Horizontal Colloid Mill Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432015 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Horizontal Colloid Mill Market Size

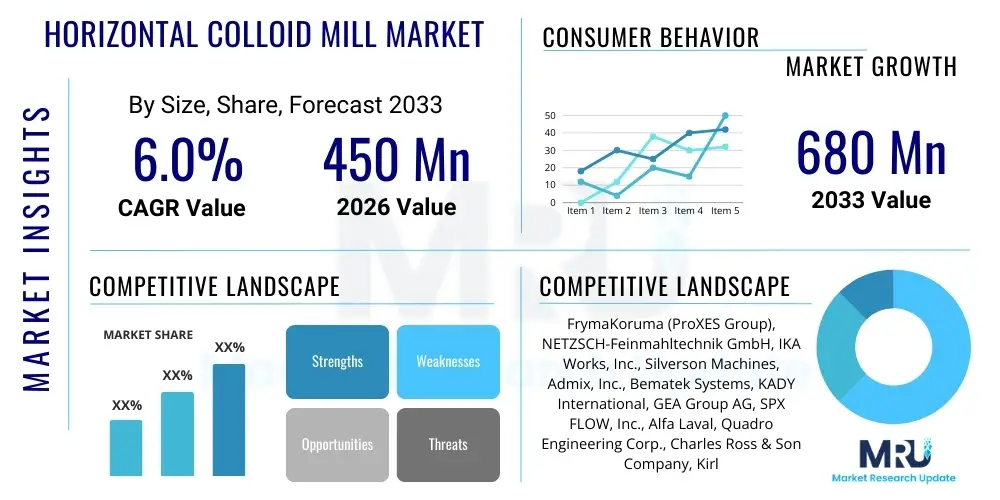

The Horizontal Colloid Mill Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.0% CAGR between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 680 Million by the end of the forecast period in 2033. This consistent growth trajectory is fundamentally driven by the expanding requirements for fine particle size reduction and superior homogenization across specialized manufacturing sectors, particularly pharmaceuticals and processed foods, where stringent quality and consistency standards necessitate high-performance processing equipment.

Horizontal Colloid Mill Market introduction

The Horizontal Colloid Mill Market encompasses the manufacturing, distribution, and utilization of high-shear mixing and homogenization equipment designed for producing fine dispersions, emulsions, and suspensions. Horizontal colloid mills operate on the principle of rotor-stator mechanical shearing, where liquid or semi-liquid materials are forced through a narrow, adjustable gap between high-speed rotating and stationary surfaces. This intense hydraulic and mechanical shear ensures effective particle size reduction, leading to highly stable and uniform final products crucial for texture, stability, and efficacy in various industrial applications.

The primary applications of horizontal colloid mills span diverse industries, including the pharmaceutical sector for producing gels, ointments, and medicinal suspensions; the food and beverage industry for manufacturing sauces, peanut butter, cocoa mass, and emulsified beverages; and the cosmetics industry for lotions, creams, and hair care products. Furthermore, they are extensively utilized in the chemical sector for processing dyes, pigments, and specialized chemical dispersions, ensuring consistent quality and stability that conventional mixers cannot achieve. The inherent benefit of horizontal configuration lies in its efficient material handling, easier maintenance, and often higher throughput capacity compared to vertical counterparts, making them preferred for continuous, large-scale industrial production environments.

Key factors driving the expansion of this market include the global rise in demand for processed and packaged foods requiring stable emulsification, the increasing complexity and volume of pharmaceutical formulations necessitating nano or ultra-fine particle sizes for enhanced bioavailability, and the stringent regulatory standards enforcing product consistency and quality across heavily regulated industries. Additionally, advancements in material science and design are leading to more efficient, corrosion-resistant mills capable of handling highly abrasive or viscous substances, further broadening their applicability and contributing to overall market penetration globally.

Horizontal Colloid Mill Market Executive Summary

The Horizontal Colloid Mill Market exhibits robust growth, underpinned by fundamental shifts in global manufacturing practices emphasizing product quality, stability, and efficiency. Business trends reveal a strong inclination towards customized and modular mill designs that offer enhanced flexibility, allowing manufacturers to rapidly switch between different product batches and viscosity requirements without significant downtime. Key manufacturers are focusing on integrating automation and sensor technologies into the mill design to facilitate real-time monitoring of shear rates, temperature, and gap settings, thus ensuring optimized process parameters and minimizing material wastage, which is particularly critical in high-value sectors like pharmaceuticals.

Regionally, the market is characterized by differential growth rates, with Asia Pacific (APAC) emerging as the leading and fastest-growing region. This acceleration in APAC is primarily attributed to massive expansion in the pharmaceutical manufacturing base, particularly in India and China, coupled with surging consumer demand for processed foods and personal care items. North America and Europe, while representing mature markets, maintain significant market share due to the early adoption of advanced processing technologies and strict regulatory frameworks demanding high-precision equipment. These regions are driving innovation concerning energy efficiency and adherence to Good Manufacturing Practices (GMP) standards.

Segment trends indicate that the stainless steel 316 material segment dominates the market due to its superior corrosion resistance, essential when handling aggressive chemical or pharmaceutical ingredients. Furthermore, the pharmaceutical and food & beverage application segments jointly account for the largest share, reflecting the mission-critical nature of homogenization and particle size reduction in these highly sensitive industries. The trend toward high-shear colloid mills is particularly notable, driven by the increasing need for producing nano-emulsions and stable, long-shelf-life liquid formulations, signaling a shift toward higher-specification, higher-cost equipment throughout the forecast period.

AI Impact Analysis on Horizontal Colloid Mill Market

User queries regarding the impact of Artificial Intelligence (AI) on the Horizontal Colloid Mill Market commonly revolve around themes of predictive maintenance, process optimization, and automation of quality control. Users are concerned about whether AI can truly enhance the performance stability of these high-shear mechanical systems and reduce unexpected operational failures. Key expectations include utilizing machine learning (ML) algorithms to analyze real-time vibration, temperature, and pressure data streams from the mill to anticipate wear and tear, thereby moving operations from reactive to predictive maintenance schedules. There is also significant interest in how AI can adjust process parameters (like rotor speed and gap setting) autonomously to maintain optimal particle size distribution and product uniformity despite variations in raw material quality, thus eliminating the need for constant manual recalibration and maximizing overall throughput efficiency.

- AI-driven predictive maintenance significantly reduces unplanned downtime by analyzing sensor data to forecast equipment failure.

- Machine learning algorithms optimize homogenization parameters (shear rate, flow) in real-time, ensuring superior and consistent product quality.

- AI enhances energy efficiency by dynamically adjusting power consumption based on material viscosity and required output consistency.

- Integration of AI with vision systems allows for automated, high-speed inspection of finished product quality and particle size analysis.

- AI facilitates better supply chain management by correlating mill performance data with raw material batch characteristics for improved traceability.

DRO & Impact Forces Of Horizontal Colloid Mill Market

The Horizontal Colloid Mill Market is significantly shaped by a confluence of driving factors, restrictive barriers, and strategic opportunities that dictate its trajectory and the competitive landscape. A primary driver is the exponentially increasing global demand for high-quality, stable emulsions and suspensions across fast-growing consumer sectors, particularly in emerging economies where industrialization is rapidly advancing. Simultaneously, stringent regulatory requirements, such as those imposed by the FDA and EMA for pharmaceutical consistency and compliance, necessitate the use of precise, high-performance equipment like horizontal colloid mills to ensure product integrity and patient safety. These drivers collectively create a sustained baseline demand for advanced milling technology.

Conversely, the market faces several restraining forces, most notably the high initial capital investment required for purchasing and installing these specialized mills, which can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, the complexity of maintenance and the requirement for highly skilled technical personnel to operate and calibrate the precision machinery pose significant operational challenges, particularly in regions where technical expertise is scarce. The continuous need to develop erosion-resistant materials capable of withstanding the high shear forces and abrasive nature of certain product matrices also presents an ongoing cost and R&D restraint for manufacturers, influencing the overall cost of ownership.

Opportunities for market expansion are centered on the rapid adoption of nanotechnology in drug delivery systems and functional food formulations, which requires mills capable of generating ultra-fine particle sizes (nano-emulsions). Manufacturers can capitalize on the growing trend toward green chemistry and sustainability by developing energy-efficient, closed-loop systems that minimize material loss and clean-in-place (CIP) complexity. Furthermore, expanding into high-growth, underserved geographic markets, coupled with offering comprehensive service contracts and digitalization solutions (Industry 4.0 integration), presents substantial avenues for revenue generation and competitive differentiation, transforming the market from purely equipment sales to integrated solutions provision.

Segmentation Analysis

The Horizontal Colloid Mill Market is comprehensively segmented based on various technical and application parameters to provide a granular view of market dynamics and potential growth areas. Key segmentation criteria include the type of mill based on operational mechanisms, the material of construction essential for chemical compatibility and durability, the specific industry application where the mill is deployed, and the capacity of the mill suited for different production scales. Understanding these segments is crucial for manufacturers to tailor their product offerings and for end-users to select equipment that meets their precise homogenization and dispersion requirements while adhering to stringent industry standards like GMP regulations.

- By Type:

- Standard Colloid Mills (Fixed gap)

- Variable Speed Colloid Mills

- High Shear Homogenization Mills (Ultra-fine particle generation)

- By Material of Construction:

- Stainless Steel 304

- Stainless Steel 316 (Dominant in Pharma/Food Grade applications)

- Specialty Alloys (For highly abrasive or corrosive media)

- By Application:

- Pharmaceuticals (Ointments, Suspensions, Gels)

- Food & Beverages (Sauces, Pastes, Emulsions, Beverages)

- Cosmetics & Personal Care (Creams, Lotions, Shampoos)

- Chemicals (Dyes, Pigments, Adhesives)

- Paints & Coatings (Dispersions and Resins)

- Others (Pulp & Paper, Textiles)

- By End-User Size:

- Large-Scale Production Facilities

- Small & Medium Enterprises (SMEs)

- Research & Development (R&D) Laboratories

Value Chain Analysis For Horizontal Colloid Mill Market

The value chain for the Horizontal Colloid Mill Market begins with the upstream suppliers responsible for providing high-grade raw materials, primarily specialized stainless steel alloys (SS 316 being critical), precision components like bearings and mechanical seals, and advanced motor technologies. The quality and purity of these raw materials directly impact the lifespan, resistance to corrosion, and operational stability of the final equipment. Strong relationships between mill manufacturers and specialized material suppliers are essential, particularly concerning certified materials required for GMP-compliant machinery used in the food and pharmaceutical sectors, ensuring traceability and material integrity throughout the production process.

Mid-stream activities involve the design, engineering, manufacturing, assembly, and rigorous testing of the horizontal colloid mills. This stage is characterized by high levels of technological expertise, focusing on precision machining of the rotor and stator components to ensure the necessary micron-level gap accuracy and high-speed balancing. Manufacturers employ advanced design software to model flow dynamics and shear performance. After manufacturing, mills undergo intensive quality assurance checks and validation processes before being distributed. Integration of modern automation features, IoT sensors, and control panels constitutes a crucial value-added step, differentiating high-end models in the market.

Downstream activities include the distribution channels, which can be direct (manufacturer-to-end-user) or indirect (through specialized industrial equipment distributors and sales agents). Direct sales are prevalent for large, customized orders or complex systems requiring post-installation technical support. Indirect channels are often leveraged for standardized models or penetrating geographically dispersed markets. Crucially, the downstream segment includes after-sales services, maintenance, spare parts supply (such as replacement rotor/stator sets), and technical training, which form a significant recurring revenue stream and enhance customer loyalty, completing the comprehensive value delivery cycle.

Horizontal Colloid Mill Market Potential Customers

The potential customer base for Horizontal Colloid Mills is highly diverse yet primarily concentrated within industries that require precise fluid processing, homogenization, and stable dispersion of immiscible phases. The pharmaceutical industry represents a cornerstone segment, utilizing these mills for producing high-quality emulsions for intravenous solutions, fine suspensions for oral dosage forms, and homogeneous bases for medicated creams and gels. Regulatory compliance and the demand for consistent particle size to ensure therapeutic efficacy make pharmaceutical companies, ranging from large multinational corporations to specialized contract manufacturing organizations (CMOs), prime targets for high-specification, GMP-compliant horizontal mills.

Equally critical are the customers within the Food and Beverage sector. This industry uses colloid mills extensively to improve the texture, stability, and mouthfeel of products such as mayonnaise, salad dressings, fruit concentrates, chocolate coatings, and various nut butters. The ability of horizontal mills to process high-viscosity products efficiently and continuously is highly valued by large-scale food processors seeking mass production capabilities while maintaining stringent food safety and quality standards. The trend toward developing clean-label and natural ingredient products further drives the need for optimized processing technology to ensure emulsion stability without excessive reliance on synthetic stabilizers.

Beyond these major segments, the chemical, paint and coatings, and cosmetics industries constitute significant potential customer groups. Chemical manufacturers require these mills for fine grinding of pigments, catalysts, and specialized chemical compounds, ensuring stable industrial dispersions. The cosmetics sector relies heavily on colloid mills to create luxurious, smooth-textured creams, lotions, and makeup formulations, where texture and long-term emulsion stability are key determinants of consumer acceptance. Targeting R&D laboratories within these corporate sectors also represents a specific niche, requiring smaller-scale, highly precise variable speed mills for new product development and scale-up studies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 680 Million |

| Growth Rate | 6.0% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | FrymaKoruma (ProXES Group), NETZSCH-Feinmahltechnik GmbH, IKA Works, Inc., Silverson Machines, Admix, Inc., Bematek Systems, KADY International, GEA Group AG, SPX FLOW, Inc., Alfa Laval, Quadro Engineering Corp., Charles Ross & Son Company, Kirloskar Process Equipment, Inc., J.P. Selecta, STEPHAN Machinery GmbH, Changzhou Kefu Machinery Co., Ltd., Donghai Colloid Mill Factory, ZY Machinery, Gansons Engineers Private Limited, Ginhong Mixer. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Horizontal Colloid Mill Market Key Technology Landscape

The technological landscape of the Horizontal Colloid Mill Market is continuously evolving, driven by the need for enhanced shear efficiency, better material handling, and adherence to advanced regulatory standards. The core technology remains the precision engineering of the rotor-stator geometry, often featuring conical or grooved designs to maximize hydraulic and mechanical shear forces within the processing gap. Recent innovations focus heavily on optimizing the internal flow patterns, often utilizing Computational Fluid Dynamics (CFD) modeling during the design phase to minimize dead zones, reduce heat generation, and achieve a narrower particle size distribution (PSD) more efficiently, especially for creating nano-emulsions required in modern pharmaceutical compounds and high-end cosmetic formulas.

A significant trend involves the integration of advanced automation and sensor technology, aligning with Industry 4.0 paradigms. Modern horizontal mills are equipped with precision variable frequency drives (VFDs) to allow operators to fine-tune the rotor speed, directly influencing the shear rate, crucial for processing shear-sensitive or highly viscous materials. Furthermore, sophisticated non-contact sensors are used to monitor the adjustable stator gap in real-time with micron-level accuracy, ensuring consistent processing parameters throughout long production runs. These digitalization efforts enhance repeatability, reduce manual error, and provide invaluable data for process validation and optimization, particularly in regulated industries where documentation and batch consistency are paramount.

Material science innovation is also key. Given the high mechanical stress and potential abrasion involved in the milling process, manufacturers are increasingly using specialized ceramics and hardened specialty alloys beyond standard SS 316, especially for the high-wear rotor and stator components when dealing with abrasive materials like titanium dioxide or silica suspensions. Furthermore, designing mills with superior Clean-in-Place (CIP) and Sterilize-in-Place (SIP) capabilities is a critical technological feature, specifically catering to the aseptic requirements of the pharmaceutical and biotech sectors. These advanced designs minimize cross-contamination risks and significantly reduce cleaning cycle times, contributing to overall operational uptime and cost efficiency.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant and fastest-growing region, fueled by massive investments in pharmaceutical manufacturing capacity, particularly in India and China, alongside explosive growth in the processed food and cosmetics markets driven by large and increasingly affluent consumer bases. Government support for indigenous manufacturing and relaxed regulatory hurdles compared to Western nations often accelerates the adoption of processing equipment.

- North America: A mature market characterized by high regulatory standards (FDA compliance) and strong adoption of cutting-edge automation technologies. Growth is concentrated in specialized, high-value segments, such as bio-pharmaceuticals, and high-specification nutraceutical production, demanding precision mills with extensive validation documentation and robust data collection features.

- Europe: This region maintains a strong market share, led by Germany, France, and the UK, benefiting from established pharmaceutical and chemical industries and a focus on high-efficiency, energy-saving equipment. European market growth is often driven by the replacement of aging infrastructure with newer, Industry 4.0-compliant horizontal mills that meet strict EU environmental and safety directives.

- Latin America (LATAM): Exhibits moderate growth, primarily driven by expanding food processing sectors in Brazil and Mexico. The market is highly price-sensitive, often favoring mills that offer a balance between throughput capacity and initial capital investment, with increasing demand for regional manufacturers capable of providing accessible local technical support.

- Middle East and Africa (MEA): Emerging market characterized by nascent growth in domestic pharmaceutical production (driven by government initiatives to reduce import reliance) and expansion in cosmetic manufacturing, especially in the Gulf Cooperation Council (GCC) countries. Market penetration is gradually improving, relying heavily on imports of reliable, durable equipment capable of operating in challenging climate conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Horizontal Colloid Mill Market.- FrymaKoruma (ProXES Group)

- NETZSCH-Feinmahltechnik GmbH

- IKA Works, Inc.

- Silverson Machines

- Admix, Inc.

- Bematek Systems

- KADY International

- GEA Group AG

- SPX FLOW, Inc.

- Alfa Laval

- Quadro Engineering Corp.

- Charles Ross & Son Company

- Kirloskar Process Equipment, Inc.

- J.P. Selecta

- STEPHAN Machinery GmbH

- Changzhou Kefu Machinery Co., Ltd.

- Donghai Colloid Mill Factory

- ZY Machinery

- Gansons Engineers Private Limited

- Ginhong Mixer

Frequently Asked Questions

Analyze common user questions about the Horizontal Colloid Mill market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a horizontal colloid mill?

The primary function is high-shear mechanical homogenization and dispersion. It is used to produce extremely fine emulsions and stable suspensions by subjecting material to intense shear forces between a high-speed rotor and a stationary stator, achieving particle size reduction typically in the micron to sub-micron range, essential for product stability and uniformity.

Which industries are the largest consumers of horizontal colloid mills?

The largest consuming industries are Pharmaceuticals and Food & Beverages. Pharmaceutical companies rely on them for high-quality ointments and suspensions, while the Food sector uses them extensively for sauces, pastes, and stabilized liquid food products that require exceptional consistency and texture stability.

What advantages do horizontal mills offer over vertical configurations?

Horizontal colloid mills typically offer higher throughput capacity, are easier to clean and maintain due to better accessibility of the rotor-stator assembly, and often provide superior stability when processing highly viscous materials, making them preferred for continuous, large-scale manufacturing operations.

How is particle size distribution controlled in modern colloid mills?

Particle size distribution is primarily controlled by adjusting the microscopic gap between the rotor and stator, coupled with precise regulation of the rotor speed (shear rate). Modern mills often integrate automated gap control systems and variable frequency drives (VFDs) for real-time, highly repeatable adjustments and superior process control.

What is the role of Stainless Steel 316 in the market?

Stainless Steel 316 (SS 316) is the dominant material of construction, particularly in pharmaceutical and food applications, due to its superior resistance to corrosion, chemical compatibility, and adherence to strict hygienic and regulatory standards (GMP). Its use ensures the integrity and purity of the processed product.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager