Hipot & Electrical Safety Testers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436806 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Hipot & Electrical Safety Testers Market Size

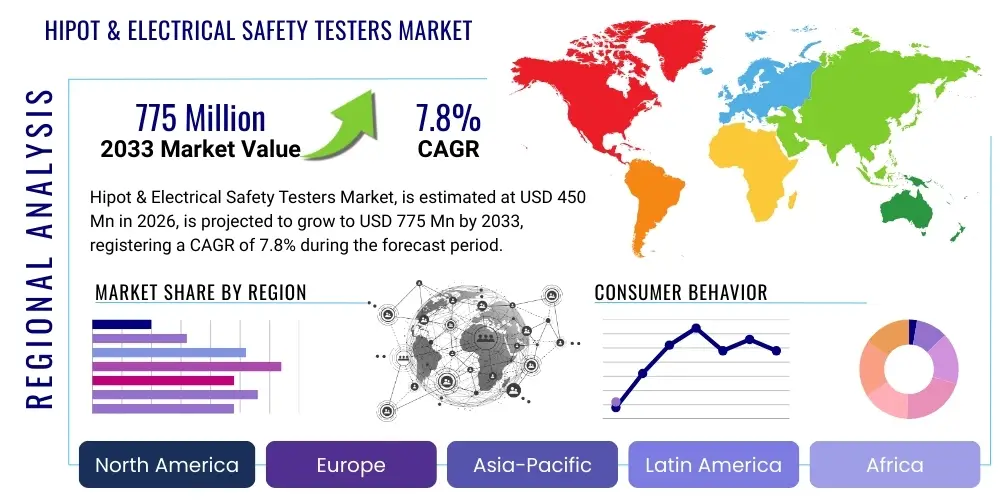

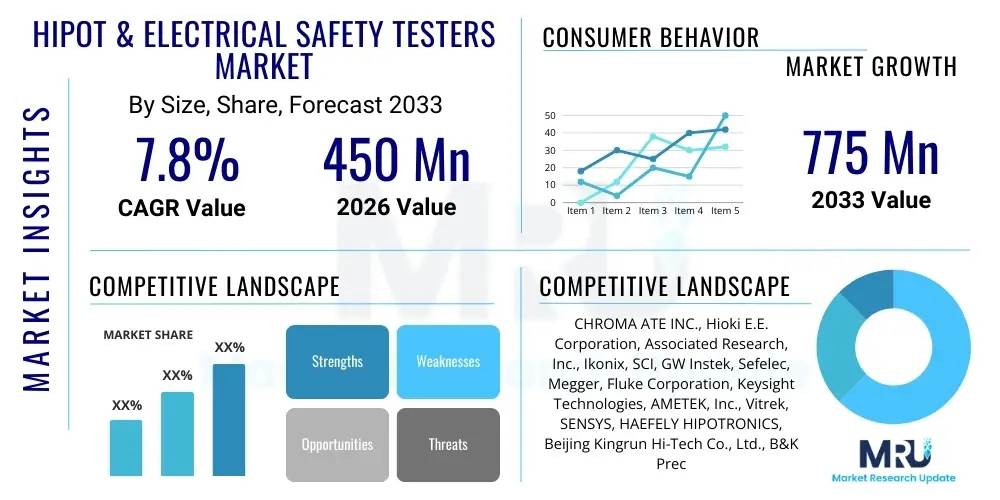

The Hipot & Electrical Safety Testers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 775 Million by the end of the forecast period in 2033.

Hipot & Electrical Safety Testers Market introduction

The Hipot (High Potential) and Electrical Safety Testers Market encompasses specialized equipment designed to verify the integrity and insulation strength of electrical devices and components. These testers are crucial for ensuring compliance with international safety standards such as IEC, UL, and CE. The primary function of Hipot testing is to apply a high voltage across two points to check for leakage current or insulation breakdown, confirming that the product is safe for end-users and can withstand operational stresses. This market segment includes various devices such as AC Hipot testers, DC Hipot testers, insulation resistance testers, ground bond testers, and leakage current meters, all integral components of quality control and compliance regimes across manufacturing industries.

The widespread adoption of these testing instruments is driven by the increasing complexity of electronic devices, stringent regulatory environments mandating zero-defect standards for electrical safety, and the continuous growth in sectors like automotive, consumer electronics, and renewable energy. Manufacturers prioritize these testers to mitigate risks associated with electrical faults, including fire hazards and equipment failure, thereby protecting brand reputation and avoiding costly recalls. The market is characterized by ongoing innovation focused on automation, enhanced precision, and integration into modern production lines.

Major applications span electrical appliance manufacturing, aerospace and defense, medical devices, industrial machinery, and power distribution infrastructure. Key benefits include enhanced product reliability, mandatory regulatory compliance, reduction of liability, and improved operational safety. Driving factors primarily involve expanding global manufacturing activities, growing consumer demand for certified safe electronic goods, and technological advancements leading to portable and multifunction testing solutions.

Hipot & Electrical Safety Testers Market Executive Summary

The Hipot & Electrical Safety Testers Market is poised for substantial growth, primarily fueled by rising global safety standards and the acceleration of electrification across transportation and industrial sectors. Business trends indicate a strong shift towards automated, multi-function test solutions that reduce manual errors and improve throughput on high-volume production lines. Manufacturers are investing heavily in testers capable of handling increased voltage demands associated with electric vehicles (EVs) and high-voltage industrial applications. Furthermore, subscription-based models for calibration services and software integration are emerging as key revenue streams for leading vendors, providing continuous compliance assurance to clients.

Regionally, Asia Pacific (APAC) dominates the market due to robust manufacturing activities in China, Japan, South Korea, and India, coupled with significant investment in power generation and distribution infrastructure. North America and Europe maintain strong market shares driven by stringent regulatory frameworks and high adoption rates of advanced automated testing systems in aerospace and medical device production. Emerging markets in Latin America and MEA are showing rapid growth potential as industrialization accelerates and regulatory bodies enforce stricter safety protocols on imported and locally manufactured electrical goods.

Segmentation trends highlight the dominance of the AC Hipot Testers segment due to their applicability across general electronics and appliances. However, DC Hipot and Insulation Resistance Testers are rapidly gaining traction, particularly in the renewable energy and high-voltage DC system sectors. In terms of end-users, the industrial and manufacturing sector remains the largest consumer, while the automotive segment is projected to exhibit the highest CAGR, propelled by the urgent need for comprehensive safety testing in EV battery systems, charging infrastructure, and high-voltage components.

AI Impact Analysis on Hipot & Electrical Safety Testers Market

Common user inquiries regarding AI's influence in the Hipot & Electrical Safety Testers Market typically revolve around whether AI can automate fault detection, predict insulation failures before they occur, and enhance data interpretation during high-volume testing. Users are concerned about integrating complex AI algorithms with existing legacy testing hardware and the potential requirements for massive datasets for effective machine learning model training. Expectations focus on AI reducing false positive rates, improving the speed of root cause analysis, and making testing regimes adaptive rather than static. The core theme is leveraging AI not just for pass/fail decisions, but for preventative maintenance and quality prediction.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into Hipot and Electrical Safety Testing procedures is transforming the efficiency and reliability of quality assurance processes. AI algorithms are increasingly being used to analyze complex, multi-variable test data, such as leakage current curves over time, partial discharge measurements, and voltage stress patterns. This analysis capability allows manufacturers to identify subtle anomalies or deteriorating insulation characteristics that might be missed by traditional fixed threshold testing methods, thus leading to predictive failure analysis and enhanced product longevity.

Furthermore, AI-driven systems contribute significantly to AEO/GEO goals by optimizing test sequences and operational parameters. By learning from historical test results and production conditions, AI can dynamically adjust the test voltage ramps or dwell times to ensure thorough testing without inducing unnecessary stress on components, thereby balancing speed and diagnostic depth. This predictive approach minimizes testing time while maximizing data fidelity, providing actionable insights into manufacturing process variations that affect long-term electrical safety.

- AI-driven Predictive Maintenance: Analyzing insulation degradation trends to anticipate failures before mandatory test limits are exceeded.

- Automated Anomaly Detection: Utilizing machine learning to identify non-standard leakage current signatures, improving diagnostic accuracy.

- Optimized Test Protocols: Dynamically adjusting test parameters based on historical failure rates and material variations.

- Enhanced Data Interpretation: Simplifying complex partial discharge and dielectric breakdown data for non-expert operators.

- Reduced False Positive Rates: Improving the distinction between measurement noise and genuine electrical faults through pattern recognition.

DRO & Impact Forces Of Hipot & Electrical Safety Testers Market

The market for Hipot and Electrical Safety Testers is fundamentally driven by stringent global regulatory standards (D), particularly in high-risk sectors like aerospace, medical devices, and electric vehicles, necessitating mandatory compliance testing. However, the high initial capital expenditure (R) required for advanced, automated multi-channel testers, combined with the continuous need for periodic calibration and skilled operator training, presents a significant restraint, especially for small and medium enterprises (SMEs). The widespread shift towards electrification, notably the rapid expansion of the Electric Vehicle (EV) industry and grid modernization initiatives, offers substantial opportunities (O) for manufacturers of high-voltage DC and AC testers.

Key impact forces shaping this market include the escalating focus on industrial automation (Impact Force 1), which demands seamless integration of testing equipment with factory execution systems (MES) and production lines, driving innovation in data connectivity and reporting capabilities. A second crucial force is the proliferation of complex electronic assemblies (Impact Force 2), requiring testers to handle multiple sequential safety checks—such as ground bond, insulation resistance, and Hipot—within a single, integrated platform. This multi-functional requirement is pushing vendors toward modular and software-defined instrumentation. The third force centers on global supply chain disruptions (Impact Force 3), which, while short-term restraints, accelerate the long-term trend toward localized, highly reliable safety compliance infrastructure.

The convergence of regulatory pressures with technological advances in component miniaturization means that testing equipment must become faster, more precise, and capable of operating under diverse environmental conditions. The increasing use of exotic materials and highly sensitive components in modern electronics requires testers with advanced diagnostic features, such as partial discharge measurement capabilities, which further elevates the market's technological barrier to entry and concurrently drives value for specialized suppliers. Successful market players are those who can effectively address the skills gap by offering intuitive, automated, and self-diagnostic testing solutions.

Segmentation Analysis

The Hipot & Electrical Safety Testers Market is comprehensively segmented based on product type, testing phase, application, and end-user industry, providing a granular view of demand dynamics across different operational environments. Segmentation by product type (AC, DC, AC/DC, Insulation Resistance, Ground Bond) reveals the diverse technical requirements across industries, with AC Hipot testers dominating the volume but DC testers showing rapid growth fueled by specialized high-voltage applications. Testing phase segmentation (Research & Development, Manufacturing/Production, Maintenance/Field Testing) highlights the differing needs for precision, speed, and portability throughout the product lifecycle.

The market structure is highly fragmented yet competitive, with segments reflecting both mature technologies and emerging high-growth niches. For instance, the manufacturing segment demands high throughput and automation, driving the adoption of multi-channel systems, while the field testing segment prioritizes ruggedness, portability, and battery life. End-user analysis is critical, showing that the growth trajectory is heavily influenced by the capital investment cycles in key sectors like automotive (EV battery testing), renewable energy (inverter and cable testing), and consumer electronics (mass production testing), each requiring tailored compliance solutions.

Understanding these segments allows market participants to tailor their offerings, moving beyond generic safety compliance tools towards specialized solutions that integrate seamlessly with specific industry requirements, such as high-temperature stability testing for aerospace components or ultra-fast cycling for consumer goods production lines. This targeted approach is essential for achieving competitive differentiation and maximizing revenue potential across varied industrial landscapes.

- Product Type:

- AC Hipot Testers

- DC Hipot Testers

- AC/DC Combined Testers

- Insulation Resistance Testers

- Ground Bond Testers (Continuity Testers)

- Leakage Current Testers

- Testing Phase:

- Research & Development (R&D) Testing

- Production Line Testing (Manufacturing)

- Field/Maintenance Testing

- End-User Industry:

- Consumer Electronics

- Automotive (Especially Electric Vehicles and Charging Infrastructure)

- Industrial Manufacturing (Machinery and Control Systems)

- Medical Devices

- Aerospace and Defense

- Power Generation and Utilities (Renewable Energy)

- Telecommunications

- Operation Type:

- Manual/Benchtop Testers

- Automated/Integrated Systems

Value Chain Analysis For Hipot & Electrical Safety Testers Market

The value chain for Hipot & Electrical Safety Testers begins with upstream suppliers, primarily providing high-precision components such as high-voltage transformers, sensitive current sensors, microprocessors, and specialized insulation materials. Manufacturers rely heavily on consistent quality and delivery from these suppliers, as the accuracy and reliability of the final testing equipment are directly tied to the quality of the core components. Research and development activities, which involve continuous improvement in waveform generation and noise reduction techniques, form a critical upstream element, ensuring testers meet increasingly complex regulatory mandates and voltage requirements, particularly for high-power DC systems.

Midstream activities involve the design, assembly, software integration, and calibration of the final testing systems. This stage is highly proprietary, requiring significant intellectual property related to safety protocols, measurement algorithms, and user interface design. Distribution channels are varied: direct sales are common for complex, high-value integrated automated systems, allowing manufacturers to provide specialized installation and training. Indirect channels, involving third-party distributors, system integrators, and authorized resellers, are often utilized for standard benchtop and portable testers, providing broader market reach and localized support, particularly in emerging markets.

Downstream activities focus on the end-user deployment and post-sales support. This includes providing mandatory calibration services, which are a major recurring revenue component for manufacturers, alongside software updates, maintenance contracts, and technical consultation services to ensure continued regulatory compliance. Potential customers, including automotive OEMs, contract manufacturers, and utility providers, demand robust support and rapid response times, underscoring the importance of a strong, localized service network to maintain operational continuity and data integrity. This focus on service ensures high customer retention and long-term market influence.

Hipot & Electrical Safety Testers Market Potential Customers

The primary potential customers and end-users of Hipot & Electrical Safety Testers are diverse, spanning virtually every sector involved in the production, installation, or maintenance of electrical and electronic equipment. Major buyers include Original Equipment Manufacturers (OEMs) in high-stakes industries such as aerospace, which mandates rigorous insulation testing for avionics and cabling, and the automotive sector, where stringent safety verification is required for high-voltage battery packs, charging systems, and electric motors to prevent critical failures. These large-scale buyers often purchase customized, high-throughput automated testing solutions integrated directly into their production lines to maximize efficiency and data logging capabilities.

Furthermore, contract manufacturing organizations (CMOs) and electronics manufacturing services (EMS) providers represent a massive buyer segment, as they must comply with the specific safety standards of multiple clients across various industries, necessitating flexible, multi-standard compliant testers. Utility companies and renewable energy providers are crucial buyers for field-testing equipment, using portable Hipot testers to verify the integrity of installed power cables, transformers, and solar panel inverter systems during installation and routine maintenance checks. The consistent need for calibration and periodic equipment replacement ensures a stable demand base from these utility operators.

Other significant customer groups include independent testing laboratories, governmental regulatory agencies, and educational institutions focused on electrical engineering and safety research. These customers prioritize high precision, documented traceability, and adaptability to a wide range of testing standards. The purchasing decision is typically driven by compliance requirements, the need for data fidelity, and the integration potential with existing quality management systems (QMS), making total cost of ownership (TCO) and long-term reliability key determinants for procurement.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 775 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CHROMA ATE INC., Hioki E.E. Corporation, Associated Research, Inc., Ikonix, SCI, GW Instek, Sefelec, Megger, Fluke Corporation, Keysight Technologies, AMETEK, Inc., Vitrek, SENSYS, HAEFELY HIPOTRONICS, Beijing Kingrun Hi-Tech Co., Ltd., B&K Precision, Slaughter Company, T&R Test Equipment, Extech Instruments. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hipot & Electrical Safety Testers Market Key Technology Landscape

The Hipot & Electrical Safety Testers market is undergoing significant technological evolution, moving beyond basic voltage application and current measurement toward sophisticated, digitalized testing methodologies. One critical technological advancement is the integration of high-speed digital signal processing (DSP) techniques, which allows for extremely rapid and precise measurement of leakage current and instantaneous breakdown detection. This technology is vital for high-volume production testing where milliseconds saved per test translate into substantial efficiency gains. Furthermore, the development of solid-state switching technology is replacing older mechanical relays, improving the lifespan and reliability of the testers while enabling faster switching between different test modes (e.g., AC Hipot to DC Insulation Resistance) without physical reconfiguration.

Another pivotal area is the adoption of advanced communication and networking capabilities. Modern testers are universally equipped with standard industrial interfaces such as Ethernet, USB, and RS-232, facilitating seamless integration with factory automation systems (Industry 4.0 environments). This connectivity enables centralized control, remote monitoring, and automated data logging, crucial for maintaining comprehensive quality records and ensuring regulatory compliance traceability. Data logging capabilities are often coupled with internal solid-state memory and cloud connectivity, enabling real-time synchronization of test results across global manufacturing sites and providing data analytics opportunities for process improvement.

The rise of complex high-voltage systems, particularly in electric vehicles, has necessitated the development of specialized testers capable of handling higher DC voltages (up to 15kV or more) and performing crucial safety tests like Partial Discharge (PD) measurement. PD detection is a key differentiator, as it identifies minute insulation defects that might not cause immediate catastrophic failure but could lead to premature product degradation. Manufacturers are investing in noise reduction techniques and sophisticated shielding to ensure accurate PD measurements, which is quickly becoming a mandatory requirement for high-reliability components in the aerospace and renewable energy sectors. Additionally, multi-functionality, consolidating all safety tests (Hipot, Ground Bond, Insulation Resistance, and Function Testing) into a single compact unit, remains a major technological focus to reduce footprint and complexity on the factory floor.

Regional Highlights

The global market for Hipot & Electrical Safety Testers displays distinct regional characteristics, driven by varying industrial development levels, regulatory environments, and manufacturing output. Asia Pacific (APAC) stands as the undisputed leader in market size and growth trajectory. This dominance is attributable to the region’s massive electronics manufacturing ecosystem, led by China, Taiwan, and South Korea, which produce the majority of the world's consumer electronics and electrical appliances. Furthermore, substantial government investments in smart grid development and renewable energy projects in India and Southeast Asia are significantly bolstering demand for high-voltage testing equipment necessary for infrastructure and utility-scale solar and wind projects. The intensity of competition in APAC manufacturing drives high demand for high-speed, automated production line testers.

North America and Europe represent mature markets characterized by high technology adoption and stringent safety standards enforced by bodies like OSHA (US) and the European Commission. These regions show consistent demand, focusing less on sheer volume and more on precision, customization, and advanced diagnostic capabilities, particularly in the highly regulated aerospace, medical device, and industrial machinery sectors. The rapid penetration of electric vehicles in both regions has created a specialized, high-growth niche for high-voltage DC safety testers, pushing manufacturers to innovate faster response times and higher voltage handling capacity for battery modules and charging stations. The demand here is primarily for advanced, fully integrated, and software-driven systems.

Latin America and the Middle East & Africa (MEA) are emerging markets experiencing accelerating industrialization and modernization of electrical infrastructure. While currently smaller in market share, these regions are projected to exhibit significant CAGRs due to increased foreign direct investment in manufacturing and heightened local regulatory enforcement aimed at improving product safety and reliability. Investment in utilities and oil & gas operations in the MEA region specifically drives the need for robust, field-portable testing equipment for maintenance and commissioning activities. Market penetration in these regions often relies on strong distribution partnerships and localized service centers to overcome logistical and technical support challenges.

- North America: Focus on high-precision medical and aerospace testing; strong growth driven by EV adoption and R&D activities; stringent UL standards compliance.

- Europe: High demand for automated, integrated systems due to Industry 4.0 initiatives; driven by rigorous CE marking and IEC standards across manufacturing.

- Asia Pacific (APAC): Largest market share due to vast electronics and appliance manufacturing base; highest volume demand for production line testers; rapid utility expansion.

- Latin America: Growing industrial base and infrastructure projects driving demand for standard benchtop and field maintenance testers.

- Middle East & Africa (MEA): Increasing investments in power generation, transmission, and oil & gas facilities necessitating reliable high-voltage field testing equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hipot & Electrical Safety Testers Market.- CHROMA ATE INC.

- Hioki E.E. Corporation

- Associated Research, Inc.

- Ikonix (Including SCI brands)

- GW Instek

- Sefelec

- Megger

- Fluke Corporation

- Keysight Technologies

- AMETEK, Inc.

- Vitrek

- SENSYS

- HAEFELY HIPOTRONICS

- Beijing Kingrun Hi-Tech Co., Ltd.

- B&K Precision

- Slaughter Company

- T&R Test Equipment

- Extech Instruments

- Good Will Instrument Co., Ltd.

- Tecpel Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Hipot & Electrical Safety Testers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Hipot Testers Market?

The primary driver is the increasing necessity for manufacturers globally to comply with highly stringent international electrical safety standards (such as IEC, UL, and CE) to mitigate product liability, ensure consumer safety, and access key export markets.

How is the Electric Vehicle (EV) industry impacting the demand for safety testers?

The EV sector is critically impacting demand by requiring specialized, high-voltage DC Hipot and Insulation Resistance testers to safely verify the integrity of high-capacity battery packs, electric motors, and charging system components, representing the fastest-growing application segment.

Which regional market holds the largest share and why?

Asia Pacific (APAC) holds the largest market share, driven by its massive, expanding manufacturing base for consumer electronics, electrical appliances, and automotive components, coupled with substantial governmental investments in power grid infrastructure and renewable energy generation.

What is the technological shift currently defining the electrical safety testing landscape?

The defining technological shift is the move toward fully automated, multi-functional testing systems integrated with factory execution systems (MES). These systems incorporate AI/ML for predictive analysis, rapid data logging, and optimized test parameter sequencing to enhance throughput and diagnostic accuracy.

What is the difference between AC Hipot and DC Hipot testing applications?

AC Hipot testing is standard for verifying the insulation strength of common AC-powered appliances and electronic components, while DC Hipot testing is typically required for components that operate under high-voltage DC stress, such as capacitors, solar panels, and high-voltage cabling in electric vehicle architectures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager