Hook & Loop Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437492 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Hook & Loop Market Size

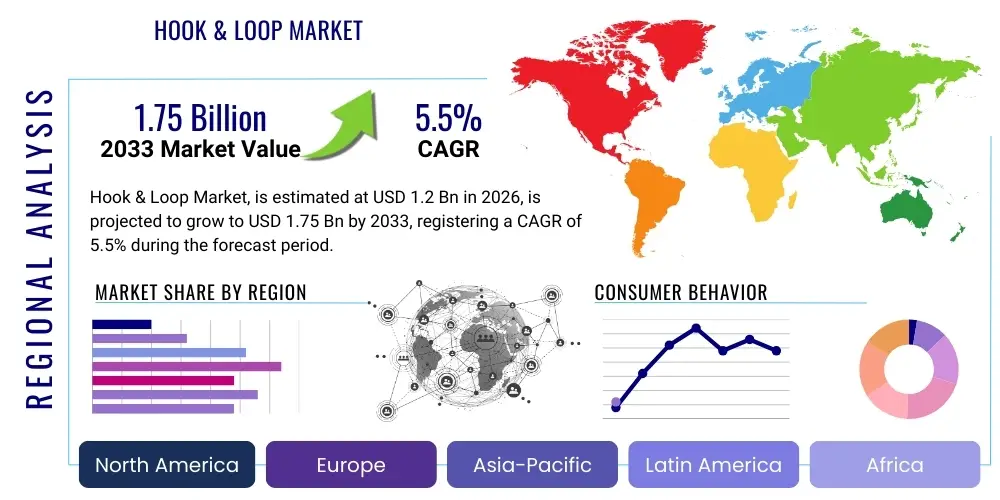

The Hook & Loop Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.75 Billion by the end of the forecast period in 2033. This consistent expansion is primarily fueled by rising demand across diverse end-use industries, particularly automotive, healthcare, and consumer goods, where efficient, reusable, and customizable fastening solutions are crucial for modern product design and assembly. The market exhibits robust stability due to the established reliability and versatility of hook and loop technology, ensuring its continued relevance despite the emergence of alternative fastening methods.

Hook & Loop Market introduction

The Hook & Loop Market encompasses the global production, distribution, and consumption of hook and loop fasteners, commonly known by the trade name Velcro. These non-adhesive, pressure-sensitive mechanical fasteners operate on the principle of two sides mating together: a "hook" side, typically made of rigid monofilament threads, and a "loop" side, made of softer, fuzzy material. This technology offers superior benefits, including high shear strength, peel resistance, reusability (up to thousands of cycles), ease of use, and adaptability to various materials such as textiles, plastics, and metals. The fundamental mechanism allows for rapid attachment and detachment, making it a preferred solution over zippers, buttons, or snap fasteners in numerous applications requiring quick access and adjustment.

Major applications for hook and loop fasteners span a wide spectrum, from military uniforms and aerospace components to everyday consumer items like apparel, footwear, and medical braces. In the automotive sector, they are extensively utilized for securing interior panels, wiring harnesses, and seat covers, contributing to reduced weight and streamlined manufacturing processes. The driving factors behind market growth include increasing adoption in the medical sector for patient mobility aids and surgical equipment organization, the rapid expansion of the textile and apparel industry, especially performance and technical clothing, and the burgeoning electronics sector where cable management and component securing are essential. Furthermore, innovation in material science, focusing on flame-retardant and high-strength variants, is opening new application avenues in industrial and construction environments.

The core benefit of these fastening systems lies in their simplicity and long-term cost-effectiveness. Unlike chemical adhesives or permanent mechanical fixings, hook and loop solutions allow for easy disassembly and maintenance, significantly reducing labor time and complexity during product servicing or replacement. The shift towards modular design in furniture, construction, and electronics further strengthens market demand. Geographical expansion in manufacturing hubs across Asia Pacific, coupled with increasing consumer awareness regarding sustainable and reusable products, provides additional impetus for market development, encouraging manufacturers to diversify their product portfolio with specialty fasteners designed for extreme temperatures, moisture resistance, or specific aesthetic requirements.

Hook & Loop Market Executive Summary

The Hook & Loop Market is characterized by moderate but stable growth, driven primarily by expanding industrial applications and continuous product innovation focused on high-performance materials and specialized attachment methods. Business trends indicate a strong move toward customization and integration into smart products, requiring fasteners that can handle signal transmission or offer enhanced shielding capabilities. Key manufacturers are prioritizing vertical integration to control material quality and reduce lead times, while strategic partnerships with major original equipment manufacturers (OEMs) in the automotive and medical device sectors are critical for securing long-term supply contracts. The competitive landscape remains fragmented, yet dominated by a few global players who invest heavily in patented technologies and specialized fastening mechanisms, particularly those designed for rigorous environments like aerospace or high-temperature industrial settings.

Regional trends reveal Asia Pacific as the fastest-growing market, largely due to explosive growth in electronics manufacturing, textile production, and infrastructure development in countries such as China, India, and Vietnam. North America and Europe, while mature, maintain significant market shares, characterized by high demand for premium, technical-grade fasteners used in complex medical and military applications, subject to stringent regulatory standards (e.g., fire safety certifications). Emerging economies in Latin America and the Middle East and Africa are gradually increasing their adoption of hook and loop technology as local manufacturing capabilities expand and consumer demand for modern products rises, though growth here is often dependent on specific economic stabilization and foreign investment levels.

Segmentation trends highlight the dominance of the nylon material segment due to its excellent balance of cost, durability, and versatility, although the polyester segment is rapidly gaining traction in applications requiring greater UV resistance and moisture stability. In terms of attachment methods, the sew-on fasteners currently hold the largest market share, reflecting their pervasive use in apparel and textiles, but the self-adhesive/pressure-sensitive segment is witnessing the highest growth rate, fueled by its ease of application in automotive interiors and DIY consumer products. The end-user analysis confirms the medical and automotive sectors as the primary revenue generators, demanding continuous innovation in areas such as hypoallergenic materials and high-strength, vibration-dampening fasteners tailored specifically for long-term reliability in critical infrastructure.

AI Impact Analysis on Hook & Loop Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Hook & Loop Market commonly revolve around the automation of manufacturing processes, the optimization of supply chains, and the potential for AI-driven material discovery leading to next-generation fastening solutions. Users express expectations for AI to enhance quality control by detecting microscopic defects in the hooks and loops that human inspection might miss, and to optimize inventory management systems that handle the vast variety of fastener specifications (colors, materials, coatings, attachment types). A major theme concerns how AI and Machine Learning (ML) can predict demand volatility across highly diversified end-use sectors, ensuring that specialized fasteners for time-sensitive industries like surgical supplies or complex electronics assembly are consistently available, thereby minimizing production delays and reducing overall operational costs for manufacturers.

- AI-Powered Quality Control: Implementation of visual inspection systems using deep learning to identify defects (e.g., misaligned loops, broken hooks) during high-speed manufacturing, drastically improving consistency and reducing waste.

- Predictive Maintenance: Using ML algorithms to monitor machinery performance (weaving looms, coating equipment) to anticipate failures, minimizing unexpected downtime and maximizing machine lifespan.

- Supply Chain Optimization: AI algorithms forecasting material requirements (nylon, polyester, specialized coatings) based on real-time global demand signals, leading to optimized raw material procurement and reduced warehousing costs.

- R&D Acceleration: Utilizing generative AI and computational chemistry to simulate and predict the performance characteristics of new synthetic polymer combinations, leading to faster development of fasteners with enhanced properties (e.g., extreme temperature tolerance, radiation resistance).

- Automated Assembly Integration: AI-guided robotic systems improving the precision and speed of integrating hook and loop fasteners into complex products (e.g., car seats, medical vests), reducing reliance on manual labor.

DRO & Impact Forces Of Hook & Loop Market

The Hook & Loop Market is primarily driven by the imperative for efficient assembly in high-volume industries, especially in the automotive sector where weight reduction and ease of maintenance are paramount. The versatility and reusability of these fasteners provide a significant competitive advantage over traditional methods, fostering widespread adoption across consumer goods and technical textiles. However, the market faces restraints, chiefly the vulnerability of standard hook and loop materials to degradation from excessive dirt, moisture, or UV exposure, which limits their lifespan in severe outdoor or industrial environments. Another significant restraint is the competitive pressure from advanced alternatives such as specialized adhesives, magnetic fasteners, and high-performance mechanical locks that offer superior long-term bonding strength or aesthetic integration, forcing hook and loop manufacturers to continuously innovate material compositions and attachment methods to maintain market share.

Opportunities abound in developing high-performance, specialized hook and loop products, particularly within the medical sector where demand for hypoallergenic, sterilization-resistant fasteners is surging for wearable devices and patient monitoring equipment. Furthermore, the global trend towards electric vehicles (EVs) presents a major opportunity, as hook and loop systems are ideal for managing intricate battery cabling and interior component assembly due to their non-conductive properties and ease of replacement. The impact forces influencing the market dynamics are categorized by factors such as material innovation, regulatory standards (especially fire safety in transport and construction), fluctuating raw material prices (nylon and polyester), and the pace of automation adoption within key end-use industries, all of which dictate pricing strategies and product development cycles for market participants.

The strategic deployment of manufacturing facilities closer to key consumer hubs, particularly in Southeast Asia, acts as a pivotal force in reducing logistics costs and improving responsiveness to regional market needs. Moreover, the environmental impact of textile waste is pushing manufacturers towards developing bio-based or fully recyclable hook and loop systems, aligning with global sustainability mandates and creating new market opportunities for eco-friendly fastening solutions. Navigating the balance between meeting stringent performance requirements for industrial applications and achieving cost-competitiveness in high-volume consumer markets remains the central challenge, requiring manufacturers to continuously refine production efficiency and explore novel polymer science to create hybrid fasteners that merge the best characteristics of traditional hook and loop with high-tech material resilience.

Segmentation Analysis

The Hook & Loop Market is extensively segmented based on material type, product type, attachment method, and end-use industry, reflecting the highly diverse nature of its applications. Segmentation provides critical insights into consumption patterns and growth pockets, enabling stakeholders to tailor their product offerings to specific requirements, whether concerning shear strength for heavy-duty applications or softness and aesthetic appeal for apparel and footwear. The categorization by material, notably nylon versus polyester, determines performance characteristics such as UV resistance, moisture absorption, and overall durability, directly influencing their suitability for outdoor or high-moisture environments. The product type split differentiates between standard woven strips, molded systems, and specialized die-cut shapes used for precise component fixing, indicating the level of customization required by various manufacturing processes.

The attachment method segmentation is crucial, distinguishing between traditional sew-on applications, which dominate textiles, and highly dynamic methods like pressure-sensitive adhesives (PSAs) and heat/sonic welding options, which are increasingly preferred in industrial assembly due to their rapid application and enhanced bond strength to rigid substrates. Analyzing the market through the lens of end-use sectors—Automotive, Healthcare, Apparel, Military, and Industrial—reveals differential growth rates and technology adoption curves. For instance, the medical sector prioritizes biocompatibility and sterilization resilience, while the automotive sector demands flame retardation and vibration stability. This detailed segmentation is vital for forecasting regional demand shifts and directing research and development investments toward high-growth, high-value segments that require proprietary technical solutions and compliance with strict industry standards.

- By Material Type:

- Nylon

- Polyester

- Polypropylene

- Others (e.g., Fire Retardant blends, specialty polymers)

- By Product Type:

- Standard Hook & Loop Tapes

- Molded Fasteners

- Die-Cut Shapes & Straps

- Specialty Fasteners (e.g., one-wrap, cable ties)

- By Attachment Method:

- Sew-On

- Pressure Sensitive Adhesive (PSA) / Self-Adhesive

- Heat/Sonic Weldable

- Mechanical Fixing (e.g., screw-on)

- By End-Use Industry:

- Apparel & Footwear

- Automotive & Transportation

- Healthcare & Medical Devices

- Military & Defense

- Industrial & Construction

- Others (e.g., Sports & Leisure, Electronics)

Value Chain Analysis For Hook & Loop Market

The value chain of the Hook & Loop Market begins with the upstream segment, which involves the sourcing and production of critical raw materials, primarily synthetic polymers like Nylon 6, Nylon 66, and various grades of Polyester and Polypropylene. Key upstream activities include the polymerization and extrusion of these materials into fibers and monofilaments of precise denier and strength specifications. Fluctuations in crude oil prices directly impact the cost structure of these polymers, making raw material procurement and risk management a crucial strategic function for hook and loop manufacturers. Efficiency in this stage, including long-term sourcing contracts and investment in sustainable polymer alternatives, dictates the eventual profitability and price competitiveness of the finished product.

The core manufacturing process, or the midstream segment, involves highly specialized technical textile operations, including weaving or knitting the loop side and molding or extruding the hook side, followed by critical finishing processes such as coating, dyeing, and cutting. Quality control, especially ensuring consistent hook density and loop resilience across batches, is paramount. The downstream segment focuses on distribution channels, which are bifurcated into direct sales to large Original Equipment Manufacturers (OEMs) in the automotive and medical sectors, and indirect sales through specialized industrial distributors, textile wholesalers, and retailers for consumer products. Direct sales channels are characterized by customized specifications and long-term contracts, while indirect channels require broad inventory and fast fulfillment capabilities to service a fragmented customer base.

The distribution network relies heavily on sophisticated global logistics to move bulk rolls or finished straps from manufacturing centers, often located in Asia Pacific, to assembly plants in North America and Europe. Effective management of this distribution channel is vital, particularly for ensuring timely delivery of specialized medical-grade fasteners where delays can impact patient care. Direct sales allow manufacturers to capture higher margins and maintain tight control over product application, providing technical support and customized solutions directly to major clients. Conversely, indirect channels leverage the reach and expertise of distributors who handle inventory holding, localized support, and smaller volume orders, thereby enabling manufacturers to penetrate niche markets without excessive overhead investment. The integration of e-commerce platforms has also become a critical indirect distribution strategy, especially for serving the DIY and small business sectors with standardized products.

Hook & Loop Market Potential Customers

The potential customers for hook and loop fasteners are highly diversified, extending across virtually every manufacturing sector that requires non-permanent, reusable, and adjustable fastening solutions. End-users fall into major categories including large-scale industrial buyers, consumer product manufacturers, and institutional purchasers. In the industrial segment, key customers include automotive assemblers (for securing headliners, floor mats, and wiring), aerospace manufacturers (for cabin interiors and insulation), and construction companies (for temporary cable management and securing components during assembly). These customers prioritize high shear strength, resistance to extreme temperatures, and compliance with rigorous industry standards like flammability ratings (e.g., FMVSS 302).

A rapidly expanding customer segment is the healthcare industry, comprising hospitals, medical device manufacturers, and producers of orthopedic soft goods. These buyers require hypoallergenic, autoclavable (sterilization-resistant) fasteners for applications such as patient restraints, surgical drapes, blood pressure cuffs, and mobility aids. The crucial requirements here center on patient safety, comfort, and the ability to withstand frequent cleaning cycles without loss of gripping performance. Furthermore, the burgeoning market for wearable technology, including fitness trackers and continuous glucose monitors, represents a high-growth customer base seeking miniaturized, low-profile, and aesthetically pleasing fastening solutions that integrate seamlessly with sensor technology and sensitive skin requirements.

Finally, the largest volume buyers often reside in the consumer sector, encompassing major apparel companies, footwear producers, and manufacturers of bags, luggage, and recreational equipment. These customers are driven by cost-efficiency, color matching, and durability through repeated washing and use. Military and defense contractors also constitute a stable and high-value customer group, requiring highly specialized, Mil-Spec-compliant fasteners for tactical gear, uniforms, body armor, and specialized equipment cases, demanding superior strength, infrared reflectance, and stealth characteristics. Serving these distinct customer types requires manufacturers to maintain flexible production lines capable of producing both commodity products and highly engineered technical fasteners, optimizing inventory management to meet varied lead times and volume requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.75 Billion |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Velcro Companies (Velcro Group), 3M Company, YKK Corporation, Kuraray Co., Ltd., APLIX S.A., HALCO USA, Fastenation Inc., Paiho Group, Tex-Tech Industries, Inc., Krahnen & Gobbers GmbH, OHJI Tape Kogyo Co., Ltd., Toung Loong Textile Mfg. Co., Ltd., Tesa SE (Beiersdorf AG), Zhejiang Huaou Textile Technology Co., Ltd., Shijiazhuang Jiejie Hook & Loop Co., Ltd., Hoookay, Milspec Industries, Inc., Grip-Lock, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hook & Loop Market Key Technology Landscape

The technological landscape of the Hook & Loop Market is characterized by continuous refinement in material science and manufacturing precision, moving beyond simple woven nylon strips to engineered polymer systems. A primary technological focus is the development of specialized hook structures, such as mushroom-head shapes and molded plastic hooks, which offer superior tensile and shear strength compared to traditional flexible nylon hooks. These advanced molded fasteners are gaining traction in industrial applications, particularly in securing heavy components in automotive and aerospace industries, as they provide high performance in non-textile assemblies and can be easily integrated via sonic welding or heat activation. Furthermore, advancements in specialized coatings and treatments are essential, including fire-retardant chemical applications and water-repellent finishes, mandatory for fasteners used in high-risk environments and outdoor gear, respectively.

Another pivotal technological area involves attachment methods, specifically the evolution of pressure-sensitive adhesives (PSAs). Modern PSAs used with hook and loop fasteners are engineered for diverse surface energies, allowing reliable adhesion to challenging substrates like low-energy plastics, powder-coated metals, and uneven composites. This technology necessitates precise chemical formulation of the adhesive layer to ensure longevity, temperature resistance, and clean removal capabilities where required. The integration of sonic and radio frequency (RF) welding technologies is also transforming assembly lines, offering a clean, fast, and highly durable method for attaching fasteners directly to thermoplastic materials without the need for sewing or liquid adhesives, significantly accelerating large-scale manufacturing processes and enhancing bond consistency.

Moreover, digital manufacturing and process automation are key technological drivers. Modern production lines utilize high-speed weaving and knitting machines equipped with advanced sensors for real-time quality monitoring and automatic adjustment of tension and pattern, optimizing fiber utilization and reducing waste. Research and development efforts are increasingly directed toward miniaturization and thin-profile fasteners for use in compact electronics and next-generation wearable medical devices, where traditional bulkiness is unacceptable. The trend towards sustainable technology also mandates the development of bio-based polymers and innovative recycling processes for nylon and polyester fasteners at the end of their lifecycle, pushing manufacturers to invest in materials science that aligns performance requirements with environmental responsibility.

Regional Highlights

The global Hook & Loop Market exhibits highly distinct regional characteristics driven by localized industrial output, technological maturity, and regulatory environments.

- Asia Pacific (APAC): This region dominates the manufacturing landscape and represents the fastest-growing market. Key drivers include massive production bases for apparel, footwear, and consumer electronics in China, Vietnam, and India. The rapid expansion of automotive production and local infrastructure projects further fuels demand. APAC manufacturers are highly focused on cost optimization and high-volume output of both commodity and mid-range specialty fasteners, serving both domestic demand and acting as the global supply hub.

- North America: Characterized by mature demand and a strong focus on high-value, technical applications, particularly in the aerospace, defense, and healthcare sectors. Demand is driven by stringent quality standards and the necessity for specialized products (e.g., fasteners meeting military specifications or FDA approval). The region leads in adoption of advanced PSA technologies and innovative molded plastic fastening systems for complex industrial assemblies.

- Europe: This region maintains a robust market share, driven primarily by the high-end automotive sector (Germany, France) and strict regulatory requirements regarding safety, fire resistance, and environmental sustainability. European consumers and manufacturers show a strong preference for high-quality, durable fasteners, often utilizing specialized textile treatments. The region is also a major consumer in the medical and industrial machinery segments, emphasizing long lifecycle and compliance with various EU technical directives.

- Latin America (LATAM): The market in LATAM is emerging, characterized by increasing industrialization, particularly in Brazil and Mexico. Growth is concentrated in the automotive assembly sector and the expanding local textile and footwear manufacturing industries. Adoption rates are gradually increasing, though the market remains sensitive to economic stability and currency fluctuations, often relying on imported specialty fasteners for high-performance applications.

- Middle East and Africa (MEA): This region represents the smallest market share but offers long-term growth potential, particularly in construction, oil & gas, and defense sectors. Demand is volatile but increasing, influenced by major government infrastructure investments (e.g., GCC countries) and the need for specialized, durable fasteners that can withstand harsh desert climates and high temperatures prevalent in the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hook & Loop Market.- Velcro Companies (Velcro Group)

- 3M Company

- YKK Corporation

- Kuraray Co., Ltd.

- APLIX S.A.

- HALCO USA

- Fastenation Inc.

- Paiho Group

- Tex-Tech Industries, Inc.

- Krahnen & Gobbers GmbH

- OHJI Tape Kogyo Co., Ltd.

- Toung Loong Textile Mfg. Co., Ltd.

- Tesa SE (Beiersdorf AG)

- Zhejiang Huaou Textile Technology Co., Ltd.

- Shijiazhuang Jiejie Hook & Loop Co., Ltd.

- Hoookay

- Milspec Industries, Inc.

- Grip-Lock, Inc.

- Fastech Corporation

- Boyang Hook & Loop Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Hook & Loop market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Hook & Loop Market?

The market growth is primarily driven by the increasing adoption of hook and loop fasteners in the automotive sector for lightweighting and interior management, the high demand from the healthcare industry for reusable and sterile medical device straps, and general efficiency gains realized from utilizing reusable fasteners over permanent solutions in manufacturing processes globally.

Which material type dominates the Hook & Loop Market and why?

Nylon dominates the market due to its excellent balance of cost, durability, high shear strength, and overall versatility, making it suitable for a vast range of applications from apparel to industrial use. However, polyester is preferred in high-UV and moisture-prone environments due to its superior resistance to environmental degradation compared to nylon.

How is the Hook & Loop Market impacted by the shift towards electric vehicles (EVs)?

The transition to EVs positively impacts the market. Hook and loop systems are crucial for securing complex wiring harnesses, battery cabling, interior insulation, and floor components in EVs, offering non-conductive, lightweight, and easily maintainable fastening solutions that meet stringent safety standards required for electric powertrains.

What role does technological innovation play in modern hook and loop fasteners?

Technological innovation focuses heavily on developing high-performance molded plastic hooks for superior strength, advanced pressure-sensitive adhesives (PSAs) for difficult surfaces, and specialty materials like flame-retardant and bio-based polymers. These innovations expand applications into demanding sectors like aerospace and medical wearables, ensuring long-term product relevance.

Which region currently offers the most lucrative growth opportunities for hook and loop manufacturers?

Asia Pacific (APAC), particularly China, India, and Southeast Asia, offers the most lucrative growth opportunities. This is due to the rapid expansion of manufacturing capabilities across key end-use industries—textiles, electronics, and automotive—combined with favorable raw material sourcing conditions and lower operating costs, driving high volume consumption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager