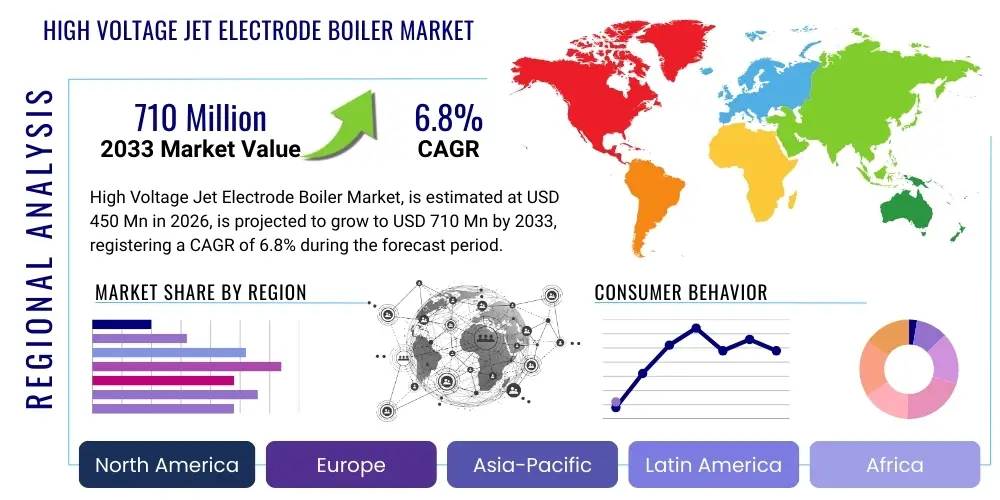

High Voltage Jet Electrode Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436747 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

High Voltage Jet Electrode Boiler Market Size

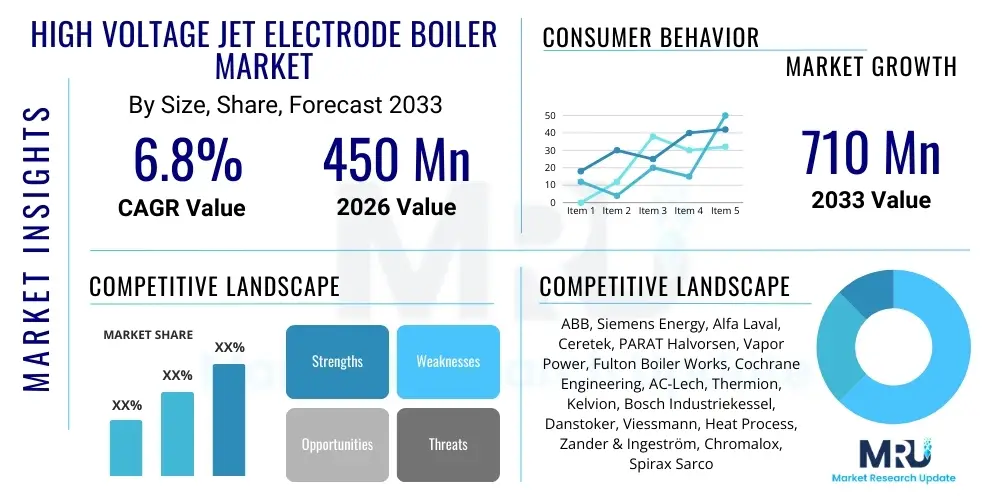

The High Voltage Jet Electrode Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $450 Million in 2026 and is projected to reach $710 Million by the end of the forecast period in 2033.

High Voltage Jet Electrode Boiler Market introduction

The High Voltage Jet Electrode Boiler (HVJEB) market encompasses specialized industrial heating systems that utilize electricity passed directly through water to generate steam or hot water efficiently, often operating at voltages exceeding 6 kV, with high voltage models typically ranging from 10 kV to 36 kV. These systems rely on the electrical resistivity of water, where the jet electrodes submerge into the water, and the electrical resistance creates heat directly within the water mass, achieving conversion efficiencies close to 99%. Unlike traditional resistance boilers, jet electrode boilers handle higher power inputs (up to 100 MW or more) and are primarily used in heavy industrial processes and large-scale district heating networks where substantial steam or thermal energy is required.

Major applications of HVJEBs include industrial sectors such as chemical processing, pulp and paper, food and beverage, and especially in large utility-scale Power-to-Heat (P2H) installations. The inherent benefit of these boilers lies in their capacity for rapid response and flexible operation, making them instrumental in utilizing surplus renewable energy (wind and solar) and stabilizing electrical grids. By converting excess electricity into storable thermal energy, HVJEBs decouple electricity generation from heat demand, providing a crucial element in modern energy transition strategies aimed at deep decarbonization of the heating sector.

The driving factors for market expansion are intrinsically linked to global climate policy, regulatory pressures mandating industrial decarbonization, and the increasing intermittency of renewable energy sources. The requirement for reliable, emission-free heating solutions that can integrate seamlessly with fluctuating grid loads positions HVJEBs as a preferred technology. Furthermore, the decreasing capital costs associated with high-voltage electrical infrastructure and the long operational lifespan of electrode boilers contribute significantly to their favorable total cost of ownership (TCO) compared to fossil fuel alternatives.

High Voltage Jet Electrode Boiler Market Executive Summary

The global High Voltage Jet Electrode Boiler market is experiencing robust growth driven by the imperative need for industrial heat decarbonization and enhanced grid flexibility. Business trends indicate a significant shift among heavy industries towards electrifying thermal processes, moving away from natural gas and oil-fired systems. This transition is accelerating investments in high-capacity boiler systems capable of integrating with Power Purchase Agreements (PPAs) tied to renewable energy generation. Key technological advancements center around optimizing control systems for faster load ramping and improving water quality management to maximize electrode longevity, thus reducing maintenance downtime and improving overall system reliability and efficiency for industrial end-users.

Regionally, Europe and North America currently dominate the market due to stringent carbon emission regulations, mature district heating infrastructures, and substantial investments in renewable energy integration programs (P2H). The European Union’s commitment to achieving net-zero emissions by 2050 places HVJEBs at the core of their energy storage and industrial modernization strategies. The Asia Pacific region, particularly China and India, is emerging as a high-growth area, fueled by rapid industrialization coupled with increasing energy security concerns, prompting adoption of large-scale electric boiler solutions for cleaner industrial parks and city heating projects.

Segment-wise, the Power-to-Heat application segment holds the largest market share and is projected to exhibit the highest CAGR, primarily because utilities and grid operators are increasingly deploying HVJEBs as non-generating assets to manage transmission congestion and frequency deviations caused by renewable energy influx. In terms of voltage level, the Above 20 kV segment is seeing rapid adoption, reflecting the market’s gravitation toward higher power capacities and integration with utility-scale transmission infrastructure. Component segments are focused on advanced control systems and smart automation capabilities, enabling predictive maintenance and optimizing operational performance based on real-time grid signals and heat demand fluctuations, thereby maximizing the economic return for asset owners.

AI Impact Analysis on High Voltage Jet Electrode Boiler Market

Common user inquiries regarding the intersection of Artificial Intelligence (AI) and the High Voltage Jet Electrode Boiler Market predominantly focus on optimizing operational efficiency, managing complex grid interactions, and enhancing predictive maintenance. Users frequently ask how AI can predict fluctuations in electricity prices to determine optimal boiler activation schedules, ensuring the boilers run when surplus renewable electricity is cheapest or when grid ancillary services pricing is highest. Concerns also revolve around the use of machine learning algorithms for diagnosing electrode wear patterns and potential system failures before they occur, minimizing the high costs associated with unexpected downtime. Furthermore, interest exists in how AI can integrate HVJEB operational data with broader building management systems or industrial process control networks for holistic energy management.

The application of AI in this niche market is poised to transform HVJEBs from static heat generators into highly dynamic, responsive grid assets. Machine learning models analyze massive datasets comprising real-time electricity market prices, weather forecasts, grid load parameters, and historical boiler performance metrics to generate prescriptive activation schedules. This optimization capability allows industrial and utility owners to leverage the boiler not just for heat, but also as a revenue-generating component providing balancing services back to the grid. This shift enhances the economic viability of electric boilers, accelerating their adoption in highly competitive industrial settings.

Moreover, AI algorithms are instrumental in fine-tuning the complex control loops required for stable, efficient operation at high voltages. They monitor parameters such as conductivity, pressure, and temperature deviations with microsecond precision, enabling rapid adjustments to the jet flow and power input to maintain peak efficiency (near 99%) while ensuring safety and compliance. This deep analytical capability also extends to simulating various operational scenarios, allowing engineers to better size and commission new installations based on anticipated future energy market dynamics, positioning AI as a crucial enabler for next-generation HVJEB deployment.

- AI-driven Predictive Maintenance: Utilizing ML to analyze vibration, acoustic, and electrical signatures to forecast electrode degradation and component failure, significantly reducing unscheduled maintenance.

- Grid Price Arbitrage Optimization: Implementation of deep learning models to predict volatile electricity prices (especially negative pricing events) and automate boiler activation to maximize arbitrage opportunities and P2H profitability.

- Real-Time Load Modulation: AI algorithms enable sub-second response times for load shedding and ramping, enhancing the boiler’s capability to provide essential frequency regulation and ancillary services to the transmission grid.

- Process Integration and Synergy: Using AI to synchronize boiler operation seamlessly with existing industrial process heat demands, renewable energy generation schedules, and thermal storage capacities for holistic energy system management.

- Enhanced Safety Monitoring: AI systems continuously monitor operational envelopes for high voltage safety compliance and detect anomalies that could lead to electrical fault conditions or pressure system failures faster than traditional control logic.

DRO & Impact Forces Of High Voltage Jet Electrode Boiler Market

The market expansion is heavily driven by global decarbonization mandates and the unique operational flexibility HVJEBs offer for managing intermittent renewable energy. However, growth is tempered by substantial initial capital outlay and complexities associated with high-voltage infrastructure installation and regulatory hurdles concerning feedwater purity. Significant opportunities exist in the expansion of district heating networks globally and the integration of these boilers with advanced thermal energy storage solutions, magnifying their value proposition as crucial components in future smart energy grids. The primary impact forces are regulatory mandates pushing for emission reduction, the volatile pricing structure of natural gas versus electricity tariffs, and the speed of renewable energy deployment, which dictates the need for flexible load management assets.

Key drivers include the transition towards Power-to-X technologies, where electric boilers serve as foundational energy conversion devices, and supportive government policies such as tax incentives and subsidies for industrial electrification. The superior efficiency (nearly 100%) and zero direct emissions profile make them environmentally and economically appealing in regions with high carbon taxes. Furthermore, the inherent safety profile of HVJEBs, which avoids combustion and associated explosion risks, is increasingly favored in confined industrial environments, adding to the driving forces promoting adoption over conventional fossil fuel boilers.

Restraints primarily encompass the need for highly sophisticated water treatment plants, as the electrode system relies on precise electrical conductivity of the water; deviations can lead to reduced efficiency or operational failure, necessitating specialized maintenance skills. The major initial investment in high-voltage transformers, switchgear, and safety interlocking systems also presents a high barrier to entry for smaller industrial players. Opportunities, conversely, lie in developing modular, containerized HVJEB solutions for faster deployment and integrating advanced cybersecurity measures to protect the sophisticated control systems from grid-level threats, thereby increasing utility confidence in these vital grid assets.

Segmentation Analysis

The High Voltage Jet Electrode Boiler market is strategically segmented based on crucial attributes including Application, Voltage Level, and Component, reflecting the diverse requirements of industrial users and utility operators. Segmentation by application clearly delineates the market penetration across different end-use sectors, with utility-scale Power-to-Heat systems exhibiting distinct demands for size and control compared to conventional Industrial Steam generation needs. Understanding these application differences is vital for manufacturers to tailor boiler capacity and integration features.

The Voltage Level segmentation (e.g., 10 kV to 20 kV versus Above 20 kV) is critical as it relates directly to the maximum power output capability and the infrastructure required for connectivity. Higher voltage boilers are synonymous with higher power ratings, making them exclusively suitable for massive district heating systems and balancing power stations, while medium voltage units cater to mid-sized industrial campuses. This structural differentiation influences pricing, installation complexity, and the target customer base, heavily informing market strategy.

Component segmentation—including the electrode systems, complex control and automation packages, and sophisticated feedwater treatment systems—highlights the technological focus areas for innovation. The performance and longevity of the jet electrodes and the precision of the conductivity control systems are key differentiators, directly impacting the TCO and operational reliability of the entire boiler installation, thus forming the basis of competitive advantages in the component supply chain.

- By Application:

- Industrial Steam Generation (Pulp & Paper, Chemical, Food & Beverage)

- District Heating Systems (City-wide heat grids, campus heating)

- Power-to-Heat (Grid Balancing, Renewable Energy Curtailment Mitigation)

- By Voltage Level:

- 10 kV to 20 kV (Medium-to-Large Industrial Applications)

- Above 20 kV (Utility-Scale and High-Capacity P2H)

- By Component:

- Jet Electrode Systems and Vessels

- Control and Automation Systems (PLC, SCADA integration)

- Feedwater Treatment Systems (Deaerators, Softeners, Chemical Dosing)

- High Voltage Switchgear and Transformers

Value Chain Analysis For High Voltage Jet Electrode Boiler Market

The value chain for the High Voltage Jet Electrode Boiler market begins with the upstream sourcing of high-grade materials, including specialized pressure vessel steel, high-purity electrode materials (often high-alloy metals), and precision electrical components such as insulators and high-voltage bushings. Upstream analysis focuses heavily on supplier stability, material quality consistency, and adherence to stringent pressure equipment and electrical safety standards (e.g., ASME, PED). Key suppliers include specialized metallurgical companies and high-voltage component manufacturers. Efficiency in this stage directly impacts the final boiler vessel integrity and electrical performance.

The manufacturing stage involves highly specialized fabrication processes, including pressure vessel welding, precise electrode assembly, and the integration of sophisticated control systems. Market leaders often maintain proprietary designs for jet electrode configurations to optimize heat transfer efficiency and minimize erosion. Following manufacturing, distribution channels are crucial. Due to the custom, project-based nature of these large systems, distribution is typically direct from the manufacturer to the industrial end-user or through highly specialized Engineering, Procurement, and Construction (EPC) firms that handle the integration into complex plant environments. Indirect channels are rare and generally limited to local representatives providing after-sales support rather than equipment sales.

Downstream analysis centers on installation, commissioning, and long-term service and maintenance. Since HVJEBs are critical assets, manufacturers must provide extensive support, including specialized training for operating high-voltage equipment and supplying proprietary replacement parts, particularly jet electrodes and highly precise conductivity probes. The final link in the chain is the end-user (e.g., utility, chemical plant) whose feedback drives continuous product improvement concerning reliability, integration capabilities (SCADA/DCS), and energy consumption profiles. The high service requirement post-sale ensures that the relationship between the manufacturer and customer remains long-term and consultative.

High Voltage Jet Electrode Boiler Market Potential Customers

The primary customers for High Voltage Jet Electrode Boilers are organizations with significant, consistent thermal energy demands coupled with the strategic imperative to decarbonize or leverage grid electricity flexibility. Utility companies and Independent Power Producers (IPPs) represent a massive end-user segment, particularly those involved in operating or supplying energy to district heating networks, using the boilers for load balancing and thermal storage capabilities essential for accommodating large penetration of intermittent renewable sources like wind and solar power. These entities view HVJEBs as essential non-combustion assets for grid reliability.

Another major segment includes heavy industrial enterprises, predominantly within the chemical, pulp and paper, and large food and beverage processing sectors. These industries require substantial volumes of process steam or hot water, and the shift to electrification is driven by high carbon taxes, environmental permits, and corporate sustainability goals. For these users, the high efficiency and lack of local emissions are compelling factors, allowing them to maintain operational output while meeting increasingly stringent environmental regulations.

Finally, municipal governments and large institutional campuses (universities, military bases) that manage their own decentralized power and heating systems are increasingly adopting HVJEBs. These customers often seek robust, long-lifespan heating solutions that eliminate onsite fuel storage and handling complexities, offering safer and cleaner operation within urban or dense campus settings. The move towards establishing local microgrids and ensuring energy resilience further propels the adoption among these institutional buyers looking for reliable, electric-based heating solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450 Million |

| Market Forecast in 2033 | $710 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB, Siemens Energy, Alfa Laval, Ceretek, PARAT Halvorsen, Vapor Power, Fulton Boiler Works, Cochrane Engineering, AC-Lech, Thermion, Kelvion, Bosch Industriekessel, Danstoker, Viessmann, Heat Process, Zander & Ingeström, Chromalox, Spirax Sarco, Babcock Wanson, Indeck Power Equipment |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Voltage Jet Electrode Boiler Market Key Technology Landscape

The core technology underpinning the High Voltage Jet Electrode Boiler market revolves around the efficient transfer of electrical energy into thermal energy using the principle of electrical resistance in water. Key innovations focus on the jet electrode assembly itself, which must manage extremely high current densities and prevent localized arcing or hot spots. Modern designs utilize advanced geometry for electrode alignment and spacing to ensure uniform heating across the entire vessel volume, maximizing efficiency and minimizing wear. Furthermore, the development of robust, specialized insulating materials capable of withstanding high voltage and high temperature steam environments is paramount for system safety and longevity, driving continuous R&D in materials science.

A critical technological focus area is the precise control and instrumentation required for seamless operation, especially when integrated into utility-scale Power-to-Heat applications. This includes sophisticated conductivity monitoring systems that automatically adjust the feedwater quality or implement blowdown procedures to maintain the precise level of electrical resistance needed for stable power draw. Advanced control packages, often using integrated PLCs and SCADA systems, enable rapid load changes (ramping up or down within seconds) in response to grid signals, allowing the boiler to participate in lucrative ancillary services markets, which is a major technological differentiator for leading vendors.

Furthermore, technology development is heavily geared towards maximizing system flexibility and modularity. Manufacturers are increasingly offering skid-mounted or containerized solutions to reduce installation time and complexity, making them attractive for fast-track industrial projects or temporary installations. Integration with external thermal energy storage (TES) solutions, such as pressurized hot water tanks or molten salt storage, is also a key technological trend. This pairing allows the HVJEB to generate heat during periods of low electricity cost (or surplus generation) and store it for later use, dramatically increasing the economic return and utility value of the installation in a highly dynamic energy landscape.

Regional Highlights

- Europe: Europe is the undisputed market leader, propelled by ambitious renewable energy targets and well-established, extensive district heating networks across Scandinavia, Germany, and Central Europe. The implementation of high carbon pricing mechanisms and regulatory frameworks favoring industrial electrification (such as the EU Green Deal) strongly incentivize the replacement of gas and oil boilers with zero-emission HVJEBs. Countries like Denmark, Germany, and Finland are pioneers in large-scale Power-to-Heat projects, utilizing these boilers for grid stabilization, absorbing excess wind power, and providing reliable urban heating.

- North America: The North American market, dominated by the United States and Canada, is characterized by diverse energy markets and increasing investment in grid modernization and decarbonization initiatives, particularly in regions with high renewable energy penetration (e.g., California, Texas, and the Pacific Northwest). Demand is robust from major industrial users seeking to comply with emerging state-level emission standards. The market is also driven by the need for flexible assets that can respond quickly to regional transmission operator signals, making HVJEBs appealing for utility-scale energy storage and balancing services.

- Asia Pacific (APAC): APAC represents the fastest-growing region, primarily due to rapid industrial expansion, urbanization, and a severe focus on mitigating urban air pollution caused by coal and fossil fuels. China and South Korea are leading the adoption, investing heavily in centralized heating systems and large-scale industrial parks that prioritize electric-based heating solutions. While the initial regulatory environment might be less stringent than in Europe, the sheer scale of industrial demand and government commitment to improving air quality ensures substantial, long-term market growth for high-capacity electric boilers.

- Latin America: The market in Latin America is nascent but promising, tied closely to the development of hydroelectric and geothermal resources, which provide stable, low-carbon electricity sources suitable for running HVJEBs. Key opportunities are emerging in industrial sectors such as mining and minerals processing (Chile, Brazil) which seek to decarbonize their operational footprints and leverage abundant local renewable energy. Market growth is dependent on ongoing infrastructure investments and governmental support for transitioning industrial energy consumption patterns.

- Middle East and Africa (MEA): The MEA market is currently small, primarily focusing on high-end industrial applications in petrochemicals and specialized manufacturing. However, the Gulf nations’ ambitious renewable energy projects (solar and wind) and diversification strategies away from oil dependency are expected to spur future demand for P2H solutions that can utilize surplus renewable power. Implementation in this region will be gradual, focusing initially on large, state-owned energy infrastructure projects that prioritize long-term asset reliability and energy independence strategies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Voltage Jet Electrode Boiler Market.- ABB

- Siemens Energy

- Alfa Laval

- Ceretek

- PARAT Halvorsen

- Vapor Power

- Fulton Boiler Works

- Cochrane Engineering

- AC-Lech

- Thermion

- Kelvion

- Bosch Industriekessel

- Danstoker

- Viessmann

- Heat Process

- Zander & Ingeström

- Chromalox

- Spirax Sarco

- Babcock Wanson

- Indeck Power Equipment

Frequently Asked Questions

Analyze common user questions about the High Voltage Jet Electrode Boiler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a High Voltage Jet Electrode Boiler in the modern energy system?

The primary function is to convert surplus or low-cost renewable electricity directly into thermal energy (steam or hot water) with nearly 100% efficiency. They serve as crucial Power-to-Heat assets, providing load flexibility to the electrical grid, preventing renewable energy curtailment, and facilitating industrial decarbonization by replacing fossil fuel boilers.

How do High Voltage Jet Electrode Boilers contribute to grid stability and renewable energy integration?

HVJEBs act as large, flexible loads that can rapidly absorb significant amounts of electricity when renewable generation exceeds demand. This rapid ramp-up capability helps stabilize grid frequency, balance supply and demand fluctuations, and allows utilities to maximize the utilization of intermittent sources like wind and solar power.

What is the typical lifespan and required maintenance for the critical components of a jet electrode boiler?

The main pressure vessel of a High Voltage Jet Electrode Boiler often has a design life exceeding 30 years. Critical jet electrodes, while robust, require periodic inspection and eventual replacement (typically every 5 to 10 years, depending on operational load and feedwater quality). Maintenance is primarily focused on strict water chemistry management and routine electrical system checks.

What are the significant cost hurdles associated with implementing a High Voltage Jet Electrode Boiler?

The most significant cost hurdles are the initial Capital Expenditure (CapEx), which includes the cost of the specialized boiler vessel, complex control systems, and essential high-voltage switchgear and transformers required to connect to the transmission network. Furthermore, rigorous feedwater treatment systems add to the initial investment complexity.

Which industrial sectors are the leading adopters of High Voltage Jet Electrode Boiler technology?

The leading adopters are utilities for large-scale District Heating and grid balancing, followed by energy-intensive industrial sectors such as Pulp and Paper, Chemicals and Petrochemicals, and large-scale Food and Beverage processing, all of which require reliable, high-pressure steam for their core manufacturing operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager