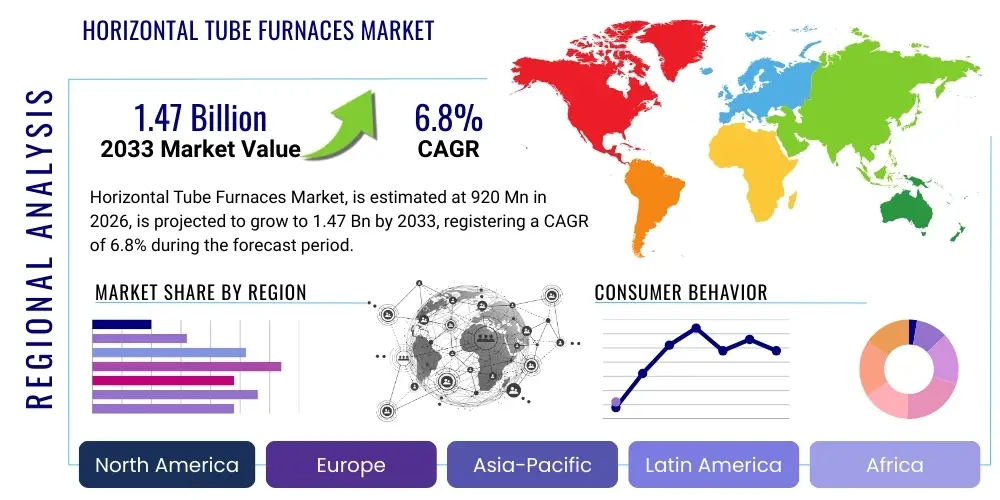

Horizontal Tube Furnaces Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440254 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Horizontal Tube Furnaces Market Size

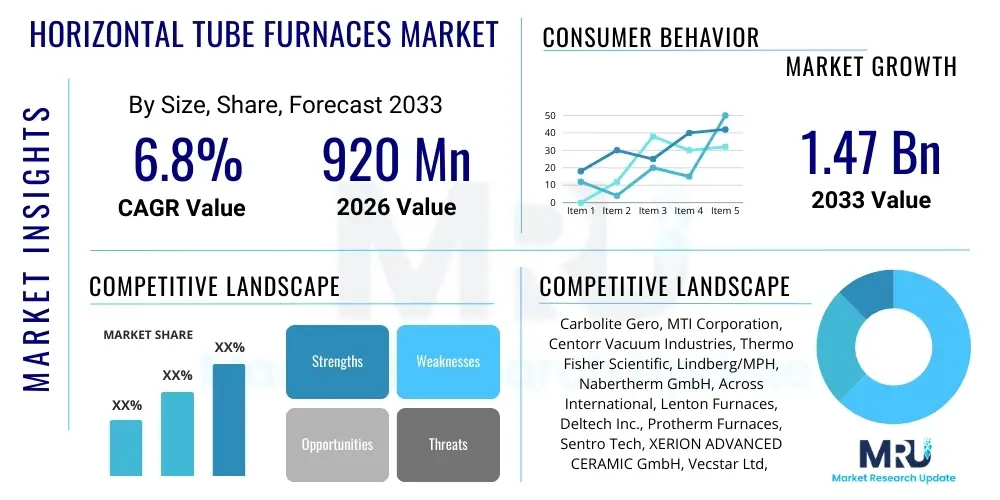

The Horizontal Tube Furnaces Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 920 million in 2026 and is projected to reach USD 1.47 billion by the end of the forecast period in 2033.

Horizontal Tube Furnaces Market introduction

The horizontal tube furnaces market encompasses advanced thermal processing equipment designed for precise temperature control across a wide range of scientific and industrial applications. These furnaces typically feature a cylindrical heating chamber, often equipped with advanced heating elements and insulation, allowing for highly uniform temperature distribution and controlled atmospheric environments, including vacuum, inert gas, or reactive gas conditions. The primary product offering involves systems capable of reaching extremely high temperatures, essential for manipulating materials at the atomic and molecular levels, making them indispensable tools in modern research and production processes. Their design facilitates excellent temperature stability and repeatability, crucial for sensitive experiments and consistent manufacturing outputs.

Major applications for horizontal tube furnaces span a multitude of sectors, including material science research, semiconductor manufacturing, metallurgy, ceramics production, crystal growth, and analytical testing. They are critical for processes such as annealing, sintering, brazing, chemical vapor deposition (CVD), and various heat treatments that demand stringent temperature profiles and environmental control. The benefits of employing these furnaces are numerous, offering exceptional temperature accuracy, improved process repeatability, enhanced material properties, and the ability to work with a diverse array of materials, from advanced ceramics to sensitive electronic components. These systems significantly contribute to innovation by enabling the development of new materials, optimizing existing manufacturing processes, and ensuring product quality in high-tech industries, thereby driving technological advancements across numerous domains.

Several key factors are driving the robust growth of the horizontal tube furnaces market. Foremost among these is the escalating global investment in research and development, particularly in advanced materials, nanotechnology, and specialized chemical syntheses, which necessitates sophisticated thermal processing capabilities. The rapid expansion of the semiconductor industry, with its continuous demand for precise wafer processing, thin-film deposition, and material modification at increasingly smaller scales, further fuels market growth. Additionally, increasing industrial automation across various manufacturing sectors, coupled with the rising demand for high-performance components in aerospace, automotive, and medical industries, compels manufacturers to adopt these highly efficient and controllable thermal systems. The emphasis on energy efficiency, process optimization, and stringent quality control in modern manufacturing also contributes significantly to the adoption of advanced horizontal tube furnaces, as they offer the reliability and precision required for critical applications.

Horizontal Tube Furnaces Market Executive Summary

The horizontal tube furnaces market is characterized by dynamic business trends, marked by a growing emphasis on customization and modular design to meet diverse application requirements across various research and industrial settings. Manufacturers are increasingly integrating advanced control systems, including programmable logic controllers (PLCs) and sophisticated human-machine interfaces (HMIs), to enhance operational precision, enable remote monitoring, and facilitate data logging for comprehensive process analysis and quality assurance. Furthermore, there is a distinct trend towards developing energy-efficient models, incorporating superior insulation materials, optimized heating element designs, and regenerative heating technologies, in response to rising energy costs and global sustainability initiatives. The market also sees significant activity in mergers, acquisitions, and strategic partnerships, as companies seek to expand their product portfolios, technological capabilities, and geographical reach, consolidating expertise and market share while fostering innovation.

From a regional perspective, the Asia Pacific (APAC) region continues to emerge as a dominant force in the horizontal tube furnaces market, driven by extensive investments in semiconductor manufacturing, burgeoning research and development activities, and a rapidly expanding industrial base, particularly in countries like China, Japan, South Korea, and India. This region benefits from a large consumer electronics market and robust government support for scientific and industrial innovation. North America and Europe, while representing mature markets, maintain strong positions due to robust academic research institutions, advanced material science initiatives, and high-tech manufacturing sectors, including aerospace, defense, and medical devices. These regions are often at the forefront of adopting innovative technologies, demanding high-performance, and specialized furnace solutions. Emerging markets in Latin America and the Middle East & Africa are also demonstrating promising growth, propelled by infrastructure development, diversification efforts from resource-based economies, and increasing industrialization, albeit from a smaller base.

Segmentation trends within the horizontal tube furnaces market reveal a pronounced shift towards multi-zone and split-tube furnace configurations, favored for their enhanced flexibility in temperature profiling, gradient control, and ease of sample loading for specific research applications. High-temperature furnaces (above 1200°C) are experiencing substantial demand, particularly from advanced materials research, specialized industrial processes requiring extreme thermal conditions, and next-generation energy storage material development. In terms of atmospheric control, vacuum and inert gas furnaces are gaining significant traction due to the increasing need for oxygen-free or contamination-free processing environments in critical applications like semiconductor fabrication, advanced ceramics, and crystal growth. The application segment sees significant growth in research & development and material processing, reflecting ongoing innovation and the industrial adoption of new material technologies. End-user industries such as semiconductors, metallurgy, and advanced ceramics remain pivotal, with continuous technological advancements driving demand for specialized and high-precision furnace solutions tailored to evolving process requirements.

AI Impact Analysis on Horizontal Tube Furnaces Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize the operation and application of horizontal tube furnaces, focusing on aspects like enhanced process control, predictive maintenance, and data-driven material discovery. Key themes include the potential for AI algorithms to optimize complex temperature profiles for specific material properties, identify subtle anomalies in furnace operation before critical failures occur, and autonomously adjust parameters to maintain ideal processing conditions even with fluctuating input variables. There is a strong expectation that AI will lead to significant improvements in efficiency, throughput, consistency, and energy usage, while also accelerating the pace of research by facilitating complex experimental design, analysis of vast datasets, and rapid iteration of material formulations. Concerns often revolve around the implementation complexity, the need for robust data infrastructure, cybersecurity threats, and the necessity for specialized expertise to effectively leverage AI in high-precision thermal processing environments, alongside the reliability and ethical validation of AI-driven decisions in critical industrial and research applications.

- Predictive Maintenance: AI algorithms analyze real-time sensor data (temperature, pressure, gas flow, heating element resistance, power consumption, vibration) to identify subtle patterns indicative of component wear or impending failures (e.g., heating elements, vacuum pumps, seals, thermocouples). This enables highly accurate prediction of maintenance needs, allowing for proactive servicing, significant reduction in unplanned downtime, and extension of equipment operational lifespan, thereby improving overall operational efficiency and reducing maintenance costs.

- Process Optimization: AI-driven control systems can dynamically adjust and refine complex furnace parameters, including temperature ramps, soak times, cooling rates, and atmospheric compositions, based on real-time feedback and desired material outcomes. By leveraging machine learning models, these systems can identify optimal processing windows, minimize energy consumption, reduce cycle times, and consistently improve product yield and quality by adapting to variations in raw materials or environmental conditions, leading to superior material properties and reduced waste.

- Autonomous Control and Adaptive Learning: Integration of AI enables self-optimizing furnace operations where systems learn from thousands of previous processing runs and experimental data. This allows furnaces to autonomously adapt parameters for new or varying material batches, compensate for minor equipment drift, and ensure highly consistent results with minimal human intervention. Such autonomous capabilities enhance repeatability, reduce the need for constant operator oversight, and allow for more complex, multi-stage processes to be executed with higher precision.

- Data-Driven Material Discovery and Characterization: AI facilitates the analysis of vast, multi-modal datasets generated during experiments, including temperature profiles, gas compositions, structural characterization data, and resulting material properties. By identifying complex correlations and hidden patterns that human analysis might miss, AI accelerates the discovery and development of new advanced materials with desired characteristics, optimizes existing material formulations, and streamlines the process of understanding material behavior under various thermal conditions.

- Enhanced Safety and Reliability: AI systems can continuously monitor for deviations from safe operating limits, detect abnormal conditions (e.g., unexpected pressure drops, gas leaks, runaway temperatures), and trigger automated safety protocols or immediate alerts. This proactive anomaly detection significantly improves operational safety, prevents potential damage to expensive equipment or valuable materials, and ensures that the furnace operates within predefined, secure parameters, contributing to a more reliable and secure thermal processing environment.

DRO & Impact Forces Of Horizontal Tube Furnaces Market

The Horizontal Tube Furnaces Market is propelled by several significant drivers. The escalating global investments in research and development, particularly in advanced materials, nanotechnology, and semiconductor technologies, create a continuous demand for precise thermal processing equipment essential for material synthesis, characterization, and device fabrication. The rapid expansion of the semiconductor industry, driven by the proliferation of IoT devices, artificial intelligence, 5G technology, and advanced computing, necessitates sophisticated furnaces for critical processes like wafer processing, annealing, oxidation, and chemical vapor deposition. Furthermore, the increasing demand for high-performance materials in industries such as aerospace, automotive (especially for electric vehicles), and medical devices, where components must withstand extreme conditions and possess superior mechanical or electrical properties, fuels the need for advanced heat treatment solutions. The pervasive push for industrial automation and process optimization across manufacturing sectors also contributes significantly, as businesses seek to enhance efficiency, reduce costs, and improve product quality through highly controlled thermal environments. Finally, the growing focus on energy efficiency and sustainability in manufacturing encourages the adoption of modern furnaces that offer better insulation, optimized heating processes, and reduced carbon footprints, aligning with environmental regulations and corporate responsibility goals globally.

Despite robust growth drivers, the market faces certain restraints. The high initial capital expenditure associated with purchasing and installing advanced horizontal tube furnaces can be a significant barrier for smaller enterprises, start-ups, or research institutions with limited budgets. The complexity of these systems often requires substantial upfront investment not just in the furnace itself, but also in supporting infrastructure like power, cooling, gas lines, and vacuum pumps. Operational costs, primarily related to energy consumption, especially for high-temperature and long-duration applications, also pose a challenge, though advancements in energy efficiency are actively addressing this. The requirement for highly skilled personnel to operate, maintain, and calibrate these sophisticated systems, coupled with a niche understanding of thermal processing principles, can also limit adoption in regions with talent shortages. Additionally, the availability of alternative heating technologies or specialized processing methods, though often application-specific, can sometimes present competitive pressure to traditional tube furnaces. Economic uncertainties, geopolitical tensions, and trade disputes can also impact investment decisions in industrial and research infrastructure, leading to deferred purchases and market fluctuations, particularly for high-value capital equipment.

Opportunities within the market are abundant, particularly in emerging economies where industrialization and scientific research are rapidly expanding, creating new avenues for market penetration and growth. The increasing trend towards customization and modular design allows manufacturers to cater to highly specific research and industrial requirements, opening niche markets for specialized furnace configurations that can perform unique processing tasks. The integration of advanced analytics, artificial intelligence (AI), and machine learning (ML) capabilities into furnace control systems presents a substantial opportunity for developing smarter, more autonomous, and highly efficient thermal processing solutions that offer predictive maintenance, real-time process optimization, and data-driven insights. Furthermore, the growing demand for materials used in renewable energy technologies, such as advanced battery components, solar cells, and fuel cells, creates a new and expanding application area for horizontal tube furnaces. Partnerships between academia and industry, as well as collaborative research initiatives, also present opportunities for developing innovative furnace designs and applications, further expanding the market's technological capabilities and commercial reach.

Segmentation Analysis

The horizontal tube furnaces market is comprehensively segmented based on various technical and application-oriented criteria, enabling a detailed understanding of its diverse landscape and dynamics. These segmentations are crucial for identifying specific market niches, understanding user preferences, and tracking technological advancements across different product categories and end-user industries. The market can be dissected by furnace type, which often relates to design and operational flexibility, as well as by the maximum operating temperature, which dictates the range of materials and processes that can be accommodated. Atmospheric control capabilities, such as vacuum or inert gas environments, represent another critical segmentation reflecting the stringent purity and environmental requirements of modern material science and semiconductor fabrication. Furthermore, the market is analyzed based on its primary applications and the specific end-user industries that leverage these advanced thermal processing tools, providing insights into demand drivers, technological needs, and future growth areas, offering a granular view of market dynamics.

- By Type:

- Single Zone Horizontal Tube Furnaces: Designed for uniform temperature across a single processing zone.

- Multi-Zone Horizontal Tube Furnaces: Offers independent temperature control across multiple zones, enabling precise temperature gradients.

- Split Tube Furnaces: Features a split chamber design for easy sample loading and unloading.

- Rotary Tube Furnaces: Used for continuous processing of powders, granules, or small components, often with atmosphere control.

- Custom/Specialty Tube Furnaces: Tailored designs for unique research or industrial process requirements.

- By Temperature Range:

- Low Temperature (Up to 800°C): Suitable for drying, curing, and low-temperature annealing.

- Medium Temperature (800°C - 1200°C): Common for general heat treatments, sintering, and material synthesis.

- High Temperature (Above 1200°C): Utilized for advanced ceramics, metallurgy, and high-temperature material processing.

- Ultra-High Temperature (Above 1800°C): For specialized applications involving refractory metals, single crystal growth, and advanced material research requiring extreme conditions.

- By Atmosphere:

- Air Atmosphere Furnaces: Standard operation in ambient air.

- Vacuum Furnaces: Essential for oxygen-sensitive materials, thin-film deposition, and ultra-clean processing.

- Inert Gas Furnaces (e.g., Nitrogen, Argon): Prevents oxidation and contamination for reactive materials.

- Reactive Gas Furnaces (e.g., Hydrogen, Ammonia): Used for reduction, nitriding, or specific chemical reactions.

- Multi-Atmosphere Capable Furnaces: Versatile systems allowing for switching between different atmospheric conditions.

- By Application:

- Research & Development (R&D): For fundamental and applied material science, chemical synthesis, and academic studies.

- Material Processing (Sintering, Annealing, Brazing): Industrial-scale heat treatments to modify material properties.

- Chemical Vapor Deposition (CVD): For thin-film growth and coating applications.

- Crystal Growth: Production of single crystals for semiconductors and optics.

- Heat Treatment & Hardening: Improving mechanical properties of metals.

- Testing & Quality Control: Material characterization and failure analysis.

- By End-User Industry:

- Academia & Research Institutions: Universities, national labs, and private research organizations.

- Semiconductor & Electronics: Wafer processing, component manufacturing, and packaging.

- Metallurgy & Metal Processing: Heat treatment of alloys, powder metallurgy, and brazing.

- Ceramics & Glass: Sintering, firing, and advanced ceramic material production.

- Medical & Pharmaceutical: Sterilization, heat treatment of medical implants, and material synthesis.

- Aerospace & Defense: Manufacturing of high-performance components and testing.

- Automotive: Production of engine components, sensors, and advanced materials for electric vehicles.

- Energy & Environmental: Materials for solar cells, batteries, fuel cells, and catalytic converters.

Value Chain Analysis For Horizontal Tube Furnaces Market

The value chain for the horizontal tube furnaces market begins with the upstream segment, which involves the sourcing and processing of critical raw materials and components essential for furnace construction. This includes specialized high-temperature resistant materials for heating elements (such as silicon carbide, molybdenum disilicide, Kanthal alloys), advanced insulation materials (like high-purity ceramic fibers, refractory bricks, and vacuum-formed ceramic boards), high-purity quartz or ceramic tubes (e.g., alumina, mullite), and precision-engineered control systems (temperature controllers, sensors, power supplies, vacuum gauges, and gas flow controllers). Suppliers in this segment focus on material quality, purity, and performance specifications to meet the stringent demands of high-temperature, controlled-atmosphere applications. The efficiency, innovation, and cost-effectiveness of these upstream operations significantly influence the final product quality, reliability, and pricing of horizontal tube furnaces, with continuous technological advancements in material science directly impacting furnace performance and lifespan.

Further along the value chain, the manufacturing and assembly phase involves integrating these diverse components into complete furnace systems. This stage requires sophisticated engineering design, precision fabrication of the furnace body, meticulous installation of heating and insulation systems, seamless integration of vacuum and gas delivery systems, and precise calibration of advanced control electronics and software. Manufacturers in this segment leverage their expertise in thermal engineering, industrial design, and automation to produce robust, reliable, and high-performance furnaces that meet exacting specifications. They focus on manufacturing efficiency, quality assurance, and adherence to international safety and performance standards. The distribution channel then connects these manufacturers with their diverse end-users. Direct sales involve manufacturers selling directly to large industrial clients, key research institutions, or government laboratories, often providing extensive customization, installation, training, and comprehensive post-sales support tailored to specific project requirements. This direct approach fosters stronger client relationships and allows for tailored solutions.

Indirect channels involve a robust network of authorized distributors, specialized resellers, and system integrators who market and sell furnaces to a broader customer base, often adding significant value through local support, installation services, preventive maintenance contracts, and technical consultation. These intermediaries play a crucial role in market penetration, especially in regions where manufacturers do not have a direct presence. Online platforms are also emerging as a viable channel for standardized or smaller laboratory-scale furnaces, enhancing market reach and accessibility for a wider array of academic and small-scale industrial customers, often supported by detailed product specifications and virtual support. The downstream segment primarily comprises the end-users who utilize horizontal tube furnaces for their specific applications, including academic and industrial research laboratories, semiconductor fabrication plants, metallurgical processing facilities, advanced ceramics manufacturers, and companies in the aerospace, automotive, and medical sectors. These end-users typically require robust technical support, timely spare parts availability, and ongoing maintenance services to ensure continuous and efficient operation of their critical thermal processing equipment. Feedback from this downstream segment is invaluable for manufacturers to innovate and improve their product offerings, addressing specific pain points, evolving technological needs, and market demands, ensuring customer satisfaction and sustained growth within the highly specialized horizontal tube furnaces market.

Horizontal Tube Furnaces Market Potential Customers

Potential customers for horizontal tube furnaces represent a diverse array of organizations and industries that require precise, high-temperature thermal processing for material synthesis, modification, or analysis. This broad customer base is unified by the critical need for highly controlled atmospheric environments, including vacuum, inert gas, or reactive gas, and exceptionally uniform temperature profiles, which are indispensable for achieving specific material properties, developing novel compounds, or performing sensitive scientific experiments. These customers range from large-scale industrial manufacturers, such as semiconductor fabrication plants and advanced ceramics producers, to highly specialized research entities, including universities, national laboratories, and corporate R&D centers. Each customer segment often presents unique requirements regarding furnace size, maximum operating temperature, atmospheric capabilities, level of automation, and integration with other analytical or processing equipment. The continuous advancement in material science and engineering across various sectors ensures a sustained and expanding demand for these specialized thermal processing solutions, making comprehensive customer engagement, tailored product development, and understanding specific application needs paramount for market success and long-term viability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 920 million |

| Market Forecast in 2033 | USD 1.47 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Carbolite Gero, MTI Corporation, Centorr Vacuum Industries, Thermo Fisher Scientific, Lindberg/MPH, Nabertherm GmbH, Across International, Lenton Furnaces, Deltech Inc., Protherm Furnaces, Sentro Tech, XERION ADVANCED CERAMIC GmbH, Vecstar Ltd, Astro Industries, T-M Vacuum Products, Pyradia, SCHMELZMETALL Deutschland GmbH, ATV Technologie GmbH, Hi-Tech Furnaces Inc., Koyo Thermo Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Horizontal Tube Furnaces Market Key Technology Landscape

The technology landscape for horizontal tube furnaces is characterized by continuous innovation aimed at enhancing performance, precision, energy efficiency, operational safety, and user-friendliness. At the core are advanced heating element materials, such as molybdenum disilicide (MoSi2), silicon carbide (SiC), and various Kanthal alloys, which allow for increasingly higher operating temperatures, rapid ramp-up rates, and extended lifespans. These elements are meticulously chosen based on the desired temperature range, atmospheric compatibility, and specific application demands, offering robust and reliable heat generation across diverse processing needs. Complementing these are sophisticated insulation materials, including high-purity ceramic fibers, advanced refractory compositions, and multi-layer vacuum insulation, which minimize heat loss, improve temperature uniformity, and significantly reduce energy consumption, contributing to both operational efficiency and enhanced safety by maintaining cooler external surface temperatures.

Beyond heating and insulation, precise temperature and atmosphere control systems are paramount to the functionality of horizontal tube furnaces. Modern furnaces integrate advanced Proportional-Integral-Derivative (PID) controllers, often coupled with multi-zone heating capabilities, to achieve incredibly accurate and uniform temperature profiles, as well as complex temperature gradients across the entire sample length. These controllers are typically linked to high-resolution thermocouples (e.g., Type B, S, R for high temperatures) or optical pyrometers for non-contact temperature measurement in extreme conditions, ensuring real-time monitoring and adaptive adjustment. Vacuum technology plays a critical role for applications requiring an oxygen-free or ultra-clean environment, involving turbomolecular pumps, rotary vane pumps, diffusion pumps, and sophisticated vacuum gauges that can achieve pressures down to 10-6 Torr or lower. These systems are crucial for preventing contamination and enabling sensitive processes in semiconductor, crystal growth, and advanced material research.

Furthermore, the integration of advanced automation and digital connectivity is rapidly transforming the horizontal tube furnaces market. Modern control software often features intuitive graphical user interfaces (GUIs), programmable recipes for complex thermal cycles, comprehensive data logging capabilities, and remote access, allowing for sophisticated experimental sequences, detailed process analysis, and remote operation from various locations. Gas delivery systems, including highly accurate mass flow controllers (MFCs) and precise gas mixing units, ensure repeatable and controlled atmospheric conditions within the tube, essential for reactive gas processes or inert environments. Safety features, such as over-temperature protection, emergency shut-offs, atmosphere monitoring, and interlocking mechanisms, are standard, ensuring safe operation for both personnel and equipment. The advent of Industry 4.0 principles is driving the development of "smart furnaces" equipped with Internet of Things (IoT) sensors and AI/ML algorithms for predictive maintenance, real-time process optimization, and data-driven insights, representing a significant technological leap in the domain of high-precision thermal processing equipment, enhancing efficiency, safety, and scientific discovery.

Regional Highlights

- North America: This region stands as a significant hub for advanced research and development, particularly in aerospace, defense, automotive, and semiconductor industries. The presence of numerous leading universities, national laboratories, and high-tech companies drives a consistent demand for state-of-the-art horizontal tube furnaces for material science, nanotechnology, advanced manufacturing processes, and energy research. The market here is characterized by a strong demand for high-precision, customized, and automated furnace solutions, with a robust emphasis on energy efficiency, safety compliance, and robust technical support. Significant investments in material innovation, additive manufacturing, and quantum computing further fuel market growth in this mature but highly innovative region, driving demand for furnaces capable of handling complex, sensitive processes.

- Europe: Europe represents a robust and technologically advanced market, propelled by strong automotive, metallurgy, ceramics, pharmaceuticals, and academic research sectors. Countries like Germany, France, the UK, and Switzerland lead in advanced manufacturing and materials engineering, driving demand for high-temperature, vacuum, and inert gas tube furnaces. The region's stringent environmental regulations and focus on sustainable manufacturing practices encourage the adoption of energy-efficient and environmentally compliant furnace technologies, often incorporating advanced heat recovery systems. European research institutions are heavily involved in developing novel materials for renewable energy, medical implants, and advanced electronics, requiring diverse and sophisticated thermal processing equipment. Strong collaborative research initiatives and stringent quality control standards further contribute to market stability and continuous innovation.

- Asia Pacific (APAC): The APAC region is the fastest-growing and largest market for horizontal tube furnaces, primarily driven by massive industrial expansion, booming semiconductor manufacturing capabilities (especially in China, Taiwan, South Korea, and Japan), and increasing governmental and private investments in research and development. The region's vast manufacturing base for electronics, automotive components, advanced materials, and renewable energy technologies generates substantial demand for both standard and highly customized furnaces across various temperature and atmosphere capabilities. Rapid urbanization, industrialization, and growing consumer markets in emerging economies like India and Southeast Asian countries also contribute significantly to market growth. Cost-effectiveness, scalability, and local manufacturing capabilities are key considerations for purchasers and suppliers in this dynamic and fiercely competitive market, leading to a high volume of transactions and continuous innovation.

- Latin America: This region exhibits an emerging but steadily growing market for horizontal tube furnaces, supported by increasing industrialization, particularly in metallurgy, mining, automotive, and construction sectors in countries like Brazil, Mexico, and Argentina. Expanding academic research and development activities, though smaller in scale compared to developed regions, are gradually contributing to the demand for laboratory-scale and mid-range industrial furnaces. Investments in infrastructure development, raw material processing industries, and the growth of local manufacturing bases create opportunities for thermal processing equipment. Market growth is often linked to foreign direct investment in manufacturing and the expansion of local research capabilities, with a focus on cost-effective yet reliable solutions that can withstand industrial demands.

- Middle East and Africa (MEA): The MEA region is experiencing gradual growth in the horizontal tube furnaces market, driven by economic diversification efforts from oil-dependent economies into manufacturing, infrastructure, and advanced materials research. Investments in higher education, scientific research institutions, and technology parks are increasing, leading to a growing demand for laboratory and pilot-scale equipment. Countries like Saudi Arabia, UAE, and South Africa are leading these initiatives, aiming to build knowledge-based economies. While still relatively nascent in terms of large-scale industrial adoption compared to other regions, the long-term prospects are positive, influenced by government visions for industrialization, technological advancement, and the establishment of local manufacturing capabilities, particularly in petrochemicals, specialized materials, and renewable energy components.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Horizontal Tube Furnaces Market.- Carbolite Gero

- MTI Corporation

- Centorr Vacuum Industries

- Thermo Fisher Scientific

- Lindberg/MPH

- Nabertherm GmbH

- Across International

- Lenton Furnaces

- Deltech Inc.

- Protherm Furnaces

- Sentro Tech

- XERION ADVANCED CERAMIC GmbH

- Vecstar Ltd

- Astro Industries

- T-M Vacuum Products

- Pyradia

- SCHMELZMETALL Deutschland GmbH

- ATV Technologie GmbH

- Hi-Tech Furnaces Inc.

- Koyo Thermo Systems

Frequently Asked Questions

What are horizontal tube furnaces primarily used for?

Horizontal tube furnaces are predominantly used for precise thermal processing of materials in research and industrial settings, enabling applications such as annealing, sintering, brazing, chemical vapor deposition (CVD), crystal growth, and various heat treatments. They are crucial for processes requiring uniform heating and controlled atmospheric environments, including vacuum, inert, or reactive gases, to modify or synthesize materials with specific properties for advanced applications.

What key factors should be considered when selecting a horizontal tube furnace?

Key factors include the required maximum operating temperature and temperature uniformity, the type of atmosphere needed (air, vacuum, inert, reactive gas), the size of the processing zone, precise temperature ramp rates and cooling capabilities, control system sophistication (manual vs. automated, multi-zone control), energy efficiency, essential safety features, and the overall budget and total cost of ownership (TCO) including consumables and maintenance.

How is AI impacting the horizontal tube furnaces market?

AI is transforming the market by enabling predictive maintenance for reduced downtime, optimizing complex process parameters for improved efficiency and consistent material quality, facilitating autonomous control and adaptive learning capabilities, and accelerating data-driven material discovery and characterization. AI integration enhances precision, consistency, and operational intelligence, making furnaces smarter, more responsive to complex experimental demands, and more energy-efficient.

What is the projected growth outlook for the horizontal tube furnaces market?

The horizontal tube furnaces market is projected for steady growth, driven by increasing global investments in R&D, continuous expansion of the semiconductor and advanced materials industries, and the rising demand for high-performance components across various high-tech sectors. The market is expected to grow at a Compound Annual Growth Rate (CAGR) of approximately 6.8% between 2026 and 2033, reaching an estimated USD 1.47 billion by the end of the forecast period in 2033.

What are the main types of horizontal tube furnaces available?

The market offers various types tailored to specific needs: single-zone furnaces provide uniform heating across one area; multi-zone furnaces allow for precise temperature gradients and sophisticated profiling; split-tube furnaces offer ease of sample loading and unloading; and rotary tube furnaces are designed for continuous processing of powders or granular materials, often with atmosphere control. Custom furnaces are also available for highly specialized research or industrial applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager