Hot Plate Stirrer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436914 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Hot Plate Stirrer Market Size

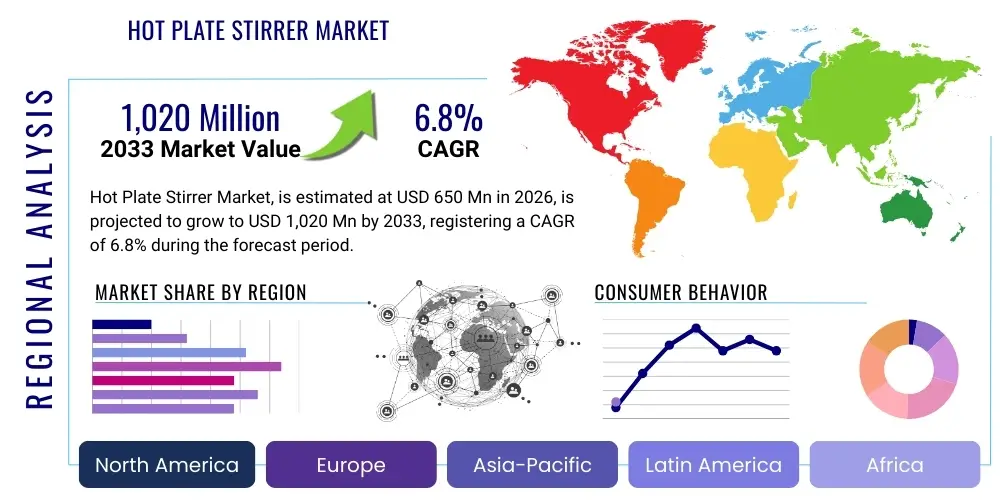

The Hot Plate Stirrer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 1,020 Million by the end of the forecast period in 2033.

Hot Plate Stirrer Market introduction

The Hot Plate Stirrer Market encompasses essential laboratory instruments designed for simultaneously heating and mixing liquid samples. These devices are fundamental components in chemical, biological, pharmaceutical, and academic laboratories globally, providing precise control over experimental parameters critical for synthesis, dissolution, and titration processes. The product essentially integrates two functions: a hot plate for controlled heating and a magnetic stirrer mechanism to induce mixing using a magnetic stir bar placed within the liquid sample. This dual functionality ensures homogeneity and consistency across various experimental setups, which is paramount for obtaining reliable and reproducible research outcomes.

Major applications of hot plate stirrers span across complex drug discovery protocols, routine quality control checks in manufacturing, and sophisticated analytical procedures. The benefits derived from these instruments, particularly the digital models, include high temperature stability, accurate speed control, minimized cross-contamination risk compared to manual mixing, and enhanced overall laboratory efficiency. The market is driven by increasing global investment in R&D activities, stringent regulatory requirements demanding precise temperature and mixing controls, and continuous technological advancements leading to the development of smart, digitally controlled, and automated hot plate stirrer models capable of integration into wider laboratory automation systems.

Hot Plate Stirrer Market Executive Summary

The global Hot Plate Stirrer market exhibits robust growth driven primarily by escalating expenditure in life sciences research, particularly in North America and Western Europe, coupled with the rapid expansion of generic and specialty pharmaceutical manufacturing in the Asia Pacific region. Key business trends indicate a strong consumer preference shift toward digital hot plate stirrers, which offer superior programmability, data logging capabilities, and advanced safety features, moving away from older analog models. Manufacturers are heavily investing in integrating IoT capabilities and developing ceramic-top models that ensure higher chemical resistance and more uniform heat distribution, addressing crucial end-user pain points regarding reliability and experimental integrity. Furthermore, sustainability and energy efficiency are emerging considerations impacting procurement decisions in developed economies.

Regionally, North America maintains its dominance due to the presence of large biotechnology and pharmaceutical companies, alongside significant governmental and private funding allocated to academic research institutions. However, the Asia Pacific region is anticipated to register the highest Compound Annual Growth Rate (CAGR), fueled by the establishment of new R&D centers, capacity expansion of Contract Research Organizations (CROs), and increasing access to laboratory equipment driven by improving economic conditions in emerging economies like China and India. Segment trends reveal that the pharmaceutical and biotechnology sector remains the largest end-user segment, while the increasing adoption of multi-position stirrers in high-throughput screening environments signifies a major technological shift aimed at maximizing laboratory output and efficiency.

AI Impact Analysis on Hot Plate Stirrer Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) primarily addresses the optimization and automation phases of laboratory experimentation involving hot plate stirrers, moving these devices beyond simple manual control. Common user questions often revolve around how AI can enhance reproducibility, predict equipment failures, automate complex reaction protocols requiring precise gradient changes, and ultimately reduce overall experimental time and material waste. Users are concerned about the ease of integration with existing Laboratory Information Management Systems (LIMS) and the potential cost implications of upgrading to AI-compatible, IoT-enabled hot plate stirrers. The consensus expectation is that AI will transform routine stirring and heating tasks into highly standardized, data-driven processes, minimizing human error and enabling sophisticated remote control and diagnostics, thereby significantly improving the efficiency and reliability of research and development workflows.

- AI integration facilitates the development of automated, closed-loop feedback systems for temperature and speed control, achieving higher precision than traditional PID controllers.

- Machine Learning algorithms analyze historical usage data (temperature spikes, stirring inconsistencies) to predict potential equipment maintenance needs, reducing downtime and extending instrument lifespan.

- AI-driven optimization tools suggest ideal stirring speeds and temperature profiles based on reaction parameters, improving reaction yield and accelerating material synthesis protocols.

- Automated data logging and compliance documentation are streamlined, as AI systems track and verify every step performed by the hot plate stirrer, ensuring regulatory adherence.

- Enhanced safety monitoring through AI detects anomalous heating patterns or unexpected viscosity changes, immediately triggering shutdown protocols to prevent thermal runaways or sample degradation.

- Integration with Robotic Process Automation (RPA) allows AI to manage multiple hot plate stirrers simultaneously within high-throughput screening environments, optimizing scheduling and workflow management.

DRO & Impact Forces Of Hot Plate Stirrer Market

The market for hot plate stirrers is substantially influenced by a confluence of driving factors, restraints, and burgeoning opportunities that dictate its trajectory. A primary driver is the accelerating pace of drug discovery and development activities across the globe, requiring precise and reproducible methods for chemical synthesis and formulation. Furthermore, regulatory bodies, particularly in the pharmaceutical and food safety sectors, impose increasingly rigorous quality control and assurance standards, necessitating the use of highly accurate and calibrated equipment like advanced digital hot plate stirrers. The shift towards automated and smart laboratory environments, where instruments communicate data seamlessly, acts as a major market impetus, pushing manufacturers toward innovation and connectivity. These drivers collectively establish a baseline demand that is resilient to economic fluctuations, especially in the health and life science domains.

However, the market faces significant restraints. The initial high capital investment required for acquiring sophisticated digital and ceramic-top hot plate stirrers, especially for smaller academic labs or labs in developing regions, can impede market adoption. Furthermore, inherent issues related to equipment calibration and maintenance complexity, particularly for multi-position units, often lead to increased operational expenditure and potential experimental variability if not managed properly. The availability of substitute technologies, such as overhead stirrers for highly viscous liquids or specialized heating mantles for large-volume heating, also slightly constrains the market growth in specific niche applications. Addressing these cost and complexity issues through modular and user-friendly designs is vital for sustained market penetration.

Opportunities for growth are plentiful, primarily stemming from technological leaps and untapped geographical markets. The rising demand for specialized instruments optimized for cell culture media preparation and bioreactor environments presents a niche high-value opportunity. Moreover, the integration of wireless data transmission (IoT) and mobile applications for remote control and monitoring creates added value, appealing to modern laboratory settings striving for maximized operational flexibility. The expansion into untapped emerging markets in Southeast Asia, Eastern Europe, and Africa, where research infrastructure is being rapidly modernized, represents a long-term strategic growth vector, contingent upon effective localization of manufacturing and distribution channels. These impact forces shape the competitive landscape and guide strategic product development for market leaders.

Segmentation Analysis

The Hot Plate Stirrer market is broadly segmented based on product type, heating technology, stirring mechanism, temperature range, and end-user applications. Understanding these segmentation dynamics is crucial for manufacturers to tailor their product offerings and marketing strategies to specific laboratory needs. The primary segmentation criterion, Product Type, distinguishes between basic analog models, which are cost-effective but offer less precision, and advanced digital models, which provide superior control, display, and data logging features. Digital models currently dominate the market value due to the stringent requirements for reproducibility in regulated industries like pharmaceuticals and clinical diagnostics. Furthermore, the market differentiates between single-position units, typically used in small-scale research, and multi-position units, which are essential for high-throughput screening and parallel synthesis applications, driving demand in Contract Research Organizations (CROs) and large industrial R&D centers.

In terms of End-User segmentation, the market is categorized into Academic and Research Institutions, Pharmaceutical and Biotechnology Companies, and Industrial Organizations (including chemical, food & beverage, and environmental testing labs). The Pharmaceutical and Biotechnology segment is the most lucrative, driven by continuous pipeline development and rigorous quality control protocols. Meanwhile, academic institutions form a substantial volume consumer base, often favoring robust, cost-effective models for educational purposes and basic research. Segmentation by Stirring Mechanism generally highlights the dominance of magnetic stirring due to its contact-less operation, which minimizes contamination, although some niche applications may still utilize alternative mechanical stirring methods for extremely high viscosity materials.

Technological segmentation often focuses on the plate material, distinguishing between ceramic and aluminum surfaces. Ceramic surfaces are favored for their excellent chemical resistance and even heat distribution, essential for sensitive biological assays and synthesis requiring high purity. Aluminum surfaces offer faster heating times and durability, often preferred in industrial or high-temperature applications where chemical spillage risk is lower. The detailed analysis of these segments helps stakeholders identify high-growth areas, such as the increasing demand for temperature-controlled stirrers suitable for cell culture environments and the integration of advanced sensors for viscosity and pH monitoring during stirring operations, expanding the market's functional utility beyond basic heating and mixing.

- By Product Type:

- Analog Hot Plate Stirrers

- Digital Hot Plate Stirrers

- Multi-Position Hot Plate Stirrers

- By Stirring Mechanism:

- Magnetic Stirring

- Overhead/Mechanical Stirring (Applied in specific high-viscosity models)

- By Plate Material:

- Ceramic Top

- Aluminum/Metal Top

- By End-User:

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutions

- Industrial Organizations (Chemicals, Food & Beverage, Environmental)

- Clinical and Diagnostic Laboratories

- By Temperature Range:

- Standard Temperature (Up to 350°C)

- High Temperature (Above 350°C)

Value Chain Analysis For Hot Plate Stirrer Market

The value chain for the Hot Plate Stirrer Market begins with the upstream activities centered around raw material procurement and component manufacturing. Key components include specialized heating elements (often ceramic or nichrome), magnetic coils or motors, high-grade control boards (microcontrollers and sensors), and durable plate materials (aluminum alloys or chemically resistant ceramics). The efficiency and reliability of the final product are heavily dependent on the quality and sourcing of these upstream materials. Suppliers of electronic components and precision sensors hold significant leverage in this segment due to the technical specifications required for precise temperature and speed regulation. Managing supply chain resilience, especially concerning microchip availability and rare-earth magnets, is a crucial strategic concern for market participants.

The subsequent phase involves manufacturing and assembly, where Original Equipment Manufacturers (OEMs) focus on instrument design, quality assurance, and adherence to international safety standards (e.g., CE, UL, TUV). This phase includes integrating sophisticated firmware for digital models, ensuring calibration accuracy, and designing ergonomic and chemically resistant housing. Following manufacturing, the distribution channel plays a pivotal role in market penetration. Distribution typically utilizes a hybrid model: direct sales channels handle major accounts (large pharmaceutical firms, government labs) to provide specialized support and customization, while indirect distribution through specialized laboratory equipment distributors and regional dealers is employed to reach a broader base of academic institutions and smaller testing laboratories.

The downstream analysis focuses on the end-users and post-sales services. End-users, including R&D scientists, QA/QC technicians, and academic researchers, rely on robust training, technical support, and accessible calibration services to ensure the longevity and accuracy of their equipment. The profitability in the downstream market is often tied to recurring revenues generated from spare parts, calibration services, and extended warranty agreements. Efficient logistics and maintenance networks are essential, particularly for multinational manufacturers serving a geographically dispersed customer base. The trend towards e-commerce platforms and digital catalogs is also impacting distribution, enabling smaller labs to procure standard models more easily, thereby streamlining the traditional distribution structure.

Hot Plate Stirrer Market Potential Customers

Potential customers for hot plate stirrers are diverse, spanning across multiple scientific and industrial verticals, all united by the need for controlled thermal and agitation processes in liquid handling. The largest and most lucrative customer base resides within the pharmaceutical and biotechnology sector. These companies, including Big Pharma, specialized biologics manufacturers, and generic drug producers, require hot plate stirrers for critical tasks such as dissolution testing, media preparation, compound screening, and synthesis of Active Pharmaceutical Ingredients (APIs). Their procurement decisions are heavily influenced by regulatory compliance (GLP/GMP standards), requiring advanced digital models with detailed logging and validation capabilities, positioning them as primary buyers of high-end equipment.

Another major segment includes academic institutions, universities, and government research laboratories (e.g., NIH, national defense labs). These customers constitute a high-volume market, driven by the continuous cycle of student training, fundamental scientific discovery, and publicly funded research projects. While often budget-conscious, their requirements span from basic analog units for educational chemistry labs to sophisticated, automated systems for advanced molecular biology research, making them key targets for both entry-level and mid-range product lines. Furthermore, the growing number of Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs) globally, particularly in Asia, represent rapidly expanding customer segments demanding multi-position and automated stirring solutions for high-throughput operational efficiency.

Industrial organizations form the third significant customer pillar, encompassing chemical processing plants, environmental monitoring agencies, and food & beverage quality control laboratories. In the chemical industry, hot plate stirrers are crucial for material testing, polymerization reactions, and catalyst evaluation. Environmental labs use them for sample preparation, extraction procedures, and chemical analysis required for compliance testing. For these industrial users, robustness, high-temperature capability, and resistance to harsh chemicals are prioritized. The increasing complexity of environmental regulations globally further solidifies the demand for reliable laboratory equipment in this sector.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 1,020 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Corning Incorporated, Thermo Fisher Scientific Inc., IKA Works GmbH & Co. KG, VWR International, LLC (Avantor), Heidolph Instruments GmbH & Co. KG, Benchmark Scientific Inc., Sartorius AG, Lab Companion (Jeio Tech), Cole-Parmer, Scilogex LLC, Accuris Instruments, Troemner LLC, Talboys (Troemner), Torrey Pines Scientific, Grant Instruments, Glas-Col, Wiseclean, Wiggens, Globe Scientific Inc., Yamato Scientific Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hot Plate Stirrer Market Key Technology Landscape

The technology landscape of the Hot Plate Stirrer Market is undergoing significant evolution, shifting from basic analog resistance heating towards sophisticated digital control and integrated sensor technology. A primary technological focus is on precision temperature management. Modern stirrers utilize advanced proportional-integral-derivative (PID) control loops combined with highly accurate Platinum resistance thermometers (Pt1000 sensors) to monitor and adjust plate and fluid temperatures instantly, significantly minimizing temperature overshoots and ensuring maximum reproducibility, which is vital for compliance-heavy applications. This transition necessitates advanced microcontrollers capable of processing complex algorithms and managing graphical user interfaces (GUIs), enhancing user experience and data visualization.

Another dominant trend is the integration of wireless connectivity and IoT capabilities. Newer models are equipped with Wi-Fi or Bluetooth modules, allowing researchers to monitor and control parameters remotely via mobile applications or centralized laboratory management systems (LIMS). This integration supports laboratory automation initiatives and facilitates centralized data collection, audit trails, and compliance reporting. Furthermore, safety technology has become a non-negotiable feature. Advanced magnetic stirrers now incorporate features like internal temperature monitoring of the device components, hot surface warning indicators (even when the unit is powered off), and residual heat protection, often governed by advanced electronic safety circuits that meet strict global safety certifications.

Material science also plays a crucial role in technological development. The shift toward specialized ceramic top plates, particularly glass-ceramic composites, is accelerating. These materials offer superior chemical resistance to acids, bases, and solvents compared to traditional aluminum, alongside improved thermal performance, ensuring highly uniform heat distribution across the stirring surface, which is critical for consistent sample processing. Manufacturers are also developing maintenance-free brushless DC motors for the stirring mechanism, enhancing reliability, reducing noise, and extending the operational life of the equipment, particularly in high-demand, continuous-use environments common in industrial quality control laboratories.

Regional Highlights

- North America: This region is characterized by high adoption rates of advanced digital and multi-position hot plate stirrers, primarily due to immense funding poured into the biotechnology, pharmaceutical, and academic sectors. The presence of global pharmaceutical giants and leading research universities drives demand for state-of-the-art, validated, and automated equipment that integrates seamlessly into complex R&D ecosystems. Strict regulatory requirements enforced by agencies like the FDA further necessitate the use of highly precise equipment with robust data logging capabilities. The US market dominates the region, showcasing a strong propensity for premium, technologically advanced instruments, making it a key focus area for market leaders specializing in automation and IoT integration.

- Europe: Western European countries, particularly Germany, the UK, and France, represent a mature and highly quality-conscious market. Growth is sustained by strong governmental support for scientific research and a well-established chemical and pharmaceutical industry base. European demand is often centered around highly ergonomic and energy-efficient instruments that adhere to stringent safety and environmental standards (e.g., RoHS, REACH compliance). While growth rates might be marginally lower than APAC, the market value remains substantial, driven by replacement cycles of aging equipment and the continuous demand for specialized stirring solutions in highly regulated clinical and diagnostic labs. Eastern Europe is emerging as a growth pocket due to infrastructural modernization and increased EU funding for regional scientific development.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by explosive growth in pharmaceutical manufacturing (especially generics), expansion of domestic biotech startups in countries like China, India, and South Korea, and massive governmental investments in building world-class research infrastructure. While price sensitivity remains a factor, the rapid expansion of CROs and CMOs necessitates the procurement of high-throughput multi-position stirrers. Japan holds a mature segment focused on high quality and precision, while the rapidly industrializing nations of Southeast Asia are becoming major consumers of both analog and mid-range digital models. Local manufacturing capabilities are also increasing, leading to more competitive pricing and localized product offerings.

- Latin America (LATAM): The LATAM market, though smaller, presents significant potential. Market growth is closely tied to economic stability and healthcare reform policies in countries like Brazil, Mexico, and Argentina. Academic institutions and local pharmaceutical manufacturers are the main consumers. Challenges include currency volatility and reliance on imports, which can influence pricing. However, increasing regional focus on clinical trials and biomedical research is steadily driving the demand for reliable, fundamental laboratory equipment, favoring robust mid-range digital models that balance precision with cost-effectiveness.

- Middle East and Africa (MEA): MEA is an emerging market characterized by increasing healthcare investments, particularly in the Gulf Cooperation Council (GCC) countries. The establishment of major research cities and dedicated healthcare zones (e.g., Dubai Healthcare City) is creating localized hubs for high-end laboratory equipment demand. In Africa, growth is fragmented but shows promise in countries focusing on localized drug production and public health research, often supported by international aid. The primary market drivers here are infrastructure development projects and government initiatives aimed at reducing dependency on imported pharmaceuticals and clinical diagnostics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hot Plate Stirrer Market.- Corning Incorporated

- Thermo Fisher Scientific Inc.

- IKA Works GmbH & Co. KG

- VWR International, LLC (Avantor)

- Heidolph Instruments GmbH & Co. KG

- Benchmark Scientific Inc.

- Sartorius AG

- Lab Companion (Jeio Tech)

- Cole-Parmer

- Scilogex LLC

- Accuris Instruments

- Troemner LLC

- Talboys (Troemner)

- Torrey Pines Scientific

- Grant Instruments

- Glas-Col

- Wiseclean

- Wiggens

- Globe Scientific Inc.

- Yamato Scientific Co., Ltd.

- VELP Scientifica

- OHAUS Corporation

- MRC Laboratory Equipment

Frequently Asked Questions

Analyze common user questions about the Hot Plate Stirrer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between analog and digital hot plate stirrers?

Analog hot plate stirrers use simple knobs and potentiometers for setting temperature and speed, offering adequate control for basic applications but lacking precise temperature feedback. Digital models, conversely, utilize microprocessors and digital displays, providing superior temperature stability, exact numerical settings, programmable operation, and crucial data logging capabilities necessary for regulatory compliance and high-precision research.

Which type of plate material, ceramic or aluminum, is generally recommended?

Ceramic tops are generally recommended for applications involving corrosive chemicals or biological samples requiring high purity, as they offer excellent chemical resistance and even heating distribution. Aluminum tops are preferred for high-temperature industrial heating applications requiring rapid heat transfer and superior durability against physical shock, though they may react with certain strong chemicals.

How is IoT and connectivity influencing the procurement of hot plate stirrers?

IoT integration allows hot plate stirrers to connect wirelessly to LIMS and central networks, enabling remote monitoring, real-time data collection, automated report generation, and predictive maintenance alerts. This capability is becoming a key differentiator, particularly in large pharmaceutical and high-throughput research laboratories focused on maximizing automation and ensuring audit-ready data integrity.

What key factors are driving the growth of the Hot Plate Stirrer market in the Asia Pacific region?

The APAC market growth is fueled by massive government investment in expanding academic and scientific research infrastructure, rapid capacity expansion of Contract Research Organizations (CROs), and the increasing establishment of generic drug manufacturing hubs, all requiring precise, reliable laboratory instruments for synthesis and quality control procedures.

What are the typical end-user applications that require multi-position hot plate stirrers?

Multi-position hot plate stirrers are essential in environments requiring parallel processing and high-throughput methodologies. Typical applications include drug screening, combinatorial chemistry, parallel synthesis of various compounds under identical conditions, and large-scale quality control testing where multiple samples must be processed simultaneously for efficiency and consistency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager