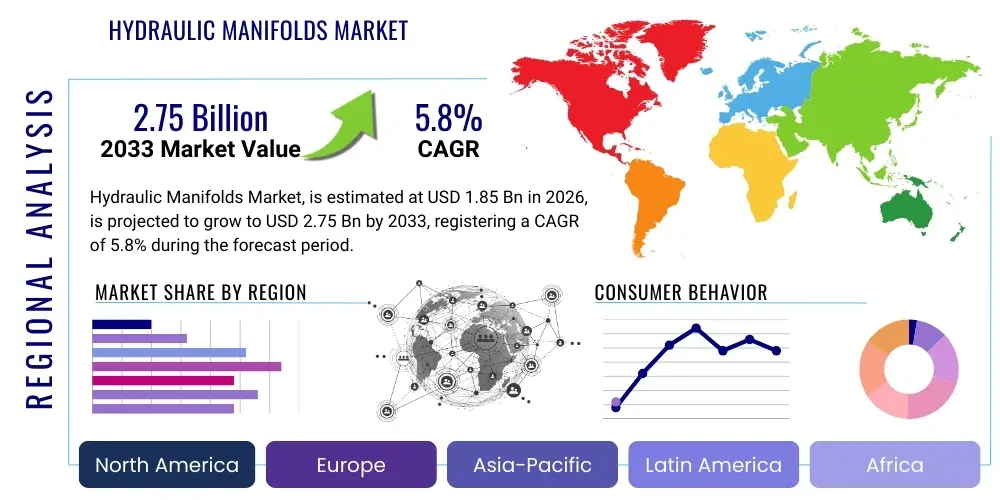

Hydraulic Manifolds Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438986 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Hydraulic Manifolds Market Size

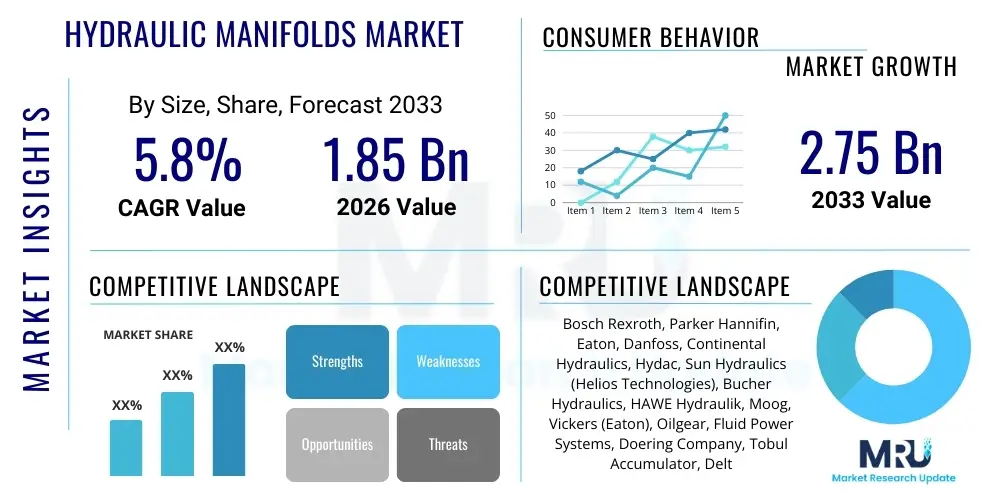

The Hydraulic Manifolds Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.85 Billion in 2026 and is projected to reach $2.75 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by robust infrastructure development worldwide, particularly in emerging economies, alongside the increasing adoption of automated and heavy machinery requiring precise and reliable fluid power control systems. The market valuation reflects sustained demand from crucial end-user sectors such as construction, agriculture, and material handling, which are increasingly seeking integrated solutions to enhance operational efficiency and system reliability in challenging environments.

Hydraulic Manifolds Market introduction

The Hydraulic Manifolds Market encompasses devices designed to regulate the flow of hydraulic fluid between pumps, actuators, and other components within a hydraulic system. A hydraulic manifold essentially acts as the central organizational unit, replacing intricate plumbing with a single, integrated block that channels fluid flow using internal passages and ports. This sophisticated integration significantly reduces potential leakage points, simplifies system assembly, and improves the overall efficiency and compactness of fluid power systems. They are critical components in ensuring precise control over massive mechanical forces and movements in diverse industrial and mobile applications, providing a cleaner, more organized approach to system design compared to traditional hard-piping methods.

Major applications of hydraulic manifolds span across highly demanding industrial sectors. In the construction industry, they are integral to heavy machinery like excavators, cranes, and bulldozers, where they manage the complex movements of hydraulic cylinders and motors with high precision. Similarly, the agriculture sector relies heavily on these components for advanced farming equipment, including sophisticated tractors and harvesters that require proportional control for implement positioning and steering. The benefits derived from utilizing hydraulic manifolds are substantial, including enhanced system performance due to optimized fluid routing, significant space savings, and minimized downtime resulting from fewer failure points. Furthermore, custom-designed manifolds allow for rapid system adaptation and maintenance, positioning them as essential elements in modern, high-performance machinery.

Driving factors propelling the market include the global trend toward automation and miniaturization of machinery, which necessitates compact and efficient fluid control solutions. Infrastructure projects, especially in rapidly urbanizing regions of Asia Pacific, fuel continuous demand for earth-moving and material handling equipment, directly boosting the manifold market. Technological advancements, such as the incorporation of advanced materials for weight reduction and increased pressure tolerance, alongside the integration of smart sensors for diagnostic capabilities, further solidify the importance and necessity of hydraulic manifolds in the industrial landscape, ensuring complex hydraulic circuits are managed reliably and efficiently.

- Product Description: Integrated blocks containing passages and ports that regulate the distribution and control of hydraulic fluid flow within fluid power systems, connecting pumps, valves, and actuators.

- Major Applications: Construction equipment (excavators, loaders), material handling systems (forklifts, cranes), agricultural machinery, mining machinery, machine tools, and aerospace testing equipment.

- Key Benefits: Reduced leakage potential, improved system compactness, simplified installation and maintenance, enhanced pressure control stability, and optimized fluid routing.

- Driving Factors: Increasing global infrastructure spending, rising demand for automated and heavy-duty equipment, and technological advancements focusing on efficiency and system integration.

Hydraulic Manifolds Market Executive Summary

The Hydraulic Manifolds Market is characterized by accelerating technological integration and robust demand stabilization across global heavy industries. Key business trends indicate a definitive shift towards modular and customizable manifold solutions, driven by original equipment manufacturers (OEMs) seeking greater flexibility and faster design cycles. There is a notable emphasis on incorporating high-pressure capabilities and utilizing advanced materials, such as specialized aluminum alloys and stainless steel, to meet stringent performance requirements in extreme operational environments like deep-sea mining and high-altitude aerospace applications. Furthermore, the convergence of hydraulic components with digital interfaces is transforming traditional manifolds into smart fluid management hubs, facilitating predictive maintenance and remote diagnostics, thus significantly enhancing the overall value proposition of these essential components.

Regional trends highlight the Asia Pacific (APAC) region as the paramount growth engine, primarily spurred by massive governmental investments in infrastructure, rapidly expanding industrialization in countries like China and India, and a burgeoning market for high-performance agricultural machinery. While North America and Europe remain mature markets, they are centers for innovation, leading the demand for technologically advanced solutions, including 3D-printed and additive manufactured manifolds which offer unparalleled geometric complexity and weight reduction. Regulatory pressures regarding environmental performance and energy efficiency in mature markets are pushing manufacturers to develop more efficient valve and manifold combinations, focusing on minimizing pressure drops and reducing system energy consumption.

Segment trends reveal that the modular product type segment is experiencing high growth due to its inherent flexibility, allowing users to easily expand or modify hydraulic circuits without complete system overhaul. In terms of end-user sectors, construction equipment maintains the largest market share, but the material handling sector is anticipated to register the highest growth rate, fueled by the expansion of automated warehousing and logistics facilities globally. Material segmentation indicates sustained dominance of cast iron for high-pressure industrial applications, while aluminum manifolds are becoming increasingly preferred in mobile applications where weight reduction and corrosion resistance are critical factors, reflecting a balanced market driven by specific application requirements.

AI Impact Analysis on Hydraulic Manifolds Market

User inquiries regarding AI's impact on the Hydraulic Manifolds Market primarily revolve around how artificial intelligence and machine learning can optimize the design phase, enable predictive failure detection, and integrate manifold systems into broader Industrial Internet of Things (IIoT) frameworks. Users are keenly interested in leveraging AI algorithms for topology optimization, asking if AI can autonomously design lighter, smaller, yet more flow-efficient manifold blocks (especially utilizing additive manufacturing data). A major concern focuses on maintenance—specifically, how sensor data integrated into hydraulic systems, processed by AI, can preemptively signal blockages, valve wear, or fluid contamination, thereby shifting maintenance from reactive to predictive models. Expectations are high for AI to enhance system reliability and minimize expensive equipment downtime, transforming manifolds from passive fluid regulators into active, intelligent system components capable of self-diagnosis and operational optimization.

- Predictive Maintenance: AI algorithms analyze real-time sensor data (pressure, temperature, flow rate) embedded within manifolds to predict component failure or system anomalies before operational breakdown occurs.

- Generative Design Optimization: Machine learning is utilized to optimize the internal flow paths and external geometry of manifold blocks, particularly for 3D printing, reducing material usage and improving pressure drop efficiency.

- Enhanced Quality Control: AI-driven vision systems inspect manufactured manifolds for machining defects or porosity during production, ensuring higher precision and consistency in final products.

- Smart System Integration: AI facilitates the integration of complex manifold circuits with centralized control systems, optimizing power usage and operational sequencing across multiple hydraulic actuators simultaneously.

- Operational Efficiency Tuning: Real-time AI analysis adjusts valve settings and fluid parameters dynamically based on load conditions, ensuring peak energy efficiency during equipment operation.

DRO & Impact Forces Of Hydraulic Manifolds Market

The Hydraulic Manifolds Market is significantly influenced by a confluence of driving forces, inherent restraints, and substantial growth opportunities, which collectively shape its trajectory and competitive landscape. The primary driver is the accelerating global need for increased operational efficiency and precise motion control in heavy machinery. Infrastructure projects, particularly in rapidly developing nations, create massive demand for reliable, high-power-density hydraulic systems. Furthermore, the trend toward customizing equipment for specialized tasks necessitates the flexibility offered by modular and custom-designed manifolds, which allow for complex circuit integration while ensuring system compactness and reduced component count. This integration capability directly addresses the efficiency goals of OEMs by simplifying assembly and lowering long-term maintenance costs, thereby strongly supporting market expansion.

Restraints, however, pose challenges to the market's sustained growth. The initial high cost associated with sophisticated, custom-engineered manifold blocks, especially those manufactured using advanced techniques like additive manufacturing, can deter adoption by smaller OEMs or in cost-sensitive applications. Furthermore, the complexity of diagnosing and repairing internal faults within monoblock manifolds can lead to significant downtime and higher maintenance expenses compared to simpler, hard-piped systems. Standardizing manifold interfaces and porting configurations across different manufacturers remains a technical challenge, often resulting in vendor lock-in and complicating system integration for end-users relying on diverse equipment suppliers. These factors require strategic navigation by industry participants to ensure broad market acceptance.

Opportunities for market players are substantial, particularly driven by technological evolution. The integration of IoT and smart hydraulic components offers a promising avenue, enabling manifolds to become ‘smart’ systems capable of real-time monitoring and communication, catering to the growing demand for Industry 4.0 compliant machinery. Emerging markets in Africa and Southeast Asia, characterized by untapped infrastructure potential, present new frontiers for geographical expansion. Moreover, the development of lightweight materials and advanced coatings for harsh environments, such as deep-sea or high-temperature industrial settings, opens doors for specialized, high-margin products. The industry's strategic focus on energy efficiency and sustainability will also drive the adoption of sophisticated proportional control manifolds that optimize energy consumption.

Segmentation Analysis

The Hydraulic Manifolds Market is comprehensively segmented based on material type, product structure, and the diverse end-user industries they serve, providing a detailed view of market dynamics and targeted growth areas. This segmentation is crucial as system requirements vary drastically—from the high pressure and robust durability required in mining equipment to the lightweight and corrosion-resistant attributes needed in mobile applications. Analyzing these segments helps stakeholders understand where technological investment is most required and where market penetration strategies should be concentrated. For instance, the high demand for precision and rapid movement in machine tools drives innovation in manifold design focusing on low pressure drop and dynamic response, whereas the need for immense power in earthmoving equipment demands sheer strength and resilience in the manifold material.

The segmentation by product type—Monoblock, Modular, and Sandwich Plate—reflects the evolution of hydraulic system design. While Monoblocks offer unparalleled compactness and robustness for fixed, non-adjustable circuits, the Modular and Sandwich Plate segments are experiencing faster growth due to their inherent flexibility and ease of maintenance and modification. This adaptability is particularly valued in high-mix, low-volume production environments or complex systems that may require future upgrades. Material segmentation, covering Cast Iron, Aluminum, and Stainless Steel, directly correlates with application pressure, weight constraints, and environmental exposure, with aluminum increasingly preferred for mobile machinery due to weight advantages, and cast iron dominating high-pressure industrial press applications due to superior strength and rigidity.

End-user segmentation clearly identifies the economic drivers of the market. The construction and material handling sectors collectively represent the dominant share, underscoring the correlation between global infrastructure spending and market health. However, sectors such as aerospace and defense are critical due to their demand for extremely high-reliability, low-tolerance customized manifolds, representing a lucrative, albeit smaller, market niche. Furthermore, the increasing mechanization of agriculture, particularly in developing economies, mandates the incorporation of sophisticated proportional manifolds to control complex implements, establishing agriculture as a consistently strong and expanding end-user segment for manifold manufacturers worldwide.

- By Material:

- Cast Iron

- Aluminum

- Stainless Steel

- Others (e.g., Ductile Iron, Brass)

- By Product Type:

- Monoblock Manifolds (Single-piece custom blocks)

- Modular Manifolds (Sectional, connectable components)

- Sandwich Plate Manifolds (Stacked layers)

- By End-User Industry:

- Construction

- Material Handling

- Agriculture

- Mining

- Automotive and Transportation

- Aerospace & Defense

- Oil & Gas

- Machine Tools and Industrial Manufacturing

Value Chain Analysis For Hydraulic Manifolds Market

The value chain for the Hydraulic Manifolds Market begins with the highly specialized sourcing of raw materials, primarily high-grade casting alloys such as grey iron, ductile iron, and aluminum. Upstream analysis focuses heavily on material procurement and preliminary processing (casting or forging), where material quality, dimensional accuracy, and metallurgical properties are paramount for the manifold's integrity under extreme pressure. Efficient management of these supply contracts is crucial as raw material costs represent a significant portion of the final product price, and fluctuations in global commodity markets directly impact manufacturing profitability. Key activities at this stage include precision casting and heat treatment, ensuring the blocks are ready for the highly demanding machining phase.

The midstream segment involves the core manufacturing processes: high-precision CNC machining, drilling, and tapping to create the complex internal passages and valve cavities. This stage demands sophisticated machinery and strict quality control, as internal surface finish and bore tolerances critically affect fluid flow efficiency and system reliability. Assembly and integration follow, where standardized or custom valves, sensors, and connecting interfaces are installed. Manufacturers in this segment increasingly invest in advanced technologies like additive manufacturing (3D printing) to create complex geometries unattainable through traditional machining, improving flow characteristics and reducing component weight. Efficient production logistics and lean manufacturing practices are key to maintaining competitiveness at this stage.

Downstream analysis covers distribution and end-use. Distribution channels are bifurcated into direct sales to large Original Equipment Manufacturers (OEMs) and sales through indirect channels, which include specialized fluid power distributors, system integrators, and Maintenance, Repair, and Operations (MRO) service providers. Direct sales facilitate deep customization and technical collaboration during the design phase, while indirect channels provide broader market reach and localized technical support for smaller customers and aftermarket needs. The final stage involves installation, commissioning, and continuous aftermarket service, including troubleshooting, parts replacement, and system upgrades, which generate significant recurring revenue for the key market players and ensure the longevity and sustained performance of the hydraulic systems.

Hydraulic Manifolds Market Potential Customers

Potential customers for the Hydraulic Manifolds Market are predominantly categorized into Original Equipment Manufacturers (OEMs) across heavy machinery sectors and specialized Maintenance, Repair, and Operations (MRO) providers serving industrial facilities. OEMs represent the largest customer base, as they integrate manifolds directly into newly designed machinery, seeking customized solutions that optimize performance, weight, and spatial constraints. These customers prioritize long-term supply agreements, technical expertise, and reliability, as the manifold is a non-negotiable critical component that dictates machine functionality. Key OEM groups include manufacturers of construction equipment (e.g., Caterpillar, Komatsu), agricultural machinery (e.g., John Deere, AGCO), and specialized industrial machinery (e.g., stamping presses, plastic injection molding machines).

The second major group consists of system integrators and fluid power distributors who purchase manifolds for custom retrofitting projects or as standardized components for diverse client needs. These customers require rapid delivery, standardized product catalogs, and strong application support. They serve smaller industrial clients who may not have in-house fluid power engineering capabilities but require customized hydraulic power units or circuit upgrades. For these buyers, availability of modular and sandwich plate components that offer circuit flexibility and easy interchangeability is a critical buying criterion, emphasizing fast turnaround times over deep design customization.

Furthermore, specialized industries with stringent reliability requirements, such as aerospace, defense, and oil and gas (including subsea equipment manufacturers), represent high-value potential customers. These buyers demand manifolds made from specialized materials (like stainless steel or exotic alloys), stringent certifications, and exhaustive testing protocols to ensure operation in extreme environments. Although the volume of sales to these sectors may be lower, the high complexity and specialized nature of these custom manifolds command premium pricing, making them attractive targets for manufacturers focusing on high-end engineering and critical applications where component failure is unacceptable.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.85 Billion |

| Market Forecast in 2033 | $2.75 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Rexroth, Parker Hannifin, Eaton, Danfoss, Continental Hydraulics, Hydac, Sun Hydraulics (Helios Technologies), Bucher Hydraulics, HAWE Hydraulik, Moog, Vickers (Eaton), Oilgear, Fluid Power Systems, Doering Company, Tobul Accumulator, Delta Power Company, Walvoil, Casappa, Poclain Hydraulics, Marzocchi Pumps |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydraulic Manifolds Market Key Technology Landscape

The technological landscape of the Hydraulic Manifolds Market is undergoing rapid transformation, moving beyond traditional CNC machining toward advanced manufacturing techniques that enhance product performance and design flexibility. One of the most disruptive technologies is Additive Manufacturing (AM), or 3D printing, particularly with metallic powders (aluminum and stainless steel). AM allows for the creation of highly complex internal flow passages that are impossible to machine conventionally, leading to significantly optimized fluid dynamics, reduced pressure drops, and therefore, superior energy efficiency. Furthermore, 3D printing enables the consolidation of multiple components into a single block, drastically reducing system weight and size, which is highly advantageous for mobile machinery where every kilogram matters, fundamentally challenging established manifold design philosophies.

Another crucial advancement involves the integration of smart components and sensor technology, central to the development of Industry 4.0 compliant hydraulic systems. Modern manifolds are increasingly being fitted with integrated pressure, temperature, and flow sensors, along with sophisticated electronics that interface directly with machine control units (MCUs) or cloud platforms. This level of digitalization allows for real-time performance monitoring, detailed diagnostics, and predictive maintenance capabilities, transforming the manifold from a purely mechanical component into an intelligent data node within the fluid power network. The data gathered facilitates proactive management of the hydraulic fluid quality and valve performance, ensuring maximum uptime and preventing costly catastrophic failures.

Furthermore, innovations in specialized materials and surface treatments are critical for improving manifold durability and expanding application ranges. The use of high-strength, lightweight aluminum alloys is becoming standard in the mobile sector, while advanced anti-corrosion coatings are being applied to manifolds destined for harsh, chemically aggressive or marine environments. The continuous development of specialized proportional and servo-valves that mate directly to the manifold is also a key technology focus. These high-response valves, coupled with precise manifold machining, enable extremely fine control over fluid flow and pressure, meeting the exacting standards required for sophisticated applications like robotics, flight simulators, and high-speed metal forming presses, driving demand for precise and reliable interface technology.

Regional Highlights

The global Hydraulic Manifolds Market exhibits distinct characteristics across major geographical regions, influenced by varying levels of industrialization, infrastructure spending, and regulatory environments. Asia Pacific (APAC) dominates the market share and is projected to experience the highest growth rate during the forecast period. This robust expansion is directly attributed to significant government investment in massive urbanization and infrastructure projects across China, India, and Southeast Asia. The rapid expansion of manufacturing capabilities, coupled with increasing demand for modern agricultural equipment and heavy construction machinery in these nations, creates a consistently high demand for cost-effective and reliable hydraulic fluid control components, positioning APAC as the strategic epicenter for future market growth.

North America and Europe represent mature, yet highly technologically advanced markets. While volume growth is generally slower compared to APAC, these regions drive innovation and demand for premium, integrated, and smart hydraulic manifold solutions. In North America, strict safety and efficiency standards, especially in the oil & gas and aerospace sectors, necessitate complex, custom-engineered manifolds offering high reliability and performance traceability. European markets, particularly Germany and Italy, focus heavily on precision engineering and Industry 4.0 integration, leading the charge in adopting 3D-printed manifolds and components equipped with advanced sensor technology to optimize energy consumption and enable remote diagnostics across their highly sophisticated industrial bases.

Latin America, the Middle East, and Africa (MEA) currently hold smaller market shares but offer substantial growth opportunities, primarily tied to the extraction industries (mining and oil & gas) and developing infrastructure. The MEA region is witnessing growing investments in energy projects and diversified economic zones, generating demand for robust, high-pressure manifolds suitable for challenging desert and offshore conditions. Latin America, particularly Brazil and Mexico, demonstrates solid growth driven by resource development and automotive manufacturing. However, market penetration in these regions often requires manufacturers to address local supply chain challenges and competitive pricing pressures, necessitating a balance between technological advancement and cost-effectiveness in their product offerings.

- Asia Pacific (APAC): Highest growth driver due to infrastructure boom, large-scale manufacturing expansion, and robust agricultural mechanization in key economies like China and India.

- North America: Market leader in smart hydraulic technology adoption, driven by stringent quality requirements in aerospace, defense, and high-end industrial machinery.

- Europe: Center for innovation in efficiency and digital integration (Industry 4.0); strong demand for specialized, custom-built manifolds across the machine tool and automotive industries.

- Latin America (LATAM): Growth fueled by mining, construction, and agricultural sectors, demanding resilient and cost-effective standard and modular manifold systems.

- Middle East & Africa (MEA): Emerging growth market primarily supported by oil & gas infrastructure development and large-scale public works projects requiring heavy machinery.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydraulic Manifolds Market.- Bosch Rexroth

- Parker Hannifin

- Eaton

- Danfoss

- Continental Hydraulics

- Hydac

- Sun Hydraulics (Helios Technologies)

- Bucher Hydraulics

- HAWE Hydraulik

- Moog

- Vickers (Eaton)

- Oilgear

- Fluid Power Systems

- Doering Company

- Tobul Accumulator

- Delta Power Company

- Walvoil

- Casappa

- Poclain Hydraulics

- Marzocchi Pumps

Frequently Asked Questions

Analyze common user questions about the Hydraulic Manifolds market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a hydraulic manifold in a fluid power system?

The primary function of a hydraulic manifold is to centralize and regulate the flow of pressurized hydraulic fluid throughout a system. It serves as a unified block that integrates multiple hydraulic components, such as valves and actuators, connecting them via precisely drilled internal passages. This consolidation eliminates the need for extensive external plumbing and fittings, leading to a more compact, leak-resistant, and efficient hydraulic circuit design, essential for precise control and system reliability.

How does the choice of material (e.g., Cast Iron vs. Aluminum) affect manifold performance and application?

Material choice significantly influences the manifold's operating characteristics and suitable applications. Cast Iron is generally preferred for high-pressure, high-rigidity industrial applications due to its superior strength and lower cost for sheer material volume. Conversely, Aluminum manifolds are lighter and offer better heat dissipation and corrosion resistance, making them ideal for mobile machinery (e.g., agricultural and construction vehicles) and aerospace applications where weight reduction is a critical design requirement for fuel efficiency and mobility.

What advantages does Additive Manufacturing (3D Printing) offer to the Hydraulic Manifolds Market?

Additive Manufacturing (AM) offers several crucial advantages, primarily enabling design complexity and component consolidation. AM allows engineers to create highly optimized internal flow paths that reduce turbulence and pressure drop, leading to enhanced energy efficiency. It also facilitates the rapid prototyping and production of custom, single-block manifolds that integrate multiple functions, reducing system size, weight, and assembly time, thereby accelerating time-to-market for specialized hydraulic solutions.

Which end-user industry holds the largest market share for hydraulic manifolds globally?

The Construction Industry currently holds the largest market share for hydraulic manifolds. This dominance is driven by the consistent global demand for heavy earth-moving equipment, such as excavators, loaders, and cranes, all of which rely heavily on complex, robust hydraulic systems for precise and powerful motion control. The increasing scale of global infrastructure and mining projects ensures sustained high volume demand from this critical end-user segment.

What is the difference between Monoblock and Modular hydraulic manifolds in terms of installation flexibility?

Monoblock manifolds are designed as single, custom-machined blocks offering maximum compactness and rigidity but limited flexibility once manufactured. They are best for fixed, non-adjustable circuits. Modular manifolds, conversely, consist of interconnected sectional blocks (often using sandwich plates), offering superior installation flexibility. Users can easily add, remove, or modify circuit elements by stacking additional valve plates, making them ideal for systems requiring future scalability, customization, or simpler maintenance procedures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Hydraulic Manifolds Market Size Report By Type (Mono-Block Manifolds, Modular Manifold Blocks), By Application (Heavy Construction Machines, Off-highway Equipment, Machine Tool, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Hydraulic Manifolds Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Mono-Block Manifolds, Modular Manifold Blocks), By Application (Heavy Construction Machines, Off-highway Equipment, Machine Tool, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager