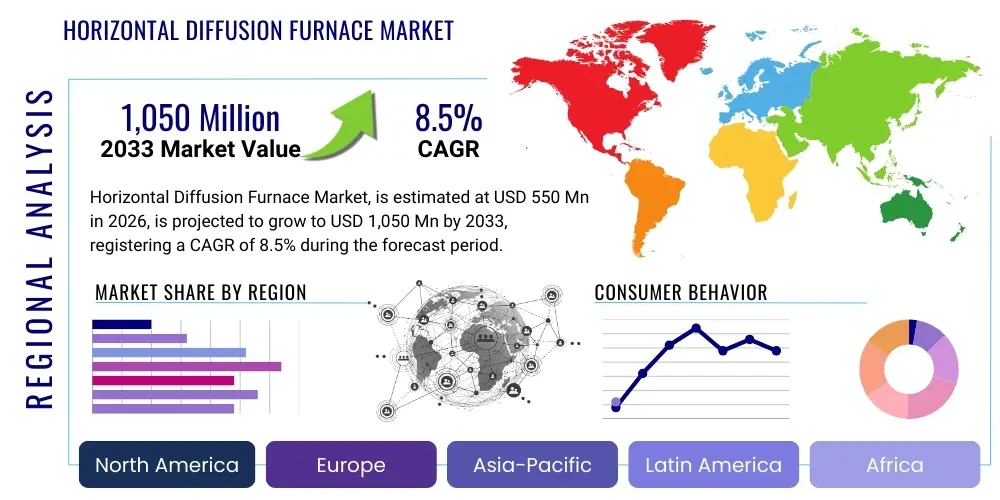

Horizontal Diffusion Furnace Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437963 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Horizontal Diffusion Furnace Market Size

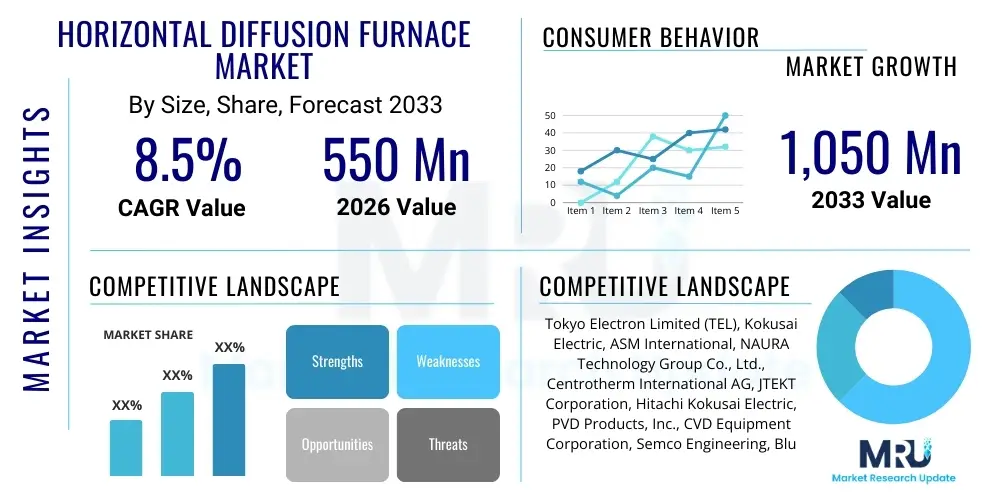

The Horizontal Diffusion Furnace Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at $550 Million in 2026 and is projected to reach $1,050 Million by the end of the forecast period in 2033.

Horizontal Diffusion Furnace Market introduction

The Horizontal Diffusion Furnace Market encompasses high-precision thermal processing equipment critical for semiconductor fabrication, photovoltaic cell manufacturing, and Micro-Electro-Mechanical Systems (MEMS) production. These systems are fundamental in processes like oxidation, annealing, and Low-Pressure Chemical Vapor Deposition (LPCVD), where precise temperature control and uniform gas flow are essential for depositing thin films and modifying material properties on silicon wafers. The introduction of atomic-level precision requirements in advanced nodes, coupled with the increasing global demand for memory and logic chips, solidifies the horizontal furnace’s role as a cornerstone technology in the microelectronics supply chain. Although facing competition from newer vertical furnace designs, the horizontal configuration remains favored for specific high-volume, cost-sensitive processes, particularly in legacy nodes and photovoltaic applications due to its established reliability and lower maintenance costs.

The primary function of the horizontal diffusion furnace is to create a controlled, high-temperature environment—often exceeding 1200°C—to induce chemical reactions or physical changes on the substrate surface. Major applications span the manufacturing of MOSFETs, integrated circuits, power devices, and large-area solar cells. The benefits derived from utilizing these systems include unparalleled control over film thickness uniformity, high throughput capabilities, and minimal defect generation, which are critical performance indicators in semiconductor manufacturing. Furthermore, the inherent design allows for easier integration of process monitoring and automation tools, enhancing yield management.

Driving factors propelling market expansion include the sustained growth in the Internet of Things (IoT) devices, automotive electronics (especially electric vehicles and autonomous driving systems), and hyperscale data centers requiring continuous expansion of semiconductor capacity. Specifically, the global push toward energy transition has boosted demand from the solar cell segment, as diffusion furnaces are essential for doping and passivation layers in high-efficiency solar cells. Technological advancements focusing on greater temperature uniformity across larger diameter wafers (300mm and increasingly 450mm research) and enhancements in gas delivery systems further fuel the replacement cycle and new capacity buildout across Asia Pacific, North America, and Europe.

Horizontal Diffusion Furnace Market Executive Summary

The Horizontal Diffusion Furnace Market is experiencing significant dynamic shifts driven primarily by sustained capital expenditure within the global semiconductor industry, particularly in the Asia Pacific region. Business trends indicate a focus on optimizing legacy 200mm and 300mm wafer processing capabilities, alongside intense research into advanced materials compatibility for next-generation devices. Key manufacturers are differentiating themselves through modular designs that allow for rapid conversion between atmospheric pressure and LPCVD processes, enhancing operational flexibility for foundries and integrated device manufacturers (IDMs). Consolidation among equipment suppliers is also observed, seeking economies of scale and better integration of process control software, thereby providing comprehensive, full-stack solutions to end-users.

Regionally, Asia Pacific maintains its dominant market position, spearheaded by substantial governmental investments in semiconductor self-sufficiency in China, coupled with ongoing expansion by major players in Taiwan, South Korea, and Japan. North America and Europe are exhibiting a notable resurgence, driven by strategic initiatives like the U.S. CHIPS Act and the EU Chips Act, aimed at localizing semiconductor fabrication capacity. This localization trend is generating significant demand for both new and refurbished horizontal furnace systems, particularly in specialized fields such as power electronics and compound semiconductor manufacturing, where specific furnace geometries are often preferred.

Segmentation trends highlight the increasing demand for Multiple Tube Furnaces due to their superior throughput and cost-efficiency in high-volume production environments. Application-wise, Semiconductor Manufacturing remains the largest revenue segment, although Solar Cell Production is witnessing the fastest growth rate, fueled by efficiency gains requiring precise thermal doping. From a process perspective, the LPCVD segment, crucial for thin film deposition of polysilicon, silicon nitride, and various oxides, is experiencing robust growth as device structures become more complex, necessitating highly conformal layers achieved through these processes.

AI Impact Analysis on Horizontal Diffusion Furnace Market

User queries regarding AI’s influence on the Horizontal Diffusion Furnace Market frequently revolve around predictive maintenance capabilities, optimization of complex thermal recipes, and enhancing process control loop efficiency. Users are primarily concerned with whether AI can significantly reduce tool downtime, improve yield stability in highly sensitive deposition processes, and automate the tuning of multi-zone heaters under variable loading conditions. The consensus expectation is that AI algorithms, particularly machine learning models applied to sensor data, will transition the market from reactive maintenance models to proactive, condition-based monitoring, ensuring maximum equipment uptime and facilitating faster ramp-up times for new process technologies by optimizing initial parameters based on simulation and historical performance data.

- AI enables predictive maintenance, minimizing unscheduled downtime through anomaly detection in temperature profiles and gas flow rates.

- Machine Learning (ML) algorithms optimize complex process recipes, reducing human error and accelerating the qualification of new materials and processes.

- AI-driven real-time process control enhances wafer-to-wafer and batch-to-batch uniformity, directly improving device yield and consistency.

- Automated fault classification and root cause analysis speed up troubleshooting, crucial for maintaining high throughput in 24/7 fabrication environments.

- Integration of Digital Twin technology allows for simulation and testing of hypothetical process changes before deployment on physical equipment.

DRO & Impact Forces Of Horizontal Diffusion Furnace Market

The market dynamics are significantly shaped by several interacting forces. Key drivers include the relentless global expansion of semiconductor fabrication capacity and the increasing complexity of 3D device structures necessitating precise thermal budgets. However, market growth is restrained by the high initial capital investment required for these systems and the intense, albeit diminishing, competition from highly integrated Vertical Diffusion Furnaces, which offer better footprint utilization in advanced wafer fabs. Opportunities lie in the rapidly expanding photovoltaic market and the potential for applying diffusion processes to emerging materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) power devices, driven by electric vehicle adoption. The impact forces are characterized by high supplier power due to the specialized nature of the technology, moderate buyer power concentrated among large IDMs and foundries, and a medium threat of substitution from alternative thermal processing methods such as Rapid Thermal Processing (RTP) for specific steps.

Segmentation Analysis

The Horizontal Diffusion Furnace market is systematically segmented based on furnace configuration (Type), the specific manufacturing process conducted (Process), and the primary industrial application (Application). This segmentation provides a granular view of market dynamics, allowing stakeholders to identify high-growth niches. The segmentation by Type, distinguishing between single and multiple tube architectures, reflects the trade-off between process isolation requirements and high-volume throughput needs. Segmentation by Process highlights the diversity of functions, ranging from fundamental oxidation layers to complex chemical vapor deposition necessary for high-aspect-ratio device features. The Application segment delineates the primary revenue streams, underscoring the market's dependence on the semiconductor and solar industries.

- By Type

- Single Tube Furnace

- Multiple Tube Furnace

- By Process

- Oxidation (Wet/Dry)

- Low-Pressure Chemical Vapor Deposition (LPCVD)

- Atmospheric Pressure Chemical Vapor Deposition (APCVD)

- Annealing (Nitridation, Activation)

- Diffusion/Doping

- By Application

- Semiconductor Manufacturing (Memory, Logic, Analog)

- Solar Cell Production (Crystalline Silicon Cells)

- MEMS and Sensor Manufacturing

- Research & Development and Pilot Lines

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Horizontal Diffusion Furnace Market

The value chain for the Horizontal Diffusion Furnace Market begins with highly specialized upstream suppliers providing critical raw materials and components, including high-purity quartzware (furnace tubes, boats), sophisticated heating elements (Kanthal, MoSi2), and advanced mass flow controllers (MFCs). These components are sourced globally, necessitating robust supply chain management due to the strict purity and dimensional tolerances required. Midstream activities involve the complex assembly, integration, and proprietary software development by the Original Equipment Manufacturers (OEMs), such as Tokyo Electron and Kokusai Electric, where intellectual property related to temperature control and gas delivery is paramount. Downstream analysis focuses on the distribution channels, which are predominantly direct sales and service models. Given the high cost and complexity of the equipment, sales are typically negotiated directly between the OEM and the end-user (foundry or IDM), supported by extensive field service and maintenance contracts, minimizing reliance on indirect distribution channels, though local agents may assist with regional installation and localized technical support.

Horizontal Diffusion Furnace Market Potential Customers

The primary end-users and buyers of Horizontal Diffusion Furnaces are institutions involved in high-volume material processing that requires stringent thermal uniformity. This customer base is dominated by major semiconductor foundries (such as TSMC, Samsung Foundry, UMC) and Integrated Device Manufacturers (IDMs) like Intel and Micron, which utilize these furnaces extensively for transistor and interconnect formation in memory and logic chips. A substantial segment of demand also originates from large-scale solar cell manufacturers (e.g., LONGi, JinkoSolar) requiring efficient doping processes. Secondary customers include dedicated power device manufacturers focusing on SiC and GaN technologies, as well as academic and industrial research laboratories that require flexible furnace systems for material science experimentation and pilot line production.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million |

| Market Forecast in 2033 | $1,050 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tokyo Electron Limited (TEL), Kokusai Electric, ASM International, NAURA Technology Group Co., Ltd., Centrotherm International AG, JTEKT Corporation, Hitachi Kokusai Electric, PVD Products, Inc., CVD Equipment Corporation, Semco Engineering, Blue M, S.F.E. Group, Tystar Corporation, BTU International, V-TEX, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Horizontal Diffusion Furnace Market Key Technology Landscape

The technological landscape of the Horizontal Diffusion Furnace market is characterized by a continuous drive toward enhanced process control, material compatibility, and throughput capacity. A core technological advancement involves multi-zone heating systems utilizing sophisticated thermocouples and PID controllers to maintain temperature uniformity across the long process tube, crucial for minimizing edge effects on larger wafers (300mm). Furthermore, the integration of advanced gas delivery systems, featuring ultra-high purity valves and dynamic mass flow controllers, ensures the precise stoichiometry required for complex LPCVD and oxidation processes, mitigating contamination risks that can severely impact yield in sub-micron fabrication.

Another significant technological focus is the development of inert load locks and automated wafer handling systems, which reduce exposure to ambient air, thereby preventing native oxide formation and particle contamination. The shift towards processes requiring higher temperatures or specialized atmospheres (e.g., hydrogen annealing) necessitates the use of advanced quartz and SiC components that offer greater thermal stability and resistance to chemical etching. Equipment manufacturers are heavily investing in proprietary software solutions for Advanced Process Control (APC) and statistical process monitoring (SPC), linking real-time data from the furnace sensors to factory-wide Manufacturing Execution Systems (MES) to optimize batch production cycles and improve traceability.

The increasing prominence of compound semiconductors (SiC, GaN) requires furnaces designed for higher processing temperatures and different ambient conditions than traditional silicon. This has spurred innovation in liner materials and chamber design to handle corrosive precursors and maintain high thermal stability over extremely long processing times. Furthermore, energy efficiency remains a critical design parameter, leading to the adoption of improved insulation techniques and rapid cooling capabilities, reducing utility costs and improving overall factory efficiency without compromising the critical temperature ramp-up and cool-down profiles.

Regional Highlights

- Asia Pacific (APAC): Dominance in Manufacturing Capacity

The APAC region holds the undisputed majority share of the Horizontal Diffusion Furnace Market, primarily due to the concentration of the world's largest semiconductor foundries and memory manufacturers in countries such as Taiwan, South Korea, China, and Japan. This region is characterized by aggressive capital expenditure cycles, driven by the expansion of 300mm wafer capacity and massive investments in advanced packaging and power device manufacturing facilities. China, specifically, is a significant growth driver, fueled by national mandates to achieve self-sufficiency in chip production, leading to rapid installation of new furnace lines for both mature and emerging process nodes. The solar cell industry, particularly in Southeast Asia and China, further contributes substantially to the demand, utilizing horizontal systems for cost-effective, high-volume production of photovoltaic cells.

- China: Largest end-user market driven by government-backed fab expansions and solar manufacturing scale-up.

- Taiwan and South Korea: Continued high demand from leading memory and logic foundries prioritizing system reliability and high throughput for established processes.

- Japan: Key hub for leading equipment suppliers and sophisticated R&D activities, focusing on next-generation materials processing.

- North America: Resurgence and Specialized Applications

North America is experiencing renewed growth, spurred by governmental subsidies and strategic moves to re-shore semiconductor production, aiming to build a resilient domestic supply chain. While historically focused on R&D and specialized low-volume applications, recent large-scale fab announcements by major IDMs are driving significant procurement of new, high-specification horizontal diffusion systems. The regional demand is often skewed toward niche applications, including defense electronics, specialized MEMS, and the pioneering of SiC/GaN power device fabrication, where precise control over diffusion profiles is critical. Equipment procured here frequently emphasizes integration with cutting-edge factory automation and AI-driven process optimization tools.

- United States: Increased investment in 300mm fabs following the CHIPS Act, driving demand for new capacity installation.

- Specialized demand: High requirement for furnaces tailored for compound semiconductor processing (SiC, GaN) and aerospace components.

- Europe: Focus on Automotive and R&D

The European market, supported by the European Chips Act, is demonstrating steady growth, concentrated heavily in Germany, France, and Italy. This region's demand is uniquely tied to the automotive sector, particularly the production of power management integrated circuits and sensors required for electric vehicles (EVs) and advanced driver-assistance systems (ADAS). European manufacturers often prioritize high-reliability, long-lifetime equipment for 200mm and 300mm legacy nodes, which are crucial for industrial and automotive electronics. Furthermore, strong collaboration between academia and industry sustains demand for research-grade horizontal furnaces suitable for material science exploration and pilot manufacturing of advanced devices.

- Germany and France: Centers for automotive electronics manufacturing, necessitating reliable thermal processing equipment.

- Regional Strategy: EU initiatives promoting localized manufacturing and R&D capability in power electronics and photonics.

- Latin America, Middle East, and Africa (LAMEA): Nascent Growth

The LAMEA region currently represents a smaller share of the market, primarily driven by investments in academic research facilities, and, to a limited extent, localized solar panel assembly plants. However, long-term opportunity exists as regional governments look to establish domestic technology ecosystems. Specific growth pockets are emerging in the Middle East, fueled by diversification efforts into high-technology manufacturing and renewable energy projects requiring solar cell components. Demand in these regions is typically characterized by smaller, specialized orders or refurbished equipment procurement for cost-sensitive applications.

- Middle East: Growing potential driven by investments in renewable energy infrastructure and industrial diversification strategies.

- LATAM: Demand centered around educational institutions and small-scale electronic assembly operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Horizontal Diffusion Furnace Market.- Tokyo Electron Limited (TEL)

- Kokusai Electric

- ASM International

- NAURA Technology Group Co., Ltd.

- Centrotherm International AG

- JTEKT Corporation

- Hitachi Kokusai Electric

- PVD Products, Inc.

- CVD Equipment Corporation

- Semco Engineering

- Blue M

- S.F.E. Group

- Tystar Corporation

- BTU International

- V-TEX, Inc.

- M.R. Furnaces

- Koyo Thermo Systems Co., Ltd.

- Applied Materials (Though focused on broader systems, remains influential)

- Angstrom Engineering

- Silicon Valley Microelectronics

Frequently Asked Questions

Analyze common user questions about the Horizontal Diffusion Furnace market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a horizontal and a vertical diffusion furnace?

Horizontal furnaces utilize a cantilever system to load wafers parallel to the floor, offering established reliability and ease of maintenance, especially for large batches or legacy processes. Vertical furnaces load wafers vertically, offering better temperature uniformity across the wafer and a smaller cleanroom footprint, often preferred for cutting-edge, critical processes like high-k gate deposition.

Which application segment drives the highest demand in the Horizontal Diffusion Furnace Market?

The Semiconductor Manufacturing segment, encompassing the production of logic chips, memory devices (DRAM, NAND), and power semiconductors, constitutes the largest revenue share due to the critical nature of oxidation, annealing, and LPCVD processes in front-end wafer fabrication.

What technological advancements are crucial for 300mm wafer processing in horizontal furnaces?

Key advancements include enhanced multi-zone heating control systems to ensure temperature stability over the larger wafer area, automated robotic handling systems for precise wafer transfer, and sophisticated gas panel designs for highly uniform layer deposition across the 300mm diameter.

How is the market influenced by the expansion of the SiC and GaN power device sectors?

The growth of Silicon Carbide (SiC) and Gallium Nitride (GaN) power devices necessitates specialized horizontal furnaces capable of operating at extremely high temperatures (often above 1300°C) and handling specific inert or corrosive ambient conditions required for activation annealing and oxidation processes, driving demand for high-specification equipment.

Which geographical region dominates the global Horizontal Diffusion Furnace Market?

The Asia Pacific (APAC) region dominates the market, primarily due to the concentration of major global semiconductor foundries and memory manufacturers in countries like China, Taiwan, and South Korea, coupled with significant governmental investment in localized fabrication capacity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager