Hybrid Stepper Motors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438358 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Hybrid Stepper Motors Market Size

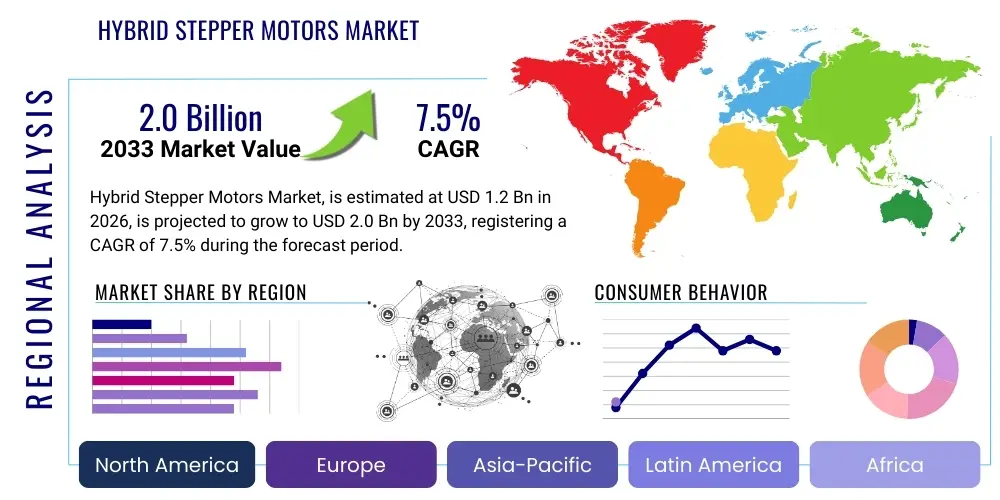

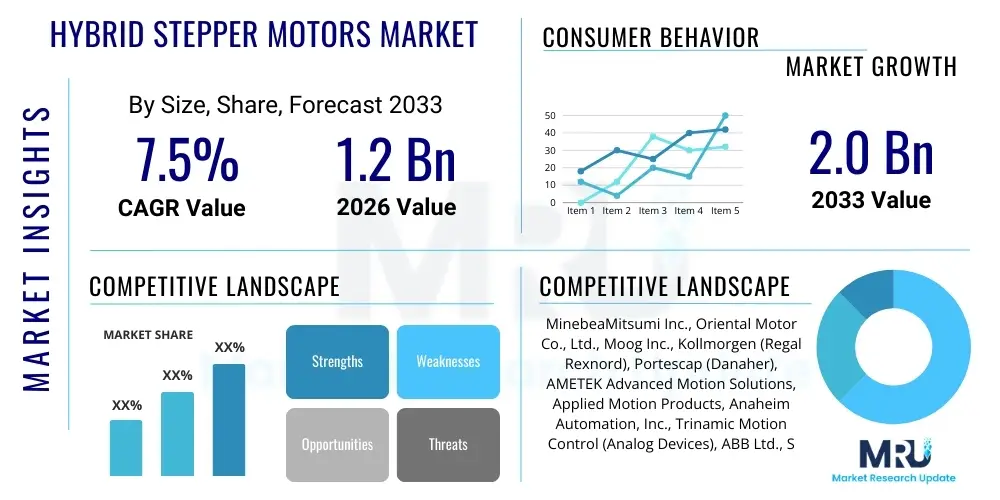

The Hybrid Stepper Motors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 2.0 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by the accelerating global transition towards precision automation across critical industries, notably in manufacturing, robotics, and complex medical equipment where high torque density and precise positioning are paramount requirements for operational efficacy and output quality.

The market expansion is closely tied to the resurgence of industrial machinery modernization efforts across Asia Pacific, driven by government incentives aimed at developing sophisticated manufacturing ecosystems. Furthermore, the persistent demand for miniaturization in electromechanical systems necessitates the use of high-performance motors, positioning hybrid stepper motors—which offer superior resolution compared to conventional permanent magnet steppers—as the preferred solution in high-density applications. The balance of cost-efficiency relative to high-end servo systems, combined with increasingly sophisticated micro-stepping capabilities, solidifies their competitive advantage in mid-to-high performance automation segments.

Technological enhancements, particularly the integration of advanced control electronics and closed-loop feedback systems, are significantly overcoming traditional limitations such as resonance and stall conditions. These improvements enable hybrid stepper motors to operate at higher speeds and efficiencies, blurring the performance gap with servo motors in many low-to-medium power applications. This enhanced reliability and performance profile makes them attractive for emerging applications in 3D printing, advanced packaging machinery, and semiconductor handling systems, fueling the sustained growth projections through 2033.

Hybrid Stepper Motors Market introduction

Hybrid stepper motors represent a critical segment within the industrial motion control landscape, combining the structural features of permanent magnet and variable reluctance stepper motors. This integration results in a motor offering higher holding torque, reduced step angles (typically 1.8 degrees or less), and superior dynamic performance compared to simpler motor designs. Their fundamental operating principle involves converting digital pulses into precise rotational movements, making them inherently suitable for applications demanding exact positioning, such as CNC machines, laboratory automation, and robotic grippers. These motors are characterized by a permanent magnet inserted into a toothed rotor core, which interacts with a stator featuring concentrated windings, providing high positional accuracy without the need for complex, costly feedback mechanisms typically associated with servo drives.

The principal applications of hybrid stepper motors span across diversified sectors, including semiconductor fabrication equipment, where micron-level precision is non-negotiable; complex medical imaging and fluid handling systems, necessitating reliability and quiet operation; and high-speed packaging machinery, requiring rapid indexing and repeatability. A key benefit driving their adoption is the simplicity of control and the intrinsic open-loop positioning capability, which often reduces overall system complexity and expense. Additionally, their robustness and capability to maintain high torque even at low speeds are invaluable assets in pick-and-place robotics and precision dosing pumps.

Major driving factors influencing market dynamics include the widespread adoption of Industry 4.0 principles, necessitating flexible and highly automated manufacturing lines. Furthermore, the global proliferation of additive manufacturing (3D printing) requires highly dependable motion systems for extrusion and platform movement, creating massive demand for high-resolution hybrid steppers. The continuous innovation in drive electronics, enabling micro-stepping down to 256 microsteps per full step, allows these motors to achieve near-servo smoothness and extremely fine resolution, thereby expanding their utility into historically servo-dominated markets. Their durability and low maintenance requirements further contribute to favorable total cost of ownership (TCO) assessments, encouraging widespread integration across new and replacement industrial installations.

Hybrid Stepper Motors Market Executive Summary

The Hybrid Stepper Motors Market is currently characterized by intense innovation focusing on enhancing efficiency, reducing physical size, and incorporating advanced control features suitable for the modern intelligent factory. Business trends are dominated by strategic mergers and acquisitions among key manufacturers seeking to consolidate technological expertise, particularly in high-resolution encoder integration and advanced driver development. The competitive landscape is shifting towards suppliers who can offer integrated motor-drive solutions (smart motors) featuring built-in microcontrollers and communication protocols (e.g., EtherCAT, CANopen), facilitating seamless integration into larger industrial networks. Furthermore, sustainability requirements are driving research into materials that minimize core losses and improve motor efficiency, aligning with global energy consumption reduction mandates.

Regional trends indicate that the Asia Pacific (APAC) region remains the dominant growth engine, fueled by extensive manufacturing growth in China, South Korea, and Japan, especially within consumer electronics production and electric vehicle (EV) battery manufacturing equipment. North America and Europe demonstrate mature markets characterized by high demand for specialized, high-precision motors for aerospace, defense, and advanced medical device manufacturing. These developed markets prioritize motors compliant with rigorous safety and quality standards, driving the premium segment focused on closed-loop stepper systems. Investment in localized production facilities in regions like Southeast Asia is increasing to mitigate supply chain risks and cater directly to rapidly expanding regional industrial hubs.

Segment trends reveal a pronounced shift towards closed-loop hybrid stepper motors, which incorporate feedback mechanisms (like optical or magnetic encoders) to prevent positional errors and stalling, addressing the primary limitation of traditional open-loop systems. While open-loop systems still dominate in cost-sensitive, moderate-precision applications, the rapid decrease in encoder cost is making closed-loop technology increasingly accessible and standard for new installations requiring higher reliability and torque utilization. By application, the semiconductor and electronics manufacturing segment exhibits the highest growth rate due to relentless miniaturization and the requirement for highly precise, repetitive motion in handling micro-components and wafers. The increasing demand for five-axis and multi-axis CNC machines also substantially boosts the demand for high-torque hybrid steppers.

AI Impact Analysis on Hybrid Stepper Motors Market

Common user inquiries regarding AI's influence on the Hybrid Stepper Motors Market frequently center on predictive maintenance capabilities, optimization of motion profiles, and the potential for AI to manage complex, multi-axis synchronization in real-time. Users are concerned with how AI integration can enhance operational uptime by anticipating motor failure and how intelligent algorithms can dynamically adjust motor control parameters (like current phasing and micro-stepping levels) to maximize efficiency and reduce energy consumption under varying load conditions. A key expectation is that AI-driven diagnostics will move beyond simple error codes to providing actionable insights into motor health and expected lifespan, thereby revolutionizing maintenance schedules and reducing unexpected downtime in critical factory environments.

Based on this analysis, the key themes summarizing AI’s influence are intelligent control optimization, enhanced diagnostics, and integration into self-optimizing automation systems. AI algorithms are increasingly deployed within motor drivers and centralized control units to implement sophisticated control strategies, such as adaptive resonance suppression, where the system learns the motor's vibration characteristics and automatically adjusts excitation frequencies to mitigate instability. This proactive control reduces noise, wear, and tear, ultimately extending the motor’s operational life and improving positional accuracy, especially during rapid acceleration and deceleration cycles.

Furthermore, the data generated by advanced stepper motor systems (positional error, winding temperature, current draw, vibration) forms the foundation for machine learning models. These models analyze massive datasets to establish baseline performance profiles and detect subtle anomalies indicative of impending component degradation, such as bearing wear or rotor magnetization loss. The ability of AI to translate complex operational data into actionable maintenance forecasts is transforming the TCO calculation for hybrid stepper motors, ensuring they remain a competitive choice against more expensive servo systems by guaranteeing higher uptime and predictability in demanding applications.

- Real-time predictive maintenance scheduling based on operational telemetry.

- Dynamic closed-loop control optimization, reducing hunting and improving settling time.

- Adaptive resonance suppression through machine learning algorithms.

- Energy consumption optimization by adjusting current levels according to real-time load assessment.

- Enhanced multi-axis synchronization and coordinated motion planning in complex robotic systems.

- Automated fault detection and root cause analysis in industrial control systems.

DRO & Impact Forces Of Hybrid Stepper Motors Market

The dynamics of the Hybrid Stepper Motors Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively form the Impact Forces dictating market trajectory. Key drivers include the overwhelming global trend toward manufacturing automation, particularly in emerging economies where scaling production capacity necessitates reliable and cost-effective motion control solutions. The inherent precision and holding torque of hybrid steppers, coupled with advancements in micro-stepping technology that enable smoother and quieter operation, make them highly attractive for high-throughput machinery. Furthermore, the miniaturization trend in medical devices and laboratory equipment strongly favors hybrid steppers due to their high torque-to-volume ratio and precise angle control, essential for micro-fluidics and scanning applications.

However, the market faces significant restraints. The primary challenge is the intensifying competition from advanced servo motors, which, despite higher cost, offer superior high-speed performance, dynamic responsiveness, and true zero-error closed-loop operation suitable for the most demanding applications. Hybrid stepper motors also suffer from inherent limitations, such as reduced torque output at high speeds and the risk of stalling under unexpected overload conditions in open-loop setups, which can necessitate costly system redesigns or adoption of more complex closed-loop control strategies. Furthermore, the technical complexity involved in tuning and integrating high-resolution micro-stepping drivers can sometimes be a barrier for smaller enterprises lacking specialized engineering resources.

Opportunities for market growth are abundant, predominantly driven by the burgeoning integration of the Industrial Internet of Things (IIoT). This transformation allows hybrid stepper motors to be equipped with smart sensor technology and network connectivity, enabling remote monitoring and enhanced diagnostic capabilities. The expanding fields of customizable 3D printing and desktop CNC milling also present fertile ground for volume expansion. Additionally, the development of specialized, weather-resistant hybrid stepper motors for outdoor applications, such as solar panel tracking systems and remote surveillance equipment, opens up entirely new vertical markets. The continued reduction in the cost of high-performance encoders and drive electronics is crucial, transforming restraints into opportunities by making high-reliability closed-loop hybrid systems the new industry standard.

Segmentation Analysis

The Hybrid Stepper Motors Market is comprehensively segmented based on technology, operational loop structure, rotor type, and the diverse applications they serve across industrial and commercial landscapes. Analyzing these segments provides crucial insights into specific growth pockets and technological preferences within the motion control ecosystem. The core segmentation by operational loop distinguishes between Open-Loop systems, favored for their simplicity and cost-effectiveness in applications where moderate precision suffices, and Closed-Loop systems, which leverage feedback mechanisms for error correction, significantly enhancing reliability and speed capability, thereby attracting premium market penetration.

Further granularity is achieved through segmentation based on the motor's physical characteristics, such as frame size (NEMA standards like NEMA 17, NEMA 23, NEMA 34), which directly correlates with the motor's torque output and intended application scale. Smaller NEMA sizes (17 and below) dominate robotics and small-scale automation, while larger sizes are reserved for heavy-duty industrial machinery. The type of driver technology employed—micro-stepping drivers versus full/half-stepping drivers—also differentiates the market, reflecting the demand for enhanced resolution and minimized resonance, pushing the high-performance segment towards sophisticated micro-stepping capabilities.

Geographical segmentation remains critical, with the high-volume manufacturing sectors in Asia Pacific dictating demand for standard NEMA motors, while the high-technology sectors in North America and Europe drive innovation and adoption of advanced, integrated closed-loop stepper motor packages designed for precision medical and aerospace applications. Understanding these segmentation nuances allows manufacturers to tailor their product lines—from offering low-cost, high-volume open-loop solutions to premium, networked closed-loop systems—to maximize market penetration and address varied end-user performance requirements efficiently.

- By Operational Loop:

- Open-Loop Hybrid Stepper Motors

- Closed-Loop (Feedback) Hybrid Stepper Motors

- By Technology:

- Micro-stepping

- Full-Step and Half-Step

- By Frame Size (NEMA Standard):

- NEMA 8 to NEMA 17 (Small Frame)

- NEMA 23 to NEMA 34 (Medium Frame)

- Above NEMA 34 (Large Frame)

- By Application:

- Industrial Machinery (CNC, Laser Cutting, Engraving)

- Semiconductor and Electronics Manufacturing

- Medical and Laboratory Equipment (Analyzers, Scanners)

- Robotics and Automation

- 3D Printing and Additive Manufacturing

- Packaging and Material Handling

- Textile Machinery

Value Chain Analysis For Hybrid Stepper Motors Market

The value chain for the Hybrid Stepper Motors Market begins fundamentally with upstream activities centered around raw material sourcing and component manufacturing. This upstream segment is highly dependent on reliable suppliers of high-grade magnetic materials, such as rare earth magnets (e.g., Neodymium), necessary for achieving the high torque density characteristic of hybrid designs. Additionally, specialized copper wiring for stator windings, high-precision bearings, and metal alloys for motor housing are critical inputs. The profitability and competitive positioning of motor manufacturers are intrinsically linked to securing stable supply and managing the volatile pricing of these essential raw materials, particularly rare earth elements used in the rotor magnet assembly.

The core manufacturing stage involves sophisticated processes including rotor lamination stamping, precise winding, assembly, and rigorous quality control testing. This stage demands high capital investment in automated machinery to ensure the micron-level dimensional accuracy required for smooth operation and minimal torque ripple. Key manufacturers often maintain tight integration between motor production and the development of proprietary driver electronics and controllers, which are essential for maximizing the performance potential of the stepper motor, especially in micro-stepping and closed-loop configurations. Innovation in this stage focuses on improving winding techniques to increase fill factor and minimize resistance, enhancing overall motor efficiency.

Downstream activities involve a complex network of distribution channels, system integrators, and end-user adoption. Products are distributed through direct sales channels for large OEM customers (Original Equipment Manufacturers, such as major robotic arms or CNC machine builders) and indirect channels utilizing technical distributors and value-added resellers (VARs) who provide localized technical support and often pre-integrate the motors into larger sub-systems. System integrators play a crucial role by providing application-specific programming and installation services, connecting the motors with PLCs (Programmable Logic Controllers) and industrial networks. The efficiency of this downstream network dictates the market reach and customer responsiveness of the primary motor manufacturers.

Hybrid Stepper Motors Market Potential Customers

The potential customer base for Hybrid Stepper Motors is vast and diverse, spanning nearly all sectors that require automated, precise, and repeatable motion control. End-users fall broadly into two major categories: Original Equipment Manufacturers (OEMs) and Maintenance, Repair, and Operations (MRO) buyers. OEMs constitute the largest segment, integrating thousands of motors annually into their final products, such as advanced industrial robots, complex multi-axis CNC milling centers, and high-speed automated assembly lines. These customers demand high reliability, competitive volume pricing, and extensive technical support for integration into proprietary system architectures. Crucially, semiconductor equipment manufacturers are major consumers, utilizing steppers for wafer handling and positioning stages where extreme precision and low vibration are prerequisites for production yields.

The second significant customer group consists of manufacturers in the medical and laboratory automation fields. Hospitals, pharmaceutical companies, and research institutions utilize hybrid stepper motors in devices like diagnostic analyzers, surgical robotics, and automated fluid handling systems. For these customers, factors such as motors certified for cleanroom environments, low audible noise, and exceptionally long lifespan are prioritized over purely low cost. The recent boom in personalized medicine and rapid point-of-care diagnostics further expands this customer segment, requiring compact, high-performance motion solutions for next-generation automated testing platforms.

Emerging markets, such as the rapidly expanding custom manufacturing and prototyping sector, driven by 3D printing (fused deposition modeling and selective laser sintering) and desktop CNC machines, also represent a significant and growing cohort of potential buyers. These customers typically purchase smaller volume, high-resolution NEMA 17 and NEMA 23 motors through e-commerce platforms and specialized distributors. Furthermore, the burgeoning field of smart logistics and warehousing automation, relying heavily on automated guided vehicles (AGVs) and sorting systems, is rapidly becoming a high-growth end-user segment for robust, high-torque hybrid stepper motors capable of handling heavy payloads and continuous duty cycles.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 2.0 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | MinebeaMitsumi Inc., Oriental Motor Co., Ltd., Moog Inc., Kollmorgen (Regal Rexnord), Portescap (Danaher), AMETEK Advanced Motion Solutions, Applied Motion Products, Anaheim Automation, Inc., Trinamic Motion Control (Analog Devices), ABB Ltd., Shenzhen MOONS' Industries Co., Ltd., Teknic Inc., Shinano Kenshi Co., Ltd., Lin Engineering (Kerk), Faulhaber Group, ElectroCraft Inc., Maxon Motor AG, Schneider Electric SE, Delta Electronics, Inc., Nidec Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hybrid Stepper Motors Market Key Technology Landscape

The Hybrid Stepper Motors Market is currently undergoing a transformative technological shift, moving away from simple pulse-and-direction control towards sophisticated, networked intelligent drive systems. A cornerstone of this evolution is the pervasive adoption of Field-Oriented Control (FOC) algorithms, which were historically exclusive to high-end AC servo motors. Applying FOC to hybrid steppers allows the motor current to be precisely managed based on the rotor position, significantly minimizing power loss, reducing motor heating, and enabling substantially higher torque utilization, especially at mid-to-high speeds where traditional control methods often falter. This integration requires advanced microprocessors within the driver electronics capable of executing complex vector control mathematics in real-time, effectively improving the motor's dynamic range and overall efficiency.

Another crucial technological advancement is the miniaturization and cost reduction of high-resolution encoders, facilitating the rapid market penetration of closed-loop hybrid stepper systems, often termed "servo-steppers" or "integrated drives." These systems combine the inherent precision of the stepper motor’s detent positions with the dynamic error correction capabilities of a servo system. By integrating optical or magnetic encoders, the drive can monitor the actual rotor position and adjust the current phase to prevent stalling and maintain positional integrity, offering performance rivaling traditional servo systems in many low-inertia applications, but at a lower system cost. Furthermore, the development of sophisticated current wave shaping techniques is mitigating the detrimental effects of mechanical resonance, a long-standing issue for stepper motors, leading to dramatically smoother and quieter operation across the entire speed spectrum.

The final layer of technological innovation concerns connectivity and system integration, aligned with IIoT architecture. Modern hybrid stepper drivers are increasingly embedding communication interfaces such as EtherCAT, PROFINET, and Ethernet/IP, enabling high-speed, deterministic control and seamless data exchange within factory automation networks. This connectivity facilitates centralized diagnostics, firmware updates, and remote configuration, turning the motor into a true network node. The trend towards integrated motor-driver units (smart motors) further simplifies cabling, reduces installation footprint, and minimizes electromagnetic interference (EMI), making installation easier and faster for OEMs, marking a paradigm shift in how motion components are deployed in modern industrial settings.

Regional Highlights

Regional dynamics heavily influence the demand and technological deployment of hybrid stepper motors, driven by disparate industrial policies, automation maturity levels, and sectorial specialization. Asia Pacific (APAC) stands out as the globally dominant market, both in terms of consumption and manufacturing capacity. Countries such as China, Japan, and South Korea are industrial powerhouses characterized by high volume production of consumer electronics, automotive components, and extensive reliance on automated assembly lines. China, in particular, drives immense demand for low-to-medium cost hybrid steppers for use in textiles, packaging, and the rapidly growing 3D printing industry. Japan and South Korea, however, focus on the premium segment, utilizing high-precision closed-loop steppers for semiconductor manufacturing and advanced robotics, cementing APAC's role as the central hub for market expansion.

North America maintains a strong position, characterized by high technological sophistication and substantial investment in high-value, stringent regulatory sectors like aerospace, defense, and advanced medical devices. The region exhibits a high adoption rate of integrated, intelligent stepper drives and closed-loop systems, emphasizing performance, compliance, and deterministic control protocols (like EtherCAT) for complex machine tooling and laboratory automation. The focus here is on customization and solutions engineered for extreme environmental reliability, reflecting the high cost of downtime in these critical applications. Furthermore, the presence of major technological innovation centers drives continuous development of next-generation motion control hardware and software integration.

Europe represents a mature, highly automated market known for strict quality standards and a strong emphasis on energy efficiency and system durability. Germany, Italy, and Switzerland are key demand centers, heavily utilizing hybrid steppers in high-precision machine tools, printing equipment, and advanced packaging lines. European manufacturers prioritize motors that comply with environmental directives and offer high efficiency. The region is also at the forefront of IIoT adoption, demanding that stepper motor solutions offer robust networking capabilities and advanced safety features. While growth rates may be slightly slower than APAC due to market saturation in traditional sectors, the demand for upgrades and specialized, high-reliability components ensures steady market value expansion.

- Asia Pacific (APAC): Dominant market volume due to extensive manufacturing base; high growth in 3D printing and general automation; focus on both cost-effectiveness and high-precision semiconductor applications.

- North America: Focus on high-value applications (Aerospace, Defense, Medical); early adopter of integrated closed-loop and intelligent drive systems; strong demand for NEMA 34+ sized motors for large industrial machinery.

- Europe: Mature market emphasizing energy efficiency, high quality, and strict regulatory compliance; strong demand from machine tool building and advanced packaging sectors; rapid integration of deterministic industrial Ethernet protocols.

- Latin America: Emerging market with growing demand driven by food and beverage processing automation and localized manufacturing expansion; focus on rugged, reliable, and moderately priced standard steppers.

- Middle East and Africa (MEA): Growth driven by infrastructure development and diversification away from oil economies; increasing application in surveillance systems, solar power tracking, and regional manufacturing startups.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hybrid Stepper Motors Market.- MinebeaMitsumi Inc.

- Oriental Motor Co., Ltd.

- Moog Inc.

- Kollmorgen (Regal Rexnord)

- Portescap (Danaher)

- AMETEK Advanced Motion Solutions

- Applied Motion Products

- Anaheim Automation, Inc.

- Trinamic Motion Control (Analog Devices)

- ABB Ltd.

- Shenzhen MOONS' Industries Co., Ltd.

- Teknic Inc.

- Shinano Kenshi Co., Ltd.

- Lin Engineering (Kerk)

- Faulhaber Group

- ElectroCraft Inc.

- Maxon Motor AG

- Schneider Electric SE

- Delta Electronics, Inc.

- Nidec Corporation

Frequently Asked Questions

Analyze common user questions about the Hybrid Stepper Motors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between open-loop and closed-loop hybrid stepper motors?

Open-loop systems are simpler and less expensive, operating without positional feedback, relying only on input pulses. Closed-loop hybrid steppers (servo-steppers) incorporate encoders to monitor actual rotor position, enabling dynamic error correction, preventing stalling, and offering higher torque at speed.

In which applications are hybrid stepper motors preferred over servo motors?

Hybrid steppers are preferred in applications requiring high holding torque at standstill or low speeds, precise incremental movement, and relatively low cost, such as 3D printers, lens focusing mechanisms, and high-precision metering pumps, where the high-speed dynamics of servos are unnecessary.

How does micro-stepping technology enhance hybrid stepper motor performance?

Micro-stepping divides the full motor step into hundreds of smaller increments by smoothly modulating the current in the motor windings. This significantly improves positional resolution, reduces resonance and vibration, minimizes audible noise, and allows for smoother motion profiles, particularly at low velocities.

Which geographical region exhibits the fastest growth rate for hybrid stepper motors?

The Asia Pacific (APAC) region, particularly driven by large-scale industrial automation and the continuous expansion of the electronics and semiconductor manufacturing sectors in China and South Korea, is projected to maintain the highest growth rate during the forecast period.

What is the impact of Industry 4.0 and IIoT on hybrid stepper motor design?

Industry 4.0 mandates require hybrid steppers to integrate smart features like embedded diagnostics, network communication protocols (e.g., EtherCAT), and condition monitoring sensors. This evolution creates intelligent, networked motor-drive units capable of self-optimization and predictive maintenance within the smart factory ecosystem.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager