Horizontal Grinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431736 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Horizontal Grinder Market Size

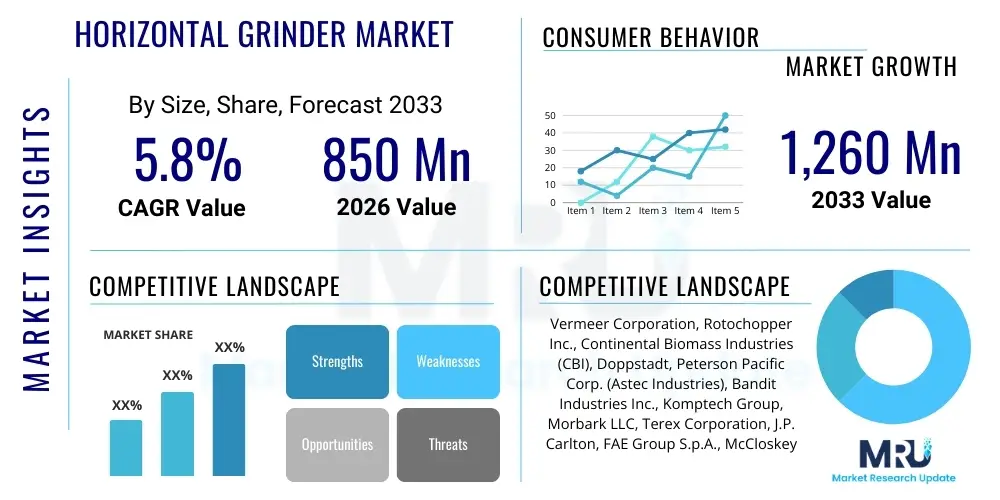

The Horizontal Grinder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $850 million in 2026 and is projected to reach $1,260 million by the end of the forecast period in 2033.

Horizontal Grinder Market introduction

The Horizontal Grinder Market encompasses heavy machinery designed for high-volume reduction of bulky organic and construction waste materials. These machines utilize a horizontal feed system and a powerful rotating drum or rotor equipped with hammers or knives to uniformly process materials such as woody debris, green waste, pallets, and construction and demolition (C&D) wood. Unlike tub grinders, horizontal grinders offer superior control over product sizing, enhanced safety features due to reduced material ejection, and higher efficiency when dealing with longer input materials, making them essential tools in modern waste management and recycling infrastructure.

Key applications driving the adoption of horizontal grinders include biomass fuel production, municipal solid waste processing, land clearing operations, and the creation of commercial mulch products. The increasing global focus on sustainable resource management, coupled with stringent regulations governing landfill use and the promotion of recycling mandates, positions horizontal grinders as critical assets. Their ability to transform low-value waste streams into reusable commodities, such as compost additives or boiler fuel feedstock, underpins their value proposition across various industrial sectors seeking circular economy solutions.

The primary driving factors for market growth include significant infrastructure investments in developing economies, the expanding scope of forestry management requiring efficient debris reduction, and the sustained demand for bioenergy globally. Furthermore, technological advancements focusing on optimizing fuel efficiency, enhancing operator safety through telematics and remote monitoring, and improving the durability of wear parts contribute positively to the market dynamics. These factors collectively ensure continuous replacement cycles and expansion into new operational niches, particularly within specialized environmental remediation projects.

Horizontal Grinder Market Executive Summary

The Horizontal Grinder Market is exhibiting robust growth, primarily fueled by rising environmental consciousness and government mandates prioritizing waste reduction and recycling across North America and Europe. Business trends indicate a strong shift towards intelligent machinery, characterized by integrated sensor technology and advanced diagnostics that minimize downtime and optimize throughput. Manufacturers are concentrating on developing versatile, high-mobility models (track-mounted) capable of handling diverse feedstock materials, catering specifically to contract grinding services and large-scale infrastructure development projects. This strategic pivot ensures operational flexibility, which is highly valued by modern end-users facing fluctuating material inputs.

Regionally, Asia Pacific is emerging as the fastest-growing market, driven by rapid urbanization, resulting in massive construction waste generation and the necessity for scalable waste processing solutions, particularly in countries like China and India. North America remains the largest market, largely due to established forestry and wood recycling industries and the early adoption of advanced, high-capacity equipment. European markets, governed by strict EU directives on waste management, show sustained demand for low-emission and highly energy-efficient electric or hybrid horizontal grinders, pushing innovation towards sustainable power sources and reduced noise pollution characteristics.

Segment trends reveal that the track-mounted segment dominates the market due to its inherent mobility advantages, crucial for remote land clearing and disaster recovery applications. Within applications, wood recycling and biomass production segments hold the largest shares, reflecting the global energy transition objectives. Furthermore, the market is seeing a trend toward highly customized rotor configurations tailored for specific materials, moving beyond general-purpose grinding. End-user demand from the waste management sector, focusing on composting and material recovery facilities (MRFs), is accelerating, requiring machines that can reliably handle contaminated or heterogeneous feed streams efficiently and safely.

AI Impact Analysis on Horizontal Grinder Market

User inquiries concerning AI's impact on horizontal grinders primarily revolve around questions regarding operational efficiency enhancement, predictive maintenance capabilities, and the potential for autonomous operation. Users are keen to understand how AI-driven algorithms can optimize engine load relative to material density, thereby reducing fuel consumption and wear part degradation. A significant concern is the integration of machine learning for feedstock analysis—can AI automatically classify material input (e.g., clean wood vs. C&D debris) and adjust the grind setting in real-time? Expectations center on predictive failure analysis, leveraging sensor data (vibration, temperature, oil pressure) to forecast necessary maintenance interventions, dramatically increasing uptime and operational safety, thus transforming traditional fleet management into a highly data-driven process.

- AI-driven Predictive Maintenance: Utilizing real-time sensor data and machine learning to forecast component failure (e.g., hammer wear, bearing stress), maximizing uptime and reducing unplanned maintenance costs.

- Optimized Operational Settings: Algorithms analyze material input characteristics (density, moisture content, contamination) and automatically adjust rotor speed, feed rate, and engine output for maximum fuel efficiency and consistent product sizing.

- Enhanced Safety and Anomaly Detection: AI monitors sound signatures and vibration patterns to identify foreign objects (e.g., metal contaminants) instantly, triggering emergency shutdowns or material rejection protocols before critical damage occurs to the rotor assembly.

- Fleet Telematics and Efficiency Benchmarking: Machine learning models process vast amounts of operational data across an entire fleet, identifying best practices, optimal geographical operating conditions, and driver efficiency scores, leading to standardized operational excellence.

- Automated Product Sizing Consistency: AI systems utilize optical sensors or material property measurements to ensure the output mulch or biomass meets precise specifications without constant manual calibration.

DRO & Impact Forces Of Horizontal Grinder Market

The Horizontal Grinder Market is significantly influenced by a complex interplay of positive drivers, restrictive challenges, and long-term opportunities, all shaped by pervasive impact forces stemming from global economic and regulatory environments. A primary driver is the global mandate for waste reduction and the transition toward bioenergy, compelling industries, particularly forestry and municipalities, to invest in efficient size-reduction equipment. Restraints typically involve the high capital expenditure required for purchasing and maintaining these large machines, coupled with the sensitivity of operational profitability to fluctuating fuel prices and the cost of durable wear parts. Opportunities exist in developing advanced material processing capabilities for specialized waste streams, such as railroad ties or contaminated urban wood, and expanding into rapidly industrializing regions where waste infrastructure is nascent but urgently required. The market forces demand that manufacturers continuously innovate in terms of throughput efficiency and compliance with increasingly stringent environmental emission standards.

Key drivers include government incentives supporting green infrastructure and renewable energy targets, particularly in North America and Europe, which stimulate the demand for biomass processing equipment. Furthermore, the recurrent need for large-scale debris management following natural disasters (e.g., hurricanes, wildfires) creates temporary but significant spikes in demand for highly mobile grinding solutions. Manufacturers are capitalizing on these drivers by offering financing and leasing options to mitigate the initial high investment barrier for smaller contractors. However, the operational challenges, such as the scarcity of skilled operators capable of maintaining sophisticated machinery and the logistical difficulties of transporting oversized track-mounted units, act as persistent restraints that hinder seamless market penetration and efficient utilization across all potential regions.

The primary opportunity lies in the development of modular and smaller-scale electric grinders, suitable for urban environments where noise and emissions are critical constraints. This aligns with the long-term trend of decentralizing waste processing. Impact forces, such as the price volatility of steel (a key input for machine manufacturing) and global supply chain disruptions affecting component delivery, continuously necessitate robust sourcing strategies and resilient production planning. Moreover, the competitive force exerted by alternative size reduction technologies, such as industrial shredders and chippers, forces horizontal grinder manufacturers to consistently demonstrate superior throughput and finished product quality to maintain their market dominance in high-capacity applications.

Segmentation Analysis

The Horizontal Grinder Market is meticulously segmented based on machine type, operational capacity, primary application, and end-user vertical, providing a granular view of demand patterns and technological preferences across different industrial ecosystems. This detailed segmentation analysis reveals that purchasing decisions are highly dependent on the operational environment, material characteristics, and regulatory compliance requirements. The Type segmentation, particularly the distinction between track-mounted and wheel-mounted units, highlights the trade-off between superior mobility in rugged terrain and faster road transportation capabilities. Application segmentation confirms the market's reliance on high-throughput recycling industries, where the ability to process high volumes efficiently dictates market share and profitability. Understanding these distinct segments is crucial for strategic market entry and targeted product development.

- By Type:

- Track-mounted Horizontal Grinders

- Wheel-mounted Horizontal Grinders

- Stationary Horizontal Grinders

- By Application:

- Wood Recycling (Pallets, Urban Wood)

- Biomass Production

- Land Clearing and Forestry Debris Reduction

- Municipal Waste Processing

- Composting and Mulching

- By End-User:

- Construction and Demolition (C&D) Waste Management

- Forestry and Logging Companies

- Municipalities and Government Agencies

- Contract Grinders and Service Providers

- Agriculture and Farming

- By Capacity:

- Low Capacity (Under 400 HP)

- Medium Capacity (400 HP – 750 HP)

- High Capacity (Above 750 HP)

Value Chain Analysis For Horizontal Grinder Market

The value chain for the Horizontal Grinder Market begins with upstream activities involving the sourcing and processing of raw materials, predominantly high-grade steel alloys for the chassis, rotor assemblies, and wear parts, alongside the acquisition of specialized components like high-horsepower industrial engines (Diesel or Electric), hydraulic systems, and advanced electronic controls. Manufacturers often form strategic, long-term relationships with specialized component suppliers to ensure quality, manage costs, and secure reliable supply chains, as the performance and longevity of the grinder are heavily reliant on the quality of these upstream inputs. Research and Development, focused on improving rotor design, material flow, and wear resistance, represents a critical value-adding step in the manufacturing phase, aiming to increase machine lifespan and operational efficiency.

The downstream analysis focuses primarily on distribution, sales, and aftermarket services. Distribution channels are predominantly indirect, relying on a global network of authorized dealers and specialized heavy equipment distributors who provide local sales, product demonstrations, and technical support. Direct sales typically occur only for large governmental contracts or major fleet buyers. The aftermarket services segment—including parts sales (hammers, screens, tips), maintenance contracts, and technical training—is a significant profit center for manufacturers and is crucial for maintaining customer satisfaction and ensuring high machine availability, which is paramount in operations where downtime is extremely costly.

The efficiency of the distribution channel is vital, particularly for ensuring prompt delivery of high-wear components, minimizing customer downtime. Direct channels allow manufacturers tighter control over pricing and customer feedback loops, facilitating rapid product improvement based on field performance data. However, the complex nature of heavy equipment servicing means that a robust indirect network capable of providing specialized engine maintenance and hydraulic system repairs is essential. Overall, value is captured through product innovation (better output quality), operational excellence (reducing manufacturing costs), and comprehensive post-sales support (maximizing machine life and performance).

Horizontal Grinder Market Potential Customers

The primary potential customers for horizontal grinders are entities engaged in high-volume organic material processing and waste reduction, requiring machinery capable of high throughput and consistent material output sizing. These end-users typically invest in grinders as central components of their material handling infrastructure to comply with environmental regulations, reduce landfill disposal costs, or monetize waste streams into sellable commodities. The diversity in applications, ranging from small-scale contract grinding to massive industrial biomass operations, necessitates manufacturers offering a wide product portfolio covering various horsepower and mobility specifications.

The largest customer segments include established organizations in the forestry and logging industries that utilize grinders for clearing residues, creating fire breaks, and producing wood chips for paper or energy production. Simultaneously, municipal and private waste management companies represent a rapidly expanding customer base, particularly those operating Material Recovery Facilities (MRFs) or large composting sites. These entities require robust, reliable grinders that can handle heterogeneous feedstocks, including contaminated wood and yard waste, transforming them into marketable mulch or compost starter materials, thereby adhering to strict waste diversion targets.

Furthermore, specialized segments such as disaster recovery contractors, land developers, and large-scale agricultural enterprises (for stubble grinding and soil preparation) constitute significant, albeit periodic, demand centers. Contract grinding services, which do not own the land or the resource but provide mobile processing services, are also crucial buyers, often favoring track-mounted, high-mobility units. Their purchasing decisions are heavily influenced by machine versatility, maintenance accessibility, and the cost-per-ton of processed material, making efficiency and longevity key selling points for manufacturers targeting this economically driven customer segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $850 million |

| Market Forecast in 2033 | $1,260 million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Vermeer Corporation, Rotochopper Inc., Continental Biomass Industries (CBI), Doppstadt, Peterson Pacific Corp. (Astec Industries), Bandit Industries Inc., Komptech Group, Morbark LLC, Terex Corporation, J.P. Carlton, FAE Group S.p.A., McCloskey International, Hammel Recyclingtechnik GmbH, DuraTech Industries, Jenz GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Horizontal Grinder Market Key Technology Landscape

The technology landscape within the Horizontal Grinder Market is characterized by continuous innovation focused on optimizing material reduction efficiency, improving operational safety, and minimizing environmental impact. Central to this evolution is the advancement in rotor and hammer technology, utilizing specialized alloy steels and tungsten carbide coatings to enhance wear resistance and prolong service intervals when processing abrasive or contaminated materials. Modern grinders feature sophisticated electronic control systems that manage engine load and hydraulic pressure dynamically, allowing the machine to maximize throughput while preventing engine lugging and unnecessary fuel consumption, often integrating advanced sensor feedback for real-time performance diagnostics.

Another significant technological trend is the pervasive integration of telematics and remote monitoring systems. These technologies allow fleet managers to track machine location, operational status, fuel consumption, and performance metrics instantaneously. This data is critical for predictive maintenance scheduling and for generating detailed compliance reports. Furthermore, manufacturers are increasingly adopting tiered combustion engines (Tier 4 Final/Stage V) to comply with stringent emissions regulations in developed markets, alongside the introduction of hybrid electric or fully electric models for niche applications requiring quiet and zero-emission operation, particularly in urban and indoor waste facilities.

Safety technology remains a paramount area of focus. Innovations include enhanced material containment systems, auto-reversing feed systems designed to quickly eject tramp metal or prevent oversized objects from entering the grinding chamber, and specialized remote controls that allow operators to maintain a safe distance during high-risk operations. The design of the grinding chamber is also evolving, incorporating features like screen change systems that are safer and faster, thereby significantly reducing non-productive downtime and improving the overall ergonomic experience for the machine operators and maintenance personnel.

Regional Highlights

- North America: This region holds the largest market share, driven by a mature forestry industry, high rates of C&D debris recycling, and robust investment in infrastructure and disaster cleanup services. The presence of major market leaders and a high disposable income facilitating investment in high-capacity, sophisticated machinery reinforces this dominance. Strict environmental regulations and the strong demand for wood-based products and biomass energy ensure continuous market stability and growth, particularly for wheel-mounted and track-mounted high-horsepower units used in expansive field operations.

- Europe: The European market is characterized by a strong emphasis on sustainability, circular economy principles, and stringent emissions standards (Stage V). Demand here is focused on highly efficient, often electric or hybrid grinders designed for noise and pollution reduction, primarily driven by municipal waste processing and biomass energy production mandates. Germany, the UK, and France are key contributors, investing heavily in modernizing their waste infrastructure and converting agricultural and forestry residues into energy feedstocks, favoring grinders with high-quality finished product consistency.

- Asia Pacific (APAC): APAC is the fastest-growing region, fueled by unprecedented urbanization, rapid industrialization, and subsequent massive increases in construction waste generation, particularly in China, India, and Southeast Asia. The region is moving quickly to establish formal waste management infrastructure, creating significant demand for mid-to-high capacity stationary and mobile grinders. Government initiatives focused on reducing reliance on landfills and promoting centralized material recovery facilities are the main growth catalysts, though price sensitivity often dictates purchasing decisions, favoring local manufacturing or cost-effective imports.

- Latin America: This market is emerging, with growth tied to expanding agricultural sectors and increasing mining operations. Demand is patchy but intensifying, driven by the need for land clearing and basic wood waste reduction. The market often seeks robust, simpler machines that are easier to maintain in remote locations. Economic stability and infrastructure development are key prerequisites for consistent market maturation in countries like Brazil and Mexico.

- Middle East and Africa (MEA): Growth in the MEA region is primarily linked to large-scale infrastructure projects, land development, and early-stage waste management initiatives, especially in the UAE and Saudi Arabia. The application focus is often on initial site clearance and debris disposal. While the market is currently small, long-term prospects are positive, dependent on governmental commitments to sustainable development and the establishment of formal recycling economies, pushing initial demand for reliable, diesel-powered mobile units.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Horizontal Grinder Market.- Vermeer Corporation

- Rotochopper Inc.

- Continental Biomass Industries (CBI)

- Doppstadt

- Peterson Pacific Corp. (Astec Industries)

- Bandit Industries Inc.

- Komptech Group

- Morbark LLC

- Terex Corporation

- J.P. Carlton

- FAE Group S.p.A.

- McCloskey International

- Hammel Recyclingtechnik GmbH

- DuraTech Industries

- Jenz GmbH

- Precision Husky Corporation

- Heller Machine Tools

- Albach Maschinenbau GmbH

- Fecon Inc.

- Waste Management Equipment Corp.

Frequently Asked Questions

Analyze common user questions about the Horizontal Grinder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a horizontal grinder and a tub grinder?

Horizontal grinders use a horizontal feed system, providing better control over material input, especially for long or difficult debris, and offer superior safety by minimizing material ejection. Tub grinders feed materials from the top into a spinning tub, generally offering higher throughput for loose materials but with greater risk of debris throw-out.

Which end-user segment drives the highest demand for high-capacity horizontal grinders?

The Forestry and Logging industry and large-scale Contract Grinding Service Providers are the primary drivers for high-capacity (over 750 HP) horizontal grinders. These segments require maximum throughput and durability for efficiently processing high volumes of forest residue, stumps, and whole trees into biomass or mulch.

How is the Horizontal Grinder Market addressing environmental concerns and emissions?

The market addresses environmental concerns by integrating high-efficiency Tier 4 Final/Stage V diesel engines, developing hybrid and electric-powered models for reduced emissions and noise, and employing advanced dust suppression systems to comply with stringent air quality regulations, particularly in urban operational areas.

What key technological innovations are expected to impact grinder maintenance and uptime?

Key innovations include the adoption of AI-driven predictive maintenance systems, leveraging telematics and vibration sensors to forecast wear part failure (e.g., hammers and bearings). Additionally, improved screen change mechanisms and enhanced accessibility to rotor assemblies are reducing non-productive repair time, increasing overall machine uptime.

Is the track-mounted or wheel-mounted segment expected to grow faster?

The track-mounted segment is generally expected to exhibit faster growth due to the increasing demand from contract grinders, disaster recovery operations, and land clearing services that require superior mobility and stability on rough, uneven, or remote terrains where traditional road travel is impractical or impossible.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager