Hole Plugs- Tapered Caps Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438568 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Hole Plugs- Tapered Caps Market Size

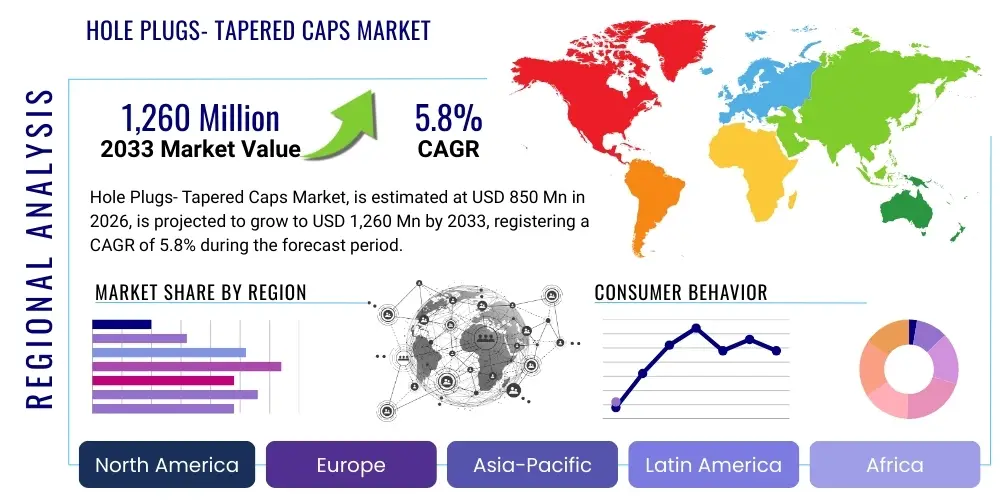

The Hole Plugs- Tapered Caps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,260 Million by the end of the forecast period in 2033.

Hole Plugs- Tapered Caps Market introduction

The Hole Plugs- Tapered Caps Market encompasses specialized plastic, rubber, and silicone components designed primarily for masking, protection, and finishing applications in diverse industrial environments. Hole plugs are essential for sealing unwanted apertures, preventing dust or debris ingress, and ensuring aesthetic finishing, while tapered caps are predominantly used during painting, powder coating, plating, and finishing processes to mask threads, studs, pipes, or ports from chemicals, heat, or abrasive treatments. These components, often manufactured using injection molding or dipping processes, provide temporary or permanent protective barriers critical for maintaining the integrity and quality of complex manufactured parts.

Major applications for these protective components span high-stakes sectors such as automotive manufacturing, aerospace engineering, heavy machinery production, and electronics assembly. In the automotive industry, for example, tapered caps protect critical connection points during E-coating or powder coating of chassis components, ensuring threads remain clear for subsequent assembly. The primary benefits derived from using high-quality hole plugs and tapered caps include enhanced efficiency in masking processes, prevention of costly rework dueable to contamination or coating defects, superior chemical and thermal resistance, and compliance with stringent quality control standards.

Driving factors for sustained market growth include the global expansion of industrial manufacturing activities, particularly in emerging economies, coupled with increasingly complex surface treatment and finishing requirements across all durable goods sectors. The rising demand for protective masking solutions that can withstand high temperatures associated with thermal spray and high-bake painting procedures is pushing innovation in material science, favoring high-performance silicone and specialized polymers. Furthermore, the imperative for companies to minimize scrap rates and improve overall product longevity continues to solidify the essential role of these protective caps and plugs in the industrial value chain.

Hole Plugs- Tapered Caps Market Executive Summary

The global Hole Plugs- Tapered Caps Market is currently characterized by robust business trends driven by the adoption of advanced materials like high-temperature vinyl and specialized silicone rubber, which cater to increasingly demanding industrial processes, particularly in high-temperature masking applications. Key business dynamics include strategic mergers and acquisitions among smaller, specialized manufacturers aiming to consolidate market share and expand product portfolios, especially towards customizable and specialty masking components. Furthermore, sustainability initiatives are influencing product development, with a growing focus on reusable, recyclable, or biodegradable plugging and capping solutions to meet evolving corporate environmental responsibilities and regulatory demands.

Regionally, the Asia Pacific (APAC) region stands out as the primary engine of growth, fueled by rapid industrialization, expansion of the automotive and electronics manufacturing bases in China, India, and Southeast Asia, and significant investments in infrastructure projects requiring durable protective components. North America and Europe maintain maturity, focusing on high-value, high-precision applications, particularly within the aerospace and medical device sectors, where stringent material traceability and performance specifications necessitate premium products. These developed markets are prioritizing automation in the application and removal of masking components to enhance process speed and repeatability.

Analysis of market segments reveals strong growth in the Silicone Material category due to its superior thermal resistance, making it indispensable for powder coating and plating processes. The End-Use segment is dominated by General Industrial applications, covering HVAC, construction components, and machinery, though Automotive and Aerospace segments exhibit the highest growth rates due to increasing production volumes and complexity of finishing requirements. Trends within the segmentation also point toward a preference for flexible, multi-purpose tapered designs that can accommodate a wider range of hole sizes and component geometries, thereby streamlining inventory and reducing operational complexity for end-users.

AI Impact Analysis on Hole Plugs- Tapered Caps Market

Common user questions regarding AI's influence in the Hole Plugs- Tapered Caps Market revolve around three primary areas: optimization of the manufacturing process, enhancement of quality control (QC), and intelligent inventory management within supply chains. Users frequently ask if AI can predict mold wear patterns in injection molding, thereby minimizing defects in cap production, or if machine learning algorithms can analyze application environments to recommend the most thermally or chemically appropriate material composition in real-time. Another significant concern relates to leveraging AI for optimizing stocking levels and predicting demand fluctuations for specific plug sizes and materials, crucial for manufacturers dealing with thousands of SKUs serving diverse industries. The overarching expectation is that AI will introduce unprecedented levels of precision and predictive capability, shifting the industry from reactive maintenance and quality checks to proactive, optimized operations, although the initial investment and data infrastructure required pose a noticeable concern.

In the short term, AI integration focuses heavily on optimizing resource allocation within molding operations. By processing sensor data from temperature controls, pressure gauges, and cycle times, AI algorithms can fine-tune injection parameters to reduce material waste, shorten cycle times without compromising dimensional tolerance, and predict potential equipment failures before they occur. This leads to higher yield rates for specific, precision-engineered products, such as vented plugs used in sensitive electronics housing, where even slight dimensional variations are unacceptable. Furthermore, AI-powered visual inspection systems using high-resolution cameras are rapidly replacing manual checks, enabling 100% inspection rates and classifying minute cosmetic or structural defects in high-volume production runs.

The strategic, long-term impact involves integrating AI across the entire value chain, from design to delivery. Generative design tools can use AI to simulate millions of geometry and material combinations based on specific application requirements (e.g., maximum temperature resistance, chemical immersion depth), leading to the creation of highly customized, application-specific tapered caps that were previously cost-prohibitive to develop. For end-users, AI-driven digital twinning of masking operations allows for optimization of masking sequences on complex parts, minimizing material usage and application time, thus subtly increasing the demand for highly specialized, precision-manufactured protective components capable of being precisely applied by robotic systems.

- AI-driven predictive maintenance optimizes injection molding schedules, minimizing unplanned downtime and production variances.

- Machine learning algorithms enhance quality control through automated visual inspection, ensuring zero-defect standards for critical applications.

- Generative design tools accelerate the development of application-specific, custom-geometry tapered caps, catering to niche industrial needs.

- Intelligent supply chain models use AI to forecast demand fluctuations for specific plug SKUs, reducing inventory holding costs and improving fulfillment rates.

- AI integration supports robotic application systems by calculating optimal placement and orientation for masking components on complex industrial parts.

DRO & Impact Forces Of Hole Plugs- Tapered Caps Market

The Hole Plugs- Tapered Caps Market is strongly influenced by a combination of key drivers, fundamental restraints, and emerging opportunities, collectively shaping the market's trajectory and defining competitive impact forces. The dominant driver remains the continuous expansion of industrial surface finishing activities globally, particularly powder coating, E-coating, and anodizing, all of which mandate precision masking. Restraints largely center on the volatility of raw material costs, particularly for specialized polymers and silicone, and the growing competition from alternative protective methods, such as reusable rubber compounds or advanced liquid masking products. Opportunities exist primarily in customization, utilizing bio-based and recycled materials, and penetrating high-growth, high-regulation sectors like electric vehicle manufacturing and advanced semiconductor production, necessitating materials with extreme heat and chemical resilience.

The primary impact force driving market expansion is the global push for enhanced manufacturing quality and efficiency. As industrial processes become faster and more automated, the demand for masking components that can withstand increasingly aggressive operating environments (e.g., high temperatures up to 600°F and concentrated chemical baths) without degradation or leaving residue is paramount. This necessitates consistent investment in research and development to produce high-performance masking materials. Conversely, the market faces restraining forces from the supply chain fragility; geopolitical tensions and logistics bottlenecks often exacerbate material price inflation, squeezing profit margins for manufacturers and forcing them to explore geographically diverse sourcing strategies or internal material compounding capabilities.

The market environment also presents significant potential for strategic disruption through technological innovation. The shift towards lightweighting in transportation sectors, driven by environmental regulations, means manufacturers are increasingly using composite and exotic metal alloys that require specialized masking solutions during their sensitive surface treatments. Furthermore, the opportunity to integrate RFID or NFC chips into higher-value, reusable tapered plugs and caps offers new avenues for asset tracking, inventory control, and digital transformation within end-user facilities. These intertwined drivers, restraints, and opportunities establish a complex and dynamic market landscape requiring agile response strategies from key players to maintain long-term competitive positioning.

Segmentation Analysis

The Hole Plugs- Tapered Caps Market segmentation provides a granular view of market dynamics based on Material Type, Product Type, and End-Use Industry. This stratification is crucial for manufacturers to tailor their production capabilities and marketing efforts towards specific industrial needs, recognizing that a silicone tapered cap designed for high-temperature powder coating is functionally distinct from a polyethylene hole plug used for general dust protection in transportation packaging. The material segment, covering high-performance polymers (e.g., silicone, EPDM rubber) and standard plastics (e.g., LDPE, HDPE), differentiates products based on their thermal and chemical resistance capabilities, directly correlating with application severity and cost. The end-use segmentation highlights market dependency on the cyclical nature of key sectors such as automotive production, which dictates volume demand, and aerospace, which defines precision and quality specifications.

Product Type segmentation further refines the market, distinguishing between tapered (conical shapes, primarily for masking threads or ports), straight (cylindrical plugs, often used for internal diameter protection or sealing), and flanged/vented designs. Flanged designs offer easier grip and removal, while vented designs are critical for equalization of pressure during painting or chemical processes, preventing distortion or bubbling. Geographic segmentation remains vital as material preferences, regulatory requirements (such as REACH compliance in Europe), and industrial growth rates vary significantly across regions, influencing localized product specifications and inventory needs. Analyzing these segments helps in identifying underserved niches, such as small-batch custom masking components for specialized manufacturing operations.

The ongoing trend shows that while volume is dominated by lower-cost LDPE plugs for general protection and transportation, the value and profit margin expansion are concentrated in the high-performance material segments, particularly specialty silicone and advanced EPDM, catering to the exacting demands of aerospace, medical devices, and electric vehicle battery casing production. The complexity of modern manufacturing necessitates suppliers who can offer bundled solutions, combining various types of plugs and caps along with custom molding services, thereby transitioning from mere component suppliers to integrated masking solution providers for Tier 1 and Tier 2 manufacturers globally.

- By Material Type:

- Polyethylene (LDPE, HDPE)

- Silicone Rubber

- Vinyl/PVC

- EPDM Rubber

- Polyester/Nylon

- By Product Type:

- Tapered Caps/Plugs (Solid and Vented)

- Straight Plugs

- Flanged Plugs

- Grommet Plugs

- Threaded Plugs

- By End-Use Industry:

- Automotive & Transportation

- Aerospace & Defense

- General Industrial Finishing (Powder Coating, Plating)

- Electronics & Electrical Equipment

- Medical Devices

- Construction & Heavy Equipment

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Hole Plugs- Tapered Caps Market

The value chain for the Hole Plugs- Tapered Caps Market begins upstream with the procurement and processing of raw materials, primarily commodity plastics like LDPE and high-performance elastomers such as specialized silicone rubber and EPDM. Suppliers of these polymer resins and chemical additives hold significant power, as the thermal and chemical resistance properties of the final product are entirely dependent on material quality and consistency. Strategic procurement contracts and vertical integration into polymer compounding allow key manufacturers to mitigate price volatility and ensure supply stability, which is crucial for maintaining competitive pricing and product performance standards in downstream applications.

The midstream phase involves the core manufacturing processes, predominantly injection molding, dip molding (for flexible vinyl caps), and compression molding (for thermoset rubber items). Investment in advanced tooling, high-precision molds, and automated production lines dictates operational efficiency and the ability to meet high-volume, tight-tolerance orders. Key activities here include tooling design, mold maintenance, quality assurance through automated vision systems, and packaging optimization. Companies that excel in customizing tooling rapidly for unique part geometries gain a competitive edge, especially in the aerospace and defense sectors where specialized masking components are common requirements.

Downstream analysis focuses on distribution and end-user engagement, where products are channeled both directly and indirectly. Direct distribution involves sales teams engaging directly with large original equipment manufacturers (OEMs) and Tier 1 suppliers in the automotive or heavy equipment sectors, often involving specialized consultation and just-in-time (JIT) delivery agreements. Indirect distribution utilizes a global network of industrial distributors, material handling suppliers, and e-commerce platforms, which serve smaller job shops and general industrial users who require smaller quantities and rapid fulfillment of standard SKUs. Effective inventory management and a robust digital sales channel are critical for maximizing market penetration and addressing the diverse purchasing preferences of the global end-user base.

Hole Plugs- Tapered Caps Market Potential Customers

Potential customers for Hole Plugs- Tapered Caps are highly diversified across the manufacturing spectrum, unified by the requirement for surface finishing, protection, or sealing during fabrication, storage, or transport. The primary end-users include large-scale manufacturers in the Automotive and Transportation sectors, such as car manufacturers and component suppliers (Tier 1 and Tier 2), who use these products extensively during painting, plating, and powertrain assembly processes. The Aerospace and Defense sector represents a high-value customer base, prioritizing specialized, high-temperature masking caps and plugs made from certified, traceable materials to protect critical components like turbine blades, hydraulic ports, and engine assemblies during high-heat coating applications.

Beyond specialized industries, the vast General Industrial Finishing market forms the largest volume segment. This includes thousands of smaller and medium-sized job shops specializing in powder coating, electroplating, and anodizing services for various products, from consumer goods housing to construction hardware. These customers prioritize cost-effectiveness, reliability, and easy availability of standard size products. Furthermore, original equipment manufacturers (OEMs) in electronics, HVAC, construction, and agricultural machinery are significant buyers, utilizing hole plugs for aesthetic finishing, ingress protection (dust and moisture), and sealing during transportation and final product assembly. The purchasing decision for these various customer types hinges on material compatibility, thermal endurance, ease of application/removal, and overall total cost of ownership.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,260 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | MOCAP, Caplugs (Protective Closures), Stockcap, Shercon Inc., VMS Plating and Masking, Polaris Plastics, Jinghong Protective Products, Hi-Tec Plastics, PUREX Industrial, R.C. Plugs, Niaga Components, EFC International, ICP Protective Solutions, AFT Fasteners, Precision Masking & Plugs (PMP) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hole Plugs- Tapered Caps Market Key Technology Landscape

The technological landscape of the Hole Plugs- Tapered Caps Market is dominated by advancements in material science and high-precision manufacturing techniques, primarily focusing on enhancing thermal stability and geometric accuracy. Injection molding remains the cornerstone technology for high-volume production of rigid plastic plugs (LDPE, HDPE), with manufacturers increasingly adopting multi-cavity molds and high-speed robotics to achieve low cycle times and consistent quality. A critical trend involves optimizing tooling materials and cooling channels to reduce warpage and ensure tight dimensional tolerances, particularly for precision-fit plugs used in demanding engineering applications where sealing integrity is paramount. Furthermore, the adoption of closed-loop process control systems, leveraging sensors and data analytics, allows for real-time adjustments to injection parameters, significantly minimizing batch variability.

For high-performance segments, particularly silicone and EPDM tapered caps used in powder coating (where temperatures exceed 400°F), the key technological focus is on dip molding and compression molding techniques. Dip molding is prized for producing highly flexible, seamless caps with superior pull strength and chemical resistance. Innovations here center on improving dipping processes to control wall thickness uniformity, particularly in larger caps, and developing proprietary silicone formulations that offer higher dielectric strength or reduced outgassing at extreme temperatures. Continuous research into polymer additives is enabling the creation of "green" masking solutions, utilizing bio-based plastics or highly durable, reusable materials designed to withstand thousands of use cycles, addressing sustainability requirements from end-users.

Digital transformation, including the integration of 3D printing (Additive Manufacturing), is increasingly impacting the rapid prototyping and low-volume, high-customization segment of the market. While not yet cost-effective for mass production, 3D printing allows for rapid creation of complex masking fixtures and specialized plugs with internal features (like vent channels or unique grip designs) that are challenging or impossible to produce using traditional molding techniques. This technology dramatically reduces the time-to-market for highly specialized protective solutions, directly benefiting niche markets such as customized robotics manufacturing and advanced research facilities requiring bespoke protective components.

Regional Highlights

- Asia Pacific (APAC): APAC is the fastest-growing market globally, primarily due to the rapid expansion of automotive production (including electric vehicles) and the electronics manufacturing hub centered in East and Southeast Asia. Countries like China, India, and Vietnam are experiencing massive industrial investment, necessitating high volumes of standard and precision hole plugs for pre-treatment, painting, and assembly lines. The competitive landscape here is fragmented, with strong local manufacturers competing on volume and price, alongside global players establishing manufacturing bases to shorten supply chains.

- North America: North America represents a mature, high-value market characterized by stringent quality demands, particularly from the aerospace, medical device, and defense sectors. These industries drive demand for premium, certified materials (silicone, fluoropolymers) capable of withstanding extreme environmental conditions and adhering to military or FDA standards. Innovation often centers around automation compatibility, with manufacturers focused on creating plugs and caps optimized for robotic application in large assembly plants to minimize labor costs.

- Europe: The European market is highly regulated, prioritizing sustainability and compliance (e.g., REACH, RoHS). This environment fuels demand for high-quality, recyclable, or reusable masking solutions, along with specialized products for precision engineering and luxury automotive finishing. Germany, France, and the UK are major consumption centers, driven by sophisticated manufacturing processes that require consistent quality and material traceability, favoring suppliers who can provide extensive documentation and certifications.

- Latin America (LATAM) and Middle East & Africa (MEA): These regions show moderate growth, primarily tied to local infrastructure development, oil and gas processing (requiring specialized corrosion protection and sealing plugs), and emerging automotive assembly operations (e.g., Brazil, Mexico, South Africa). The market here is often served through established distribution networks, with demand typically concentrated on general industrial LDPE plugs and specialized caps for pipeline and heavy machinery maintenance and storage applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hole Plugs- Tapered Caps Market.- MOCAP (Protective Solutions)

- Caplugs (Protective Closures)

- Stockcap

- Shercon Inc.

- Polaris Plastics

- Hi-Tec Plastics

- Jinghong Protective Products

- Purex Industrial Masking

- Niaga Components

- EFC International

- VMS Plating and Masking

- Precision Masking & Plugs (PMP)

- MDI Advanced Protection Solutions

- Component Supply Company (CSC)

- Rubber & Silicone Products Co.

- Teknor Apex

- AFT Fasteners

- Plasticoid Company

- CGS Components

- Essentra Components

Frequently Asked Questions

Analyze common user questions about the Hole Plugs- Tapered Caps market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of tapered caps versus straight plugs in industrial finishing?

Tapered caps are primarily used for masking applications, such as protecting threaded studs or ports during processes like powder coating or electroplating, providing a tight internal seal. Straight plugs, conversely, are typically used for sealing or external protection of openings and providing debris prevention in non-finishing applications.

Which material offers the best performance for high-temperature masking, and why is it preferred?

Silicone rubber offers the best performance for high-temperature masking (up to 600°F/315°C), making it indispensable for powder coating and e-coating. It is preferred due to its superior thermal stability, flexibility, chemical inertia, and ability to be reused multiple times without hardening or leaving residue.

How is the growth of the electric vehicle (EV) sector impacting the demand for hole plugs and tapered caps?

The EV sector drives specialized demand for high-performance, heat-resistant, and flame-retardant plugs and caps, particularly for battery pack sealing, high-voltage component protection, and masking during protective treatments of aluminum chassis components, increasing the market's value segment.

What are the key drivers for market growth in the Asia Pacific region?

Market growth in APAC is primarily driven by massive governmental investments in infrastructure, the rapid expansion of the regional automotive manufacturing base, and high industrial output, leading to extensive demand for both protective and masking components in surface treatment facilities.

Are reusable or single-use protective components dominating the market trend?

While single-use LDPE plugs still dominate volume in general industrial and packaging, the trend in high-value masking applications (aerospace, high-temp coating) is strongly shifting toward durable, reusable silicone and EPDM components to improve cost efficiency over the product lifecycle and align with global sustainability mandates.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager