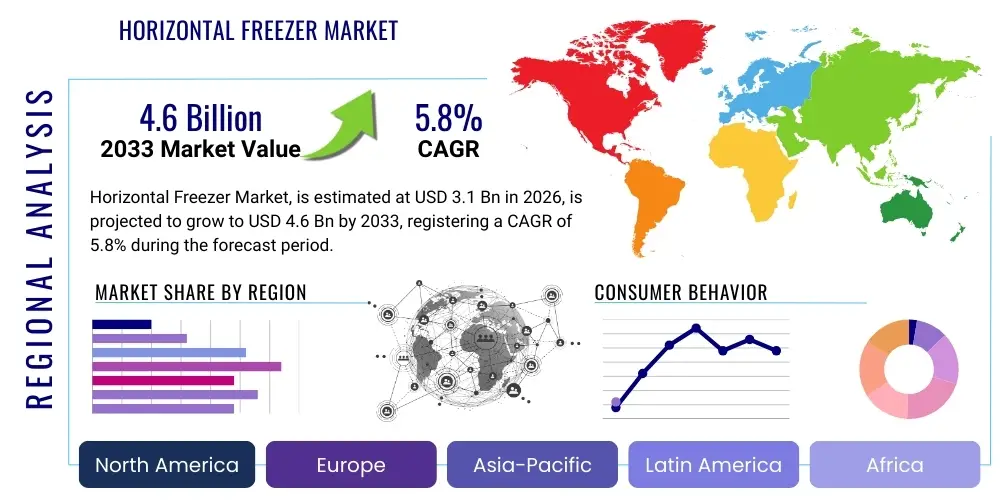

Horizontal Freezer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438655 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Horizontal Freezer Market Size

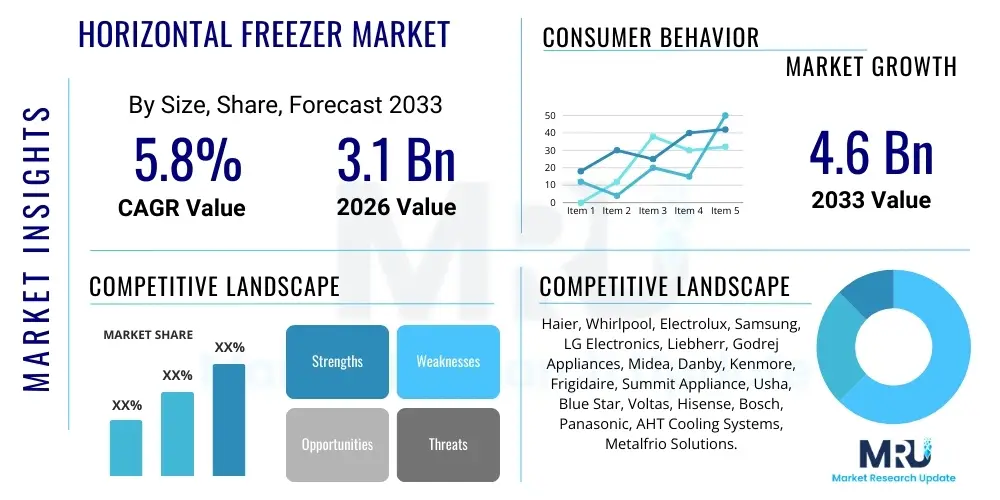

The Horizontal Freezer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $3.1 Billion in 2026 and is projected to reach $4.6 Billion by the end of the forecast period in 2033. This consistent growth is primarily driven by the increasing global adoption of frozen food products, coupled with significant expansion in the commercial sectors, particularly in retail grocery chains, supermarkets, and hospitality industries requiring reliable, large-capacity cold storage solutions. The growing preference for energy-efficient and highly durable storage options also contributes substantially to market valuation gains over the forecast horizon.

Horizontal Freezer Market introduction

The Horizontal Freezer Market encompasses the sales and distribution of chest freezers, which are defined by their lid opening upward and offering substantial, energy-efficient storage capacity, particularly suited for long-term freezing of perishable goods. These appliances are vital components in the cold chain infrastructure, catering to both residential consumers who require bulk food storage capabilities and commercial entities such as restaurants, food processing units, and specialized retail outlets that demand reliable low-temperature preservation. The design intrinsic to horizontal freezers, characterized by static cold air retention upon opening, contributes significantly to their superior energy efficiency compared to upright models, establishing them as a foundational element in modern refrigeration technology across developed and emerging economies.

The primary applications of horizontal freezers span food preservation, medical storage (especially for vaccines and biological samples in specialized ultra-low temperature variants), and retail display in grocery environments. Key driving factors accelerating market expansion include rapid urbanization leading to increased demand for convenient frozen meals, advancements in compressor technology resulting in quieter and more sustainable appliances, and robust government initiatives promoting energy labeling and efficiency standards. Furthermore, the global shift towards diversified and extended cold storage solutions, necessitated by complex supply chains and bulk purchasing behaviors, cements the integral role of horizontal freezers within the consumer and business landscapes.

The benefits derived from adopting horizontal freezers are multifaceted, including maximized storage volume relative to footprint, exceptional thermal stability crucial for maintaining food quality, and reduced operating costs due to superior insulation and design efficiency. These advantages, combined with the continuous innovation in features such as digital temperature controls, rapid freeze functions, and integrated smart connectivity options, ensure sustained demand. As the market matures, manufacturers are increasingly focusing on aesthetic improvements, customizable internal organization systems, and the integration of eco-friendly refrigerants to align with stringent environmental regulations and evolving consumer preferences for sustainability.

Horizontal Freezer Market Executive Summary

The Horizontal Freezer Market is poised for stable yet significant expansion, primarily fueled by shifting business trends emphasizing cold chain optimization, particularly in fast-growing economies in Asia Pacific and Latin America. Key business trends include the commercial sector’s accelerated investment in large-capacity, heavy-duty chest freezers to support the booming quick-service restaurant (QSR) segment and the expansion of modern retail formats. Technological advancements centered around inverter compressors and improved insulation materials are driving higher energy efficiency, becoming a critical purchasing determinant for both commercial buyers and eco-conscious residential users, shaping competitive dynamics among leading global manufacturers.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, attributed to its large population base, increasing disposable incomes, and the rapid development of organized retail infrastructure and cold storage logistics networks, particularly in countries like China and India. North America and Europe maintain a mature but stable market presence, characterized by high replacement rates and a strong consumer focus on premium, smart-enabled freezer models featuring advanced temperature management. Conversely, emerging markets in the Middle East and Africa (MEA) are demonstrating high growth potential, driven by infrastructure projects and increasing consumer awareness regarding food safety and long-term storage solutions.

Segment-wise, the commercial application segment dominates revenue share due to the intensive storage requirements of foodservice and retail industries, while the residential segment exhibits steady growth, driven by the increased volume of household grocery purchases and the need for overflow storage. In terms of capacity, the 200L to 400L range remains highly popular, striking an optimal balance between space utilization and storage capacity for typical household and small commercial needs. Furthermore, the distribution trend shows a discernible acceleration toward online sales channels, providing consumers with greater product variety, comparison tools, and logistical convenience, though offline channels continue to dominate due to consumer preference for physical inspection of large appliances.

AI Impact Analysis on Horizontal Freezer Market

User queries regarding the impact of Artificial Intelligence (AI) on the Horizontal Freezer Market largely center on predictive maintenance, energy optimization, and supply chain efficiency. Users frequently ask how AI can extend the lifespan of freezer components, whether AI algorithms can minimize energy consumption based on usage patterns and ambient conditions, and how integration with smart home ecosystems improves user experience. There is significant interest in AI-driven diagnostics that could alert users to potential system failures before they occur, reducing expensive inventory losses. Furthermore, commercial users are keen on understanding how machine learning can optimize inventory management within large freezer banks, ensuring efficient stock rotation and minimizing spoilage in large retail and warehousing operations.

The adoption of AI in horizontal freezers is transitioning these traditionally static appliances into sophisticated, networked devices capable of autonomous decision-making and optimization. AI algorithms analyze historical temperature data, door opening frequency, and fluctuating external temperatures to dynamically adjust compressor cycles, leading to significant reductions in power usage while maintaining precise internal conditions. This capability is particularly critical for ultra-low temperature freezers utilized in the medical and pharmaceutical sectors, where stable temperature control is non-negotiable for preserving high-value, sensitive materials. The integration of advanced diagnostics powered by AI facilitates early fault detection, enabling predictive servicing models that dramatically enhance operational reliability and reduce costly downtime, directly addressing key concerns about operational continuity.

Beyond internal optimization, AI enhances the user interface and overall consumer interaction with horizontal freezers. Natural Language Processing (NLP) allows for voice-activated controls and inventory inquiries, making management intuitive, especially in large commercial kitchens or busy household settings. For commercial operators, AI-driven demand forecasting, integrated with point-of-sale systems, allows for optimized ordering and utilization of freezer capacity, minimizing storage costs and ensuring product availability. The future trajectory involves AI facilitating seamless integration into the broader smart grid, allowing freezers to participate in demand-response programs, temporarily adjusting cooling loads during peak hours for mutual energy savings, demonstrating a significant shift toward smart, sustainable cold storage infrastructure.

- AI-driven Predictive Maintenance: Analyzing compressor performance and refrigerant status to anticipate mechanical failures, scheduling maintenance proactively, and significantly extending appliance lifespan.

- Energy Consumption Optimization: Implementing machine learning algorithms to learn user habits and ambient conditions, dynamically adjusting cooling cycles to maximize energy efficiency and lower utility costs (Smart Eco Modes).

- Integrated Inventory Management: Utilizing computer vision and weight sensors, paired with AI analysis, to track stored items, monitor expiration dates, and automatically generate replenishment alerts for commercial users.

- Smart Diagnostic Capabilities: Remote monitoring and self-diagnosis of operational anomalies, transmitting detailed error codes to service providers for faster and more accurate repairs.

- Temperature Stability Assurance: AI models continuously fine-tuning temperature fluctuations to maintain ultra-precise preservation conditions, critical for sensitive pharmaceuticals and vaccines.

- Enhanced User Experience: Voice control integration and personalized cooling recommendations based on the type of stored goods, improving accessibility and operational efficiency.

DRO & Impact Forces Of Horizontal Freezer Market

The dynamics of the Horizontal Freezer Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the Impact Forces dictating market trajectory. Key drivers include the secular growth in global consumption of processed and frozen foods, necessitating increased household and commercial storage capacity, alongside persistent efforts by manufacturers to introduce highly energy-efficient models utilizing advanced insulation and inverter technology, addressing both cost and environmental concerns. These demand-side drivers are powerfully supported by the supply-side improvements in cold chain logistics infrastructure, especially in developing regions where market penetration is rapidly increasing.

Conversely, significant restraints hinder market growth, prominently featuring the high initial purchase price associated with large capacity, feature-rich horizontal freezers, which can be prohibitive for certain segments of residential consumers or small businesses. Furthermore, the inherent design requirement for substantial floor space poses a challenge, especially in densely populated urban centers or small commercial establishments where spatial constraints are paramount. Regulatory hurdles regarding the phase-out of certain high Global Warming Potential (GWP) refrigerants also necessitate costly research and development efforts, temporarily impacting production costs and market pricing, adding complexity to compliance strategies for international brands.

Opportunities for expansion are abundant, particularly in the realm of smart refrigeration technologies, where connectivity, remote monitoring, and integration with the Internet of Things (IoT) ecosystems open up new value propositions for consumers and businesses alike. The expansion into specialized segments, such as biomedical and laboratory freezing applications requiring ultra-low temperature capabilities, represents a highly lucrative, high-margin niche. Moreover, aggressive penetration into underserved rural markets through improved distribution networks and the offering of solar or hybrid-powered freezers presents a long-term growth avenue, capitalizing on the need for reliable storage in areas with inconsistent power supply, ensuring market resilience against conventional limitations.

The collective impact forces suggest a market characterized by moderate competition and innovation. While the core product design remains relatively standard, differentiation is increasingly achieved through energy efficiency ratings, smart features, and specialized segment targeting (e.g., medical versus standard commercial). The pressure from environmental regulations acts as a strong positive force for innovation, pushing the industry toward sustainable refrigerants and lower power consumption, thereby creating barriers to entry for manufacturers unwilling to invest in green technology. The robust underlying demand from the expanding global population and changing food habits ensures that the drivers outweigh the restraints in the long term, guaranteeing sustained, albeit gradual, market expansion throughout the forecast period.

Segmentation Analysis

The Horizontal Freezer Market is extensively segmented across multiple parameters to accurately capture the diverse needs of end-users and the varying product offerings available globally. Segmentation allows for targeted marketing strategies and detailed competitive analysis, focusing on distinctions related to capacity, application type, and the underlying technology driving efficiency. The primary differentiation often revolves around the capacity size, which directly dictates the suitability of the appliance for residential, small commercial, or large industrial applications. Furthermore, the structural difference between chest freezers and specialized dual-zone units provides key differentiation in functionality and price points, influencing purchasing decisions across the consumer base.

The application segment provides a critical view of market consumption patterns, clearly dividing the market into dominant commercial usage—spanning supermarkets, hypermarkets, convenience stores, and the burgeoning food service industry—and the essential residential segment, driven by household demand for bulk storage. Commercial buyers typically prioritize durability, large capacity, and high energy efficiency for continuous operation, whereas residential users often focus on size constraints, aesthetic integration, and noise reduction features. The growth within the commercial segment is intrinsically linked to global retail expansion and the complex requirements of modern cold chain management, providing the most significant revenue stream for the overall market.

Analysis of distribution channels reveals the evolving mechanism of product delivery, where traditional brick-and-mortar retail stores and specialized appliance outlets (Offline) maintain significant control due to the large size and complexity of logistics for freezers. However, the rapidly expanding e-commerce sector (Online) is carving out a substantial share, particularly offering competitive pricing, comprehensive product reviews, and convenient home delivery services, appealing strongly to tech-savvy consumers. Understanding these segmentation nuances is crucial for stakeholders to effectively position products, optimize supply chains, and invest in areas exhibiting the highest potential for future growth and competitive advantage.

- By Type:

- Chest Freezers (Single-Zone)

- Dual-Zone Freezers (Combining freezer and refrigerator compartments)

- By Capacity:

- Below 200 Liters (Small Capacity)

- 200 Liters – 400 Liters (Medium Capacity)

- Above 400 Liters (Large Capacity)

- By Application:

- Commercial (Food Service, Retail Stores, Healthcare)

- Residential (Household Use)

- By Distribution Channel:

- Offline Retail (Supermarkets, Specialty Stores)

- Online Retail (E-commerce Platforms, Company Websites)

Value Chain Analysis For Horizontal Freezer Market

The Value Chain of the Horizontal Freezer Market begins with upstream activities involving raw material procurement, focusing heavily on metals (steel, aluminum for casings and cooling coils), plastics, and crucial components like compressors, condensers, and advanced insulating materials (e.g., polyurethane foam). Efficiency and cost management at this initial stage are pivotal, as fluctuations in global commodity prices directly impact manufacturing costs. Key suppliers of specialized components, particularly energy-efficient inverter compressors and eco-friendly refrigerants, hold significant bargaining power, driving the technological standards and sustainability profiles of the final products. Manufacturers strategically engage in long-term contracts with reliable suppliers to ensure stability in material quality and pricing, crucial for maintaining competitive retail costs.

Midstream activities encompass the manufacturing, assembly, and quality control processes. This stage involves complex engineering focused on maximizing thermal performance, minimizing noise, and integrating smart technologies. Economies of scale are essential, favoring large global players with automated production lines in key geographical hubs, particularly in Asia. Strict adherence to international safety and energy efficiency standards (like Energy Star or equivalent regional certifications) necessitates substantial investment in advanced testing and compliance procedures. Product differentiation often occurs here through proprietary insulation techniques, design aesthetics, and the incorporation of unique internal storage systems to appeal to specific market segments, enhancing perceived value beyond mere cooling capability.

Downstream activities involve distribution, marketing, sales, and post-sales service. Distribution channels are varied, including direct sales to large commercial clients, specialized wholesale distribution to smaller retailers, and increasingly, direct-to-consumer sales via e-commerce platforms. The logistics of moving large, heavy appliances require specialized infrastructure, contributing significantly to final consumer cost. Direct and indirect distribution channels operate simultaneously; direct channels facilitate high-volume commercial contracts, offering customization and installation services, while indirect channels utilize extensive retail networks and third-party logistics providers (3PLs) to reach dispersed residential consumers efficiently. Effective after-sales service, including warranties, maintenance, and spare parts availability, is a critical component of brand reputation and customer retention, completing the value cycle and informing future product design improvements.

Horizontal Freezer Market Potential Customers

The primary end-users and buyers of horizontal freezers represent a diverse demographic spanning individual households, small-to-medium enterprises (SMEs), and large institutional entities, all requiring reliable, long-duration cold storage. Residential customers are categorized by their need for bulk storage, often stemming from membership in wholesale clubs, large family size, or participation in home food preservation activities like butchering or gardening. They prioritize energy efficiency, noise level, and manageable size that fits within garage or basement spaces. The increasing popularity of secondary freezers within homes, driven by changes in shopping habits following global health crises, has solidified the residential segment as a stable base for market demand.

On the commercial side, the potential customer base is highly segmented. Food service industries, including large restaurants, catering companies, and institutional kitchens (schools, hospitals), are perpetual consumers, prioritizing maximum capacity, robust construction for frequent use, and compliance with stringent food safety regulations. Retail establishments, encompassing supermarkets, convenience stores, and specialized frozen food outlets, require freezers designed for merchandising, often featuring clear glass tops or advanced temperature zoning for various product displays. These customers prioritize reliability, visual appeal, and ease of access for both staff and customers, making the unit an integral part of their sales strategy.

Furthermore, specialized industrial and medical segments form a critical, high-value customer group. Laboratories, research facilities, and pharmaceutical companies require highly precise, often ultra-low temperature horizontal freezers for storing biological samples, vaccines, and reagents. These buyers are less price-sensitive and focus intensely on temperature uniformity, alarm systems, regulatory compliance (e.g., FDA standards), and documented performance traceability. This niche demands customized, high-specification products that represent a significant opportunity for manufacturers capable of meeting exacting technical criteria and providing specialized maintenance services.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $3.1 Billion |

| Market Forecast in 2033 | $4.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Haier, Whirlpool, Electrolux, Samsung, LG Electronics, Liebherr, Godrej Appliances, Midea, Danby, Kenmore, Frigidaire, Summit Appliance, Usha, Blue Star, Voltas, Hisense, Bosch, Panasonic, AHT Cooling Systems, Metalfrio Solutions. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Horizontal Freezer Market Key Technology Landscape

The technological landscape of the Horizontal Freezer Market is undergoing a rapid evolution, primarily driven by twin objectives: enhancing energy efficiency and integrating smart functionalities. Core innovation revolves around advanced compressor technology. The shift from traditional fixed-speed compressors to variable-speed inverter compressors represents a significant advancement, allowing the freezer to modulate cooling output based on actual demand rather than cycling on and off completely. This not only dramatically reduces energy consumption but also minimizes temperature fluctuations, thereby improving food preservation quality and extending the lifespan of the appliance itself. Furthermore, manufacturers are heavily investing in next-generation insulation materials, such as vacuum insulated panels (VIPs), which offer superior thermal retention properties compared to conventional polyurethane foam, allowing for thinner walls and increased internal storage volume without compromising energy performance, crucial for maximizing capacity utilization.

A second major technological trend is the proliferation of digital controls and smart connectivity features, aligning the horizontal freezer with the broader Internet of Things (IoT) ecosystem. Modern horizontal freezers are increasingly equipped with Wi-Fi capabilities, enabling remote temperature monitoring, diagnostic alerts, and integration with smart home management systems. High-resolution digital displays allow for precise temperature setting and monitoring, moving beyond simple mechanical thermostats. Advanced sensors are being deployed to monitor parameters such as door seal integrity, frost buildup, and ambient temperature, feeding data back into control algorithms that optimize defrost cycles and maintain optimal performance, reducing the need for manual intervention and improving operational reliability, especially in commercial settings where downtime is critical.

Finally, sustainability and compliance are driving material and refrigerant innovation. The global phase-down of high Global Warming Potential (GWP) refrigerants, mandated by international agreements such as the Kigali Amendment to the Montreal Protocol, is pushing the industry toward natural refrigerants like R600a (isobutane) and R290 (propane). While these refrigerants require specialized manufacturing and safety handling procedures due to their flammability, they offer significantly reduced environmental impact and often contribute to higher energy efficiency when paired with optimized heat exchange systems. This focus on green technology is not just regulatory compliance but a strategic differentiator, appealing to environmentally conscious consumers and organizations seeking to minimize their carbon footprint in their cold chain operations.

Regional Highlights

Regional analysis indicates varying maturity levels and growth drivers across major geographical segments, reflecting disparities in economic development, regulatory environments, and consumer preferences regarding refrigeration technology and food habits.

- Asia Pacific (APAC): Positioned as the fastest-growing market, APAC's momentum is driven by rapid infrastructure development, particularly the expansion of cold chain logistics and modern organized retail (supermarkets and convenience stores). Countries like China and India are experiencing massive urbanization and rising disposable incomes, leading to increased demand for both residential and large-scale commercial freezers. Government support for food processing and storage industries further catalyzes market expansion in this dynamic region.

- North America: A mature market characterized by high consumer awareness regarding energy efficiency and premium features. Demand is steady, fueled primarily by replacement cycles and the continued trend of bulk purchasing among households. Strong regulatory frameworks governing energy consumption (e.g., Energy Star requirements) necessitate continuous innovation from manufacturers, emphasizing smart technology integration and superior insulation.

- Europe: This region exhibits stable growth, highly influenced by stringent environmental regulations, pushing the swift adoption of natural refrigerants (R290, R600a). Western European countries prioritize sophisticated design, optimal energy ratings (A++ and above), and integration into compact spaces. Eastern Europe, while rapidly modernizing, represents significant potential for commercial expansion as cold chain infrastructure matures.

- Latin America (LATAM): Showing robust growth potential, LATAM markets benefit from improving economic stability and increasing investment in modern retail infrastructure. Demand for horizontal freezers, particularly in the mid-capacity range, is rising as penetration rates increase across commercial and lower-to-middle income residential segments, especially in Brazil and Mexico.

- Middle East and Africa (MEA): Emerging markets with significant long-term potential. Growth is currently localized but strong, driven by large commercial and governmental projects, particularly in food security initiatives and vaccine storage (requiring specialized medical freezers). Demand often centers on robust, high-durability units capable of performing reliably in high ambient temperatures, often favoring deep chest designs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Horizontal Freezer Market.- Haier Group Corporation

- Whirlpool Corporation

- Electrolux AB

- Samsung Electronics Co. Ltd.

- LG Electronics Inc.

- Liebherr Group

- Midea Group Co., Ltd.

- Godrej Appliances (A unit of Godrej & Boyce Mfg. Co. Ltd.)

- Danby Appliances Inc.

- Kenmore (Transformco)

- Frigidaire (Electrolux subsidiary)

- Summit Appliance (Felix Storch, Inc.)

- Usha International Ltd.

- Blue Star Limited

- Voltas Limited

- Hisense Group

- Bosch Home Appliances

- Panasonic Corporation

- AHT Cooling Systems GmbH

- Metalfrio Solutions SA

- Vestfrost Solutions A/S

- Fricon S.A.

- Hoshizaki Corporation

- Thermo Fisher Scientific (Specialized Medical Freezers)

- Carrier Global Corporation (Commercial Refrigeration)

- Zero Zone, Inc.

- True Manufacturing Co., Inc.

- Arneg Group

- Tefcold A/S

- Foster Refrigerator

Frequently Asked Questions

Analyze common user questions about the Horizontal Freezer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key advantages of a horizontal freezer over an upright freezer?

Horizontal freezers, also known as chest freezers, are significantly more energy-efficient because cold air naturally stays inside when the lid is opened. They also offer a larger, often uninterrupted storage space and are less prone to freezer burn due to superior temperature consistency, making them ideal for long-term bulk food storage.

Which technologies are driving energy efficiency improvements in the Horizontal Freezer Market?

The primary technologies driving efficiency are inverter compressor systems, which adjust cooling speed dynamically, and advanced insulation materials like Vacuum Insulated Panels (VIPs), which drastically reduce thermal transfer. The shift to natural refrigerants (R600a/R290) also contributes to better overall energy performance and environmental sustainability.

How is the adoption of IoT impacting the functionality of commercial horizontal freezers?

IoT integration allows commercial freezers to offer critical smart functionalities, including remote temperature monitoring, real-time diagnostic alerts for predictive maintenance, and automatic inventory management tracking. This enhances operational reliability, reduces product loss, and streamlines compliance reporting for food safety standards.

Which application segment holds the largest market share in the Horizontal Freezer Market?

The Commercial application segment consistently holds the largest market share. This is attributed to the high volume of freezers required by supermarkets, hypermarkets, convenience stores, and the massive global food service industry, all of which rely on large-capacity units for continuous operation and product display.

What is the most critical factor for consumers when selecting a horizontal freezer?

For residential consumers, energy efficiency (low running cost) and optimal storage capacity relative to physical footprint are highly critical. For commercial buyers, long-term durability, reliable temperature stability, and adherence to specific regulatory standards are the most decisive purchasing factors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager