Hydraulic Dock Lift Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433260 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Hydraulic Dock Lift Equipment Market Size

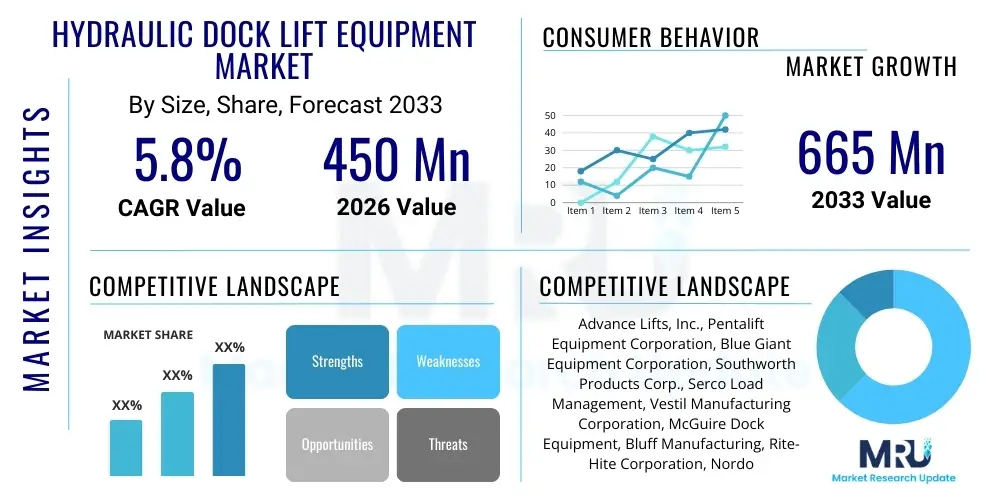

The Hydraulic Dock Lift Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $450 Million USD in 2026 and is projected to reach $665 Million USD by the end of the forecast period in 2033.

Hydraulic Dock Lift Equipment Market introduction

The Hydraulic Dock Lift Equipment Market encompasses specialized machinery designed to vertically transport heavy loads, such as pallets, forklifts, or heavy machinery, between different elevations, typically from ground level to truck bed height or dock height. These lifts are critical components in modern logistics and material handling infrastructure, providing a safe and efficient solution for environments lacking permanent loading docks or where versatility in handling different truck heights is necessary. The fundamental design relies on a robust electro-hydraulic system to power the scissor mechanism, ensuring smooth, stable, and reliable lifting capabilities in high-throughput distribution centers and manufacturing facilities. The increasing global focus on workplace safety standards and ergonomic material movement further solidifies the essential role of these lifts.

The primary function of hydraulic dock lifts is to bridge the vertical gap between vehicles and the facility floor, facilitating the loading and unloading process. Unlike simple dock plates or levelers, hydraulic lifts offer a full range of vertical movement, accommodating various vehicle sizes, including flatbed trucks and standard trailers, which makes them indispensable for diverse supply chain operations. Major applications span warehousing, e-commerce fulfillment centers, third-party logistics (3PL) providers, retail backrooms, and heavy industrial settings, particularly where continuous, heavy-duty operation is required. Key benefits include enhanced operational efficiency, reduced risk of material damage, and significant mitigation of musculoskeletal injuries associated with manual handling and awkward lifting positions, directly impacting insurance liability and employee retention.

Market growth is predominantly driven by the exponential expansion of the e-commerce sector globally, necessitating rapid development of new warehouses and distribution hubs that require optimized material flow solutions. Furthermore, stringent regulatory mandates regarding worker safety, particularly OSHA regulations in North America and equivalent directives in Europe, compel companies to invest in ergonomic and mechanized handling equipment. Technological advancements, such as improved hydraulic fluid performance, durable pump designs, and integrated safety systems like velocity fuses and emergency stops, enhance the reliability and longevity of these assets, providing a favorable return on investment for end-users facing increasing pressure to minimize turnaround times and maximize throughput.

Hydraulic Dock Lift Equipment Market Executive Summary

The Hydraulic Dock Lift Equipment Market is characterized by robust demand stemming from the global acceleration of industrial automation and the continued expansion of logistics networks. Business trends indicate a strong move toward customization, with end-users increasingly demanding specialized lift capacities, platform sizes, and integration capabilities (such as compatibility with automated guided vehicles or specialized racking systems). Key players are focusing on developing heavy-duty models capable of handling higher capacity requirements driven by dense storage strategies and larger vehicle types. Furthermore, the incorporation of diagnostic monitoring features and remote maintenance services is becoming a competitive differentiator, moving the market structure towards a service-oriented model alongside equipment sales.

Regionally, North America and Asia Pacific remain the primary growth engines. North America leads in terms of adoption of advanced, high-capacity lifts, driven by established regulatory frameworks and high labor costs, which mandate efficiency-enhancing investments. The Asia Pacific region, specifically China and India, exhibits the highest growth rate, fueled by rapid industrialization, massive investments in infrastructure development, and the burgeoning local e-commerce market. Europe maintains a steady demand, focusing heavily on safety compliance and environmental sustainability, encouraging manufacturers to produce hydraulic systems using biodegradable fluids and energy-efficient power units. Emerging markets in Latin America and MEA are beginning to show increased procurement as international logistics firms expand their footprints.

Segment trends reveal that the stationary lift segment dominates the market due to its permanent installation, stability, and higher load capacity, making it the preferred choice for dedicated loading docks. However, the portable/mobile segment is witnessing accelerated growth, particularly in urban logistics and temporary operational sites where flexibility is paramount. In terms of lift mechanism, the double scissor lift configuration is highly sought after for applications requiring high vertical reach while maintaining platform stability. The retail and warehousing segment holds the largest market share by end-user, but the manufacturing sector, particularly automotive and heavy machinery manufacturing, is rapidly increasing its uptake due to the need for efficient transfer of materials during production processes.

AI Impact Analysis on Hydraulic Dock Lift Equipment Market

Common user inquiries regarding the intersection of Artificial Intelligence (AI) and hydraulic dock lift equipment frequently center on enhanced operational safety, predictive maintenance capabilities, and potential integration within fully autonomous warehousing systems. Users seek to understand how AI algorithms can analyze real-time sensor data—such as hydraulic pressure fluctuations, motor current consumption, and cycle counts—to predict component failure long before a breakdown occurs, thereby minimizing costly downtime. Concerns also revolve around AI’s role in optimizing lift usage based on fluctuating load volumes and dynamic scheduling requirements, and how computer vision can improve safety by detecting improper load placement or unauthorized personnel near the operating area. The overarching expectation is that AI will transform dock operations from reactive maintenance and manual supervision to proactive, data-driven management, ensuring higher uptime and compliance.

- AI-driven predictive maintenance scheduling based on sensor data analysis, reducing unplanned downtime by predicting hydraulic seal failure or motor wear.

- Implementation of machine learning algorithms for optimizing lift speed and acceleration profiles based on load weight and specific handling requirements, maximizing energy efficiency.

- Integration of computer vision and AI processing to monitor the loading zone, verifying safe forklift entry, correct load centering, and compliance with operational safety protocols.

- Utilization of natural language processing (NLP) in maintenance logs and operator feedback systems to rapidly identify recurring operational issues and system limitations.

- Autonomous optimization of dock allocation and scheduling, coordinating hydraulic lift cycles with Automated Guided Vehicles (AGVs) and warehouse management systems (WMS).

- Enhanced cybersecurity measures applied to IoT-enabled lifts, utilizing AI to detect and mitigate unauthorized access or anomalies in operational data transmission.

- Development of adaptive control systems that use AI to compensate for slight variations in truck bed height or approach angle, ensuring perfect alignment and minimizing jolts during transfer.

DRO & Impact Forces Of Hydraulic Dock Lift Equipment Market

The market for hydraulic dock lift equipment is influenced by a dynamic interplay of factors that both propel growth and impose limitations. Key drivers include the overwhelming global demand for quick and reliable logistics solutions, fueled by e-commerce proliferation, leading to massive investments in new warehousing capacity worldwide. Regulatory pressures emphasizing industrial safety, particularly standards related to material handling and ergonomics (such as ANSI MH30.2), necessitate the adoption of mechanized lifting solutions over manual methods, directly benefitting the hydraulic lift sector. Furthermore, the inherent durability, high load capacity, and relative simplicity of hydraulic technology provide a cost-effective and long-lasting alternative to purely mechanical or complex electronic systems, ensuring continued market preference.

Despite strong drivers, several restraints impact the market trajectory. The substantial initial capital expenditure required for purchasing and installing heavy-duty hydraulic dock lifts can be prohibitive for small and medium enterprises (SMEs), particularly in developing economies. Maintenance complexity and the necessity for specialized technicians to handle hydraulic systems, including fluid checks, seal replacements, and pressure adjustments, represent ongoing operational costs. Moreover, the hydraulic systems, while reliable, carry the environmental risk of oil leakage, which necessitates stringent environmental protocols and disposal mechanisms. Economic volatility and fluctuations in commodity prices (steel and component costs) can also affect the final price of the equipment, impacting procurement decisions in price-sensitive regions.

Opportunities for market expansion are abundant, centered largely on technological innovation and market penetration. The major opportunity lies in integrating advanced monitoring systems (IoT and telematics) into lifts, offering end-users real-time diagnostics, remote control capabilities, and detailed usage analytics, thereby transforming lifts into smart assets. Another significant avenue is the development of ultra-low profile or subsurface installed lifts that minimize required pit depth, making installation easier and less costly, especially in existing facilities or leased spaces. The shift toward electrification and the development of energy-efficient electro-hydraulic pumps also present opportunities for manufacturers to tap into environmentally conscious enterprises. The overall impact forces heavily favor growth, driven primarily by non-negotiable safety standards and the relentless expansion of global supply chain demands, forcing continuous replacement and upgrading of older, less efficient equipment.

Segmentation Analysis

The Hydraulic Dock Lift Equipment Market is comprehensively segmented based on its structural design, lifting capacity, mechanism type, and primary end-user applications. This categorization allows manufacturers and stakeholders to precisely target specific industrial requirements, ranging from lightweight, high-mobility applications in retail backrooms to heavy-duty, continuous operations in manufacturing hubs. The dominant segmentation variables reflect operational necessity, distinguishing between permanent, high-capacity installations (stationary) and flexible, temporary lifting needs (portable), which influences design complexity, price point, and installation requirements across different geographical markets.

- By Product Type:

- Stationary Hydraulic Dock Lifts (Permanent installation, higher capacity)

- Portable Hydraulic Dock Lifts (Mobile, lower capacity, used for flexible loading zones)

- By Lift Capacity:

- Light-Duty (Up to 6,000 lbs)

- Medium-Duty (6,001 lbs to 15,000 lbs)

- Heavy-Duty (Above 15,000 lbs)

- By Mechanism/Design:

- Single Scissor Dock Lifts

- Double Scissor Dock Lifts (For higher vertical reach)

- Telescopic Scissor Dock Lifts (For specialized, constrained spaces)

- By End-User Industry:

- Warehousing and Logistics (E-commerce fulfillment, 3PL)

- Manufacturing (Automotive, Heavy Machinery, Food & Beverage)

- Retail and Wholesale

- Transportation and Freight (Rail terminals, Air cargo hubs)

- Government and Defense

- By Operation:

- Electric-Powered Hydraulic Lifts

- Air-Powered Hydraulic Lifts

Value Chain Analysis For Hydraulic Dock Lift Equipment Market

The value chain for hydraulic dock lift equipment begins with upstream suppliers, who provide critical raw materials and highly specialized components. This stage involves the procurement of high-grade steel necessary for the robust scissor mechanisms and platforms, industrial-grade hydraulic fluid, and precision-engineered components such as hydraulic cylinders, pumps, hoses, power units (motors and reservoirs), and advanced control systems (PLCs and safety sensors). The quality and reliability of these upstream inputs directly dictate the performance characteristics and lifespan of the final dock lift product. Strong supplier relationships are essential for maintaining stable costs, ensuring material compliance with safety standards, and facilitating just-in-time manufacturing processes.

Midstream activities center around the design, fabrication, assembly, and quality assurance processes carried out by the original equipment manufacturers (OEMs). This stage includes detailed engineering design adhering to international standards (e.g., CE marking, ANSI compliance), specialized welding, and the careful integration of the electro-hydraulic system, ensuring precise synchronization and fail-safe operation. OEMs differentiate themselves through modular design, customization capabilities (especially load capacity and platform size), and the implementation of advanced testing protocols to guarantee structural integrity and hydraulic system reliability. Manufacturing efficiency and minimizing production lead times are critical competitive factors at this level.

Downstream activities involve the distribution, installation, maintenance, and end-of-life servicing of the equipment. Distribution channels are varied, involving direct sales teams for large industrial clients requiring custom solutions, and indirect distribution through specialized material handling dealers and integrators who provide local sales, installation, and after-market support. The installation process is often complex, requiring specialized civil engineering (pit construction for stationary models) and electrical connectivity. Aftermarket services, including preventative maintenance contracts and rapid parts replacement, contribute significantly to the manufacturer's recurring revenue stream and enhance customer loyalty, completing the full value cycle.

Hydraulic Dock Lift Equipment Market Potential Customers

Potential customers for hydraulic dock lift equipment are predominantly enterprises engaged in logistics-intensive operations where consistent, safe, and high-volume movement of goods between floor level and transport vehicles is mandatory. The core market comprises major players in the warehousing and distribution sector, including third-party logistics (3PL) providers and large retail chains that operate expansive fulfillment and cross-docking centers. These organizations require heavy-duty, stationary lifts capable of handling multiple shifts and ensuring rapid truck turnaround times, directly linking lift efficiency to overall supply chain performance metrics. Their purchasing decisions are heavily influenced by total cost of ownership (TCO), reliability, and compliance with high safety standards.

Another significant customer segment is the manufacturing industry, particularly within the automotive, aerospace, and heavy machinery sectors. These end-users utilize dock lifts not only for traditional loading and unloading but also as essential components integrated into assembly lines or production flow systems, such as moving components between floor levels or positioning specialized equipment. The demands from this segment are highly specific, often requiring custom platform shapes, specialized safety interlocks, and precise height tolerances to interface seamlessly with automated production equipment. Manufacturers of food and beverage products and pharmaceuticals also represent key buyers, prioritizing stainless steel construction and wash-down capabilities to meet stringent hygiene regulations.

The emerging customer base includes smaller enterprises and businesses operating in urban environments where space constraints and temporary loading needs necessitate portable solutions. Retail outlets, urban delivery hubs, rental companies, and construction sites that frequently change operational locations are increasingly adopting mobile hydraulic dock lifts. These buyers prioritize ease of mobility, minimal installation requirements, and operational flexibility. Government and municipal entities, including military logistics operations and public utility depots, also constitute a stable customer base, focused on durable, standardized equipment capable of operating reliably in harsh or demanding environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450 Million USD |

| Market Forecast in 2033 | $665 Million USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Advance Lifts, Inc., Pentalift Equipment Corporation, Blue Giant Equipment Corporation, Southworth Products Corp., Serco Load Management, Vestil Manufacturing Corporation, McGuire Dock Equipment, Bluff Manufacturing, Rite-Hite Corporation, Nordock Inc., Autoquip Corporation, Wuxi Tongyang Machinery Co., Ltd., Attlas Industry, Beacon Industries, Inc., Roton, Lokrite, Copperloy, Inc., Global Industrial Company, Flexlift Hubarbeitsbühnen GmbH, ALIMAK Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydraulic Dock Lift Equipment Market Key Technology Landscape

The core technology driving the hydraulic dock lift market remains the electro-hydraulic system, which utilizes a motor and pump assembly to pressurize hydraulic fluid, subsequently driving piston cylinders that power the scissor mechanism. Recent technological advancements are focused heavily on improving system efficiency, reliability, and precision control. Modern lifts increasingly incorporate sophisticated variable speed and variable frequency drive (VFD) technology in the motor power units. This allows for smoother acceleration and deceleration profiles, reducing wear and tear on mechanical components and significantly minimizing electrical power consumption during operation, aligning with increasing industrial sustainability goals and minimizing peak demand charges.

A major area of innovation is the integration of advanced safety and monitoring technologies. Velocity fuses are now standard safety features, automatically locking the platform in place if a sudden, uncontrolled drop in hydraulic pressure occurs, a critical safety measure in compliance with ANSI MH30.2 standards. Furthermore, smart safety systems utilize photoelectric sensors, laser scanners, and pressure mats to create comprehensive safety envelopes around the lift perimeter, automatically halting operation if an obstruction or unauthorized presence is detected. These embedded safety technologies minimize human error and liability, enhancing the equipment's overall appeal in safety-conscious operational environments.

The rise of the Industrial Internet of Things (IIoT) is fundamentally transforming the maintenance landscape for hydraulic dock lifts. Manufacturers are embedding telematics and connectivity modules that transmit real-time operational data—such as lift cycle counts, hydraulic oil temperature, pressure readings, and motor current draw—to cloud-based platforms. This data enables predictive maintenance, allowing service providers to schedule proactive interventions before component failure, transitioning from time-based maintenance to condition-based maintenance. This not only maximizes uptime but also helps customers optimize their asset utilization by providing detailed usage metrics and performance benchmarks, ultimately driving down TCO.

Regional Highlights

North America holds the largest market share, characterized by high adoption rates of heavy-duty and custom-engineered dock lifts, primarily due to the established infrastructure of large-scale distribution centers and a strong emphasis on regulatory compliance related to worker safety (OSHA and ANSI). The region benefits from high labor costs, which serve as a persistent economic driver for automation and efficiency-enhancing equipment like hydraulic lifts. The United States, in particular, dominates regional demand, driven by massive e-commerce and retail warehousing investments, alongside stable demand from the automotive manufacturing sector.

The Asia Pacific (APAC) region is projected to register the fastest growth rate during the forecast period. This accelerated expansion is attributable to rapid industrialization, burgeoning cross-border trade, and significant governmental investment in developing modern logistics and port infrastructure, particularly in China, India, and Southeast Asian nations. While price sensitivity remains higher in some APAC markets, the increasing maturity of local supply chains and the influence of international logistics firms operating in the region are driving demand for high-quality, efficient hydraulic dock lifts to meet growing volume throughput requirements.

Europe represents a mature market with steady growth, focusing intensely on advanced safety features, ergonomic design, and environmental standards. Western European nations, including Germany, the UK, and France, prioritize lifts that offer exceptional durability and compliance with stringent EU machinery directives and environmental guidelines (such as systems compatible with biodegradable hydraulic oils). Latin America and the Middle East & Africa (MEA) markets are considered emerging but promising. Growth in these regions is tied closely to local infrastructure projects, economic stability, and the establishment of sophisticated international trade hubs and logistics corridors, spurring gradual but consistent adoption of mechanized loading solutions.

- North America: Dominant market share; driven by high labor costs, stringent safety regulations (ANSI/OSHA), and expansive e-commerce distribution networks; high demand for integrated, heavy-duty stationary lifts.

- Asia Pacific (APAC): Highest projected CAGR; fueled by rapid urbanization, infrastructure investment, and burgeoning local manufacturing and logistics sectors (especially in China and India); increasing focus on scalable and cost-effective solutions.

- Europe: Mature market focusing on regulatory compliance (CE marking), ergonomics, and sustainability; strong demand for energy-efficient electro-hydraulic systems and lifts compatible with environmentally friendly fluids.

- Latin America (LATAM): Emerging growth driven by modernization of port facilities and expanding internal supply chains; market characterized by a mix of new installations and replacement cycles.

- Middle East & Africa (MEA): Growth tied to diversification efforts away from oil economies, leading to investment in logistics hubs (e.g., UAE, Saudi Arabia) and localized manufacturing sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydraulic Dock Lift Equipment Market.- Advance Lifts, Inc.

- Pentalift Equipment Corporation

- Blue Giant Equipment Corporation

- Southworth Products Corp.

- Serco Load Management

- Vestil Manufacturing Corporation

- McGuire Dock Equipment

- Bluff Manufacturing

- Rite-Hite Corporation

- Nordock Inc.

- Autoquip Corporation

- Wuxi Tongyang Machinery Co., Ltd.

- Attlas Industry

- Beacon Industries, Inc.

- Roton

- Lokrite

- Copperloy, Inc.

- Global Industrial Company

- Flexlift Hubarbeitsbühnen GmbH

- ALIMAK Group

Frequently Asked Questions

What are the primary safety features required for modern hydraulic dock lifts?

Modern hydraulic dock lifts must comply with standards like ANSI MH30.2 and typically include velocity fuses (preventing rapid free-fall), emergency stop buttons, toe guards, non-skid deck surfaces, and comprehensive safety skirts to prevent entanglement. Integrated sensor systems often provide additional layers of safety by detecting obstructions or unauthorized movement.

How does the integration of IoT technology benefit the operational life of hydraulic dock lifts?

IoT integration allows for continuous remote monitoring of key operational metrics, such as hydraulic pressure and cycle counts. This data facilitates predictive maintenance scheduling, enabling repairs before component failure occurs, significantly reducing unplanned downtime, optimizing resource allocation, and extending the overall asset lifespan.

What is the difference between a stationary hydraulic dock lift and a portable hydraulic dock lift?

Stationary lifts are permanently installed, often requiring pit construction, and are designed for high-capacity, continuous use at dedicated loading docks. Portable lifts are mobile, require minimal installation, offer lower lifting capacities, and are ideal for flexible loading zones or sites needing temporary material handling solutions.

Which end-user segment is driving the highest demand for hydraulic dock lift equipment?

The Warehousing and Logistics segment, particularly those focused on e-commerce fulfillment and third-party logistics (3PL), is driving the highest demand. These operations require high-throughput, reliable equipment to handle the massive volumes and rapid turnaround times necessitated by online retail growth.

What are the key restraint factors affecting market growth in developing regions?

The primary restraint factors in developing regions include the high initial capital investment required for procurement and complex installation, limited availability of skilled technicians for specialized hydraulic maintenance, and, in some cases, less strict enforcement of workplace safety regulations compared to established markets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager