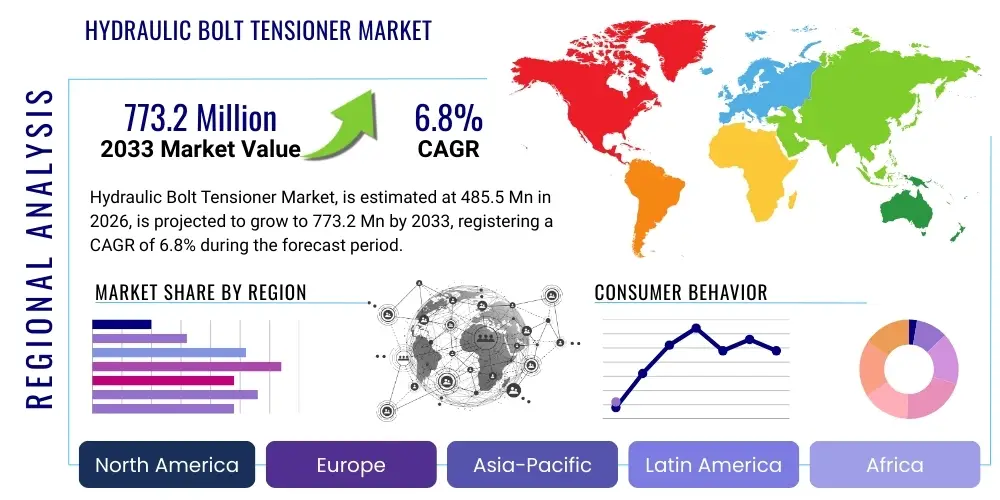

Hydraulic Bolt Tensioner Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440091 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Hydraulic Bolt Tensioner Market Size

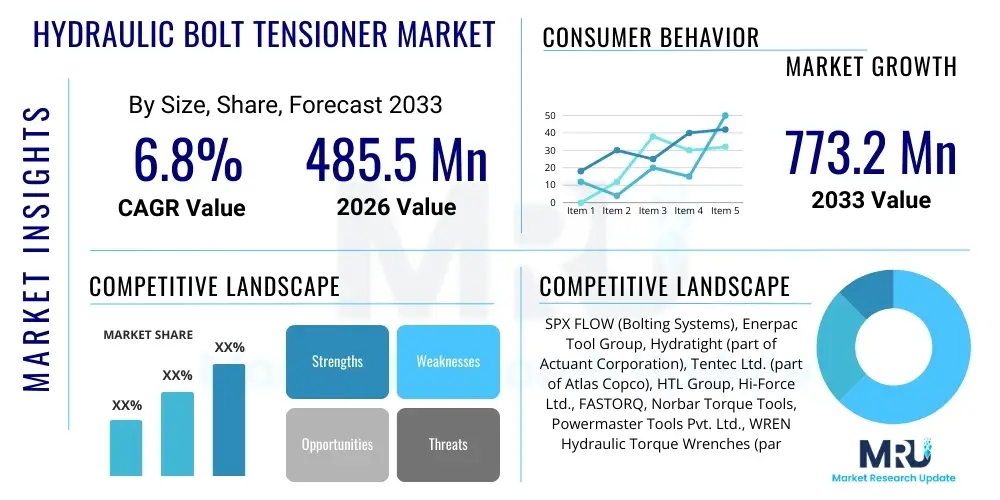

The Hydraulic Bolt Tensioner Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 485.5 million in 2026 and is projected to reach USD 773.2 million by the end of the forecast period in 2033. This growth is primarily driven by increasing industrial infrastructure development globally, stringent safety regulations necessitating precise fastening, and a rising demand for efficient and reliable bolting solutions across various heavy industries. The market's expansion is further supported by technological advancements leading to more precise, user-friendly, and durable hydraulic bolt tensioning systems, making them indispensable in critical applications where joint integrity is paramount.

Hydraulic Bolt Tensioner Market introduction

Hydraulic bolt tensioners are specialized tools designed to apply a precise and uniform load to large bolts and studs, crucial for ensuring the integrity and safety of bolted joints in critical applications. Unlike traditional torque wrenches that apply rotational force, tensioners directly stretch the bolt, achieving a more accurate and consistent clamping force without inducing torsional stresses. This method significantly enhances the reliability and longevity of bolted connections, making it indispensable in heavy industries.

The primary applications for hydraulic bolt tensioners span across sectors such as oil and gas, power generation (including nuclear, thermal, and wind energy), heavy machinery manufacturing, marine, mining, and construction. They are essential for securing flanges, casings, large engines, pressure vessels, and structural components where high precision and uniform bolt loading are non-negotiable. The benefits of using hydraulic bolt tensioners include superior joint integrity, reduced assembly and disassembly times, enhanced safety for operators, and extended lifespan of bolted components due to the elimination of localized stress concentrations.

Driving factors for the market include the global expansion of industrial and energy infrastructure, a heightened focus on operational safety and efficiency across industries, and the increasing adoption of preventive maintenance strategies. Furthermore, the rising complexity of industrial equipment demanding higher precision in assembly, coupled with the need to minimize downtime and prevent catastrophic failures, continues to fuel the demand for advanced hydraulic bolt tensioning solutions. Regulatory mandates for safety and environmental protection also play a significant role in promoting the use of these reliable tools.

Hydraulic Bolt Tensioner Market Executive Summary

The Hydraulic Bolt Tensioner Market is experiencing robust growth, propelled by several key business, regional, and segment trends. From a business perspective, there's a growing emphasis on rental services and integrated bolting solutions, providing cost-effective alternatives for industries that may not require outright purchase. Manufacturers are also focusing on product innovation, incorporating features like digital gauges, remote monitoring capabilities, and lighter, more ergonomic designs to enhance user experience and operational efficiency. Strategic partnerships and acquisitions are also becoming prevalent as companies seek to expand their market reach and technological portfolios, adapting to a dynamic industrial landscape that increasingly prioritizes precision, safety, and productivity in maintenance and construction operations.

Regional trends indicate significant growth in emerging economies, particularly in Asia Pacific, driven by rapid industrialization, infrastructure development, and substantial investments in energy projects. North America and Europe, while mature markets, continue to demand advanced, high-precision tensioning systems due to stringent safety regulations and an aging industrial infrastructure requiring extensive maintenance and upgrades. The Middle East and Africa region shows strong potential, fueled by ongoing oil and gas exploration, refinery expansions, and power plant constructions. Latin America also presents opportunities with its growing mining and energy sectors, necessitating robust and reliable bolting solutions for heavy equipment and installations.

In terms of segment trends, the demand for higher pressure tensioners capable of handling larger diameter bolts is on the rise, reflecting the increasing scale and complexity of industrial applications. Automated and semi-automated hydraulic tensioning systems are gaining traction due to their ability to further reduce human error, improve speed, and enhance safety during operations. Furthermore, the market is observing a shift towards application-specific tensioners tailored for industries like wind energy, where unique bolt configurations and environmental conditions necessitate specialized tools. The emphasis on comprehensive service offerings, including calibration, maintenance, and training, alongside product sales, is also a significant trend, adding value across the entire product lifecycle and solidifying customer relationships.

AI Impact Analysis on Hydraulic Bolt Tensioner Market

User inquiries regarding AI's impact on the Hydraulic Bolt Tensioner Market often revolve around how artificial intelligence can enhance precision, automate processes, improve safety, and contribute to predictive maintenance strategies. Common questions address the integration of AI with existing tensioning systems, the potential for intelligent decision-making in bolting sequences, the role of AI in quality control, and the implications for operator skill requirements. There is also interest in whether AI can optimize tensioning schedules for complex installations, reducing downtime and extending equipment lifespan. Users are keen to understand the practical applications of AI in this niche, particularly concerning data analysis from tensioning operations to inform future best practices and prevent failures. Concerns may also include the initial investment required, data security, and the potential for job displacement, though the prevailing sentiment leans towards AI as an enabler for more efficient, safer, and reliable bolting operations.

- AI-driven predictive maintenance for bolted joints: Leveraging sensor data from tensioned bolts to predict potential loosening or failure, enabling proactive maintenance interventions before critical issues arise.

- Optimized tensioning sequences and load distribution: AI algorithms can analyze joint parameters and recommend optimal tensioning patterns and loads for complex bolt configurations, ensuring uniform stress distribution and preventing over or under-tensioning.

- Automated quality control and reporting: AI can monitor tensioning operations in real-time, detecting deviations from specified parameters, generating automated compliance reports, and ensuring adherence to safety standards.

- Enhanced operator training and assistance: AI-powered simulations and augmented reality tools can provide realistic training environments for operators, improving skill acquisition and offering real-time guidance during complex bolting procedures.

- Remote monitoring and diagnostics: AI can enable remote monitoring of hydraulic bolt tensioners and bolted assemblies, allowing for diagnostics, troubleshooting, and performance optimization from a central location, reducing on-site inspection needs.

- Smart tool integration: Integration of AI with smart tensioners capable of self-calibrating, recording tensioning data, and communicating with central control systems for a fully connected and intelligent bolting ecosystem.

- Material stress analysis and fatigue life prediction: AI can analyze stress data on bolts and materials post-tensioning to predict fatigue life more accurately, aiding in design improvements and maintenance scheduling.

DRO & Impact Forces Of Hydraulic Bolt Tensioner Market

The Hydraulic Bolt Tensioner Market is significantly influenced by a confluence of drivers, restraints, and opportunities, shaping its growth trajectory and competitive landscape. Key drivers include the escalating global demand for energy, necessitating new power generation facilities and extensive oil & gas infrastructure. Concurrently, stringent industrial safety regulations across various sectors, coupled with an increasing emphasis on preventive maintenance to minimize costly downtime, compel industries to adopt reliable and precise bolting solutions. The continuous expansion of heavy industries, marine, and construction sectors worldwide further fuels the demand for these essential tools, recognizing their role in ensuring the integrity and longevity of critical assets.

However, the market also faces notable restraints. The high initial capital investment associated with acquiring advanced hydraulic bolt tensioning systems can be a deterrent for smaller enterprises or projects with limited budgets. The requirement for specialized operator training and skilled personnel to correctly operate and maintain these precision tools poses another challenge, particularly in regions with a shortage of technical expertise. Furthermore, intense competition from alternative bolting methods, such as traditional torque wrenches, although less precise, offers a lower-cost option that can sometimes be preferred for less critical applications, potentially limiting market penetration for hydraulic tensioners in certain segments.

Opportunities for growth are abundant and varied. Emerging economies, undergoing rapid industrialization and infrastructure development, represent untapped markets with substantial potential for hydraulic bolt tensioner adoption. The development of "smart" or IoT-enabled tensioners, offering enhanced connectivity, data logging, and diagnostic capabilities, presents a significant innovation pathway, appealing to industries focused on digitalization and predictive maintenance. Moreover, the expansion of rental services for tensioning equipment provides a flexible and cost-effective solution, broadening market access and reducing entry barriers for potential users. Strategic diversification into new application areas, such as renewable energy infrastructure (e.g., wind turbine installation and maintenance), also offers robust avenues for market expansion, leveraging the inherent advantages of precise bolting in these critical sectors.

Segmentation Analysis

The Hydraulic Bolt Tensioner Market is comprehensively segmented based on various critical parameters, including product type, pressure range, application, and end-user industry. These segmentations provide a granular view of the market dynamics, allowing for a detailed understanding of demand patterns, technological preferences, and regional consumption trends. The product type segmentation typically differentiates between top-side tensioners and subsea tensioners, reflecting their distinct operational environments and design requirements. Pressure range segmentation categorizes tensioners based on their maximum operational pressure capabilities, catering to different bolt sizes and load specifications. Application-based segmentation highlights the diverse sectors where these tools are indispensable, while end-user segmentation focuses on the primary industries driving demand, offering insights into their specific operational needs and investment capacities.

- By Product Type:

- Top-Side Tensioners

- Subsea Tensioners

- By Pressure Range:

- Up to 1500 bar (21,750 psi)

- 1500 bar to 2500 bar (21,750 psi to 36,250 psi)

- Above 2500 bar (36,250 psi)

- By Operation Type:

- Manual Tensioners

- Semi-Automatic Tensioners

- Automatic Tensioning Systems

- By Application:

- Flange Bolting

- Engine Casing Bolting

- Heat Exchanger Bolting

- Pipeline Connections

- Turbine Assembly

- Structural Bolting

- Pressure Vessel Bolting

- Others (e.g., Valve Maintenance, Compressor Assembly)

- By End-User Industry:

- Oil & Gas

- Power Generation (Thermal, Nuclear, Hydro, Wind)

- Heavy Machinery Manufacturing

- Marine & Shipbuilding

- Mining

- Construction

- Aerospace

- Chemical & Petrochemical

- Others (e.g., Steel Mills, Cement Plants)

Value Chain Analysis For Hydraulic Bolt Tensioner Market

The value chain for the Hydraulic Bolt Tensioner Market encompasses a comprehensive series of activities, beginning with the sourcing of raw materials and extending to the final delivery and after-sales support to end-users. Upstream activities involve the procurement of specialized high-grade steels, hydraulic seals, precision machined components, and advanced electronic sensors. Key players in this stage include material suppliers and component manufacturers who adhere to strict quality standards to ensure the durability and reliability of the final product. The quality and availability of these specialized materials directly impact the manufacturing cost and performance characteristics of the tensioners, making strong supplier relationships crucial for manufacturers.

Midstream activities primarily focus on the manufacturing and assembly of the hydraulic bolt tensioners. This stage involves precision machining, hydraulic system integration, calibration, and rigorous quality testing. Manufacturers invest significantly in R&D to develop innovative designs, improve efficiency, and enhance user safety, often incorporating advanced materials and digital technologies. After manufacturing, products move into distribution channels. These can be direct, where manufacturers sell directly to large industrial clients or through their own sales force and service centers. Alternatively, indirect channels involve a network of authorized distributors, resellers, and rental companies that provide wider market reach, local support, and specialized rental services, which are particularly important for capital-intensive equipment like hydraulic bolt tensioners.

Downstream activities include sales, marketing, installation support, maintenance, and after-sales services. Direct distribution allows manufacturers to maintain close relationships with key clients, offering tailored solutions and direct technical support. Indirect channels, through distributors, provide local market expertise, inventory management, and often offer value-added services such as training, calibration, and repair. Rental companies play a crucial role by providing flexible access to equipment for projects with varying durations or budget constraints, expanding market accessibility. End-users benefit from comprehensive support, ensuring optimal performance and longevity of their tensioning equipment. The effectiveness of both direct and indirect channels is critical for market penetration and customer satisfaction, with a growing trend towards integrated solution providers who offer both products and extensive service packages.

Hydraulic Bolt Tensioner Market Potential Customers

The primary potential customers for the Hydraulic Bolt Tensioner Market are diverse, spanning a wide array of heavy industries where critical bolted joints are essential for operational safety, structural integrity, and long-term performance. These end-users are typically large-scale industrial entities that operate complex machinery, extensive infrastructure, and high-pressure systems where precise and reliable bolt loading is paramount. The decision to invest in hydraulic bolt tensioners is often driven by a combination of factors including stringent safety regulations, the need to minimize maintenance downtime, the desire to extend equipment lifespan, and the imperative to prevent catastrophic failures that could lead to significant financial losses and environmental damage. These customers prioritize tools that offer high accuracy, efficiency, and robust construction capable of withstanding demanding industrial environments.

Key segments of potential customers include the oil and gas sector, which utilizes hydraulic tensioners extensively for offshore platforms, refineries, pipelines, and subsea installations to ensure the integrity of flanges and pressure vessels. The power generation industry, encompassing nuclear, thermal, hydro, and increasingly wind energy, relies on these tools for turbine assembly, generator maintenance, and securing critical structural components in demanding environments. Heavy machinery manufacturers and maintenance providers constitute another significant customer base, employing tensioners for assembling and servicing large industrial equipment such as presses, excavators, and mining machinery. The marine and shipbuilding industry also represents a substantial market, using tensioners for securing propulsion systems, stern tubes, and large structural elements on vessels and offshore structures.

Furthermore, construction companies involved in large-scale infrastructure projects, such as bridges, high-rise buildings, and industrial plants, are increasingly adopting hydraulic bolt tensioners for structural bolting where high pre-load accuracy is required. The chemical and petrochemical industries, dealing with corrosive environments and high-pressure reactors, depend on these tools to maintain leak-free bolted connections. Mining operations, with their heavy-duty equipment and need for robust structural integrity, also form a significant customer segment. Essentially, any industry where large-diameter bolts are used in critical applications, and where safety, precision, and efficiency are top priorities, represents a potential customer for hydraulic bolt tensioning solutions. These customers often seek not only the tools but also comprehensive service packages including training, calibration, and maintenance to ensure optimal performance and compliance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 485.5 Million |

| Market Forecast in 2033 | USD 773.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SPX FLOW (Bolting Systems), Enerpac Tool Group, Hydratight (part of Actuant Corporation), Tentec Ltd. (part of Atlas Copco), HTL Group, Hi-Force Ltd., FASTORQ, Norbar Torque Tools, Powermaster Tools Pvt. Ltd., WREN Hydraulic Torque Wrenches (part of CEJN Group), ITH Bolting Technology, TorcUP Inc., Durapac, Applied Bolting Technology, Boltight (part of Nord-Lock Group), Hytorc, Torque Tension Systems Ltd., Titan Technologies, R&D Technology Pty Ltd., Bolting Solutions (India) Pvt. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydraulic Bolt Tensioner Market Key Technology Landscape

The Hydraulic Bolt Tensioner Market is continually evolving, driven by advancements in materials science, hydraulic engineering, and digital technologies, aiming to deliver enhanced precision, efficiency, and safety. A significant technological trend involves the integration of advanced materials, such as high-strength alloys and lightweight composites, into tensioner designs. These materials not only improve the durability and robustness of the tools but also contribute to making them lighter and more ergonomic, thereby reducing operator fatigue and increasing portability. The development of more compact and powerful hydraulic pumps, capable of delivering higher pressures with reduced footprint, further enhances the efficiency and versatility of tensioning systems, allowing for faster and more precise operations in confined spaces. These innovations address the critical industry need for tools that are both resilient and adaptable to a wide range of challenging industrial environments.

Digitalization and smart technologies are profoundly shaping the key technology landscape. Modern hydraulic bolt tensioners are increasingly equipped with digital gauges and sensors that provide real-time pressure readings, data logging capabilities, and often integrate with external monitoring systems. This allows for precise control over the applied load and enables comprehensive documentation of bolting procedures, crucial for quality assurance and regulatory compliance. Furthermore, the incorporation of Internet of Things (IoT) capabilities means these smart tensioners can communicate wirelessly, transmitting operational data to central databases for analysis, predictive maintenance scheduling, and remote diagnostics. This connectivity facilitates more informed decision-making, streamlines maintenance workflows, and ensures optimal performance of bolted joints over their operational lifespan, moving towards a more intelligent and integrated bolting ecosystem.

Ergonomics and automation also represent critical areas of technological advancement. Manufacturers are focusing on designs that improve ease of use, reduce setup times, and minimize manual effort. This includes features like quick-release couplings, self-retracting pistons, and modular designs that allow for greater flexibility in adapting tensioners to different bolt sizes and application requirements. The development of semi-automatic and fully automatic tensioning systems, particularly for large-scale projects or applications requiring simultaneous tensioning of multiple bolts, significantly reduces human error and drastically improves operational speed and safety. These automated solutions often incorporate advanced control algorithms and safety interlocks, representing a major leap forward in optimizing bolting processes for critical industrial applications, pushing the boundaries of what is achievable in terms of precision and efficiency in heavy industry maintenance and construction.

Regional Highlights

- North America: A mature market characterized by stringent safety regulations and a high demand for advanced, precision bolting solutions in the oil and gas, power generation, and heavy manufacturing sectors. Significant investments in infrastructure upgrades and renewable energy projects further drive demand for sophisticated hydraulic tensioning systems, with a strong emphasis on automation and data integration.

- Europe: A key market driven by robust industrial output, particularly in Germany, the UK, and Scandinavia. The region exhibits high adoption rates due to strict environmental and safety standards, especially within the wind energy, nuclear power, and marine industries. Innovation in smart tensioners and rental services are prominent trends.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, infrastructure development, and significant investments in the energy sector (including oil & gas, thermal power, and renewables) in countries like China, India, and Southeast Asia. The expanding manufacturing base and increasing awareness of safety and efficiency are propelling market expansion.

- Latin America: This region presents substantial growth opportunities, primarily driven by its vast mining operations, expanding oil and gas industry (especially offshore), and developing energy infrastructure. Brazil, Mexico, and Chile are key contributors, with demand for durable and reliable tensioning tools being a priority.

- Middle East and Africa (MEA): Dominated by the extensive oil and gas industry, substantial investments in petrochemical projects, and ongoing infrastructure development. Countries like Saudi Arabia, UAE, and Qatar are significant markets, requiring high-pressure tensioning solutions for critical applications in harsh environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydraulic Bolt Tensioner Market.- SPX FLOW (Bolting Systems)

- Enerpac Tool Group

- Hydratight (part of Actuant Corporation)

- Tentec Ltd. (part of Atlas Copco)

- HTL Group

- Hi-Force Ltd.

- FASTORQ

- Norbar Torque Tools

- Powermaster Tools Pvt. Ltd.

- WREN Hydraulic Torque Wrenches (part of CEJN Group)

- ITH Bolting Technology

- TorcUP Inc.

- Durapac

- Applied Bolting Technology

- Boltight (part of Nord-Lock Group)

- Hytorc

- Torque Tension Systems Ltd.

- Titan Technologies

- R&D Technology Pty Ltd.

- Bolting Solutions (India) Pvt. Ltd.

Frequently Asked Questions

Analyze common user questions about the Hydraulic Bolt Tensioner market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a hydraulic bolt tensioner and how does it work?

A hydraulic bolt tensioner is a tool that stretches a bolt using hydraulic pressure to achieve a precise and uniform preload. It works by applying force to the bolt's end, elongating it before the nut is tightened, ensuring accurate tension without torsional stress.

What are the primary benefits of using hydraulic bolt tensioners over traditional torque wrenches?

Hydraulic bolt tensioners offer superior accuracy and consistency in bolt loading, eliminate torsional stress, enhance joint integrity, reduce assembly time, and significantly improve safety for operators compared to torque wrenches.

In which industries are hydraulic bolt tensioners most commonly used?

They are predominantly used in heavy industries such as oil and gas, power generation (including wind and nuclear), marine, mining, heavy machinery manufacturing, and large-scale construction for critical bolted connections.

What are the key factors driving the growth of the Hydraulic Bolt Tensioner Market?

Market growth is driven by increasing industrial infrastructure development, stringent safety regulations, a rising demand for efficient and precise bolting solutions, and the need for reliable preventive maintenance across heavy industries.

What technological advancements are impacting the Hydraulic Bolt Tensioner Market?

Key advancements include the integration of digital gauges, IoT connectivity for real-time monitoring and data logging, advanced material usage for lighter and more durable tools, and the development of automated tensioning systems for enhanced efficiency and safety.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager