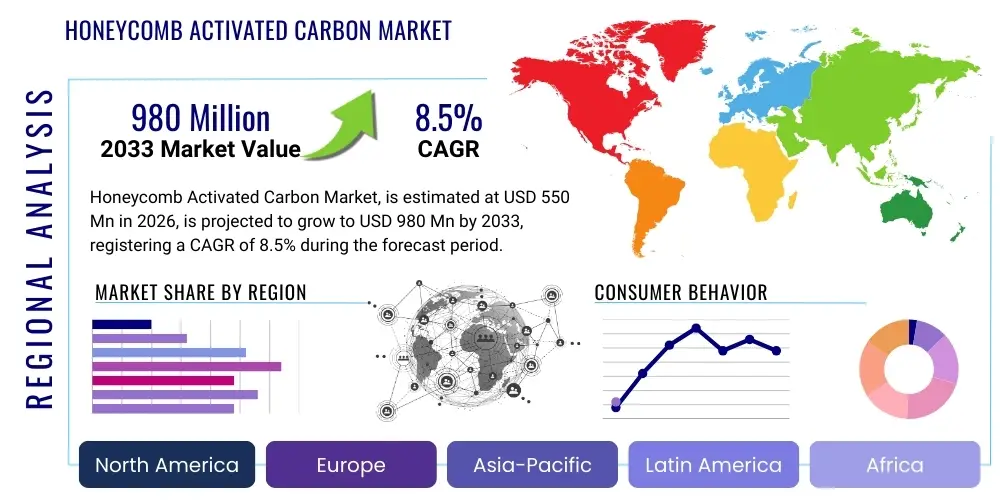

Honeycomb Activated Carbon Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436599 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Honeycomb Activated Carbon Market Size

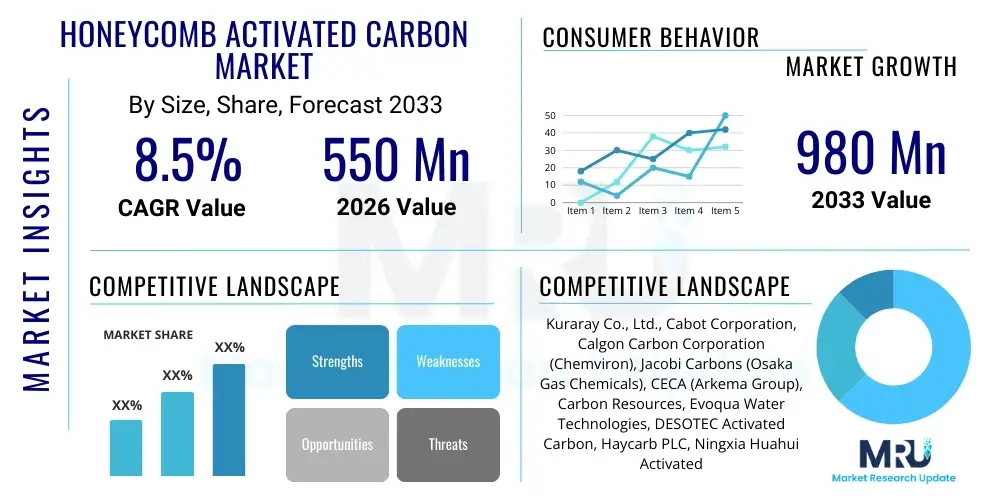

The Honeycomb Activated Carbon Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at $550 Million in 2026 and is projected to reach $980 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by increasingly stringent global environmental regulations targeting air quality, coupled with rapid industrialization across emerging economies which necessitates advanced air purification systems capable of efficient volatile organic compound (VOC) abatement and solvent recovery.

Honeycomb Activated Carbon Market introduction

Honeycomb Activated Carbon (HAC) is a specialized adsorption material characterized by a monolithic, porous structure offering extremely low-pressure drop and high mechanical strength, making it ideal for large air volume treatment applications. Unlike granular or powdered activated carbon, the honeycomb configuration allows for efficient air flow while maximizing the contact area for the adsorption of harmful gaseous pollutants, notably volatile organic compounds (VOCs), hydrogen sulfide (H2S), and odors. This unique geometric design provides superior kinetic performance, ensuring efficient removal rates in dynamic environments such as automotive cabin air filtration and large industrial scrubbers, thereby establishing HAC as a critical component in modern air quality management systems.

The primary applications of Honeycomb Activated Carbon span across several high-growth sectors, including automotive air pollution control, industrial solvent recovery, HVAC systems for commercial and residential buildings, and specialized air purification in semiconductor manufacturing and pharmaceutical industries. Its inherent benefits, such as durability, regenerability, and efficiency in handling high flow rates with minimal energy expenditure, position it favorably against conventional filtration media. The growing global commitment to reducing indoor and outdoor air pollution, formalized through various international treaties and national regulations, serves as the predominant driving factor sustaining the robust market growth for HAC.

The product is typically manufactured using raw materials like coal, coconut shell, or wood pulp, which are bound together using proprietary binders and then extruded into the characteristic honeycomb structure before being thermally activated. The resulting product exhibits a high internal surface area, critical for effective adsorption. Market growth is further accelerated by ongoing innovations in material science aimed at enhancing adsorption capacity for specific pollutants (e.g., nitrogen oxides or mercury), ensuring HAC remains the preferred solution for demanding environmental protection scenarios.

Honeycomb Activated Carbon Market Executive Summary

The Honeycomb Activated Carbon market is witnessing robust growth, largely propelled by decisive regulatory enforcement regarding air quality, particularly in North America and Europe, and explosive industrial expansion across the Asia Pacific region. Key business trends indicate a strong focus on capacity expansion and strategic partnerships between HAC manufacturers and major automotive OEMs, particularly as regulations like Euro 7 and stringent EPA standards necessitate improved evaporative emission control systems. Furthermore, market competition is intensifying around developing chemically impregnated HAC variants designed for superior performance against hard-to-adsorb gases, such as ammonia and formaldehyde, driving higher product complexity and value.

Regional trends highlight the Asia Pacific (APAC) as the fastest-growing market segment, attributed to rapid urbanization, increasing levels of industrial VOC emissions, and corresponding government initiatives in countries like China and India focused on pollution remediation. Conversely, mature markets like North America and Europe emphasize technological innovation, focusing on the integration of HAC into advanced smart ventilation and HVAC systems for superior indoor air quality (IAQ). Investment flows are concentrated on scaling up the production of high-density, low-pressure-drop HAC structures to meet the evolving demands of large-scale industrial filtration facilities, solidifying the global shift towards efficient, monolithic adsorbents.

Segmentation analysis reveals that the Application segment of Automotive Emission Control and Cabin Air Filtration holds the largest market share, driven by mandated governmental requirements for vehicle manufacturers. The Raw Material segment sees coconut shell-based activated carbon gaining traction due to its sustainable sourcing and higher microporosity, offering enhanced performance in gas phase adsorption compared to coal-based alternatives. Overall, the market trajectory is highly sensitive to policy changes regarding environmental protection and energy efficiency, pushing manufacturers toward sustainable production methods and products designed for extended operational lifespan and easier regeneration.

AI Impact Analysis on Honeycomb Activated Carbon Market

User queries regarding the impact of Artificial Intelligence (AI) on the Honeycomb Activated Carbon market primarily revolve around optimizing manufacturing efficiency, enhancing quality control consistency, and integrating AI for predictive maintenance within HVAC and industrial filtration systems utilizing HAC. Users are keen on understanding how AI can facilitate the precise tailoring of carbon pore structures to target specific pollutants, moving beyond traditional trial-and-error methods. Key themes emerging include the potential for AI-driven process automation to reduce production costs, the role of machine learning in interpreting sensor data for optimal regeneration cycles in large-scale air treatment plants, and the use of algorithms to simulate and predict the lifespan and performance decay of HAC filters under various environmental stresses.

The incorporation of AI and machine learning models offers transformative potential in refining the complex activation and extrusion processes of HAC manufacturing. By utilizing predictive analytics, manufacturers can optimize parameters such as temperature, pressure, and binder concentration in real-time, resulting in highly consistent product quality and maximized adsorption capacity, thereby reducing batch variability and waste. This level of optimization is crucial for meeting stringent industrial specifications, particularly in specialized fields like semiconductor manufacturing where contaminant levels must be kept exceptionally low. Furthermore, AI tools are expected to accelerate R&D efforts in developing novel carbon surface modifications and impregnations tailored for specific, persistent pollutants.

Downstream, AI integration significantly impacts the operational efficiency of systems where HAC is deployed. Predictive maintenance algorithms, leveraging IoT sensors embedded within industrial scrubbers and automotive air systems, monitor pollutant breakthrough curves and differential pressure across the HAC media. This data, processed by AI, allows facility managers or vehicle systems to precisely determine the optimal time for filter replacement or regeneration, avoiding premature disposal or detrimental system downtime due to filter exhaustion. This shift from time-based maintenance to condition-based maintenance maximizes the useful life of the expensive carbon media, offering substantial cost savings and enhancing overall environmental compliance reliability.

- AI-driven optimization of thermal activation parameters leading to maximized pore structure uniformity and surface area.

- Machine learning applied to quality control for real-time defect detection during the extrusion phase of HAC panels.

- Predictive analytics enabling condition-based monitoring of HAC saturation levels in industrial gas purification systems.

- Enhanced R&D via AI simulation, accelerating the development of specialized, pollutant-specific impregnated honeycomb structures.

- Automated system controls in HVAC using AI to regulate airflow based on real-time VOC load, extending HAC filter lifespan.

DRO & Impact Forces Of Honeycomb Activated Carbon Market

The Honeycomb Activated Carbon market dynamics are shaped by a powerful interplay of environmental mandates (Drivers), complex production logistics (Restraints), and emerging technological applications (Opportunities). The dominant driver is the globally increasing regulatory pressure, particularly concerning the reduction of Volatile Organic Compounds (VOCs) emissions from industrial sources and transportation. This regulatory push, exemplified by stricter EPA standards and the European Industrial Emissions Directive (IED), creates consistent, mandatory demand for high-efficiency filtration solutions like HAC. Concurrently, rapid industrialization, particularly in manufacturing and chemical processing sectors in Asia, necessitates scalable and durable air purification systems, further fueling market expansion.

However, the market faces significant restraints primarily related to the high initial capital investment required for establishing HAC manufacturing facilities, which involve specialized extrusion and high-temperature activation furnaces. Furthermore, the operational cost associated with raw material sourcing (which can be volatile, especially for coconut shell carbon) and the energy-intensive nature of the activation process pose profitability challenges. Competition from established, lower-cost adsorption media, such as conventional granular activated carbon (GAC) in less flow-sensitive applications, also limits market penetration in certain segments, forcing HAC manufacturers to continually justify the premium associated with their low-pressure-drop solution.

Opportunities for profound market growth exist within the burgeoning Electric Vehicle (EV) sector, where HAC is crucial for battery off-gassing management and enhanced cabin air quality, differentiating them from traditional internal combustion engine applications. Moreover, advancements in material science are leading to high-performance, regenerable HAC media designed for specific hard-to-capture pollutants, opening avenues in specialized industrial segments like biogas purification and nuclear air treatment. The cumulative impact of these forces strongly favors specialized, high-performance HAC products, driving innovation toward sustainability, regenerability, and targeted chemical performance, ensuring long-term market vitality despite current cost constraints.

- Drivers:

- Strict global environmental regulations (EPA, REACH, Euro 7) mandating VOC and industrial emission control.

- Rapid growth of the automotive sector, requiring advanced evaporative emission control (EEC) systems.

- Increasing awareness and demand for improved Indoor Air Quality (IAQ) in commercial and residential settings.

- Expansion of chemical, pharmaceutical, and semiconductor industries requiring ultra-pure air systems.

- Restraints:

- High manufacturing cost associated with the specialized extrusion and high-temperature activation processes.

- Volatility in raw material pricing, particularly coconut shells and coal used for carbon production.

- Competition from conventional, less expensive granular activated carbon (GAC) in certain lower-flow applications.

- Technical complexity and energy intensity of implementing and maintaining regeneration systems for HAC in smaller facilities.

- Opportunities:

- Growing adoption of electric vehicles (EVs) and the need for battery off-gassing and thermal management filtration.

- Development of chemically impregnated HAC for targeted removal of non-VOC pollutants (e.g., ammonia, H2S, mercury).

- Expansion into specialized applications such as biogas purification and solvent recovery in high-value manufacturing.

- Advancements in regenerative technologies extending the effective lifespan of HAC units.

- Impact Forces Analysis:

- Bargaining Power of Suppliers (Medium to High): Dependent on the type of raw material (coconut shell being highly segmented and controlled).

- Bargaining Power of Buyers (Medium): Large end-users (Automotive OEMs, major industrial companies) negotiate volumes, but material specialization limits supplier switching.

- Threat of New Entrants (Low to Medium): High capital expenditure and complex technical expertise required for high-quality HAC production pose significant barriers.

- Threat of Substitutes (Medium): Substitute technologies like thermal oxidation, biofiltration, and conventional GAC exist, but none match the low-pressure drop/high-flow efficiency of HAC entirely.

- Intensity of Competitive Rivalry (High): Market dominated by established players competing heavily on price, performance characteristics (adsorption capacity, pressure drop), and regulatory compliance.

Segmentation Analysis

The Honeycomb Activated Carbon market is intricately segmented based on raw material source, the primary application, and the specific end-user industry, reflecting the diverse functional requirements across different industrial settings. Analyzing these segments provides a clear understanding of market dynamics, growth pockets, and technological preferences. The core differentiation often lies in the choice of raw material, which directly influences the resultant porosity and adsorption characteristics; for instance, wood-based carbon is favored for larger molecule adsorption, while coconut shell carbon excels in microporous structures suited for lighter gas molecules.

The Application segment is arguably the most dynamic, with Environmental Protection dominating due to governmental mandates, encompassing large-scale industrial exhaust treatment and solvent recovery operations where volume throughput is critical. Conversely, the Automotive segment demands exceptionally high-performance and durable HAC units capable of functioning reliably under varying temperatures and vibration stresses, primarily focusing on evaporative emission control systems (EECS) and cabin air filtration systems. Market participants strategically focus their product development efforts on tailoring specific cell densities and impregnation chemistries to capture segment-specific value, especially within niche markets like specialized air treatment for museums or archives.

Geographically, market segmentation reflects varying levels of industrialization and regulatory maturity. Mature markets prioritize advanced, chemically impregnated HAC solutions, while rapidly industrializing regions emphasize high-volume, cost-effective standard HAC panels. Understanding these preferences is vital for market forecasting and business strategy, ensuring that manufacturing capacities are aligned with regional demand for either performance-driven specialty products or volume-driven general filtration media.

- By Raw Material:

- Coconut Shell Based Honeycomb Activated Carbon

- Coal Based Honeycomb Activated Carbon

- Wood Based Honeycomb Activated Carbon

- Others (e.g., Petroleum Pitch Based)

- By Application:

- Solvent Recovery

- Odor Removal and Deodorization

- Air Purification (General HVAC)

- Industrial Exhaust Gas Treatment (VOC Abatement)

- Automotive Emission Control Systems (EECS)

- Cabin Air Filtration

- Nuclear Grade Air Treatment

- By End-Use Industry:

- Automotive & Transportation

- Chemical and Petrochemical Processing

- Electronics and Semiconductor Manufacturing

- Pharmaceutical and Healthcare

- Food & Beverage Processing

- Residential and Commercial HVAC

- Waste Management and Water Treatment Plants (Gas Phase)

Value Chain Analysis For Honeycomb Activated Carbon Market

The value chain for the Honeycomb Activated Carbon market begins with the upstream procurement of carbonaceous raw materials, predominantly coal, coconut shells, and wood, sourced globally. This initial stage is characterized by resource intensity and logistics complexity, especially securing sustainable sources of coconut shells, which are favored for their low ash content and high inherent microporosity. The stability of raw material supply directly influences production costs and the final product's quality specifications. Upstream analysis also includes the provision of specialized organic and inorganic binders necessary for maintaining the structural integrity of the honeycomb matrix during the extrusion process, requiring close relationships with specialty chemical suppliers.

The core midstream activity involves the transformation of raw materials into the finished HAC product, encompassing several highly technical steps: material grinding, mixing with binders, specialized high-pressure extrusion to form the monolithic block, drying, and the crucial high-temperature activation (carbonization and activation) phase. This manufacturing stage requires significant capital expenditure and highly controlled environmental conditions to achieve the desired porosity, cell density, and mechanical strength characteristics. Quality control at this stage is paramount, utilizing specialized testing equipment to measure adsorption kinetics and pressure drop, thereby generating the final, high-value activated carbon product.

The downstream segment involves distribution and final application. Direct channels are common when supplying large Original Equipment Manufacturers (OEMs), such as automotive companies or industrial air scrubber integrators, where customized specifications and technical support are required. Indirect channels, involving specialized distributors and technical sales agents, serve smaller industrial users, HVAC installers, and aftermarket replacement demands. The primary end-users, detailed as potential customers, are industrial entities and regulatory-driven sectors whose demand is inelastic due to mandatory compliance requirements, emphasizing the critical link between regulatory enforcement and stable downstream demand.

Honeycomb Activated Carbon Market Potential Customers

The primary customers for Honeycomb Activated Carbon are entities that require efficient, low-pressure-drop gas phase purification systems for either regulatory compliance or product quality assurance. The largest volume buyers are typically within the Automotive OEM sector. These manufacturers utilize HAC extensively in their evaporative emission control systems (EECS), which capture gasoline vapors that would otherwise vent into the atmosphere, making regulatory adherence a non-negotiable purchasing driver. Additionally, automotive customers purchase HAC for cabin air filters to enhance passenger comfort and health by removing pollutants and odors.

Industrial sectors, particularly chemical processing and petrochemical facilities, represent another substantial customer base. These entities require HAC for large-scale solvent recovery operations, capturing valuable organic solvents used in processes like painting, printing, or manufacturing, both for environmental compliance and economic benefit through solvent reuse. Furthermore, manufacturers in specialized high-purity environments, such as electronics, semiconductors, and pharmaceuticals, are premium customers, demanding ultra-high-grade, sometimes nuclear-grade, impregnated HAC to remove trace contaminants that could compromise highly sensitive manufacturing processes or drug purity.

Lastly, large commercial and residential HVAC system manufacturers and facility managers constitute a growing customer segment, driven by increasing public concern regarding indoor air quality (IAQ). These customers integrate HAC into advanced filtration units designed to eliminate common indoor pollutants, cooking odors, and external traffic fumes, particularly in urban environments. The purchasing decision for this segment often balances price against longevity and regenerability, favoring solutions that minimize ongoing maintenance costs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million |

| Market Forecast in 2033 | $980 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kuraray Co., Ltd., Cabot Corporation, Calgon Carbon Corporation (Chemviron), Jacobi Carbons (Osaka Gas Chemicals), CECA (Arkema Group), Carbon Resources, Evoqua Water Technologies, DESOTEC Activated Carbon, Haycarb PLC, Ningxia Huahui Activated Carbon Co., Ltd., PICA Carbon GmbH, Toyo Tanso Co., Ltd., Active Carbon Technologies, Veolia Water Technologies, Ingevity Corporation, Jiangsu Zhuping Activated Carbon Co., Ltd., Hubei Tongli Activated Carbon Co., Ltd., Shaanxi Xinhua Activated Carbon Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Honeycomb Activated Carbon Market Key Technology Landscape

The technological landscape of the Honeycomb Activated Carbon market is primarily defined by advancements in extrusion methods, binder chemistry, and surface modification techniques essential for maximizing adsorption performance while minimizing pressure drop. The core technology centers around the extrusion process, which must consistently produce a monolithic structure with uniform cell geometry and high mechanical integrity, often involving specialized die-head designs and precise control over the paste viscosity. Innovations in binder technology, moving towards eco-friendly and high-strength organic binders, are critical to ensuring the final product can withstand high airflow velocities, thermal cycling, and humidity without compromising structural integrity or leaching contaminants.

A major technological focus is the development of advanced chemical impregnation techniques. Standard HAC is suitable for general VOC adsorption, but specialized applications require carbon surfaces functionalized with metal oxides, halides, or specific catalysts to effectively capture pollutants like mercury, hydrogen sulfide, sulfur dioxide, or ammonia, which are poorly adsorbed by basic carbon. Researchers are exploring novel impregnation methods, such as plasma treatment and micro-encapsulation, to achieve highly stable and durable surface chemistries, thereby broadening the application range of HAC into complex industrial gas streams and even military defense applications requiring highly specialized filtration.

Furthermore, the technology surrounding regeneration and recycling is becoming increasingly vital due to economic and environmental mandates. Advanced thermal swing adsorption (TSA) and pressure swing adsorption (PSA) systems are employed to desorb trapped contaminants from the HAC structure, allowing for reuse. Current technological efforts aim to optimize regeneration protocols through AI-driven process control, reducing the energy consumption required for desorption and ensuring that the carbon's adsorption capacity is restored efficiently without causing irreversible damage to the pore structure. This emphasis on longevity and sustainability is key to reducing the total lifecycle cost of the HAC solution for end-users.

Regional Highlights

Regional dynamics significantly influence the Honeycomb Activated Carbon market, reflecting variations in regulatory strictness, industrialization rates, and automotive production capacity. North America and Europe represent mature markets characterized by stringent and well-enforced environmental regulations, particularly concerning vehicle emissions (EPA Tier 3, Euro 6/7 standards) and industrial VOC abatement (REACH, IED). These regions exhibit high demand for premium, specialized, and often chemically impregnated HAC used in critical applications like automotive evaporative emission control systems and advanced indoor air purification in commercial buildings. Innovation adoption is high, favoring sustainable sourcing and advanced regeneration technologies.

The Asia Pacific (APAC) region stands out as the primary engine of global market growth. This is driven by rapid industrial expansion, high levels of urbanization, and subsequently, severe air quality issues, compelling governments in China, India, and Southeast Asian nations to implement aggressive environmental cleanup policies. The demand in APAC is massive and two-fold: high-volume, cost-effective HAC for general industrial exhaust treatment, and growing demand for high-performance units for the region's rapidly expanding automotive manufacturing base. Government incentives and mandatory pollution control standards in key manufacturing hubs are creating unparalleled opportunities for market penetration.

Latin America (LATAM) and the Middle East & Africa (MEA) currently hold smaller market shares but demonstrate high growth potential. LATAM demand is largely influenced by industrial mining operations and petrochemical processing, requiring specific HAC products for odor and trace pollutant removal. MEA’s growth is nascent but accelerating due to infrastructure projects, increasing vehicle ownership, and governmental initiatives focusing on environmental sustainability in the GCC countries. However, market growth in these regions is often hampered by slower adoption of advanced regulatory frameworks and greater price sensitivity compared to developed regions.

- Asia Pacific (APAC): Highest growth rate; driven by stringent Chinese environmental policies (e.g., "Blue Sky Protection Campaign") and massive automotive production volume; focus on industrial VOC abatement and large-scale air purification projects.

- North America: Mature market; stable demand dictated by federal and state-level EPA regulations; emphasis on high-performance HAC for evaporative emission control and specialized industrial air treatment (e.g., refineries).

- Europe: Regulatory-driven market (REACH, Euro 7); strong focus on Indoor Air Quality (IAQ) and sustainable product sourcing; high adoption of impregnated carbon for targeted pollutant removal in both residential and commercial sectors.

- Latin America (LATAM): Emerging market; growth tied to petrochemical, mining, and manufacturing sector expansion; demand concentrated in localized air and odor control applications.

- Middle East & Africa (MEA): Growth potential linked to large infrastructure development projects and increasing energy sector activities; market expansion subject to evolving regional environmental governance and industrial diversification efforts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Honeycomb Activated Carbon Market.- Kuraray Co., Ltd.

- Cabot Corporation

- Calgon Carbon Corporation (Chemviron)

- Jacobi Carbons (Osaka Gas Chemicals)

- CECA (Arkema Group)

- Carbon Resources

- Evoqua Water Technologies

- DESOTEC Activated Carbon

- Haycarb PLC

- Ningxia Huahui Activated Carbon Co., Ltd.

- PICA Carbon GmbH

- Toyo Tanso Co., Ltd.

- Active Carbon Technologies

- Veolia Water Technologies

- Ingevity Corporation

- Jiangsu Zhuping Activated Carbon Co., Ltd.

- Hubei Tongli Activated Carbon Co., Ltd.

- Shaanxi Xinhua Activated Carbon Co., Ltd.

- Fuji Filter Manufacturing Co., Ltd.

- Sichuan Activated Carbon Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Honeycomb Activated Carbon market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Honeycomb Activated Carbon (HAC) over conventional Granular Activated Carbon (GAC)?

HAC offers significantly lower pressure drop and superior kinetic performance, making it highly efficient for high-flow rate gas phase applications like large industrial scrubbers and automotive systems. Its monolithic structure ensures durability and consistent airflow, preventing channeling and maximizing adsorption efficiency.

Which industries are the largest end-users driving demand for Honeycomb Activated Carbon?

The Automotive industry, particularly for evaporative emission control systems (EECS) and cabin air filtration, and the Chemical/Petrochemical industry, utilizing HAC for large-scale solvent recovery and industrial exhaust gas treatment, represent the largest market segments.

How does the choice of raw material affect the performance of Honeycomb Activated Carbon?

The raw material determines the carbon's pore structure. Coconut shell carbon typically yields higher microporosity, ideal for small molecule VOC adsorption, while coal-based or wood-based carbon often results in larger pore distributions suited for handling higher molecular weight organic compounds.

What is the role of chemical impregnation in modern HAC applications?

Chemical impregnation involves treating the carbon surface with specialized compounds (e.g., metal oxides) to enable the removal of specific pollutants that standard carbon cannot effectively adsorb, such as ammonia, mercury vapor, or hydrogen sulfide (H2S), broadening HAC's use in specialized regulatory environments.

What impact are environmental regulations having on the future growth of the HAC market?

Environmental regulations, such as increasingly stringent VOC emission limits globally and tightening standards for vehicle exhaust (like Euro 7), are the most critical drivers. These regulations create mandatory, non-discretionary demand for high-performance filtration solutions, ensuring sustained market growth and technological innovation in HAC.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager