Hospital Flax Supply Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434391 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Hospital Flax Supply Market Size

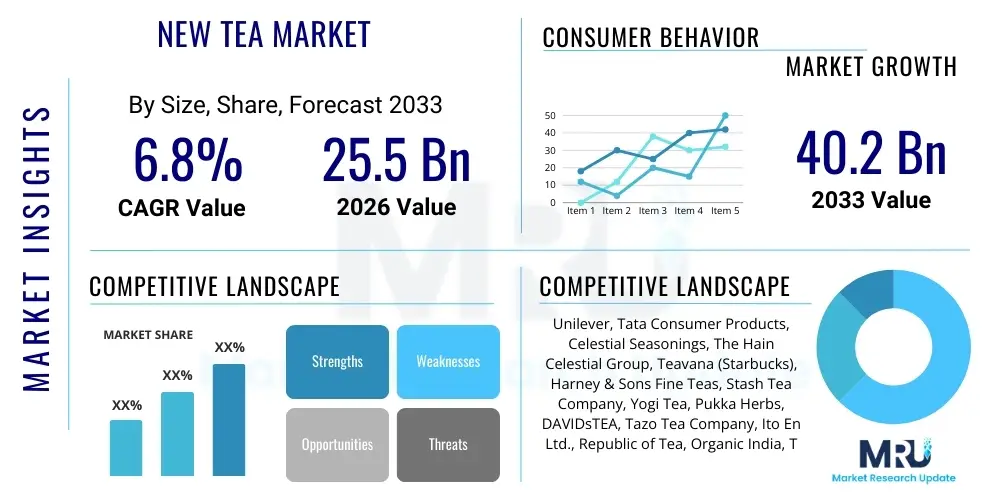

The Hospital Flax Supply Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 13.5 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by the continuous expansion of global healthcare infrastructure, particularly in emerging economies, coupled with stringent regulatory standards requiring high levels of hygiene and sanitation in patient care settings. Furthermore, the increasing prevalence of hospital-acquired infections (HAIs) has placed significant emphasis on utilizing specialized, high-quality textiles and efficient laundry systems, thereby driving consistent demand across acute care facilities.

Market expansion is also heavily influenced by evolving procurement models. Many large hospital systems are transitioning from in-house laundry operations to outsourced services, seeking cost efficiencies, guaranteed compliance, and reduced capital expenditure associated with equipment maintenance and staffing. This shift favors large, integrated textile service providers that offer full-cycle management, including inventory tracking, sterilization, and logistics. The market size calculation reflects both the direct sales of flax/linen products and the revenue generated by associated services such as rental and cleaning contracts, which constitute a significant portion of the total market value.

Hospital Flax Supply Market introduction

The Hospital Flax Supply Market encompasses the entire spectrum of textile products essential for operation within healthcare environments, including bedding, patient gowns, surgical drapes, scrubs, towels, and specialized cleaning cloths. These products, often collectively referred to as 'hospital linens' or 'flax,' are critical components of patient care, contributing directly to comfort, safety, and infection control protocols. The sector is characterized by a mix of reusable and disposable products, with material composition varying widely—from traditional cotton and linen blends to advanced polyester blends and non-woven synthetics engineered for specific performance metrics like fluid resistance, fire retardancy, and durability under rigorous washing cycles.

Major applications of hospital flax supply include inpatient care, surgical theaters, intensive care units (ICUs), and emergency departments, where frequent changes and high-volume usage are mandatory. Key benefits of effective flax management include minimizing cross-contamination risks, improving operational efficiency through streamlined inventory, and enhancing the overall patient experience. Driving factors fueling market growth involve demographic shifts, such as the aging population requiring more frequent and prolonged hospitalization, coupled with the increasing adoption of outsourced linen services across North America and Europe. Regulatory bodies like the Joint Commission and national health agencies impose strict guidelines on textile hygiene, ensuring sustained demand for compliant, professional supply chains.

Hospital Flax Supply Market Executive Summary

The Hospital Flax Supply Market is experiencing dynamic shifts, summarized by a strong trend toward centralization and outsourcing, driven by acute cost pressures and the need for enhanced infection control compliance within hospital administration. Business trends indicate accelerated merger and acquisition activities among large commercial laundry service providers, aiming to achieve economies of scale and expand geographical coverage, particularly targeting multi-hospital networks. Sustainability is emerging as a critical competitive differentiator, compelling suppliers to invest in eco-friendly processing technologies and durable, long-life reusable textiles. The integration of advanced inventory management technologies, such as RFID tagging, is revolutionizing internal logistics, reducing loss rates, and optimizing utilization rates across the supply chain.

Regionally, North America maintains market dominance due to high healthcare expenditure, sophisticated infrastructure, and stringent regulatory environments, leading to higher adoption rates of premium linen services and automated tracking systems. However, the Asia Pacific (APAC) region is projected to register the fastest growth rate, fueled by massive investments in hospital construction, expanding middle-class access to private healthcare, and increasing awareness regarding infection prevention protocols. Segment trends show a sustained preference for reusable linens in high-volume areas like general wards due to long-term cost-effectiveness, while specialized units (e.g., operating rooms) continue to see robust growth in high-performance disposable drapes and gowns, driven by the perceived zero risk of contamination.

AI Impact Analysis on Hospital Flax Supply Market

User inquiries regarding AI's influence in the Hospital Flax Supply Market predominantly focus on optimizing logistics, predicting demand fluctuations, and enhancing quality control. Common questions explore how AI can minimize linen loss (a significant operational cost), automate inventory ordering based on real-time patient flow data, and identify potential failure points in the textile life cycle, such as predicting when a linen item needs replacement due to wear and tear. Key themes emerging from this analysis underscore the expectation that AI and Machine Learning (ML) will transform linen management from a reactive operational task into a proactive, data-driven utility, ultimately improving cost management and ensuring a constant, compliant supply of textiles without overstocking or shortages.

The application of AI extends beyond simple inventory counting. It is anticipated to play a crucial role in predictive maintenance of industrial laundry equipment, maximizing throughput and reducing downtime. Furthermore, advanced image recognition algorithms could be deployed during the sorting and quality assurance processes to automatically detect stains, rips, or non-compliant materials, ensuring that only textiles meeting the highest standards return to patient wards. This sophisticated integration is crucial for maintaining clinical integrity and streamlining the highly complex logistical demands of large healthcare networks.

- AI-powered demand forecasting optimizes ordering cycles based on historical usage and predictive modeling of patient census fluctuations, reducing waste and minimizing stockouts.

- Machine Learning algorithms analyze RFID data to identify high-loss zones or trends, significantly improving loss prevention strategies for expensive specialty items.

- Computer vision systems enable automated quality inspection of textiles post-laundering, ensuring compliance with strict hygiene standards and detecting minor damage proactively.

- Predictive maintenance schedules for industrial laundry machinery are generated by AI, minimizing unexpected failures and maximizing operational efficiency.

- Route optimization software, driven by AI, enhances the efficiency of linen distribution and collection logistics within complex hospital campuses.

DRO & Impact Forces Of Hospital Flax Supply Market

The dynamics of the Hospital Flax Supply Market are governed by a complex interplay of Drivers, Restraints, and Opportunities, collectively representing the Impact Forces. Key drivers include mandatory regulatory compliance regarding hygiene and infection control (especially post-pandemic), coupled with the continuous expansion and modernization of global healthcare facilities. Opportunities arise from technological advancements, specifically in smart inventory systems (RFID, IoT), and the growing preference for outsourced, integrated linen management services that offer greater reliability and predictability than in-house operations. These factors collectively push market growth by ensuring consistent demand for high-quality, traceable textiles and associated specialized services.

However, significant restraints exist, notably the substantial upfront capital investment required for establishing high-capacity, highly automated industrial laundries, creating high barriers to entry. Fluctuations in raw material costs (cotton, polyester fibers) and rising energy and labor expenses in processing constitute structural headwinds that compress profit margins for suppliers. Moreover, the environmental impact associated with industrial water usage and chemical consumption in laundering presents an ongoing challenge, pushing firms toward sustainable, but often more costly, green cleaning technologies.

The dominant impact forces shaping the market are the regulatory pressure to mitigate Hospital-Acquired Infections (HAIs) and the constant economic pressure on healthcare providers to reduce operating costs. These forces create a paradoxical environment where providers must invest in superior, specialized products and services (driver) while simultaneously seeking the most cost-efficient operational models (restraint). Success in this market hinges on demonstrating superior clinical compliance through verifiable processes while delivering exceptional cost value through optimized logistics and material life cycles.

Segmentation Analysis

The Hospital Flax Supply Market is fundamentally segmented based on factors reflecting the product type, material composition, usability, and the end-user environment, providing granular insight into demand patterns and competitive landscapes. Product type segmentation distinguishes between high-volume, general-purpose items like bedding and specialized, high-performance items such as surgical drapes, which require different manufacturing standards and logistical handling. Usability segments (Reusable vs. Disposable) reflect strategic choices made by healthcare systems balancing environmental concerns, long-term operational costs, and immediate infection control needs.

Material composition is crucial, differentiating traditional natural fibers (cotton/flax blends) from synthetic or non-woven materials, each offering distinct advantages in terms of fluid barrier properties, durability, and cost-per-use metrics. End-user segmentation highlights the varying demands across different healthcare settings; for instance, large private hospitals typically prioritize premium, RFID-tracked reusable inventory, while smaller clinics or ambulatory surgical centers might rely more heavily on disposable kits for efficiency. Understanding these segments is vital for suppliers to tailor product offerings and service contracts effectively, ensuring compliance with specific institutional requirements and budget constraints.

- By Usability:

- Reusable Flax

- Disposable Flax

- By Product Type:

- Bedding and Linen (Sheets, Pillowcases, Blankets)

- Patient and Staff Apparel (Gowns, Scrubs, Lab Coats)

- Surgical Textiles (Drapes, Wraps, Covers)

- Wipes and Cleaning Cloths

- By Material:

- Cotton and Cotton Blends

- Polyester and Synthetic Blends

- Non-woven Materials

- Specialty Fibers (e.g., Flame Retardant, Anti-microbial)

- By End-User:

- Hospitals (Public, Private, Teaching)

- Clinics and Ambulatory Surgical Centers (ASCs)

- Nursing Homes and Long-Term Care Facilities

- Specialty Healthcare Facilities (e.g., Rehabilitation Centers)

Value Chain Analysis For Hospital Flax Supply Market

The value chain for the Hospital Flax Supply Market is highly intricate, starting with raw material sourcing and culminating in the critical, repetitive logistics cycle of distribution, usage, collection, processing (laundering/sterilization), and redistribution. Upstream analysis focuses on the procurement of raw fibers (cotton, synthetic polymers) and textile manufacturing, which involves significant quality control to ensure fabrics meet medical-grade specifications for durability and barrier properties. Key suppliers in this phase must manage volatile commodity prices and complex global supply chains, often engaging in long-term contracts with large fabric mills.

The midstream is dominated by industrial textile manufacturers and, critically, the specialized healthcare laundry and linen management service providers. These organizations handle the essential processing steps: inventory management, highly regulated washing and sterilization, repair, and packaging. Direct channel distribution involves large suppliers contracting directly with major hospital systems, often providing rental services rather than outright sales. Indirect distribution typically utilizes third-party logistic providers or smaller, local laundry services, especially for independent clinics or regional facilities, adding complexity but offering greater local reach.

Downstream analysis centers on the hospitals and end-users, where the actual consumption and critical return logistics occur. Efficiency in the downstream environment is paramount, relying heavily on sophisticated internal hospital tracking and centralized soiled linen collection points. The effectiveness of the overall supply chain is measured by the turnaround time, the loss rate, and compliance with sterile processing standards, making logistics and technology integration (RFID) a primary differentiator across the value chain.

Hospital Flax Supply Market Potential Customers

The primary customers and end-users of the Hospital Flax Supply Market are diverse healthcare institutions that necessitate constant, reliable access to clean, compliant medical textiles for patient safety and operational continuity. Large private hospital networks represent the highest-value customers, often seeking fully outsourced, integrated services covering supply, tracking, and compliance management for their vast inventories. These integrated delivery networks (IDNs) prioritize comprehensive service level agreements (SLAs) that guarantee turnaround times and minimal loss rates, leveraging their purchasing power for favorable, long-term rental contracts.

Public healthcare systems, including government-operated hospitals and veteran affairs facilities, form another crucial segment. While often procuring services through competitive bidding and focusing heavily on cost efficiency, they still require the same rigorous adherence to clinical hygiene standards. Ambulatory Surgical Centers (ASCs) and specialized clinics are rapidly growing customer segments. These facilities often prefer the convenience and guaranteed sterility of disposable surgical packs and apparel, driven by their lower volume but high demand for sterile environments without the overhead of complex in-house or reusable logistics.

Furthermore, the long-term care sector, encompassing nursing homes, rehabilitation centers, and assisted living facilities, represents a steady customer base with unique requirements centered around patient comfort and high-frequency bed changes. Suppliers targeting this segment often focus on cost-effective, durable, and comfortable linens, recognizing the different infection control profiles compared to acute care hospitals.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 13.5 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Medline Industries, Aramark Uniform Services, Angelica Corporation, ImageFIRST Healthcare Laundry Specialists, Encompass Group LLC, Standard Textile Co., Crothall Healthcare, Elis Services S.A., Synergy Health, Cintas Corporation, Unitex Healthcare Laundry Services, Vestis Healthcare, Healthcare Linen Services Group, Mission Linen Supply, TRSA members, G&K Services (A Cintas Company), Ameripride Services Inc., Ecotex Healthcare Laundry Services, Fashion Seal Healthcare, Superior Uniform Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hospital Flax Supply Market Key Technology Landscape

The technology landscape in the Hospital Flax Supply Market is rapidly evolving, driven primarily by the need for enhanced efficiency, precision in inventory management, and unwavering compliance with sterilization standards. The most transformative technology is Radio Frequency Identification (RFID). RFID tags, embedded directly into reusable linens, allow healthcare systems and service providers to track every item's location, usage cycle, and wash history in real-time. This drastically reduces loss rates, which traditionally account for a significant percentage of operational costs, and provides auditable data essential for regulatory compliance and predictive inventory management. The implementation of IoT sensors in collection bins and storage areas further enhances this visibility, creating a truly smart linen supply ecosystem.

In the processing phase, highly automated industrial laundry systems utilizing advanced water and energy recovery systems are becoming the standard. These technologies reduce the environmental footprint and operational costs associated with high-volume washing. Furthermore, barrier technology in textile manufacturing is critical; this involves utilizing advanced composite materials and specialized weaving techniques to create fabrics that provide superior protection against fluid penetration while remaining durable enough to withstand hundreds of harsh cleaning cycles. The integration of chemical metering systems and validated high-temperature sterilization processes ensures maximum pathogen reduction, meeting the stringent demands of surgical and intensive care environments.

The future technology landscape involves greater adoption of predictive analytics platforms. These platforms utilize the massive data generated by RFID and inventory systems to predict seasonal fluctuations in demand, optimize truck routing, and even forecast the remaining lifespan of individual linen items before they need retiring. This shift toward data-driven decision-making represents a move from conventional material handling to integrated logistics and utility management, offering healthcare clients superior cost control and operational reliability.

Regional Highlights

- North America: This region is the largest and most mature market, characterized by highly concentrated commercial laundry services, advanced adoption of textile tracking technologies (especially RFID), and extremely strict hygiene regulations enforced by federal and state agencies. The market is driven by high per-capita healthcare spending and a preference for outsourced services by major hospital chains, demanding premium, high-tech linen solutions. The focus here is on maximizing inventory utilization and demonstrating verifiable compliance data.

- Europe: The European market displays heterogeneity, with Western Europe (Germany, UK, France) showing high maturity and robust outsourced linen sectors, similar to North America. Growth is steadily driven by the privatization of healthcare services and increased environmental mandates pushing suppliers toward sustainability in washing processes and material choices. Eastern European markets are rapidly modernizing, offering high growth potential as older, in-house laundry operations transition to modern commercial services.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, propelled by exponential growth in healthcare infrastructure, particularly in countries like China, India, and Southeast Asia. Market expansion is driven by both government initiatives to improve public health standards and massive private investment in establishing multi-specialty hospitals. While currently price-sensitive, demand for high-quality, specialized textiles and professional management services is rising sharply due to increased awareness of HAIs.

- Latin America (LATAM): The LATAM market is characterized by medium growth, primarily concentrated in urban centers of Brazil, Mexico, and Argentina. Economic instability often restrains high capital investment, leading to a balance between reusable and disposable supplies. The market is gradually shifting toward professionalism, driven by international accreditation standards influencing local private hospitals to adopt more formal linen management protocols.

- Middle East and Africa (MEA): Growth in the Middle East is significant, especially within the GCC countries, supported by massive government investment in world-class medical cities and healthcare tourism. These facilities require the highest international standards, favoring premium imported textiles and advanced outsourced laundry management. The African continent presents varied opportunities, largely driven by development aid and improving public health infrastructure, with a higher preference for standardized, durable, and cost-effective textile solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hospital Flax Supply Market.- Medline Industries

- Aramark Uniform Services

- Angelica Corporation

- ImageFIRST Healthcare Laundry Specialists

- Encompass Group LLC

- Standard Textile Co.

- Crothall Healthcare (Compass Group)

- Elis Services S.A.

- Synergy Health (Steris plc)

- Cintas Corporation

- Unitex Healthcare Laundry Services

- Vestis Healthcare

- Healthcare Linen Services Group (HLSG)

- Mission Linen Supply

- Ecotex Healthcare Laundry Services

- Fashion Seal Healthcare (Superior Group of Companies)

- Tingue Brown & Co.

- Ameripride Services Inc.

- Clean Uniform Company

- Alsco Uniforms

Frequently Asked Questions

Analyze common user questions about the Hospital Flax Supply market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Hospital Flax Supply Market?

The primary driver is the necessity for stringent infection control protocols and compliance with mandatory regulatory standards globally, necessitating high-volume replacement and professional sterilization of medical textiles to mitigate Hospital-Acquired Infections (HAIs).

Are reusable or disposable hospital linens dominating the market, and why?

Reusable linens currently hold a larger share in general hospital use due to their long-term cost-effectiveness and increasing durability, supported by outsourced laundry services. However, disposable linens are experiencing faster growth in high-risk areas like operating rooms due to guaranteed sterility and zero risk of cross-contamination.

How is technology impacting operational efficiency in hospital linen management?

Technology, particularly the implementation of RFID tags and IoT-enabled tracking systems, is fundamentally improving operational efficiency by enabling real-time inventory visibility, drastically reducing linen loss, automating demand forecasting, and ensuring auditable regulatory compliance.

Which geographical region offers the highest growth potential for flax supply vendors?

The Asia Pacific (APAC) region, driven by extensive healthcare infrastructure investment and expanding private sector access, offers the highest projected CAGR, presenting significant opportunities for suppliers specializing in scalable, high-quality linen and associated managed services.

What are the main sustainability challenges faced by the Hospital Flax Supply industry?

The main challenges involve the high environmental impact of industrial laundering, specifically excessive water and energy consumption, and the use of harsh chemicals. The industry is responding by adopting water recycling technologies, ozone laundry systems, and promoting durable, eco-certified textile fibers.

The market faces constant pressure from regulatory bodies to maintain the highest levels of textile hygiene, driving continuous innovation in material science and laundry validation processes. Suppliers must navigate complex global raw material logistics while managing intense competitive pricing pressure from both in-house hospital operations and large, established outsourced service providers. The shift towards integrated supply chain management, where textile service companies act as clinical support partners rather than mere material vendors, is defining the modern market structure. This integration leverages data analytics to predict optimal inventory levels for specific hospital units, reducing excess inventory costs while minimizing the risk of critical shortages.

Furthermore, capital expenditure in this sector is heavily weighted toward high-efficiency industrial equipment capable of processing millions of pounds of laundry annually while meeting stringent energy efficiency and environmental standards. Market consolidation, particularly in North America and Europe, signifies a maturing industry where larger players benefit from economies of scale, often utilizing sophisticated hub-and-spoke distribution models to service extensive geographical areas. Small and medium-sized providers often differentiate themselves through highly specialized services, such as linen specifically designed for pediatric or bariatric care, or by focusing on niche geographic markets that large corporations neglect.

The COVID-19 pandemic significantly accelerated the adoption of specialized disposable protective apparel and reinforced the necessity of resilient, secure supply chains for all textiles. This heightened focus on pandemic preparedness means hospitals are now maintaining larger safety stocks and demanding suppliers have robust contingency plans, adding another layer of complexity to inventory management and procurement strategies. Investment in automation is critical across the board, from automated folding and sorting robots in the laundry facility to automated guided vehicles (AGVs) transporting clean linen within the hospital environment, aiming to reduce labor dependency and increase throughput.

The demand elasticity in the Hospital Flax Supply Market is relatively low, as linens are non-negotiable operational necessities. However, hospitals exhibit high price sensitivity regarding service contracts. This forces suppliers to continually demonstrate value through metrics like loss reduction, superior cleanliness verification, and operational reliability. Therefore, market success is less about breakthrough product innovation and more about optimization and standardization of service delivery at a mass scale, backed by robust data tracking and quality assurance protocols.

Ethical sourcing and labor practices within the textile manufacturing phase are gaining increased scrutiny from healthcare organizations committed to corporate social responsibility (CSR). Suppliers are increasingly required to provide transparency regarding their raw material origins and manufacturing partners, especially concerning cotton and fiber production, leading to greater emphasis on certifications like Oeko-Tex and the pursuit of circular economy models for textile waste management. The lifecycle assessment of reusable linens, including the environmental cost of washing versus the manufacturing cost of disposables, remains a central point of debate and strategic planning for large healthcare networks.

The Hospital Flax Supply Market is fundamentally intertwined with the broader healthcare maintenance sector. As hospitals become more specialized and focus shifts toward outpatient and minimally invasive procedures, the demand structure for flax products adapts. While inpatient bed linens might see stable growth, demand for surgical textiles and specialized patient comfort products tailored for shorter recovery stays continues to accelerate. Strategic diversification into related service areas, such as surgical instrument reprocessing or facility services, allows key players to offer integrated facility maintenance packages, enhancing client stickiness and expanding revenue streams beyond core textile supply.

The geopolitical landscape also impacts market stability, especially concerning the global sourcing of raw textile materials and finished goods from major manufacturing hubs in Asia. Trade disputes, tariffs, and logistical bottlenecks (such as global shipping container shortages) can directly affect the cost and availability of critical items, pushing major vendors to diversify their manufacturing and sourcing bases to ensure supply resilience. This global supply chain complexity necessitates sophisticated risk management capabilities for all major market participants.

Finally, standardization efforts, often spearheaded by industry groups like the Textile Rental Services Association (TRSA), aim to create universal benchmarks for cleanliness, handling, and tracking. Adherence to these standards is increasingly required in tender processes, solidifying the market's professional nature and establishing high entry barriers for smaller, non-specialized firms. This drive for standardized excellence ensures that the essential textile support services maintain clinical quality across diverse operational settings.

The integration of advanced textile science is moving the market beyond simple cotton and polyester. Innovations include fabrics that incorporate anti-microbial treatments directly into the fibers, providing a secondary layer of protection against pathogens even before laundering. Other material advancements focus on enhanced moisture-wicking and breathability for patient comfort, particularly in long-term care settings, balancing clinical performance with human factors. The materials segment is becoming increasingly complex, requiring specialized knowledge from procurement managers and suppliers alike.

Furthermore, capital expenditure in this sector is heavily weighted toward high-efficiency industrial equipment capable of processing millions of pounds of laundry annually while meeting stringent energy efficiency and environmental standards. Market consolidation, particularly in North America and Europe, signifies a maturing industry where larger players benefit from economies of scale, often utilizing sophisticated hub-and-spoke distribution models to service extensive geographical areas. Small and medium-sized providers often differentiate themselves through highly specialized services, such as linen specifically designed for pediatric or bariatric care, or by focusing on niche geographic markets that large corporations neglect. The increasing complexity of linen types, driven by clinical specifications, necessitates specialized processing equipment, which further increases the capital intensity of the industry.

The adoption rate of outsourced services continues to climb, driven by the compelling total cost of ownership (TCO) argument. Hospitals recognize that managing large-scale industrial laundry operations is non-core business and often involves substantial hidden costs related to utility consumption, specialized maintenance, labor management, and the risk of regulatory non-compliance. By outsourcing, healthcare providers effectively transfer these risks and operational burdens to specialized service companies, enabling greater focus on core patient care activities. This fundamental strategic shift is underpinning much of the revenue growth reported by major service providers.

Regulatory scrutiny around surgical textile processing is particularly intense, demanding validated sterilization cycles and rigorous tracking for every item used in the operating room. This critical requirement has boosted the segment of specialized surgical packs and drapes, both reusable (requiring certified sterile processing) and high-performance disposable options. The need for documented proof of sterilization and proper handling drives suppliers to invest heavily in tracking technology and quality management systems (QMS) that integrate seamlessly with hospital electronic records.

The pricing model in the market is transitioning from simple cost-per-pound or per-piece to complex rental contracts based on cost-per-adjusted-patient-day, reflecting the integrated nature of the service offered. These contracts include provisions for inventory management, loss coverage, and guaranteed stock levels, essentially turning the linen supply into a utility service with defined uptime and quality metrics. This sophisticated contracting requires strong analytical capabilities from service providers to manage profitability while adhering to strict service agreements.

Sustainability mandates are pushing innovation not only in processing but also in product design. Vendors are developing textile lines specifically designed for extended lifecycles, incorporating reinforced seams, tear-resistant fabrics, and dyes that withstand repeated harsh chemical exposure without degradation. This focus on durability directly combats textile waste and aligns with the corporate sustainability goals of major hospital systems, making 'green' product lines a competitive necessity rather than a mere advantage.

Finally, the market’s reliance on complex logistics highlights the fragility of internal hospital supply chains without specialized management. Shortages or delays in linen delivery directly impact patient throughput and potentially compromise patient safety. Therefore, the value proposition of key market players increasingly centers on guaranteed resilience and seamless logistical execution, utilizing geographically distributed processing hubs and sophisticated buffer stock management to mitigate localized disruptions and ensure continuous, compliant supply.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager