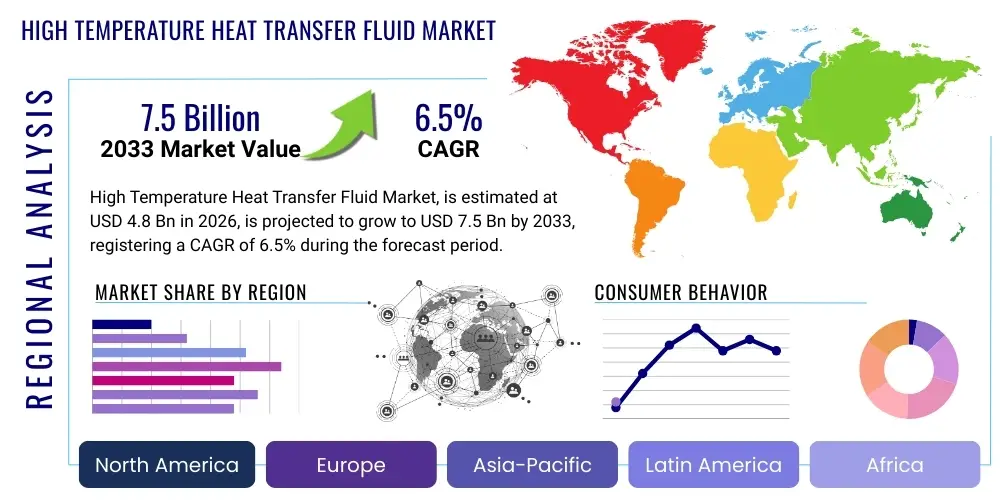

High Temperature Heat Transfer Fluid Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438687 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

High Temperature Heat Transfer Fluid Market Size

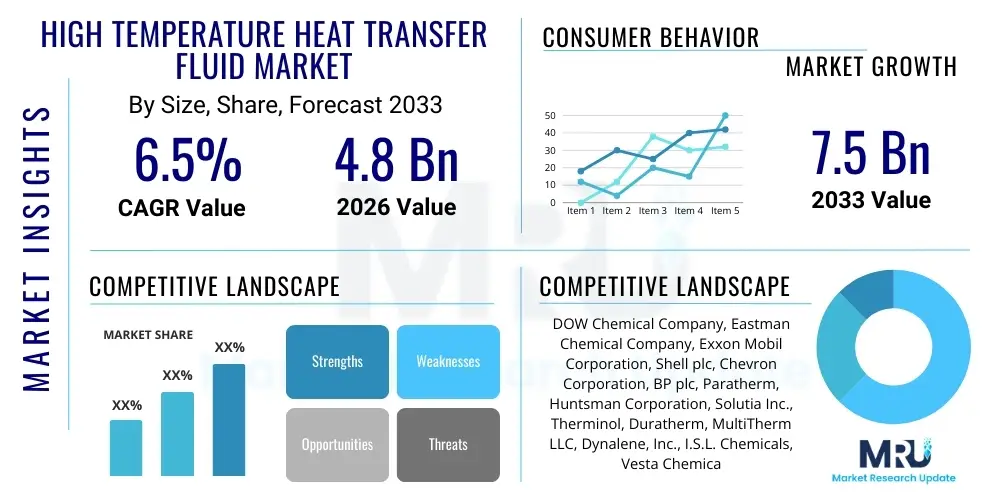

The High Temperature Heat Transfer Fluid Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by the expanding operational requirements of large-scale industrial processes, particularly within the energy sector and specialized manufacturing, which necessitate efficient and stable thermal management solutions under extreme conditions.

High Temperature Heat Transfer Fluid Market introduction

High Temperature Heat Transfer Fluids (HTHTFs) are specialized media designed to efficiently transfer thermal energy in industrial systems operating above 350°C, offering superior thermal stability and operational efficiency compared to conventional methods. These fluids, encompassing synthetic organic fluids, molten salts, and certain high-grade mineral oils, are crucial components in processes requiring precise temperature control and sustained high thermal performance, ensuring safety and optimizing productivity. Major applications span the chemical and petrochemical industry, where they are integral for reaction control and distillation, the concentrated solar power (CSP) sector, utilizing them for energy storage and generation, and the plastics and polymer manufacturing sectors for uniform heating and molding.

The primary benefits of utilizing HTHTFs include enhanced energy efficiency, reduced system downtime due to superior oxidation resistance, and the ability to operate safely at very high temperatures and low pressures, minimizing the risk associated with pressurized steam systems. Key driving factors propelling market expansion include the global surge in renewable energy projects, especially CSP plants, the continuous technological advancements leading to the development of fluids with higher thermal stability and extended lifespan, and increasing investments in industrial infrastructure across rapidly developing economies seeking to optimize energy usage and production output.

High Temperature Heat Transfer Fluid Market Executive Summary

The High Temperature Heat Transfer Fluid Market is characterized by significant business transformation, driven by the global imperative for energy efficiency and stringent environmental compliance, which favors high-performance synthetic fluids over traditional mineral oil-based products. Key business trends include increased research and development focused on bio-based and non-toxic heat transfer solutions to meet sustainability goals, coupled with strategic mergers and acquisitions aimed at consolidating specialized technology and expanding regional distribution networks. Companies are increasingly investing in sophisticated fluid analysis services to maximize operational lifecycles and ensure predictive maintenance for clients in capital-intensive industries.

Regionally, the Asia Pacific (APAC) market is exhibiting the fastest growth due to massive industrialization, high population density driving energy demand, and substantial government backing for solar power projects, particularly in China and India, making it the dominant consumer region. Conversely, North America and Europe emphasize technological innovation, focusing on upgrading existing infrastructure with advanced fluids that offer lower volatile organic compound (VOC) emissions and enhanced thermal decomposition resistance, maintaining high market value despite slower volume growth. The regulatory landscape, especially in the European Union, dictates a shift toward biodegradable and safer handling fluids.

Segment trends highlight the dominance of Synthetic Fluids, particularly Diarylethane and modified Terphenyls, within the type segment, owing to their exceptional thermal stability required by modern CSP and specialized chemical synthesis reactors. Within the application segmentation, the Concentrated Solar Power (CSP) segment is poised for explosive growth, driven by ambitious global renewable energy targets and the essential role HTHTFs play in molten salt systems for thermal energy storage (TES). The petrochemical sector remains a foundational segment, demanding consistent supply of high-grade fluids for continuous process heating cycles.

AI Impact Analysis on High Temperature Heat Transfer Fluid Market

User queries regarding AI's influence predominantly center on how artificial intelligence can optimize the performance, longevity, and safety of heat transfer fluid systems in industrial environments. Users express interest in predictive maintenance algorithms capable of analyzing real-time sensor data—such as temperature variances, pressure drops, and chemical composition changes—to forecast fluid degradation and determine the optimal time for replacement or purification, thereby reducing operational expenditure and preventing catastrophic system failure. Furthermore, there is growing curiosity about AI’s role in simulating new fluid formulations, speeding up the R&D cycle for next-generation HTHTFs with superior thermal properties, and optimizing complex process heating cycles in manufacturing plants for maximum energy efficiency.

- AI-driven Predictive Maintenance: Utilizing machine learning models to analyze fluid condition data (oxidation levels, total acid number) to accurately predict remaining fluid life and schedule preemptive maintenance.

- Optimized Process Control: AI algorithms optimize fluid flow rates and temperature setpoints in real-duty cycles, enhancing energy efficiency and preventing localized overheating or thermal stress.

- Accelerated Material R&D: Machine learning facilitates the simulation and screening of thousands of potential molecular structures for new synthetic fluids, drastically reducing the time required to develop high-stability products.

- Enhanced Safety Monitoring: AI systems continuously monitor operational parameters to detect anomalies indicative of leaks, contamination, or impending component failure, significantly improving industrial safety standards.

- Supply Chain Optimization: Leveraging AI for demand forecasting and inventory management of specialized fluids, ensuring timely delivery to critical industrial end-users.

DRO & Impact Forces Of High Temperature Heat Transfer Fluid Market

The market dynamics are defined by a confluence of strong economic drivers, significant technological opportunities, and constraining regulatory factors. Drivers, such as the global focus on sustainable energy production and the rapid expansion of industrial sectors requiring precise thermal management (e.g., specialty chemicals and plastics), are creating persistent demand. Restraints, including the high initial cost of synthetic HTHTFs, complex regulatory requirements surrounding disposal, and concerns over fluid degradation and safety risks at extremely high temperatures, temper the growth rate. Opportunities arise primarily from advancements in non-corrosive, environmentally benign fluid chemistries and the integration of these fluids into large-scale thermal energy storage systems linked to renewable power sources, offering new high-value applications.

Key drivers include the massive global investment in Concentrated Solar Power (CSP) facilities, especially in sunbelt regions, which rely on high-temperature fluids like molten salts for energy storage and generation. Furthermore, the steady growth in the chemical and petrochemical processing industries, requiring fluids capable of operating reliably under demanding conditions for synthesizing specialized polymers and fine chemicals, contributes significantly to market expansion. The technological push toward achieving higher operating efficiency in industrial boilers and reactors necessitates the adoption of thermally superior fluids, further amplifying market growth.

Restraints primarily revolve around the operational challenges inherent to these fluids. High-performance synthetic fluids often carry a significant premium compared to conventional heat transfer media, impacting the total cost of ownership, particularly for small and medium-sized enterprises. Environmental regulations, notably in Europe and North America, impose strict guidelines on the handling, recycling, and disposal of certain organic fluids, pushing manufacturers to invest heavily in biodegradable alternatives. Moreover, the risk of thermal cracking and fouling—where high temperatures break down the fluid, reducing efficiency and damaging equipment—requires constant monitoring and expensive purification or replacement procedures, acting as a major constraint.

Impact forces currently skew towards the drivers, particularly due to the global energy transition. The undeniable need for high-efficiency thermal energy storage (TES) solutions in renewable grids elevates the strategic importance of HTHTFs. Technological advancements in fluid purification systems and the synthesis of next-generation fluids with improved thermal stability and reduced toxicity are capitalizing on market opportunities, suggesting a moderate to high positive impact force propelling market value throughout the forecast period, especially as industrial giants seek operational longevity and carbon footprint reduction.

Segmentation Analysis

The High Temperature Heat Transfer Fluid market is comprehensively segmented based on the fluid type, which dictates its operating capabilities and cost structure, and the diverse applications across various heavy and specialized industries. Understanding these segments is crucial for strategic market positioning, as performance requirements vary significantly between a Concentrated Solar Power plant, demanding extreme stability and non-flammability, and a typical chemical processing unit focused on precise reaction control. The fluid types range from cost-effective mineral oils to highly specialized synthetic aromatic fluids and inorganic molten salts, each catering to distinct temperature thresholds and operational pressures. Application analysis reveals the dominant roles of the petrochemical, solar power, and heavy manufacturing sectors in driving demand and defining product specifications.

Further detailed segmentation allows market players to target specific industries with tailored product offerings that comply with industry-specific safety standards and performance benchmarks. For instance, the Food & Beverage segment requires fluids classified as non-toxic and often NSF H1 approved, while the Oil & Gas sector prioritizes thermal cracking resistance and high flash points. Regional segmentation is vital, reflecting variances in regulatory environments and the concentration of high-temperature industrial infrastructure, such as the rapid deployment of CSP in the Middle East and North Africa versus the steady modernization of chemical plants in Western Europe. This granular segmentation approach informs both manufacturing investment decisions and targeted sales strategies for global market penetration.

- By Type:

- Mineral Oils (Standard and Highly Refined)

- Synthetic Fluids

- Aromatic Fluids (e.g., Diarylethane, Alkylbenzenes)

- Silicone Fluids

- Glycol-Based Fluids (for specific temperature ranges)

- Molten Salts (Inorganic Fluids)

- By Application:

- Chemical & Petrochemical Processing

- Concentrated Solar Power (CSP)

- Oil & Gas (Refining and Production)

- Plastics, Polymers & Fiber Manufacturing

- Food & Beverage Processing

- Pharmaceuticals

- HVAC and Other Industrial Heating

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain)

- Asia Pacific (China, Japan, India, South Korea)

- Latin America (Brazil, Argentina)

- Middle East & Africa (MEA) (UAE, Saudi Arabia, South Africa)

Value Chain Analysis For High Temperature Heat Transfer Fluid Market

The value chain for the High Temperature Heat Transfer Fluid Market begins with the upstream sourcing and refining of raw materials, primarily crude oil derivatives for mineral oils, and specialized chemical precursors (such as diphenylene oxide or various silicon compounds) for synthetic fluids. Raw material quality is paramount, as purity directly influences the thermal stability and longevity of the final fluid product. Manufacturers then engage in complex synthesis and blending processes, often involving proprietary additives (antioxidants, corrosion inhibitors) to enhance performance and meet specific regulatory requirements, marking the most capital-intensive phase of the value chain, where technological expertise provides a key competitive advantage.

The distribution network forms a critical midstream link, involving specialized chemical distributors capable of handling, storing, and transporting these sensitive fluids safely and in compliance with strict chemical transportation laws. Direct distribution is common for large, continuous consumers like major petrochemical complexes or utility-scale CSP plants, where manufacturers maintain direct relationships for bulk supply and technical support. Indirect channels, using specialized third-party chemical logistics providers, serve smaller industrial end-users and regional markets, ensuring broad accessibility and localized technical support.

Downstream analysis focuses on the services integrated with the fluid supply, including installation, commissioning, maintenance, and end-of-life management. Crucial downstream activities involve fluid sampling and analysis services, which utilize advanced laboratory techniques to monitor fluid health (e.g., degradation kinetics, acidity) and recommend timely action, thereby maximizing system uptime for the end-user. The final step involves compliant recycling or disposal services for spent fluids, which is increasingly regulated, necessitating specialized partnerships between fluid providers and waste management companies to complete the sustainability loop and meet customer demands for responsible operation.

High Temperature Heat Transfer Fluid Market Potential Customers

Potential customers for High Temperature Heat Transfer Fluids are predominantly entities operating heavy industrial processes that require reliable, efficient, and sustained heat application at temperatures often exceeding 300°C. The largest buyer segments include large-scale energy producers, such as operators of Concentrated Solar Power (CSP) facilities, who purchase vast quantities of molten salts or synthetic fluids critical for thermal energy storage and conversion cycles. Chemical and petrochemical corporations represent another cornerstone, utilizing these fluids in reactors, distillation columns, and heat exchangers for processes like petroleum refining, plastic production (e.g., PET, Nylon), and synthesis of specialized fine chemicals.

Other significant end-users include manufacturers in the plastics and rubber industries, relying on precise temperature control for injection molding and extrusion processes, and the food processing sector, where fluids are used for large-scale frying, cooking, and sterilization, requiring food-grade, non-toxic options. The decision-making process for these customers is driven not merely by cost, but primarily by operational reliability, fluid thermal lifespan, safety certifications, and the depth of technical support provided by the supplier. Long-term contractual arrangements are common, emphasizing consistent supply and integrated fluid monitoring services to ensure operational continuity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | CAGR 6.5 % |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DOW Chemical Company, Eastman Chemical Company, Exxon Mobil Corporation, Shell plc, Chevron Corporation, BP plc, Paratherm, Huntsman Corporation, Solutia Inc., Therminol, Duratherm, MultiTherm LLC, Dynalene, Inc., I.S.L. Chemicals, Vesta Chemical. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Temperature Heat Transfer Fluid Market Key Technology Landscape

The technology landscape in the High Temperature Heat Transfer Fluid market is characterized by ongoing innovation aimed at enhancing thermal stability, reducing environmental impact, and extending operational life. A primary technological focus involves the refinement and synthesis of advanced aromatic fluids, such as modified terphenyls and diarylethanes, which offer significantly higher maximum operating temperatures (up to 400°C) and superior resistance to thermal cracking and oxidation compared to conventional mineral oils. This synthetic chemical engineering ensures reliable performance in demanding applications like CSP towers and high-temperature vacuum distillation units. Furthermore, advancements in specialized additive packages, including novel antioxidants and metal deactivators, are critical for mitigating corrosion and sludge formation within industrial systems, thereby protecting expensive equipment and ensuring continuous heat transfer efficiency.

Another crucial technological area is the development and commercial deployment of inorganic heat transfer media, notably molten salt technology, which is essential for large-scale thermal energy storage (TES) in the CSP sector. Molten salts (typically mixtures of sodium, potassium, and lithium nitrates) boast exceptional thermal stability, non-flammability, and high volumetric heat capacity, enabling them to store vast amounts of energy at temperatures exceeding 550°C. While requiring complex handling systems to prevent freezing, their integration is pivotal for making solar energy dispatchable, representing a significant technological shift impacting market demand towards specialized fluids and storage systems.

The peripheral technology supporting the fluid itself, known as fluid monitoring and purification technology, is rapidly evolving. Advanced sensor technologies, often coupled with AI-driven predictive analytics, allow real-time monitoring of fluid parameters like viscosity, acid number, and particle contamination without requiring system shutdowns. In-line filtration and fluid reclamation technologies, which chemically or physically remove degradation byproducts and contaminants, significantly extend the operational lifespan of expensive synthetic fluids. This focus on life-cycle management and diagnostic tools minimizes fluid consumption and waste, aligning technological advancements with sustainability goals and providing substantial cost savings to end-users.

Regional Highlights

The global market for High Temperature Heat Transfer Fluids exhibits diverse growth dynamics across major geographical regions, heavily influenced by industrial policy, regulatory structures, and the maturity of renewable energy infrastructure.

- Asia Pacific (APAC): APAC represents the most dynamic and fastest-growing regional market, primarily driven by massive infrastructure investment in China, India, and Southeast Asian nations. The region's expanding chemical and petrochemical industries, coupled with rapidly increasing power generation needs, fuel demand for all types of HTHTFs. China, in particular, is a global leader in both CSP deployment and high-volume plastics manufacturing, necessitating consistent supply of both synthetic and mineral oil-based fluids. The relaxed regulatory environment compared to Western counterparts, combined with lower operational costs, facilitates aggressive market expansion, making it a critical hub for both consumption and production.

- North America (NA): North America is a highly mature market characterized by stringent safety regulations and a strong emphasis on high-performance, long-life synthetic fluids. Growth is fueled by the continuous modernization of aging chemical facilities and refineries, demanding fluids with lower maintenance requirements and superior thermal properties. The U.S. remains a key market, focusing intensely on fluid analysis and purification services to extend the operational life of existing fluid inventories. Innovation and environmental compliance drive regional strategy, favoring suppliers who offer non-fouling, low-toxicity fluid solutions.

- Europe: Europe is defined by its leadership in environmental regulation, driving the demand for bio-based and non-hazardous heat transfer fluids. Although industrial growth is steadier than in APAC, the region's commitment to decarbonization and the extensive network of district heating and specialized chemical production facilities ensure consistent high-value demand. Countries like Germany and Spain are critical due to their specialized chemical industries and early adoption of concentrated solar technology. The European market prioritizes fluid efficiency, compliance with REACH regulations, and sustainable end-of-life disposal methods.

- Middle East and Africa (MEA): MEA is rapidly emerging as a high-potential market, largely dominated by major CSP projects and extensive oil and gas operations. Countries such as the UAE, Saudi Arabia, and Morocco are investing heavily in CSP technology to diversify their energy mix, creating a significant demand surge for molten salts and advanced synthetic fluids. The ongoing expansion of petrochemical complexes across the Arabian Gulf also guarantees robust, long-term demand for thermally stable HTHTFs for refining and processing.

- Latin America: The market in Latin America, led by Brazil and Argentina, shows stable growth supported by expanding chemical manufacturing bases and increasing investment in food processing and industrial machinery manufacturing. While mineral oils still hold a strong position due to cost constraints, rising industrial standards and complexity are slowly driving adoption of specialized synthetic fluids.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Temperature Heat Transfer Fluid Market.- DOW Chemical Company

- Eastman Chemical Company

- Exxon Mobil Corporation

- Shell plc

- Chevron Corporation

- BP plc

- Paratherm

- Huntsman Corporation

- Solutia Inc. (Now integrated into Eastman Chemical)

- Therminol (Eastman Chemical product line)

- Duratherm

- MultiTherm LLC

- Dynalene, Inc.

- I.S.L. Chemicals

- Vesta Chemical

- Radco Industries

- Clariant AG

- Lanxess AG

- Global Heat Transfer

- Sonneborn LLC

Frequently Asked Questions

Analyze common user questions about the High Temperature Heat Transfer Fluid market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between synthetic and mineral oil-based HTHTFs?

Synthetic fluids offer superior thermal stability and higher maximum operating temperatures (often above 350°C), alongside greater resistance to thermal degradation and fouling, making them essential for complex, high-stress industrial applications like Concentrated Solar Power. Mineral oils are generally more cost-effective but possess lower thermal limits and shorter operational lifespans.

Which application segment drives the highest growth in the HTHTF market?

The Concentrated Solar Power (CSP) segment is projected to exhibit the highest growth rate due to global efforts in energy transition and the critical reliance of CSP plants on specialized fluids (especially molten salts) for efficient thermal energy generation and storage, ensuring power dispatchability.

What are the key safety considerations when using high-temperature heat transfer fluids?

Key safety considerations involve managing the fluid’s flash point, ensuring proper system sealing to prevent leaks or exposure to air (which causes oxidation), and diligent monitoring for thermal cracking, which can produce volatile and flammable degradation byproducts. Specific regulations regarding fluid toxicity and required personal protective equipment (PPE) must be strictly followed.

How does AI contribute to extending the lifespan of heat transfer fluids?

AI significantly extends fluid lifespan by employing predictive maintenance algorithms that analyze real-time sensor data to accurately forecast fluid degradation kinetics, enabling operators to schedule preemptive purification or additive treatments precisely when needed, rather than relying on fixed replacement schedules, thereby minimizing waste and maximizing utilization.

Which region currently holds the largest market share for HTHTFs?

Asia Pacific (APAC), particularly China and India, holds the largest market share by volume and value due to the vast scale of their industrial expansion, including rapid growth in petrochemical processing, plastics manufacturing, and substantial governmental investment in large-scale renewable energy infrastructure projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager