Horizontal Sewage Pumps Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432445 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Horizontal Sewage Pumps Market Size

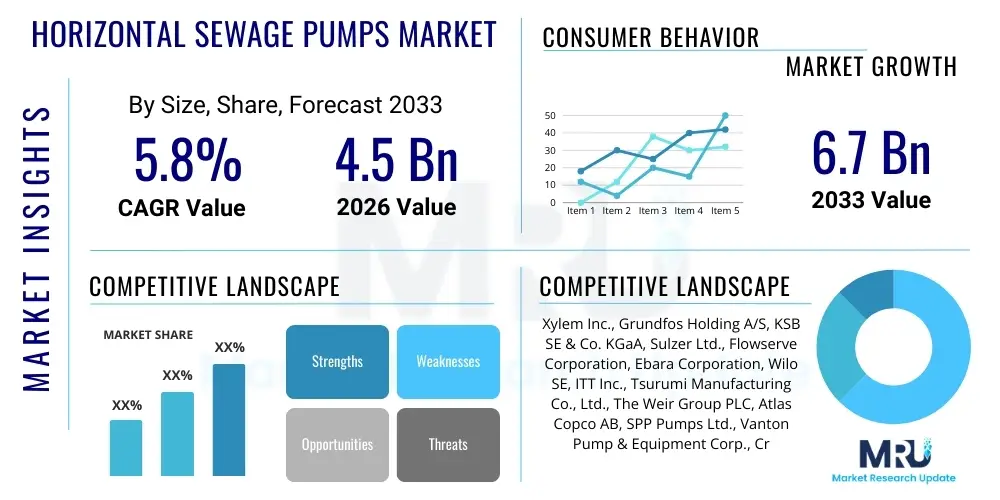

The Horizontal Sewage Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. This consistent expansion is driven by escalating global infrastructure spending, particularly in wastewater treatment and urbanization projects across developing economies. The market benefits significantly from the mandatory regulatory environment dictating the proper handling and disposal of municipal and industrial sewage, ensuring a steady replacement and installation demand cycle.

The market is estimated at USD 4.5 Billion in 2026, reflecting the substantial investment required for robust municipal sanitation systems worldwide. The inherent reliability, ease of maintenance, and suitability of horizontal configurations for stationary, high-volume pumping stations contribute to this strong baseline valuation. Furthermore, advancements in materials science, focusing on corrosion resistance and durability, are enhancing the lifespan and performance of these essential assets, stabilizing initial investment costs for operators.

The Horizontal Sewage Pumps Market is projected to reach USD 6.7 Billion by the end of the forecast period in 2033. This anticipated growth is underpinned by the urgent need to upgrade aging water infrastructure in North America and Europe, coupled with rapid urbanization in Asia Pacific, which necessitates the construction of entirely new sewage networks. Technological integration, particularly the adoption of smart monitoring systems and energy-efficient designs, also plays a crucial role in boosting market revenue by making horizontal pumps more attractive economically and environmentally to large utilities and industrial facilities.

Horizontal Sewage Pumps Market introduction

The Horizontal Sewage Pumps Market encompasses the design, manufacturing, distribution, and utilization of non-clog centrifugal pumps characterized by a horizontal shaft arrangement, primarily used for transporting raw sewage, effluent, and highly contaminated liquids containing solids and fibrous materials. These pumps are essential components of municipal wastewater treatment plants, industrial processing facilities, and large commercial sewage systems where high flow rates and reliable solid handling capabilities are paramount. The product spectrum ranges from standardized end-suction pumps to specialized chopper or cutter pump designs, tailored to prevent clogging in critical applications.

Major applications for horizontal sewage pumps span the entire wastewater infrastructure, including sewage lift stations, primary and secondary sludge transfer, storm water management, and heavy-duty industrial sump drainage. The core benefit of selecting a horizontal configuration often relates to maintenance accessibility, as the motor and wet end components are easily accessible without removing the entire pump from the suction piping, thereby minimizing downtime and labor costs. Furthermore, these pumps are engineered for demanding continuous duty cycles, offering robust performance in abrasive and corrosive environments that typical clean water pumps cannot withstand.

The market is primarily driven by macro-environmental factors such as population growth, stringent global environmental regulations mandating efficient sewage treatment, and sustained capital expenditure on urban infrastructure development, particularly in emerging economies. The necessity for reliable fluid transfer solutions in dense urban areas, coupled with technological innovation focused on improving hydraulic efficiency and reducing energy consumption (a major operating cost), continues to spur market demand, positioning horizontal sewage pumps as foundational elements of modern sanitation systems.

Horizontal Sewage Pumps Market Executive Summary

The Horizontal Sewage Pumps Market is experiencing robust growth fueled by converging business trends, intensified regulatory pressure for environmental compliance, and rapid demographic shifts toward urban centers globally. Key business trends include the increasing integration of Internet of Things (IoT) sensors and smart monitoring capabilities into pump systems, facilitating predictive maintenance and optimized operational efficiency for municipal utilities. Furthermore, manufacturers are focusing on modular designs and enhanced material alloys, such as duplex stainless steel and specific polymers, to offer superior corrosion resistance and extend operational life in extremely harsh sewage environments, thus reducing the total cost of ownership for end-users.

Regionally, the Asia Pacific (APAC) market is poised for the most dynamic expansion, driven by massive government-led initiatives in China, India, and Southeast Asia to address inadequate sanitation infrastructure necessitated by explosive urbanization. Concurrently, North America and Europe continue to drive demand through infrastructure renewal projects aimed at replacing legacy pump systems with high-efficiency models that adhere to increasingly strict energy consumption standards. Latin America and the Middle East & Africa (MEA) present emerging opportunities, primarily linked to large-scale urban development projects and industrial expansion, particularly in the oil and gas and manufacturing sectors which require specialized effluent handling solutions.

Segmentation trends highlight a pronounced shift towards higher capacity, non-clog impeller designs, reflecting the rising complexity and volume of solids found in modern sewage streams. While municipal applications remain the dominant segment by volume, the industrial segment, particularly water-intensive industries like food & beverage and chemicals, is growing rapidly due to the need for tailored, durable pumping solutions that can handle variable effluent characteristics. The market also observes a trend favoring energy-efficient motors (IE3 and IE4 standards) to mitigate operational expenses, demonstrating a commitment across all segments to sustainability and cost optimization.

AI Impact Analysis on Horizontal Sewage Pumps Market

Common user questions regarding AI's impact on horizontal sewage pumps center on how artificial intelligence can move maintenance practices from reactive to predictive, improving reliability and reducing costly system failures associated with clogging or equipment wear. Users are highly interested in AI’s capability to analyze real-time data streams from flow meters, vibration sensors, and power consumption monitors to accurately forecast potential blockages or component degradation, thereby minimizing downtime in critical municipal services. There is also significant curiosity about AI-driven optimization of pump speed and flow control based on fluctuating sewage intake, leading to considerable energy savings and extended equipment lifespan, addressing the major operational concerns of utility managers regarding reliability and efficiency.

- AI-driven Predictive Maintenance: Utilizing machine learning algorithms to analyze operational parameters (vibration, temperature, power draw) to anticipate mechanical failures or imminent clogs, enabling scheduled, proactive repairs rather than reactive emergency interventions.

- Energy Optimization and Smart Pumping: Employing AI models to dynamically adjust pump speed and flow rates in response to real-time inflow patterns, minimizing idling time and ensuring pumps operate within their optimal efficiency curve, leading to substantial reductions in electricity consumption.

- Anomaly Detection for System Health: Implementing AI for continuous monitoring to instantly detect and flag unusual operational data points, such as sudden pressure drops or increased motor strain, which often indicate blockages or transient system disturbances, ensuring rapid response.

- Data Integration and Digital Twin Modeling: Using AI to process data from various sources (SCADA, weather forecasts, billing systems) to create high-fidelity digital twins of pumping stations, simulating various scenarios for training, planning, and infrastructure vulnerability assessment.

- Automated Reporting and Compliance: AI systems can automate the generation of operational efficiency reports and regulatory compliance documents by analyzing historical performance data, reducing administrative burdens for utility staff.

- Optimized Inventory Management: Predicting component failure rates based on operational wear allows AI to forecast necessary spare parts requirements, leading to optimized stocking levels and reduced capital tied up in inventory.

DRO & Impact Forces Of Horizontal Sewage Pumps Market

The Horizontal Sewage Pumps Market is profoundly shaped by a combination of strong drivers, inherent restraints, substantial opportunities, and critical impact forces that collectively dictate its growth trajectory and competitive landscape. Primary drivers include rapid global urbanization and the resultant surge in municipal wastewater volumes requiring efficient conveyance systems, alongside increasingly stringent governmental regulations, particularly in developed economies, mandating the continuous upgrade and modernization of existing sewage infrastructure to meet higher effluent standards. Conversely, significant restraints involve the high initial capital expenditure required for installing these complex pumping stations and the pervasive issue of highly corrosive and abrasive media, which necessitate frequent maintenance and premature replacement of components if not properly managed.

Opportunities for market expansion are centered on the adoption of advanced, energy-efficient pumping technologies, such as those meeting IE4 standards, driven by global pressure to reduce utility energy costs and carbon footprints. Furthermore, there is a burgeoning demand for smart pumps integrated with IoT and AI capabilities, enabling remote diagnostics and predictive maintenance, particularly appealing to large municipal systems seeking operational efficiencies. The increasing development of mega-cities in Asia and Africa provides a consistent stream of greenfield projects requiring new installations, while infrastructure aging in established markets provides fertile ground for replacement cycles.

Key impact forces include volatile raw material pricing, particularly for specialized metal alloys like stainless steel and cast iron, which affects manufacturing costs and final product pricing. Geopolitical instability also influences large-scale infrastructure financing and project timelines. The competitive force of substitution, specifically the comparison with vertical turbine or submersible pumps, forces manufacturers to continually innovate and highlight the superior maintenance benefits and standardized design flexibility of horizontal configurations. The overall societal emphasis on environmental sustainability acts as a powerful, positive impact force, ensuring sustained governmental commitment to wastewater management investments globally.

Segmentation Analysis

The Horizontal Sewage Pumps Market is meticulously segmented based on critical operational and structural characteristics, allowing manufacturers and end-users to precisely match equipment specifications to complex application requirements. Key segmentation variables include the pump type, which determines operational methodology; the material of construction, vital for enduring corrosive sewage environments; capacity and power, dictating applicability to small commercial buildings versus large municipal lift stations; and the end-use application, distinguishing municipal needs from diverse industrial demands. This granular segmentation is essential for understanding market dynamics and tailoring product development efforts to meet specialized infrastructure requirements worldwide.

- By Type:

- Single-Stage Horizontal Pumps

- Multi-Stage Horizontal Pumps

- Self-Priming Horizontal Pumps

- Chopper/Cutter Horizontal Pumps

- By Material:

- Cast Iron Pumps (Dominant for municipal use)

- Stainless Steel Pumps (For corrosive industrial effluent)

- Bronze and Alloy Pumps (Specialized applications)

- By Capacity/Power:

- Low Capacity Pumps (Up to 50 HP)

- Medium Capacity Pumps (51 HP - 200 HP)

- High Capacity Pumps (Above 200 HP)

- By Application/End-Use:

- Municipal Wastewater Treatment Plants (WTPs)

- Industrial Sewage Management (Chemical, Food & Beverage, Pulp & Paper)

- Commercial and Residential Buildings (Large complexes, lift stations)

- Storm Water Pumping and Flood Control

Value Chain Analysis For Horizontal Sewage Pumps Market

The value chain for the Horizontal Sewage Pumps Market commences with upstream activities centered on raw material procurement, primarily sourcing high-grade cast iron, stainless steel, specialized alloys, and electric motors. Efficiency at this stage is crucial, as material costs constitute a significant portion of the total manufacturing expense, making reliable supplier relationships and strategic sourcing paramount. Following manufacturing, which involves precision casting, machining, assembly, and rigorous hydraulic testing, the products move into distribution channels. Manufacturing specialization in non-clog designs and energy efficiency is a key value-add at this stage, differentiating premium manufacturers from commodity producers.

The distribution network plays a pivotal role in linking complex, customized products to highly specialized end-users. Distribution channels are typically segmented into direct sales, utilized for massive, tailored municipal projects and major industrial contracts, and indirect sales, leveraging authorized distributors, channel partners, and system integrators. These intermediaries provide critical local market knowledge, technical installation support, and essential after-sales service, which is vital for maintaining the continuous operation of sewage infrastructure. The margin capture shifts significantly throughout the chain, with high margins often achieved in the design and manufacturing phase, and sustained revenue generation through post-sale services and spare parts provisioning.

Downstream activities involve the installation, commissioning, operation, and maintenance of the pumps at the end-user site, whether a municipal lift station or an industrial processing plant. Direct interaction with the end-user (municipal engineers or plant operators) provides invaluable feedback for product improvement and technical support services. The lifecycle service component, including repairs, preventative maintenance contracts, and spare parts supply, represents a substantial and stable revenue stream, emphasizing the long-term relationship between manufacturers and utility providers, distinguishing the market from typical consumer product value chains.

Horizontal Sewage Pumps Market Potential Customers

The primary consumers and end-users of horizontal sewage pumps are large public sector entities responsible for maintaining urban sanitation infrastructure, complemented by diverse industrial clients with complex effluent handling requirements. Municipal Wastewater Authorities and City Utilities form the cornerstone of the customer base, driving the largest volume of sales due to the universal necessity of sewage collection and treatment across urban environments. These customers prioritize reliability, compliance with strict non-clog standards, operational lifespan, and adherence to energy efficiency mandates (e.g., IE3/IE4 standards) when making purchasing decisions for major lift stations and treatment facilities.

The industrial sector represents a critical, high-value segment, encompassing industries that produce highly contaminated or abrasive effluent. Key industrial buyers include Food & Beverage processors, which require pumps capable of handling high-solid organic waste; Pulp & Paper mills, dealing with fibrous slurries; Chemical Manufacturing plants, needing chemically resistant materials; and the Mining sector, utilizing these pumps for dewatering and slurry transportation. These industrial customers often demand customized pump designs, specific corrosion-resistant alloys, and specialized mechanical seals to ensure operational continuity in challenging process environments, making solution providers preferred vendors.

Furthermore, large commercial entities and infrastructural development projects also constitute significant buyers. This includes developers of large residential complexes, shopping centers, airports, and hospitals that must operate self-contained or large-scale internal sewage lift stations before connecting to the main municipal network. Engineering, Procurement, and Construction (EPC) firms involved in major infrastructure projects frequently procure these pumps as part of complete water and wastewater system packages, serving as essential intermediaries between manufacturers and the ultimate utility owners.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Xylem Inc., Grundfos Holding A/S, KSB SE & Co. KGaA, Sulzer Ltd., Flowserve Corporation, Ebara Corporation, Wilo SE, ITT Inc., Tsurumi Manufacturing Co., Ltd., The Weir Group PLC, Atlas Copco AB, SPP Pumps Ltd., Vanton Pump & Equipment Corp., Crane Pumps & Systems, Ruhrpumpen Group, Gorman-Rupp Company, Metso Outotec Corporation, Shakti Pumps (India) Ltd., Shanghai Kaiquan Pump (Group) Co., Ltd., Toyo Denki Seizo K.K. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Horizontal Sewage Pumps Market Key Technology Landscape

The technological landscape of the Horizontal Sewage Pumps Market is primarily focused on enhancing non-clogging capabilities, maximizing energy efficiency, and integrating smart monitoring systems for predictive diagnostics. Innovations in impeller design are paramount, including vortex impellers and specialized non-clog designs that utilize advanced computational fluid dynamics (CFD) modeling to handle high concentrations of solids and fibrous materials found in modern sewage streams without efficiency loss. These hydraulic improvements directly address the most persistent operational challenge: downtime due to blockages, significantly lowering maintenance costs and improving overall system reliability, which is a key purchasing factor for municipal end-users.

Furthermore, the shift toward highly efficient motor technology (specifically motors compliant with IE3 and increasingly IE4 standards) is defining the market, driven by rising global electricity costs and regulatory mandates aimed at reducing industrial energy consumption. Manufacturers are also heavily investing in advanced materials science, employing specialized alloys, ceramics, and corrosion-resistant coatings to drastically extend the operating life of pump casings and impellers exposed to harsh, abrasive, and chemically aggressive wastewater. This focus on material robustness is crucial for long-term operational sustainability in both municipal and chemical handling environments.

The most transformative technology trend is the integration of Industrial Internet of Things (IIoT) sensors and robust communication platforms into the pumps, creating "smart pumps." These systems monitor parameters such as vibration, bearing temperature, seal condition, flow rate, and pressure in real-time. This connectivity allows for remote diagnostics and the application of Artificial Intelligence (AI) for predictive maintenance routines, moving away from time-based maintenance schedules. This holistic technological approach ensures optimum pump performance, reduces the likelihood of catastrophic failure, and enables utilities to operate their networks with unprecedented levels of visibility and control, solidifying the market's trajectory toward digitalized water management systems.

Regional Highlights

The global Horizontal Sewage Pumps market exhibits significant regional variation, influenced by disparate urbanization rates, regulatory frameworks, and infrastructure investment cycles. Asia Pacific (APAC) stands out as the fastest-growing region, driven by massive public sector investments in new sanitation infrastructure across China, India, and Southeast Asia, necessitated by the unprecedented migration of populations into mega-cities. The urgent need to address pollution and ensure basic sanitation coverage fuels continuous demand for high-capacity, reliable horizontal pumping systems in these emerging economies.

North America and Europe represent mature markets characterized by replacement demand and a strong focus on energy efficiency and system optimization. In these regions, the primary driver is the need to upgrade decades-old infrastructure to comply with stricter environmental standards and reduce operational expenses through the adoption of smart, highly efficient pump technology, often integrating advanced IoT monitoring capabilities. Regulatory bodies actively push for the replacement of older, less efficient pump sets, providing a stable foundation for steady market demand.

Latin America (LATAM) and the Middle East & Africa (MEA) are emerging regions experiencing robust growth tied directly to capital projects, resource development, and rapid urban sprawl. In the MEA, particularly the Gulf Cooperation Council (GCC) countries, demand is concentrated in large-scale desalination and urban development projects, requiring significant high-capacity sewage transfer stations. LATAM demand is often localized but strong, linked to governmental efforts to improve public health standards and expand wastewater treatment access, often supported by international development financing.

- North America (U.S., Canada): Focus on infrastructure renewal, adoption of high-efficiency pumps (IE4 compliance), and integration of advanced monitoring systems for predictive maintenance in mature municipal networks.

- Europe (Germany, UK, France, Italy): Stringent environmental regulations driving demand for sustainable and energy-efficient solutions; strong market presence of European manufacturers and emphasis on digital optimization of existing assets.

- Asia Pacific (China, India, Japan, Southeast Asia): Highest growth region propelled by rapid urbanization, massive investment in new municipal wastewater infrastructure, and development of industrial corridors requiring dedicated effluent treatment systems.

- Latin America (Brazil, Mexico): Market expansion tied to public health initiatives, urbanization in large metropolitan areas, and growing industrial base (e.g., mining and food processing) demanding robust sewage handling equipment.

- Middle East & Africa (UAE, Saudi Arabia, South Africa): Demand concentrated in mega-city construction, new infrastructure projects related to oil/gas processing, and addressing water scarcity through improved wastewater reuse capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Horizontal Sewage Pumps Market. These companies drive innovation in hydraulic efficiency, non-clog technology, and digital integration, significantly shaping global competition and product standards.- Xylem Inc.

- Grundfos Holding A/S

- KSB SE & Co. KGaA

- Sulzer Ltd.

- Flowserve Corporation

- Ebara Corporation

- Wilo SE

- ITT Inc.

- Tsurumi Manufacturing Co., Ltd.

- The Weir Group PLC

- Atlas Copco AB

- SPP Pumps Ltd.

- Vanton Pump & Equipment Corp.

- Crane Pumps & Systems

- Ruhrpumpen Group

- Gorman-Rupp Company

- Metso Outotec Corporation

- Shakti Pumps (India) Ltd.

- Shanghai Kaiquan Pump (Group) Co., Ltd.

- Toyo Denki Seizo K.K.

Frequently Asked Questions

Analyze common user questions about the Horizontal Sewage Pumps market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Horizontal Sewage Pumps Market?

The primary driver is accelerated global urbanization, particularly in Asia Pacific and Africa, which necessitates the continuous construction and expansion of municipal wastewater collection and treatment infrastructure to handle dramatically increased volumes of sewage and effluent.

How do horizontal pumps compare technologically to submersible pumps in sewage applications?

Horizontal sewage pumps offer superior accessibility for maintenance and repair because the motor and coupling are situated above the liquid level, reducing downtime compared to submersible pumps which require extraction from the pit for servicing. However, submersible pumps conserve space and are easier to install in deep pits.

Which material is most commonly used for horizontal sewage pump construction?

Cast iron remains the most common and cost-effective material for standard municipal sewage applications due to its strength and affordability. However, stainless steel and specialized high-chrome alloys are increasingly used in industrial settings where the sewage is highly corrosive or abrasive.

What role does AI or IoT play in modern horizontal pumping systems?

AI and IoT enable "smart pumping" by integrating real-time sensors to monitor operational health. This facilitates predictive maintenance, allowing utilities to schedule repairs before failures occur, and optimizes pump speeds for maximum energy efficiency based on variable inflow rates, significantly reducing operating costs.

What is the expected Compound Annual Growth Rate (CAGR) for the market through 2033?

The Horizontal Sewage Pumps Market is projected to grow at a stable CAGR of approximately 5.8% between 2026 and 2033, driven by regulatory compliance mandates, infrastructure replacement cycles in developed nations, and extensive greenfield sanitation projects in developing regions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager