chemical Synthesis

- Research and Academia

- Cosmetics and Personal Care

- Food and Beverages

- Environmental Testing

- Clinical Diagnostics

- Material Science

- Other Industries

Value Chain Analysis For High Purity Solvent Market

The value chain for the High Purity Solvent Market is an intricate network that begins with the sourcing of raw materials and culminates in the end-user application, involving several critical stages that add value and ensure product quality. At the upstream analysis stage, the process primarily involves the procurement of base solvents and precursors, predominantly derived from petrochemical sources such as crude oil and natural gas, or increasingly, from bio-based feedstocks like corn, sugarcane, or lignocellulosic biomass. Key raw material suppliers provide industrial-grade solvents, which then undergo rigorous purification to meet the exacting high purity standards. This stage is critical as the quality of the starting material directly impacts the cost and complexity of the subsequent purification steps.

The core of the value chain involves the manufacturing and purification processes carried out by specialized high purity solvent producers. This midstream segment employs advanced technologies such as fractional distillation, adsorption, membrane filtration, ion exchange, and various chromatographic techniques to remove impurities to parts-per-billion or parts-per-trillion levels. Quality control is paramount at this stage, involving sophisticated analytical methods like gas chromatography (GC), high-performance liquid chromatography (HPLC), and mass spectrometry (MS) to verify purity. Packaging in inert, contamination-free containers is also a crucial aspect, designed to maintain purity during storage and transit. This meticulous purification and quality assurance are the primary value-adding activities, transforming bulk chemicals into highly specialized products.

Downstream analysis focuses on the distribution and end-user consumption. The distribution channel is multifaceted, comprising both direct sales and indirect channels. Large-scale pharmaceutical companies, electronics manufacturers, and major research institutions often procure high purity solvents directly from manufacturers through established contracts and specialized logistics. Indirect channels involve a network of regional and global distributors who specialize in chemical distribution, warehousing, and supplying to a diverse range of smaller laboratories, academic institutions, and specialized industries. These distributors provide essential services such as smaller batch sizes, technical support, and localized delivery, acting as a crucial link between producers and the broader market. The efficiency and reliability of these distribution channels are vital for ensuring timely and pristine delivery to end-users, underscoring the importance of a robust and well-managed supply chain in maintaining the integrity and value of high purity solvents.

High Purity Solvent Market Potential Customers

The High Purity Solvent Market serves a diverse and continually expanding base of potential customers who require materials of uncompromising quality for their critical operations. These end-users are primarily driven by the need for precision, reliability, and the elimination of contaminants that could adversely affect their products, processes, or analytical results. The pharmaceutical industry stands as a cornerstone customer, utilizing high purity solvents extensively in drug discovery, synthesis of active pharmaceutical ingredients (APIs), excipient production, and various stages of drug purification and formulation. The biotech sector is equally vital, demanding these solvents for molecular biology applications such as DNA/RNA synthesis, protein purification, cell culture media preparation, and bioprocessing, where even trace impurities can compromise biological activity or experimental outcomes.

Another major segment of potential customers includes the electronics and semiconductor manufacturing industries. These sectors require ultra-pure solvents for critical cleaning processes of wafers, photoresists, and other sensitive electronic components. The integrity of microchips and other intricate electronic devices depends heavily on the purity of the solvents used, as any residue or impurity can lead to device malfunction or failure. Research and academic institutions also represent a significant customer base, employing high purity solvents across a broad spectrum of scientific disciplines, including chemistry, biology, physics, and materials science, for experimental procedures, analytical testing, and the development of new technologies, where experimental reproducibility and accuracy are paramount.

Beyond these core industries, other crucial potential customers include chemical synthesis companies that require high purity solvents for producing specialty chemicals, polymers, and advanced materials. Environmental testing laboratories utilize them for precise sample preparation and analysis to detect pollutants and contaminants. The clinical diagnostics sector uses high purity solvents in the formulation of reagents and in various diagnostic assays. Furthermore, the burgeoning fields of nanotechnology and advanced materials are constantly seeking innovative high purity solvent solutions tailored to their specific needs. This broad and demanding customer landscape underscores the indispensable role of high purity solvents in driving innovation and maintaining quality across a multitude of high-tech and regulated industries globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 6.5 Billion |

| Market Forecast in 2033 | USD 10.3 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Merck KGaA, Avantor (VWR International), FUJIFILM Wako Pure Chemical Corporation, Honeywell International Inc., Romil Ltd., Tedia Company, Inc., Alfa Aesar (Thermo Fisher Scientific), ACP Chemicals Inc., GFS Chemicals, Inc., J.T.Baker (Avantor), Kanto Chemical Co., Inc., Spectrum Chemical Mfg. Corp., Lichrosolv (Merck KGaA), Chemsol India, CP Chemicals, Daejung Chemicals & Metals Co., Ltd., Reagecon Diagnostics Ltd., Secco-Solv (Merck KGaA), Wako Pure Chemical Industries Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Purity Solvent Market Key Technology Landscape

The technological landscape of the High Purity Solvent Market is characterized by a continuous drive for enhanced purification efficiency, improved analytical precision, and sustainable production methods. At the core of high purity solvent manufacturing are advanced purification technologies. These include sophisticated multi-stage fractional distillation, which separates components based on their boiling points with high precision, and adsorption techniques utilizing various adsorbents like activated carbon, silica, or alumina to remove specific impurities. Membrane filtration, particularly ultrafiltration and nanofiltration, is increasingly employed for particulate and microbial contaminant removal, offering energy-efficient alternatives to traditional methods. Furthermore, ion exchange resins are crucial for removing ionic impurities, while specialized chromatographic purification methods are used for achieving ultra-high purity grades required for highly sensitive applications like LC-MS.

Beyond purification, robust analytical techniques form another critical pillar of the technology landscape, ensuring the quality and integrity of high purity solvents. Gas Chromatography (GC) and High-Performance Liquid Chromatography (HPLC) coupled with various detectors (FID, ECD, UV, MS) are standard for identifying and quantifying trace organic impurities. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is essential for detecting inorganic and metallic contaminants at ultra-low levels. Spectroscopic methods, such as UV-Vis and FTIR, are used for identifying functional groups and overall purity assessment. Nuclear Magnetic Resonance (NMR) spectroscopy also provides detailed structural information on potential contaminants. These analytical tools are not only used for final product testing but are integrated throughout the manufacturing process for in-process quality control, enabling real-time adjustments and ensuring batch-to-batch consistency.

Emerging technologies are also shaping the future of the market, focusing on green chemistry principles and process intensification. This includes the development of bio-based solvents derived from renewable resources, which offer reduced environmental footprints. Continuous flow chemistry, as opposed to batch processes, is gaining traction for more efficient and safer solvent production, allowing for better control over reaction conditions and improved scalability. Advanced automation and process analytical technology (PAT) are being integrated into manufacturing lines to monitor critical quality attributes in real-time, thereby reducing human error, enhancing operational efficiency, and further elevating purity levels. These technological advancements collectively contribute to meeting the ever-increasing demands for higher purity, greater sustainability, and more cost-effective solutions in the global high purity solvent market.

Regional Highlights

- North America: A mature market characterized by significant R&D investments in pharmaceuticals and biotechnology. The presence of leading research institutions and a robust electronics industry drives consistent demand for ultra-high purity solvents. Stringent regulatory frameworks from agencies like the FDA also ensure high quality standards.

- Europe: Exhibits strong demand, particularly from Germany, France, and the UK, which are hubs for chemical, pharmaceutical, and automotive industries. Emphasis on green chemistry and sustainable solvent solutions is a key regional trend, driven by strict environmental regulations and consumer preference for eco-friendly products.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid industrialization, expanding electronics manufacturing bases (e.g., China, South Korea, Taiwan), and booming pharmaceutical and biotechnology sectors in countries like India and Japan. Increasing foreign direct investment and a growing middle class contribute to escalating demand for high-quality products, directly impacting solvent consumption.

- Latin America: An emerging market with growing healthcare infrastructure and increasing investments in pharmaceutical production and chemical industries, particularly in Brazil and Mexico. While smaller in scale compared to developed regions, it presents significant growth opportunities due to economic development and increasing access to advanced technologies.

- Middle East and Africa (MEA): Shows gradual growth, driven by diversification efforts from oil-dependent economies into manufacturing, healthcare, and research. Investments in new industrial complexes and the development of local pharmaceutical capabilities are slowly increasing the demand for high purity solvents, albeit from a lower base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Purity Solvent Market.- Thermo Fisher Scientific

- Merck KGaA

- Avantor (VWR International)

- FUJIFILM Wako Pure Chemical Corporation

- Honeywell International Inc.

- Romil Ltd.

- Tedia Company, Inc.

- Alfa Aesar (Thermo Fisher Scientific)

- ACP Chemicals Inc.

- GFS Chemicals, Inc.

- J.T.Baker (Avantor)

- Kanto Chemical Co., Inc.

- Spectrum Chemical Mfg. Corp.

- Lichrosolv (Merck KGaA)

- Chemsol India

- CP Chemicals

- Daejung Chemicals & Metals Co., Ltd.

- Reagecon Diagnostics Ltd.

- Secco-Solv (Merck KGaA)

- Wako Pure Chemical Industries Ltd.

Frequently Asked Questions

What are high purity solvents primarily used for?

High purity solvents are primarily used in highly sensitive applications across industries such as pharmaceuticals, biotechnology, electronics, and chemical synthesis. They are critical for drug discovery and manufacturing, DNA/RNA synthesis, semiconductor cleaning, analytical testing (e.g., chromatography), and advanced research, where even trace impurities can compromise processes or product quality.

What drives the demand for high purity solvents?

The demand for high purity solvents is driven by the continuous growth of high-tech industries, increasing stringency of regulatory standards for product quality and safety, and advancements in scientific research requiring ultra-clean reagents. Miniaturization in electronics and complex synthesis in pharmaceuticals further accelerate this demand.

What are the different grades of high purity solvents?

High purity solvents are available in various grades tailored for specific applications, including HPLC Grade, LC-MS Grade, GC Grade, Electronic Grade, Reagent Grade, Spectrophotometric Grade, ACS Grade, DNA/RNA Synthesis Grade, and Biotech Grade. Each grade specifies the maximum allowable levels of various impurities to meet particular industry requirements.

How do environmental regulations impact the high purity solvent market?

Environmental regulations significantly impact the market by encouraging the development and adoption of greener, more sustainable solvent alternatives, such as bio-based solvents or those with reduced VOC emissions. They also impose strict guidelines on solvent handling, storage, and disposal, influencing manufacturing processes and supply chain management within the industry.

What are the key challenges in the high purity solvent market?

Key challenges include the high cost associated with advanced purification technologies, stringent quality control requirements, the complexity of maintaining purity during storage and distribution, and increasing environmental concerns related to solvent usage. Developing and commercializing sustainable, high-performance green solvents also presents a significant challenge.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager