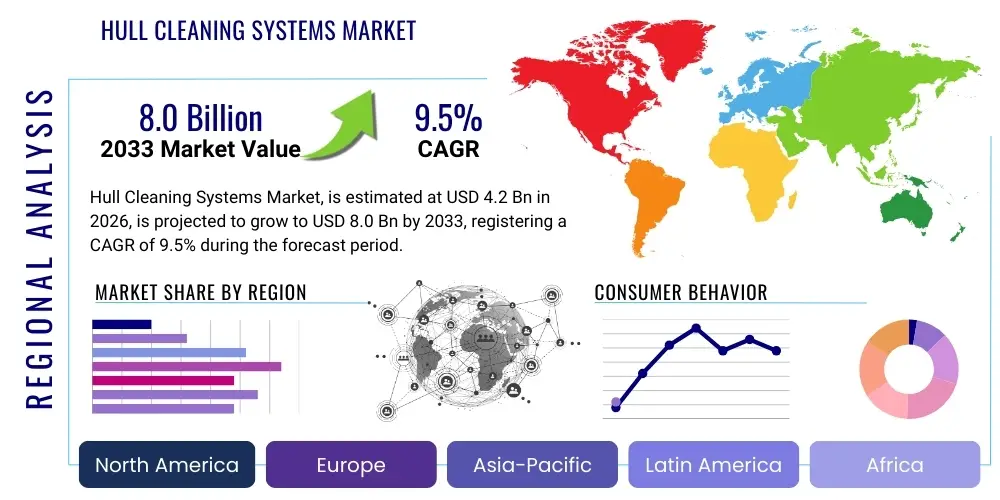

Hull Cleaning Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437119 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Hull Cleaning Systems Market Size

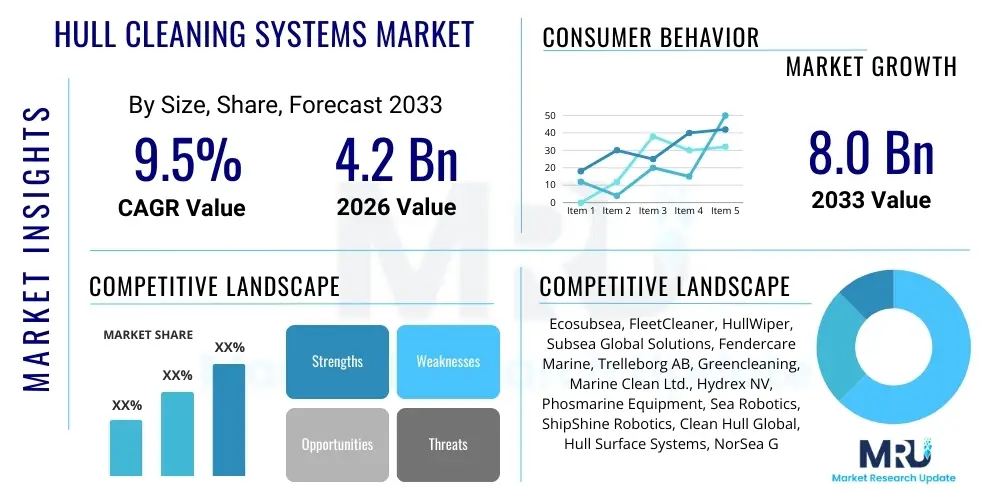

The Hull Cleaning Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at $4.2 Billion in 2026 and is projected to reach $8.0 Billion by the end of the forecast period in 2033.

Hull Cleaning Systems Market introduction

The Hull Cleaning Systems Market encompasses specialized technologies, equipment, and services designed to remove biofouling—including micro-organisms, plants, algae, and mollusks—from the submerged surfaces of ships and marine structures. Effective hull cleaning is paramount for maintaining optimal vessel hydrodynamics, significantly reducing drag, thereby decreasing fuel consumption and minimizing greenhouse gas emissions. The primary offerings in this market range from conventional manual diving operations to highly sophisticated, remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) equipped with advanced scrubbing, brushing, or cavitation jetting tools. These systems are predominantly utilized by commercial shipping lines, naval fleets, oil and gas offshore operators, and port authorities.

The driving factors for market expansion are intrinsically linked to stringent global environmental regulations, particularly those set forth by the International Maritime Organization (IMO), focusing on energy efficiency (EEDI/EEXI) and carbon reduction targets. Furthermore, the rising costs of bunker fuel necessitate ship operators to prioritize hull maintenance to achieve immediate operational cost savings. Technological advancements, suchor as the integration of sensor technology, artificial intelligence for autonomous navigation and detection of fouling density, and the development of environmentally safe cleaning mechanisms that capture debris, are bolstering market adoption. The application spectrum is broad, covering container ships, bulk carriers, tankers, cruise ships, and various specialized vessels, all of which require regular, efficient, and environmentally sound hull maintenance to ensure compliance and profitability.

Key benefits derived from utilizing professional hull cleaning systems include substantial reductions in fuel expenditure, prolonged lifespan of anti-fouling coatings, prevention of invasive species transfer across marine ecosystems (a critical biosecurity concern), and overall optimization of vessel scheduling through minimized downtime. As the global fleet grows and environmental pressures intensify, the demand for precise, verifiable, and eco-friendly hull cleaning solutions is accelerating, shifting the industry standard from reactive maintenance to proactive, predictive hull management based on real-time biofouling assessment.

Hull Cleaning Systems Market Executive Summary

The Hull Cleaning Systems market is experiencing a significant pivot towards automated and environmentally responsible solutions, driven by major global business trends favoring sustainability and operational efficiency. Current business trends show increasing capital investment in robotic cleaning systems (ROVs/AUVs) that minimize human intervention, enhance cleaning quality, and allow for cleaning operations in challenging weather conditions or sensitive port environments where manual cleaning is restricted. Regulatory stringency regarding biofouling management and the transfer of non-indigenous aquatic species (NIAS) across geopolitical zones is the primary macroeconomic driver compelling early adoption of innovative systems. Furthermore, the market is characterized by strategic collaborations between cleaning service providers, anti-fouling coating manufacturers, and sensor technology companies to offer integrated hull management solutions, moving beyond standalone cleaning services toward predictive maintenance contracts.

Regionally, the market is highly dynamic. The Asia Pacific (APAC) region, dominated by major shipping hubs such as China, Singapore, and South Korea, is projected to maintain the highest growth rate due to massive shipbuilding activities, high shipping traffic density, and increasing investment in port infrastructure automation. North America and Europe, however, lead in technological deployment and regulatory sophistication, particularly concerning the containment and disposal of removed biofouling debris, favoring advanced closed-loop cleaning systems. Latin America and the Middle East and Africa (MEA) are emerging markets, primarily driven by expanding offshore oil and gas operations and the need to maintain specialized vessel fleets, albeit often relying on more conventional cleaning methods while infrastructure for sophisticated robotic systems develops.

Segment trends reveal a dominant share held by the services segment, encompassing the actual operation and deployment of cleaning tools, indicating the market's structure is service-oriented rather than pure hardware sales. However, the hardware segment, specifically robotic and automated systems, is witnessing the fastest growth due to superior efficiency and data integration capabilities. Segmentation by mechanism shows a strong preference for brush/scrubber-based systems due to their proven effectiveness, but cavitation jetting technology is gaining traction for very light or "slime" fouling removal due to its gentleness on high-performance coatings. Overall, the market trajectory indicates a future where real-time data on fouling accumulation dictates autonomous cleaning schedules, optimizing the balance between operational cost, environmental impact, and regulatory compliance.

AI Impact Analysis on Hull Cleaning Systems Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize hull cleaning, focusing on questions related to autonomy, efficiency, coating preservation, and environmental compliance monitoring. The common themes center on the feasibility of fully autonomous cleaning missions, the ability of AI to differentiate between various fouling types (e.g., slime vs. barnacles) for optimized cleaning pressure, and the integration of predictive analytics to determine the optimal cleaning window based on vessel route, speed, and environmental conditions. Users are particularly concerned about AI's role in ensuring minimal damage to expensive anti-fouling coatings while maximizing fuel savings, thereby linking AI implementation directly to vessel profitability and longevity. Furthermore, the potential for AI-driven systems to provide verifiable compliance data regarding debris capture and environmental safety is a major area of expectation, addressing regulatory scrutiny and enhancing transparency.

- AI enables real-time sensor data fusion (acoustic, optical, pressure) to map fouling density and species distribution across the hull surface.

- Predictive maintenance schedules are generated using machine learning models that analyze historical route data, water temperature, salinity, and coating effectiveness degradation rates.

- Autonomous underwater vehicle (AUV) navigation and path planning are optimized by AI to ensure complete hull coverage with minimal human oversight, reducing cleaning time.

- AI algorithms control cleaning mechanism pressure and speed dynamically, preventing damage to specialized anti-fouling and foul-release coatings while ensuring effective biofouling removal.

- Enhanced environmental compliance reporting is achieved through AI processing of captured debris volume, type categorization, and automated audit trails for regulatory bodies.

- Computer vision and deep learning techniques allow for automated inspection and early detection of coating failures or localized heavy fouling patches requiring specific treatment.

DRO & Impact Forces Of Hull Cleaning Systems Market

The Hull Cleaning Systems Market dynamics are principally shaped by the interplay of stringent regulatory demands, technological advancements in robotics and sensing, and the overriding economic need for fuel efficiency in global shipping operations. Key drivers include mandatory global environmental compliance related to EEDI (Energy Efficiency Design Index) and IMO's carbon intensity reduction goals, which directly link hull condition to operational viability. Restraints primarily involve the high initial capital expenditure associated with sophisticated robotic systems, concerns about potential damage to advanced anti-fouling coatings (especially during aggressive cleaning), and regulatory fragmentation across various ports regarding permissible cleaning methods and disposal requirements. Opportunities lie in developing integrated hull performance monitoring systems (IHPMS) that combine AI analytics, cleaning robotics, and coating health assessment into a unified, subscription-based service model. The overall impact forces heavily favor market growth, compelling stakeholders to invest in automation and sustainable technologies to mitigate operational risk and achieve long-term economic benefits.

Detailed Analysis of Drivers

The most compelling driver for the expansion of the hull cleaning market is the escalating cost of marine bunker fuel, which constitutes a major portion of a vessel's operating expenses. Biofouling, even in minimal amounts (such as micro-fouling or slime), can increase frictional resistance significantly, resulting in a substantial penalty on fuel consumption. Ship operators are therefore driven by immediate economic necessities to adopt proactive hull cleaning regimes. Studies consistently show that maintaining a smooth hull surface can yield fuel savings ranging from 4% to 20%, depending on the vessel type and fouling severity, making professional hull cleaning a rapid return-on-investment activity rather than merely a compliance cost.

Furthermore, global environmental stewardship mandates, particularly the IMO’s requirement for ships to manage biofouling effectively to prevent the transfer of Invasive Aquatic Species (IAS), are crucial. Regulatory frameworks are increasingly pushing for verified, environmentally sound cleaning practices that prevent debris dispersal into the marine environment. This has accelerated the development and adoption of high-precision, closed-loop hull cleaning systems that capture and filter the debris, thereby meeting the highest standards of biosecurity and environmental protection, particularly in sensitive coastal waters and marine protected areas.

The third significant driver is the growing size and complexity of the global commercial fleet. Modern mega-container ships and specialized LNG carriers, with their vast hull surface areas, necessitate scalable and efficient cleaning solutions that manual methods cannot deliver. This industrial scale requirement directly fuels demand for autonomous and semi-autonomous robotic systems capable of cleaning large surface areas quickly and effectively during short port stays, minimizing costly vessel downtime and integrating seamlessly with tight logistical schedules.

Detailed Analysis of Restraints

One major constraint facing market growth is the high initial investment required for sophisticated, robotic hull cleaning systems. These AUVs and ROVs involve complex sensor packages, specialized hydraulics, and advanced data processing capabilities, placing them out of reach for smaller fleet operators or localized service providers without substantial capital backing. The perceived risk associated with adopting unproven or nascent technologies, coupled with the difficulty of securing financing for these high-value assets, slows down the broad market penetration of state-of-the-art cleaning solutions.

Another critical restraint is the potential for hull cleaning activities, if improperly executed, to damage expensive and technologically advanced anti-fouling coatings. Modern foul-release coatings (silicone-based) and sophisticated ablative paints require careful treatment. Aggressive cleaning methods or use of unsuitable brushes can strip away the active layers or create surface roughness, paradoxically accelerating future fouling and necessitating premature re-coating, which is an extremely costly procedure. This risk profile often leads operators to delay cleaning or choose less effective but safer low-frequency cleaning methods, thereby limiting the market potential for high-intensity cleaning services.

Finally, the lack of standardized global regulations regarding in-water hull cleaning (IWHC) poses a significant challenge. Different ports and national authorities have varying restrictions on when, where, and how cleaning can be performed, particularly regarding debris capture and discharge limitations. This regulatory patchwork creates operational uncertainty for service providers and limits the ability of international fleets to implement a uniform, global hull cleaning strategy. Navigating these disparate regulations requires specialized certification and localized compliance adherence, complicating international service delivery.

Detailed Analysis of Opportunities

The primary market opportunity lies in the burgeoning integration of IoT, AI, and Big Data analytics to create comprehensive Hull Performance Monitoring (HPM) systems. These systems move beyond reactive cleaning by providing predictive recommendations, leveraging real-time operational data (speed, trim, weather) and environmental conditions to calculate the exact optimal moment for cleaning intervention. This shift from time-based or visible-fouling-based cleaning to performance-optimized cleaning represents a massive value proposition for ship owners, enabling maximum fuel efficiency gains and minimizing unnecessary service costs.

A second major opportunity exists in the development of specialized, non-aggressive cleaning chemistries and mechanisms specifically tailored for new-generation, ultra-smooth foul-release coatings. As the industry transitions away from biocidal coatings, there is an unmet demand for cleaning solutions that can remove microbial slime effectively using technologies like soft ultrasound, low-pressure water jets, or specialized magnetic brushes that guarantee zero coating abrasion. Developing proprietary technologies that are certified by leading coating manufacturers will unlock significant market share in the premium segment.

Finally, the expansion into specialized niche markets, such as cleaning for offshore floating structures (FPSOs, drilling rigs) and large naval vessels, presents substantial, untapped revenue streams. These structures have unique requirements due to their extended deployment periods and specialized coating needs. Offering long-term, fixed-price contracts based on autonomous, persistent monitoring and cleaning of these high-value, stationary assets provides an attractive, recurring revenue model for advanced system providers.

Segmentation Analysis

The Hull Cleaning Systems Market is meticulously segmented based on the technology utilized (systems vs. services), the type of cleaning mechanism deployed, the application scope (vessel type), and the operating location (in-port vs. in-transit). The dominance of the Service segment reflects the specialized skills required for operating and maintaining advanced cleaning hardware, often preferred by fleet owners over direct equipment ownership. Technological segmentation highlights the shift from manual and semi-automatic systems toward highly efficient, robotic, and autonomous platforms, driven by the need for verifiable cleaning results and minimal environmental impact. Analyzing these segments provides strategic insights into investment priorities, regional adoption rates, and technological innovation pathways necessary for addressing specific maritime industry needs.

- By Operation Type:

- In-Port/In-Harbor Cleaning

- In-Transit/Stationary Offshore Cleaning

- By System Type:

- Robotic/Automated Systems (ROVs, AUVs)

- Semi-Automatic Systems (Portable Machines)

- Manual/Diver-Assisted Cleaning

- By Mechanism:

- Brush/Scrubber Systems

- Water Jet/Cavitation Systems

- Combined Systems (Brush and Water Jet)

- By Application (Vessel Type):

- Commercial Vessels (Container Ships, Tankers, Bulk Carriers)

- Naval Vessels

- Offshore Support Vessels (OSVs, FPSOs, Rigs)

- Cruise Ships and Ferries

- By Component:

- Hardware (Robots, Control Units, Hoses)

- Services (Operation, Maintenance, Inspection, Reporting)

Value Chain Analysis For Hull Cleaning Systems Market

The value chain for Hull Cleaning Systems begins with specialized upstream suppliers who provide core enabling technologies, including high-grade composite materials, propulsion components (thrusters), sophisticated sensor arrays (acoustic and optical), and control software developers specializing in robotic path planning and remote piloting systems. This upstream segment is characterized by high technical expertise and a need for stringent quality control to ensure operational reliability in harsh marine environments. The key activities at this stage focus on R&D for miniaturization, power efficiency, and increasing the operational depth and duration of cleaning robots. Collaboration with marine robotics specialists is essential here, driving innovation in magnetic adherence technology and debris collection mechanisms, ensuring the core hardware is robust and effective.

Midstream activities involve the integration and assembly of these components into deployable cleaning systems, followed by the crucial service delivery phase. Service providers acquire the robotic units and establish operational bases in major global port hubs. The distribution channel is predominantly direct, where service providers engage directly with ship management companies, port authorities, and fleet owners through long-term service contracts. These providers are responsible for training specialized remote pilots and divers, ensuring regulatory compliance across different jurisdictions, and maintaining a robust logistics chain for rapid deployment. The efficiency and reliability of the service provider, measured by minimum vessel downtime and verifiable cleaning standards, form the core competitive advantage in this segment.

The downstream component involves the end-users—the commercial shipping lines, naval forces, and offshore operators—who are the ultimate beneficiaries. Indirect distribution is minimal but includes partnerships with coating manufacturers, classification societies (like DNV and Lloyd’s Register), and marine consultancies who recommend specific cleaning systems or certified service providers as part of an integrated vessel performance package. The ultimate value proposition delivered downstream is enhanced vessel profitability through measurable fuel savings and adherence to global biosecurity protocols, transforming hull cleaning from a necessary cost into a critical operational efficiency tool.

Hull Cleaning Systems Market Potential Customers

The primary cohort of potential customers for hull cleaning systems consists of large-scale commercial fleet operators responsible for managing extensive fleets of container ships, bulk carriers, and oil or gas tankers that frequently traverse multiple climatic zones. These entities are highly sensitive to fuel prices and regulatory compliance, making reliable and efficient hull cleaning an operational imperative. Their purchasing decisions are driven by the system's ability to demonstrate verifiable ROI through guaranteed fuel savings, the non-abrasive nature of the cleaning technology (to protect high-value coatings), and the capacity of the service provider to offer global coverage and rapid deployment capabilities during short port calls.

A secondary, high-value customer group includes the owners and operators of specialized marine vessels, such as Floating Production Storage and Offloading (FPSO) units, Mobile Offshore Drilling Units (MODUs), and deep-sea research vessels. These assets often remain stationary for extended periods, leading to severe localized fouling requiring specialized, heavy-duty cleaning systems designed for deep-water deployment and prolonged underwater operation. For these customers, the emphasis is less on speed during port calls and more on structural integrity assessment during cleaning and the system's ability to operate autonomously without interrupting production schedules.

Government entities, including national navies and coast guards, also represent significant potential customers. Naval fleets require specialized cleaning services tailored to high-performance hull forms and strict security protocols, often favoring systems that can minimize detection risk during operations and provide meticulous inspection reports on hull integrity. Furthermore, major port authorities globally are emerging as customers, investing in shared cleaning infrastructure and mandatory inspection/cleaning services for visiting vessels, primarily driven by localized environmental regulations aimed at preventing the introduction of non-native species into harbor ecosystems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $4.2 Billion |

| Market Forecast in 2033 | $8.0 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ecosubsea, FleetCleaner, HullWiper, Subsea Global Solutions, Fendercare Marine, Trelleborg AB, Greencleaning, Marine Clean Ltd., Hydrex NV, Phosmarine Equipment, Sea Robotics, ShipShine Robotics, Clean Hull Global, Hull Surface Systems, NorSea Group, Submaris, AkzoNobel (Cleaning Services/Systems), Hempel A/S (Integrated Solutions), Jotun (Cleaning Compatibility), Underwater Services Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hull Cleaning Systems Market Key Technology Landscape

The technology landscape of the Hull Cleaning Systems Market is undergoing rapid transformation, characterized by the shift from hydraulic and pneumatic tools to advanced mechatronics and software-driven systems. Central to this evolution is the increasing sophistication of Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs). Modern robotic cleaners feature powerful magnetic adherence systems capable of traversing complex hull geometries, integrating multi-axis motion control for precise cleaning. A key technological advancement involves the development of specialized cleaning tools, such as interchangeable brush heads made of composite polymers or non-metallic fibers, designed to clean different types of coatings and fouling without causing micro-abrasion. Furthermore, the incorporation of high-definition cameras, 3D sonar, and acoustic sensors allows operators to monitor the cleaning process in real-time, verifying the degree of fouling removal and ensuring the integrity of the coating remains intact post-cleaning.

Another dominant trend is the focus on environmentally responsible technologies, specifically closed-loop cleaning systems. These state-of-the-art systems utilize advanced filtration units installed onboard the support vessel or pier side to capture 100% of the biofouling debris and removed coating particles. This debris capture and disposal process adheres to strict international environmental standards, which often prohibit the release of biological material into local waters, particularly in sensitive port areas. The filtration technology typically involves multi-stage separation, including hydrocyclones, micro-filtration membranes, and UV sterilization, ensuring that only clean water is returned to the sea. The commercial viability of these systems hinges on their processing throughput capacity and the ease of managing the captured solid waste, making the filtration technology a core differentiator in competitive markets.

Finally, the convergence of digital technologies is enhancing the overall service delivery model. Hull cleaning systems are increasingly linked to the Internet of Things (IoT), transmitting operational data, performance metrics, and high-resolution inspection images directly to cloud-based platforms. These platforms utilize AI and machine learning for predictive fouling rate modeling, optimizing the timing and duration of the next cleaning cycle based on predictive algorithms that consider the vessel’s operational profile and environmental data. This proactive, data-driven approach, coupled with advanced propulsion and energy storage solutions (lithium-ion batteries) for AUVs, is extending the operating range and autonomy of the cleaning devices, paving the way for fully autonomous, scheduled hull management operations worldwide.

Regional Highlights

The regional dynamics of the Hull Cleaning Systems Market are strongly influenced by the volume of maritime traffic, the proximity to major shipbuilding and repair centers, and the specific mandates imposed by regional regulatory bodies concerning environmental protection and biosecurity. Each major region demonstrates a unique maturity level in adopting automated cleaning technologies and enforcing debris containment rules, creating distinct market opportunities and challenges for service providers.

North America and Europe represent mature markets characterized by stringent environmental regulations and a high adoption rate of premium, closed-loop robotic systems. European ports, particularly those in the Nordic countries and the Mediterranean, have been proactive in mandating IWHC standards that require debris capture, favoring technologically advanced providers. North America, especially the US West Coast, focuses heavily on biosecurity concerns related to invasive species transfer (NIS), driving demand for verifiable cleaning reports and high-efficacy systems. The market here is driven less by cost savings and more by regulatory risk mitigation and the integration of cleaning services with port logistical operations.

Asia Pacific (APAC) is the largest and fastest-growing region, fueled by massive commercial fleet ownership, high vessel throughput in mega-ports (e.g., Shanghai, Singapore, Busan), and rapid industrialization across coastal economies. While the adoption of manual and semi-automatic systems remains high due to lower labor costs, the region is rapidly transitioning to automated systems to handle the sheer volume of ships and address developing local environmental restrictions, particularly in major shipping lanes. The opportunity in APAC centers on providing scalable, high-throughput robotic services capable of matching the rapid turnaround times required by regional logistics chains.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging markets primarily focused on servicing specialized fleets linked to offshore oil and gas production, along with growing trade routes. The MEA region, particularly the UAE and Saudi Arabia, is investing in modern port facilities and localized services to support tanker traffic and naval operations, showing increasing interest in automated solutions to improve operational security and efficiency in high-temperature environments. LATAM growth is tied to commodity exports and expanding naval presence, where service providers are competing on robust, simple-to-maintain equipment and localized support networks.

- Asia Pacific (APAC): Highest volume market driven by China, South Korea, and Singapore; strong demand for scalable robotic systems to manage container ship and bulk carrier fleets; increasing regulatory focus on environmental compliance is accelerating adoption of closed-loop technology.

- Europe: Highly regulated market favoring premium, certified, closed-loop cleaning services; emphasis on protecting advanced foul-release coatings and minimizing environmental discharge; leads in R&D for next-generation, non-abrasive cleaning tools.

- North America: Market dominated by strict biosecurity regulations aimed at preventing Non-Indigenous Species (NIS) transfer; strong demand from specialized markets like naval and cruise fleets; technology adoption driven by third-party certification and verifiable data reporting.

- Middle East & Africa (MEA): Growth driven by offshore oil and gas industry requirements and strategic port development along key trade routes; demand for specialized systems capable of operating in high-salinity and high-temperature waters; focus on robust equipment with minimal maintenance needs.

- Latin America (LATAM): Developing market with increasing investments in commercial shipping infrastructure; characterized by a mix of manual, semi-automatic, and nascent robotic services; market growth linked to commodity export volume and fleet modernization initiatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hull Cleaning Systems Market.- Ecosubsea

- FleetCleaner

- HullWiper (GAC Group)

- Subsea Global Solutions

- Fendercare Marine

- Trelleborg AB (Selected Marine Solutions)

- Greencleaning

- Marine Clean Ltd.

- Hydrex NV

- Phosmarine Equipment

- Sea Robotics

- ShipShine Robotics

- Clean Hull Global

- Hull Surface Systems

- NorSea Group

- Submaris

- AkzoNobel (Services Division)

- Hempel A/S (Integrated Solutions)

- Jotun (Cleaning Compatibility Services)

- Underwater Services Inc.

Frequently Asked Questions

Analyze common user questions about the Hull Cleaning Systems market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary economic benefits of utilizing robotic hull cleaning systems?

The primary economic benefit is substantial fuel savings, ranging from 4% to 20%, achieved by maintaining an ultra-smooth hull surface and reducing hydrodynamic drag. Automated systems also minimize vessel downtime compared to manual methods, maximizing operational time and profitability.

How do current IMO regulations influence the demand for advanced hull cleaning systems?

IMO regulations, particularly those related to the Energy Efficiency Existing Ship Index (EEXI) and Carbon Intensity Indicator (CII), incentivize ship operators to minimize biofouling. Additionally, IMO mandates related to biosecurity (transfer of invasive species) drive demand for verified, closed-loop systems that capture all removed debris.

What is the main technological challenge facing the robotic hull cleaning industry?

The main technological challenge is developing non-abrasive cleaning mechanisms that are effective against severe hard fouling (e.g., barnacles) without damaging the increasingly sophisticated and costly anti-fouling and foul-release coatings applied to modern vessels. Balancing cleaning efficacy with coating preservation remains critical.

Are closed-loop hull cleaning systems mandatory globally, and what defines them?

Closed-loop systems are not yet mandatory globally but are increasingly required in sensitive ports and jurisdictions (e.g., parts of Europe and Australia). They are defined by their ability to capture and filter all biofouling debris and cleaning effluent, preventing the discharge of harmful organisms or contaminants into the port environment.

Which geographical region leads the market in the adoption of automated hull cleaning technology?

Europe and North America currently lead in the adoption of high-value, fully automated and regulated closed-loop cleaning technology, driven by strict environmental mandates and high labor costs. However, Asia Pacific is the fastest-growing market in terms of overall unit deployment and service volume due to dense shipping traffic.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager