Hopkinson Pressure Bar Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432537 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Hopkinson Pressure Bar Market Size

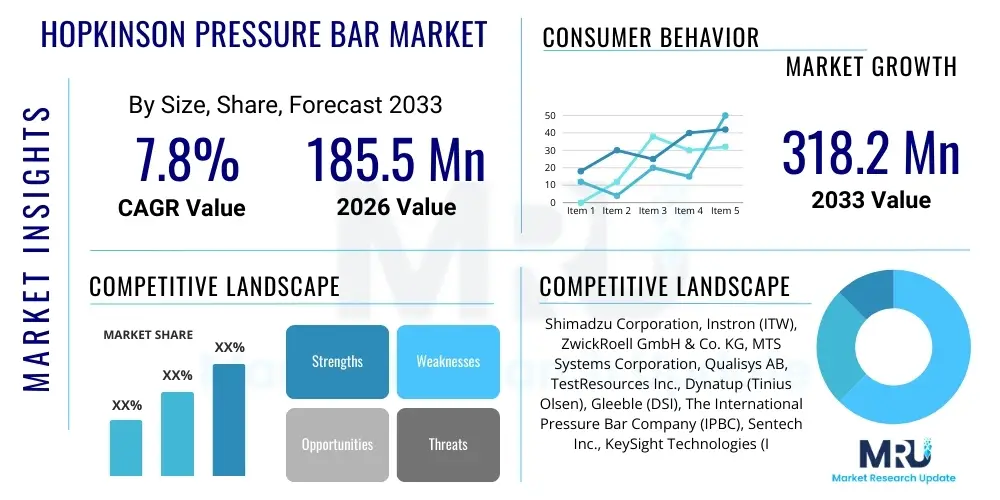

The Hopkinson Pressure Bar Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 185.5 Million in 2026 and is projected to reach USD 318.2 Million by the end of the forecast period in 2033. This growth trajectory is fundamentally driven by escalating requirements across the aerospace, defense, and automotive safety sectors for accurate, high-strain rate mechanical characterization of advanced materials, including composites, ceramics, and new metallic alloys. The necessity to simulate crashworthiness, ballistic impact, and extreme environmental conditions demands sophisticated testing apparatus, positioning the Hopkinson Pressure Bar (HPB) as an indispensable tool for material scientists and engineers globally.

The specialized nature of the HPB market implies high barriers to entry, characterized by the need for precision engineering, high-speed data acquisition systems, and expert calibration services. While the unit volume is relatively low compared to mass-market instruments, the high value associated with customization, software integration, and maintenance contracts ensures robust market valuation. Furthermore, increased government and private investment in material science research and development, particularly in nations focused on bolstering domestic defense capabilities and advancing sustainable transportation technologies, significantly fuels the demand for these critical testing instruments, thereby sustaining the forecasted strong CAGR throughout the projection period.

Hopkinson Pressure Bar Market introduction

The Hopkinson Pressure Bar (HPB), often referred to as the Split Hopkinson Pressure Bar (SHPB) system, is a highly specialized scientific instrument designed to measure the dynamic mechanical properties of materials under high strain rates, typically ranging from 102 s-1 to 104 s-1. This dynamic testing is crucial for understanding how materials behave when subjected to sudden, intense loads, such as those encountered during impacts, explosions, or high-speed deformation processes. The fundamental principle involves generating a well-defined stress pulse that travels through two long, high-strength bars—the incident bar and the transmission bar—with the small specimen sandwiched in between. Strain gauges mounted on these bars record the incident, reflected, and transmitted waves, allowing precise calculation of the material's stress-strain curve under dynamic loading conditions.

Major applications of the Hopkinson Pressure Bar span critical sectors including defense and aerospace, where accurate assessment of ballistic resistance and structural integrity under impact is paramount. In the automotive industry, HPB systems are vital for testing crash components and developing new lightweight materials that offer superior energy absorption capabilities. Beyond these industries, academic research institutions and specialized material science laboratories utilize HPB systems extensively for fundamental research into material failure mechanisms, constitutive modeling, and the performance evaluation of novel materials such such as advanced ceramics, polymeric composites, and metallic foams. The ability of the HPB method to isolate high strain rate effects without significant inertia limitations makes it superior to traditional quasi-static testing methods.

The primary benefits derived from using HPB technology include highly accurate determination of dynamic yield strength, ultimate tensile strength, and strain-rate sensitivity, which are essential inputs for advanced numerical simulations (like Finite Element Analysis). Driving factors for market expansion include the global shift towards incorporating lightweight and ultra-high-strength materials in construction and manufacturing, the continuous modernization of military defense systems requiring validated impact-resistant armor, and increasingly stringent global safety standards mandating comprehensive crash testing protocols. These drivers collectively necessitate reliable, high-fidelity dynamic material characterization tools, cementing the importance of the Hopkinson Pressure Bar in the modern engineering landscape.

Hopkinson Pressure Bar Market Executive Summary

The Hopkinson Pressure Bar market exhibits robust growth, fueled predominantly by technological advancements in materials science and heightened global security concerns. Key business trends include increased integration of highly sophisticated digital data acquisition systems (DAS) capable of sampling rates exceeding 1 MHz, alongside specialized software for automated wave separation and stress calculation, minimizing human error and accelerating research cycles. Furthermore, niche manufacturers are increasingly offering customized bar material and geometry solutions, tailoring systems for extreme temperature testing (cryogenic or high heat) to meet specialized aerospace and energy sector requirements. Business models are shifting towards offering complete solutions, encompassing hardware, specialized testing fixtures, calibration services, and long-term maintenance contracts, rather than just standalone equipment sales, enhancing recurring revenue streams for key players.

Regionally, the market is currently dominated by North America and Europe, driven by established defense research infrastructures and mature automotive industries prioritizing safety innovation. However, the Asia Pacific (APAC) region, particularly China, South Korea, and India, is emerging as the fastest-growing market segment. This surge in APAC is attributed to rapid industrialization, massive investments in domestic defense production, and the proliferation of material science research universities acquiring cutting-edge testing capabilities. Infrastructure development in regions like the Middle East is also spurring demand, particularly in the construction and energy sectors requiring advanced characterization of structural materials under dynamic loads, indicating a geographic diversification of sales over the forecast period.

Segmentation trends highlight the dominance of the Split Hopkinson Pressure Bar (SHPB) configuration due to its versatility in both compression and tension testing. While traditionally focused on metallic specimens, the highest growth segment is projected to be composite and ceramic materials testing, reflecting the aerospace industry’s push for lighter structures. The end-use application segment confirms the leading role of Academic and Government Research Institutions in driving initial adoption and methodological innovation, closely followed by the Defense sector, which mandates stringent material qualification standards. The trend is moving towards miniaturization and automation of HPB systems to accommodate smaller, more complex specimens and improve throughput in high-volume industrial testing environments.

AI Impact Analysis on Hopkinson Pressure Bar Market

Common user questions regarding the influence of Artificial Intelligence (AI) on the Hopkinson Pressure Bar market center heavily on how machine learning algorithms can improve data processing accuracy, automate complex calibration procedures, and integrate experimental results with predictive material modeling. Users frequently inquire about AI's potential to filter noise and separate complex waveforms in highly dynamic tests, traditionally a manual and subjective process. Another critical area of interest revolves around leveraging AI for autonomous design of experiments (DoE), where algorithms optimize impact parameters (e.g., striker velocity, specimen geometry) to achieve desired strain rates efficiently, minimizing physical test runs and associated costs. Furthermore, there is significant expectation that AI could rapidly validate complex constitutive models by comparing high-throughput HPB data against theoretical predictions, accelerating the development cycle for new materials used in high-impact scenarios.

The incorporation of AI and machine learning techniques is poised to revolutionize the post-processing phase of HPB experiments. Current methodologies often involve substantial manual effort in signal alignment, baseline correction, and calculating dynamic stress-strain curves, all of which are susceptible to user variability. AI algorithms offer automated, objective processing pipelines, significantly enhancing the repeatability and reliability of dynamic material properties derived from HPB tests. By employing neural networks trained on vast datasets of successful and failed experiments, AI can quickly identify subtle anomalies or discrepancies in wave propagation, ensuring data integrity and allowing researchers to focus more on material interpretation rather than data cleanup. This shift in operational efficiency directly translates into faster material certification and deployment, particularly crucial in fast-paced sectors like defense and competitive automotive R&D.

Beyond data analysis, AI is also impacting the design and optimization of the bar systems themselves. Generative design techniques, fueled by AI, can propose novel bar geometries or materials that improve wave quality, reduce dispersion effects, and extend the functional range of the HPB apparatus. In real-time monitoring, AI can detect potential equipment failures or environmental disturbances that might compromise test validity, triggering immediate corrective actions. This level of smart integration transforms the HPB from a highly specialized mechanical tool into an intelligent, autonomous testing platform capable of generating validated, high-fidelity input data essential for cutting-edge simulation software, ultimately reducing the gap between experimental observation and theoretical prediction in dynamic mechanics.

- AI streamlines data processing and signal filtering, enhancing the accuracy of dynamic stress-strain curve calculations.

- Machine learning algorithms enable automated optimization of test parameters (striker design, velocity) for targeted strain rates, reducing experimental trial cycles.

- Predictive maintenance and anomaly detection using AI ensure higher equipment uptime and improved data integrity during high-speed tests.

- AI aids in rapid validation of complex constitutive material models against real-world HPB experimental data, accelerating material certification.

- Integration with computational fluid dynamics (CFD) and finite element modeling (FEM) for smarter, integrated simulation environments.

DRO & Impact Forces Of Hopkinson Pressure Bar Market

The dynamics of the Hopkinson Pressure Bar market are shaped by a complex interplay of Drivers, Restraints, Opportunities, and inherent Impact Forces. A primary driver is the accelerating global demand for high-performance, lightweight materials in critical applications, which necessitates precise characterization of material behavior under dynamic loading, a unique capability provided by HPB systems. Secondly, continuous military modernization programs globally require validation of advanced armor and protective structures against high-velocity impacts, mandates which rely heavily on dynamic testing standards met by HPB technology. Conversely, significant restraints include the extremely high initial capital investment required for purchasing, installing, and calibrating a complete HPB system, alongside the necessity for highly specialized technical expertise to operate and maintain the equipment accurately. Furthermore, the complexity of obtaining repeatable results across different labs presents a standardization challenge that can sometimes limit the broader industrial adoption of the method.

Opportunities for market expansion are abundant, particularly in the development of modular and portable HPB systems that cater to field testing requirements and smaller research facilities with limited space. The growing trend of incorporating HPB testing into industrial quality control processes, especially in manufacturing sectors dealing with shock-sensitive components like electronics and specialized composites, represents an untapped revenue stream. Furthermore, the rapid growth of additive manufacturing (3D printing) requires dynamic testing of novel geometries and materials produced via these methods, opening up new specialized HPB configurations. The market is also seeing an opportunity in the standardization and development of global testing protocols, which would enhance the comparability and acceptance of HPB data across international borders, thereby broadening the user base beyond niche research laboratories and defense contractors.

The inherent impact forces governing this specialized market are centered around technological innovation and regulatory pressure. Technological impact forces include the persistent drive to increase maximum achievable strain rates and improve signal-to- noise ratio through advanced sensors and optics (e.g., high-speed cameras synchronized with strain gauges), pushing the boundaries of dynamic material characterization. Regulatory impact forces, driven primarily by government defense and safety agencies (like NHTSA or EASA), continuously introduce stricter material safety and performance standards, thereby guaranteeing sustained demand for the highest fidelity testing instruments like the HPB. The competitive landscape is intensely focused on precision and customization, meaning even small technological advances in data acquisition speed or specialized bar materials can significantly impact market share among the few key manufacturers.

Segmentation Analysis

The Hopkinson Pressure Bar market is systematically segmented based on Type, Material, Application, and End-User, reflecting the diverse requirements of the dynamic testing landscape. Analyzing these segments provides crucial insights into growth pockets and technological preferences. The Type segmentation primarily differentiates between the Split Hopkinson Pressure Bar (SHPB), used for material characterization, and the Direct Impact HPB (DIHPB), often used for specialized structural testing. Material segmentation is vital as it dictates the required impedance and length of the pressure bars, categorized generally into steel, titanium, aluminum, and ceramic bars, each tailored for different sample materials and test strain levels. This structure allows manufacturers to cater to the specific needs of high-strain-rate researchers, ranging from polymers to ultra-hard alloys and composites.

Application-wise, the market is heavily skewed towards dynamic characterization for Ballistics/Impact Simulation and Crashworthiness Analysis. These applications demand extreme precision and reliability, justifying the high cost of the equipment. End-user segmentation reveals a dual market structure: on one hand, the dominant Academic and Research Institutions drive methodological development and basic material studies; on the other, the Defense & Aerospace sector represents the highest revenue generating segment due to stringent requirements for customized, high-specification systems and continuous replacement cycles. Understanding the interplay between these segments is critical for strategic market penetration, focusing sales efforts on regions undergoing rapid defense modernization or those investing heavily in automotive safety R&D.

- Type

- Split Hopkinson Pressure Bar (SHPB)

- Split Hopkinson Tensile Bar (SHTB)

- Split Hopkinson Torsion Bar (SHTTB)

- Direct Impact Hopkinson Pressure Bar (DIHPB)

- Miniaturized Hopkinson Bar Systems

- Bar Material

- High Strength Steel (Maraging Steel, Stainless Steel)

- Titanium Alloys

- Aluminum Alloys

- Ceramic/Polymer Bars (for soft materials testing)

- Application

- Ballistic and Impact Simulation

- Crashworthiness Analysis

- Material Failure Mechanism Studies

- Dynamic Fracture and Fatigue Testing

- Protective Structures Testing (e.g., armor)

- End-User

- Academic & Government Research Institutions

- Defense & Aerospace

- Automotive & Transportation

- Materials Science Laboratories

- Energy Sector (e.g., nuclear and oil & gas pipeline integrity)

Value Chain Analysis For Hopkinson Pressure Bar Market

The value chain of the Hopkinson Pressure Bar market begins with Upstream Analysis, focusing on the procurement of highly specialized raw materials, primarily ultra-high-strength, high-uniformity steel and specialized alloys like aerospace-grade titanium. The selection and sourcing of these materials are paramount, as bar material quality directly impacts the fidelity of the propagating stress wave and the system’s longevity. Key suppliers in this stage are specialized metal refineries and precision engineering material distributors. The complexity of material sourcing, coupled with strict requirements for dimensional tolerance and surface finish, often leads to high input costs, representing a significant portion of the final product price.

The core of the value chain is the Manufacturing and Assembly stage. This involves intricate precision machining of the pressure bars, often requiring specialized grinding and lapping techniques to ensure extremely low surface roughness and perfect collinearity. This stage also includes the integration of complex electronic components: high-bandwidth strain gauges, sophisticated high-speed data acquisition systems (DAS), and synchronized high-velocity camera triggering mechanisms. Since systems are frequently customized, manufacturers must maintain highly skilled in-house engineering and calibration teams. Distribution Channel analysis shows that direct sales are overwhelmingly predominant, given the technical complexity and the need for close consultation between the manufacturer and the specialized end-user (e.g., university professor or defense laboratory). Indirect distribution is rare but sometimes involves specialized regional scientific equipment representatives who handle installation and initial training.

Downstream Analysis focuses on Post-Sales Support, which is a crucial profit center in this market. This includes on-site installation, rigorous calibration procedures, specialized software training, and long-term maintenance contracts, especially the periodic recalibration of strain gauges and sensors. Direct sales ensure deep customer relationships, allowing for the rapid feedback necessary for continuous product improvement and the development of specialized fixtures. The primary bottleneck in the value chain is the precision manufacturing capacity and the availability of highly specialized technical consultants, emphasizing that value is derived less from volume and more from intellectual property and technical service delivery throughout the product lifecycle.

Hopkinson Pressure Bar Market Potential Customers

The primary End-Users and buyers of Hopkinson Pressure Bar systems are institutions and organizations involved in material research, safety testing, and structural integrity assessment under dynamic conditions. Academic institutions, particularly university departments specializing in mechanical engineering, materials science, and civil engineering, represent a foundational customer base. These entities purchase HPB systems primarily for fundamental research, Ph.D. projects, and generating data for constitutive models that underpin engineering simulation software. Their buying decisions are often influenced by grant funding cycles, institutional reputation, and the need for versatile systems capable of testing various material types and configurations (compression, tension, torsion).

The Defense and Aerospace sectors constitute the highest-value potential customer segment. Government defense agencies, national laboratories, and prime aerospace contractors (e.g., manufacturers of jet engines, spacecraft, and military vehicles) utilize HPB systems for critical material qualification. Their requirements center on testing specialized components and protective materials, such as ballistic armor, high-temperature composite components, and lightweight metallic alloys, under conditions simulating severe operational stress and impact events. Purchasing decisions in this sector are driven by stringent regulatory compliance, national security requirements, and the need for bespoke, often large-scale, high-energy systems that guarantee the highest level of data reliability and security.

Furthermore, the automotive industry, particularly leading Original Equipment Manufacturers (OEMs) and major component suppliers focused on safety systems (e.g., crash structures, airbags, and pedestrian protection systems), represents a rapidly growing customer segment. As vehicles incorporate increasing amounts of multi-material systems (high-strength steel, aluminum, carbon fiber composites), precise knowledge of their dynamic failure mechanisms is essential for accurate crash simulation and vehicle certification. These industrial buyers prioritize systems that offer automated testing protocols, high throughput, and seamless integration with existing Finite Element Analysis (FEA) software platforms, making ease of use and long-term service support key purchasing criteria.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.5 Million |

| Market Forecast in 2033 | USD 318.2 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Shimadzu Corporation, Instron (ITW), ZwickRoell GmbH & Co. KG, MTS Systems Corporation, Qualisys AB, TestResources Inc., Dynatup (Tinius Olsen), Gleeble (DSI), The International Pressure Bar Company (IPBC), Sentech Inc., KeySight Technologies (Indirectly), Kistler Group, National Instruments Corporation (NI), Hubei Sanxia Science & Technology, TNO (Netherlands Organisation for Applied Scientific Research), Fraunhofer Institute (Affiliated Labs) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hopkinson Pressure Bar Market Key Technology Landscape

The technological landscape of the Hopkinson Pressure Bar market is characterized by advancements focused on enhancing measurement accuracy, broadening the range of dynamic testing parameters, and improving data acquisition reliability. A core technological aspect is the continuous refinement of sensing elements. While traditional foil strain gauges remain standard, there is a growing adoption of advanced piezoresistive sensors and fiber optic sensors (FOS) which offer superior bandwidth, reduced thermal drift, and improved immunity to electromagnetic interference. These advancements are crucial for accurately capturing the ultra-fast stress wave propagation events, ensuring clean signal collection even at strain rates exceeding 104 s-1. Furthermore, manufacturers are focusing heavily on developing robust synchronization technologies to align the data streams from strain gauges with ultra-high-speed cameras (up to millions of frames per second) used for digital image correlation (DIC), which provides full-field strain measurements, moving beyond single-point strain readings.

Data acquisition systems (DAS) represent another critical technology focus. The sheer speed of the phenomena studied by HPB systems mandates DAS capable of sampling rates in the gigahertz range, coupled with high channel counts and large onboard memory to capture the entire transient event. Modern HPB systems utilize proprietary software integrated with these high-speed digitizers, offering advanced signal processing capabilities, including automated wave separation, dispersion correction algorithms, and fast Fourier transform (FFT) analysis. This technological integration simplifies the complex task of extracting true material response from the raw wave data, a major historical challenge in HPB methodology. The focus is shifting towards compact, modular DAS systems that allow for easy upgrades and flexible configurations, crucial for laboratories with evolving research needs.

Lastly, the integration of computational modeling technologies with experimental setups defines the cutting edge of the HPB market. Manufacturers are increasingly providing standardized output formats and dedicated interfaces that directly feed HPB experimental data into commercial Finite Element Analysis (FEA) packages, such as ABAQUS or LS-DYNA. This facilitates the rapid calibration and validation of complex constitutive material models (e.g., Johnson-Cook, Zerilli-Armstrong), which are indispensable for simulating large-scale structures like vehicles or military installations. The ability to seamlessly translate high-fidelity experimental results into verified simulation parameters ensures the continued relevance of HPB technology in the era of computational engineering, driving demand for technologically superior, integrated systems.

Regional Highlights

- North America: This region holds a commanding position in the Hopkinson Pressure Bar market, primarily due to the significant and sustained investment by the United States Department of Defense (DoD) in advanced materials research for military and aerospace applications. Key drivers include rigorous testing standards for ballistic protection, development of hypervelocity weapon systems, and expansive research programs within national laboratories and tier-one universities. The strong presence of major aerospace and automotive manufacturers necessitates continuous dynamic material characterization, ensuring robust demand for sophisticated, high-end HPB systems. Canada also contributes to demand through its focus on materials used in extreme environmental conditions, particularly oil and gas infrastructure, and northern aerospace operations.

- Europe: Europe represents a mature but technologically dynamic market, led by Germany, France, and the UK. The region is driven by stringent automotive safety regulations (Euro NCAP standards) demanding precise crashworthiness data and strong academic research tradition, often supported by European Union funding initiatives focusing on advanced manufacturing and lightweight materials (e.g., Horizon Europe programs). European manufacturers often lead in precision engineering and standardization efforts for HPB systems, focusing on modularity and high-quality data acquisition, appealing strongly to industrial R&D centers and calibration labs seeking globally verifiable results.

- Asia Pacific (APAC): APAC is projected to experience the highest growth rate during the forecast period. This acceleration is spearheaded by China and India, driven by rapidly expanding domestic defense industries, massive infrastructure projects requiring new high-performance materials, and substantial governmental investment in scientific research facilities and universities. China, in particular, is aggressively acquiring advanced testing capabilities to reduce reliance on Western technology and accelerate innovation in its automotive and high-speed rail sectors. The demand here is often bifurcated, spanning both high-volume standardized systems for industrial labs and customized, ultra-high-speed systems for elite governmental research institutes.

- Latin America (LATAM): The LATAM market remains nascent, characterized primarily by academic demand centered in countries like Brazil and Mexico, focusing mainly on fundamental material science research. Market expansion is dependent on governmental funding for R&D infrastructure upgrades and increased industrial investment, particularly in the domestic aerospace components manufacturing and raw materials processing sectors, which are beginning to adopt dynamic testing protocols.

- Middle East and Africa (MEA): Demand in MEA is concentrated around government-backed defense modernization programs and large-scale energy sector projects (oil, gas, and nuclear). Countries like Saudi Arabia and the UAE are investing in specialized research centers to support long-term economic diversification goals, creating a niche market for high-specification HPB systems used in structural integrity assessment and defense technology evaluation. Growth is highly dependent on geopolitical stability and long-term public spending commitments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hopkinson Pressure Bar Market.- Shimadzu Corporation

- Instron (ITW)

- ZwickRoell GmbH & Co. KG

- MTS Systems Corporation

- Qualisys AB

- TestResources Inc.

- Dynatup (Tinius Olsen)

- Gleeble (DSI)

- The International Pressure Bar Company (IPBC)

- Sentech Inc.

- KeySight Technologies (Indirectly)

- Kistler Group

- National Instruments Corporation (NI)

- Hubei Sanxia Science & Technology

- TNO (Netherlands Organisation for Applied Scientific Research)

- Fraunhofer Institute (Affiliated Labs and Commercial Spin-offs)

- Fuji Technical Research Inc.

- Sintech Corporation

- Veryst Engineering

- Michigan Scientific Corporation

Frequently Asked Questions

What is the primary function of a Hopkinson Pressure Bar (HPB) system?

The primary function of an HPB system is to accurately measure the dynamic mechanical properties (stress-strain behavior) of materials under extremely high strain rates, typically between 500/s and 10,000/s. This is crucial for understanding how materials behave during high-velocity impacts, ballistic events, and crash scenarios where traditional testing methods are inadequate.

Which industries are the major end-users of Hopkinson Pressure Bar technology?

The major end-users of HPB technology are the Defense and Aerospace sectors, requiring material characterization for armor and structural components; the Automotive industry for crashworthiness analysis; and Academic and Governmental Research Institutions for fundamental material science studies and constitutive model validation.

What are the key technical challenges associated with operating an SHPB system?

Key technical challenges include achieving perfect axial alignment and collinearity of the pressure bars, accurately performing signal dispersion correction (to account for wave distortion), managing high levels of electrical noise during impact, and ensuring accurate synchronization between strain gauge data acquisition and high-speed optical measurements.

How is the adoption of composite materials impacting the HPB market demand?

The increasing adoption of lightweight composite and ceramic materials in aerospace and automotive applications drives significant HPB market demand. These materials often exhibit highly strain-rate-sensitive behavior, necessitating dynamic testing to accurately determine their failure criteria and energy absorption capabilities, often requiring specialized, non-metallic pressure bars.

What role does Artificial Intelligence play in modern Hopkinson Pressure Bar data analysis?

AI, particularly machine learning, plays a crucial role in automating the complex post-processing of HPB data. AI algorithms are used for noise reduction, automated wave separation, and optimizing dispersion correction parameters, thereby significantly enhancing the speed, accuracy, and repeatability of dynamic stress-strain curve calculations compared to manual methods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager