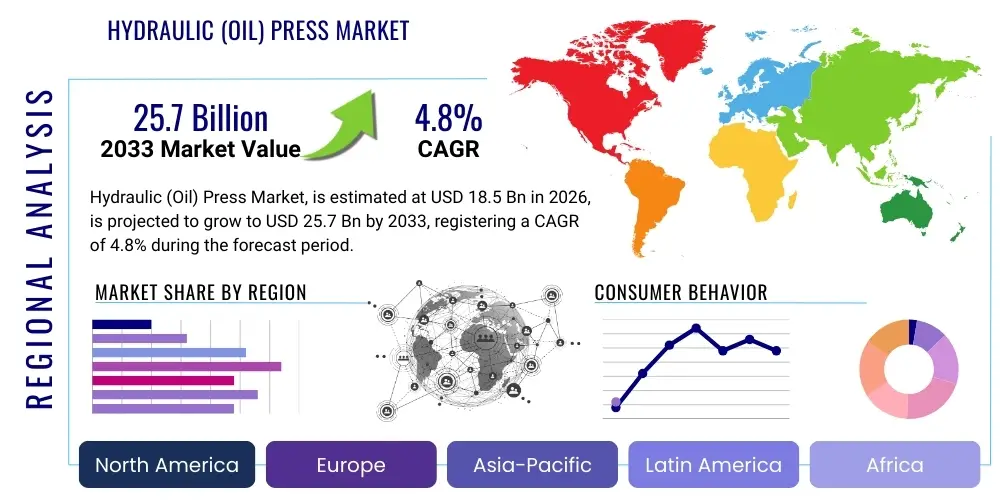

Hydraulic (Oil) Press Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436898 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Hydraulic (Oil) Press Market Size

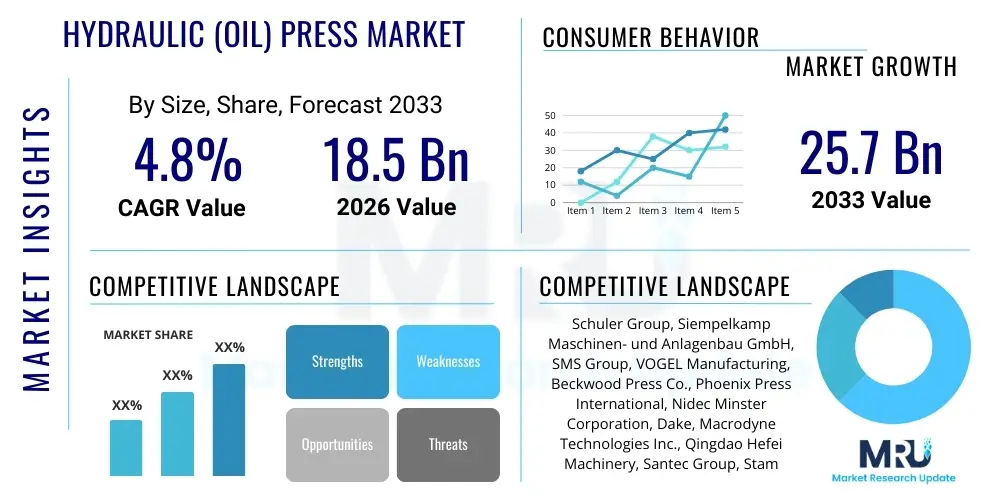

The Hydraulic (Oil) Press Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $18.5 Billion in 2026 and is projected to reach $25.7 Billion by the end of the forecast period in 2033.

Hydraulic (Oil) Press Market introduction

The Hydraulic (Oil) Press Market encompasses the manufacturing, distribution, and utilization of machinery that employs hydraulic fluid power to generate compressive force. These systems operate based on Pascal's principle, utilizing an incompressible fluid—typically oil—to transfer force from a small cylinder to a larger cylinder, thereby magnifying the input force significantly. Hydraulic presses are foundational equipment across heavy industries due to their ability to deliver massive force over precise distances, ensuring high repeatability and control during forming, stamping, forging, and molding processes. The inherent versatility of hydraulic presses allows them to handle a wide range of materials, including various metals, composites, plastics, and powders, making them indispensable in modern manufacturing supply chains.

Product descriptions within this market vary significantly based on configuration and capacity, ranging from C-frame and H-frame (four-column) presses to highly specialized servo-hydraulic and deep drawing presses. Major applications span critical sectors such as automotive manufacturing for body panel stamping and parts assembly, aerospace for high-precision forming of complex alloys, and the general machinery sector for bending and blanking operations. Furthermore, the electronics and consumer goods sectors utilize smaller, high-speed hydraulic presses for component assembly and precision cutting. These machines are engineered for robustness, precision, and longevity, often incorporating advanced controls and automation features to integrate seamlessly into Industry 4.0 environments, thereby optimizing production efficiency and minimizing material waste.

Key benefits driving market adoption include the ability to achieve full tonnage throughout the entire stroke, offering superior flexibility compared to mechanical presses; their inherent overload protection capabilities; and the relative ease of maintenance and variable speed control. Driving factors for market growth are strongly linked to the expansion of global infrastructure projects, the accelerating demand for light-weighting components in the automotive and aerospace industries, and technological advancements focusing on energy efficiency and smart hydraulic systems. The integration of sensors and predictive maintenance capabilities is further enhancing the appeal and reliability of modern hydraulic press solutions across demanding manufacturing environments.

Hydraulic (Oil) Press Market Executive Summary

The global Hydraulic (Oil) Press Market demonstrates robust expansion, primarily driven by the escalating demand for high-precision metal forming and material processing equipment across industrialized and rapidly developing economies. Business trends indicate a pronounced shift towards customized, heavy-duty hydraulic presses capable of handling high-strength, low-alloy (HSLA) steels and advanced composite materials, crucial for meeting stringent regulatory standards in transportation and infrastructure. Manufacturers are heavily investing in research and development to integrate sophisticated control systems, such as proportional valves and servo-drives, optimizing energy consumption and improving operational accuracy, thereby enhancing the competitive landscape and fostering technological differentiation among key industry players globally. Strategic collaborations focusing on localized manufacturing and service provision are becoming pivotal to capturing market share efficiently.

Regional trends highlight Asia Pacific (APAC) as the dominant and fastest-growing region, fueled by massive investments in automotive manufacturing, electronics assembly, and general industrial expansion, particularly in China, India, and Southeast Asian nations. North America and Europe maintain stable growth, characterized by strong demand for specialized, high-tonnage presses used in aerospace and defense sectors, along emphasizing the adoption of advanced automation solutions to counter high labor costs and maintain high-quality production standards. The Middle East and Africa (MEA) region, while smaller, presents emerging opportunities tied to infrastructure development and localized heavy equipment production, necessitating robust and reliable hydraulic machinery. Economic stability and governmental policies supporting manufacturing capacity expansion are critical determinants of regional market performance.

Segmentation trends confirm that the C-Frame and H-Frame (Four Column) press types continue to hold the largest market share due to their widespread applicability and structural rigidity. However, the fastest growth is observed in the segment encompassing specialized deep drawing and specialized forming presses, driven by the complexity of modern industrial designs requiring multi-stage processes. Application-wise, the automotive sector remains the primary end-user, though the demand from the electrical and electronics sector for precision stamping is rapidly increasing. Technology segmentation showcases a growing preference for advanced servo-hydraulic systems over conventional pure hydraulic systems, reflecting the industry's focus on achieving the ideal balance between high force capacity and precise, energy-efficient operation.

AI Impact Analysis on Hydraulic (Oil) Press Market

User queries regarding the impact of Artificial Intelligence (AI) on the Hydraulic (Oil) Press Market primarily revolve around operational efficiency, predictive maintenance capabilities, and the integration of smart manufacturing protocols. Common concerns focus on whether AI can significantly reduce downtime, optimize press parameters automatically for different materials, and ensure quality control in complex stamping operations. Users also seek information on the economic feasibility of retrofitting existing machinery with AI monitoring systems and the security implications of connecting industrial assets to networked AI platforms. The central theme emerging from user questions is the expectation that AI should transform the traditional, force-intensive domain of hydraulic pressing into a highly automated, data-driven, and proactive manufacturing process, minimizing human intervention and maximizing throughput and resource utilization.

The application of AI algorithms, particularly machine learning (ML), is revolutionizing how hydraulic presses are managed and operated. AI enables real-time monitoring of critical parameters such as pressure, temperature, vibration, and ram speed. By analyzing vast datasets generated during production cycles, ML models can detect subtle anomalies that precursors to equipment failure, thereby shifting maintenance strategies from reactive or scheduled to highly accurate predictive maintenance. This proactive approach dramatically reduces unexpected downtime, optimizes spare parts inventory management, and extends the operational life of expensive components like hydraulic pumps and seals. Furthermore, AI assists in process optimization, where algorithms automatically adjust parameters—suchasing the pressing profile or holding time—to ensure consistent product quality despite variations in raw material properties or environmental conditions, particularly critical in deep drawing applications.

- AI enables predictive maintenance, drastically reducing unscheduled downtime and optimizing service intervals based on component wear patterns.

- Machine Learning algorithms facilitate real-time parameter optimization, leading to improved stamping accuracy and consistent part quality across production batches.

- Integration of Computer Vision (CV) systems with AI for automated quality inspection of formed parts, identifying defects faster than manual inspection.

- AI-driven energy management systems analyze operational cycles to minimize pump runtime and pressure losses, resulting in significant energy savings.

- Enhanced process simulation and digital twin creation using AI, allowing for safer and more efficient virtual prototyping of complex press operations.

DRO & Impact Forces Of Hydraulic (Oil) Press Market

The Hydraulic (Oil) Press Market is influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape the competitive landscape and strategic direction. Key drivers include the robust growth of the global automotive industry, particularly the transition towards electric vehicles (EVs) necessitating specialized stamping and forming for lighter, complex battery casings and body components. Restraints primarily involve the high initial capital investment required for high-tonnage hydraulic presses, coupled with the rising operational complexity and the need for specialized training to manage advanced servo-hydraulic systems. Opportunities lie significantly in developing smarter, energy-efficient presses compatible with Industry 4.0 standards and expanding application segments such as powder metallurgy and composite material processing, offering high growth potential in niche industrial markets.

The Impact Forces analysis reveals high bargaining power from suppliers, particularly those providing specialized high-performance hydraulic components like pumps, valves, and control electronics, which are critical for the reliability and precision of modern presses. Buyer power is moderate to high, as large automotive and aerospace manufacturers possess significant leverage due to the high volume of procurement and strict specifications they impose. The threat of new entrants is considered low to moderate, given the high barrier to entry associated with required capital expenditure, technical expertise, and established supply chain relationships. However, the threat of substitutes, primarily mechanical and servo-mechanical presses, remains substantial, as these alternatives offer comparable performance in certain applications, particularly high-speed, shallow-draw operations, compelling hydraulic press manufacturers to innovate continuously on precision and versatility.

The market’s dynamism is further shaped by macro-economic factors, including fluctuating raw material prices (especially steel and specialized alloys), and stringent environmental regulations demanding lower noise pollution and better fluid management in manufacturing environments. These factors necessitate continuous innovation in design, focusing on reducing machine footprints, enhancing energy recovery mechanisms, and optimizing the use of less hazardous hydraulic fluids. Successful market navigation requires a proactive strategy that addresses environmental compliance while leveraging technological advancements in automation and digitalization to maintain a competitive edge and appeal to sophisticated end-users globally.

Segmentation Analysis

The Hydraulic (Oil) Press Market is comprehensively segmented based on Type, Tonnage Capacity, Application, and End-Use Industry, providing a granular view of market dynamics and identifying specific growth pockets. Segmentation by Type differentiates between standard H-Frame (Four Column), C-Frame (Gap Frame), Straight Side, and specialized presses like Deep Drawing and Trimming presses, each catering to distinct geometric and force requirements. The Tonnage Capacity segmentation is crucial, separating light-duty presses (under 100 tons) used predominantly in small workshops and assembly lines from heavy-duty presses (over 500 tons) essential for forging, automotive stamping, and large-scale structural component production. This segmentation reflects the varied operational needs and capital investment capacities across the industrial spectrum, influencing purchasing decisions.

Furthermore, segmentation by Application specifies the primary usage area, including Forging, Stamping, Deep Drawing, Assembly, and Powder Compacting, highlighting the diversity of processes achievable with hydraulic power. The End-Use Industry segmentation is vital for strategic market mapping, covering Automotive, Aerospace & Defense, Electrical & Electronics, General Machinery, and Others (including Construction, Appliances, and Shipbuilding). The automotive industry consistently dominates this segment due to the cyclical demand for new vehicle models and the complex forming requirements for modern chassis and body components. The increasing sophistication in material science and manufacturing processes dictates that manufacturers offer highly customized solutions tailored to the specific volumetric and pressure requirements of each segment, thereby driving differentiated product portfolios.

- By Type:

- C-Frame Press (Gap Frame Press)

- H-Frame Press (Four Column Press)

- Straight Side Press

- Deep Drawing Press

- Forging Press

- Trimming/Blanking Press

- Transfer Press

- By Tonnage Capacity:

- Below 100 Tons

- 100 to 500 Tons

- 500 to 1000 Tons

- Above 1000 Tons

- By Application:

- Metal Forming (Stamping and Bending)

- Forging and Hot Pressing

- Assembly and Bonding

- Deep Drawing and Extrusion

- Powder Compacting and Sizing

- By End-Use Industry:

- Automotive

- Aerospace and Defense

- Electrical and Electronics

- General Machinery and Equipment

- Construction

- Consumer Goods

- Others (Shipbuilding, Appliances)

Value Chain Analysis For Hydraulic (Oil) Press Market

The value chain for the Hydraulic (Oil) Press Market begins with upstream activities focused on the procurement of critical raw materials and highly specialized components. Upstream analysis involves sourcing high-grade steel and specialized alloys for the main structure (frame, columns, bolster plate) to ensure structural rigidity and longevity, which is paramount given the extreme forces involved. Crucially, the supply of hydraulic components—pumps, valves (especially proportional and servo valves), cylinders, seals, and filters—forms a critical dependency. Suppliers of these components often possess highly specialized technical expertise, dictating quality and performance standards. Efficient inventory management and securing reliable long-term supply contracts with specialized component manufacturers are vital for press builders to maintain cost competitiveness and delivery timelines.

The midstream stage involves the core manufacturing processes: design, machining, fabrication, assembly, and integration of control systems. Manufacturers focus on precision engineering, adhering to strict tolerances during the machining of cylinder bores and ram guides to minimize leakage and maximize accuracy. The integration of advanced control systems, including PLCs and HMI interfaces, is essential for modern presses, ensuring programmability and operational feedback. Distribution channels are varied, incorporating direct sales models for high-tonnage, customized presses to major industrial clients (e.g., automotive OEMs) and indirect channels utilizing authorized dealers and distributors for standard, lower-tonnage machines. The effectiveness of the indirect network is crucial for penetrating regional markets and providing localized after-sales support and spare parts supply promptly.

Downstream analysis focuses on installation, commissioning, after-sales service, and maintenance. Given the complexity and capital cost of hydraulic presses, continuous service support, including preventative maintenance contracts and the rapid availability of specialized repair technicians, is a significant value addition and a competitive differentiator. Direct engagement allows manufacturers to gather crucial operational data for iterative design improvements, while indirect channels rely on well-trained local partners to maintain customer satisfaction. The long lifespan of hydraulic presses means that the secondary market for parts and refurbishment services also constitutes a significant segment of the downstream value chain, contributing substantially to overall market value over the equipment's lifetime.

Hydraulic (Oil) Press Market Potential Customers

Potential customers for the Hydraulic (Oil) Press Market are predominantly high-volume manufacturing entities and specialized fabrication workshops requiring substantial, controlled force application for material modification. The primary end-users are concentrated in the automotive sector, including Original Equipment Manufacturers (OEMs) and Tier 1 suppliers, who utilize large hydraulic presses for stamping complex body panels, chassis components, and increasingly, high-strength battery enclosures for electric vehicles. These buyers prioritize high tonnage capacity, deep drawing capabilities, and the integration of automation for continuous, high-speed production cycles, making precision and reliability non-negotiable purchasing criteria.

The aerospace and defense industries represent a highly lucrative customer segment, demanding specialized hot and cold forming presses capable of handling exotic materials like titanium, Inconel, and various composite matrices used in structural aircraft components and engine parts. These customers require extremely high precision, stringent quality certifications, and often prefer customized press designs (such as hydroforming presses) optimized for low-volume, high-value component production. The purchasing cycle in these sectors is generally longer, focusing heavily on proven performance history and compliance with international regulatory standards, emphasizing the need for robust quality assurance from press manufacturers.

Other significant customer segments include electronics manufacturers, particularly for fine blanking and small component assembly; companies involved in powder metallurgy for compacting metal powders into intricate shapes; and general fabrication shops requiring versatile machinery for bending, punching, and assembly of industrial equipment. These diverse end-users emphasize different criteria: electronics firms look for high-speed, high-precision small presses, while general machinery manufacturers seek versatility and ease of use. Therefore, a successful strategy involves tailoring marketing and product specifications precisely to the tonnage and control requirements of these heterogeneous buying groups.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $18.5 Billion |

| Market Forecast in 2033 | $25.7 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schuler Group, Siempelkamp Maschinen- und Anlagenbau GmbH, SMS Group, VOGEL Manufacturing, Beckwood Press Co., Phoenix Press International, Nidec Minster Corporation, Dake, Macrodyne Technologies Inc., Qingdao Hefei Machinery, Santec Group, Stamtec, Komatsu Ltd., Pama S.P.A., Fagor Arrasate, Mitsubishi Heavy Industries, Hare Press, Enerpac Tool Group, RK Machinery, Gasbarre Products Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydraulic (Oil) Press Market Key Technology Landscape

The technology landscape of the Hydraulic (Oil) Press Market is rapidly evolving, driven by the push for energy efficiency, enhanced precision, and integration into smart factory ecosystems. The most significant technological advancement is the widespread adoption of Servo-Hydraulic Systems. Unlike conventional hydraulic presses that use constant-speed pumps and throttle valves to regulate flow, servo-hydraulic systems utilize variable-speed pumps driven by servo motors. This allows the press to use only the necessary amount of power required for each stage of the stroke (fast approach, pressing, and return), drastically reducing idle energy consumption and heat generation. Servo-hydraulics provide superior control over ram speed and position throughout the entire cycle, making them ideal for complex deep drawing and intricate forming applications where precision is paramount.

Another crucial technological development involves advanced control and monitoring systems, leveraging high-resolution sensors and PLC technology. Modern hydraulic presses are equipped with sophisticated pressure transducers, temperature probes, and position encoders that feed real-time data into integrated human-machine interfaces (HMIs). This integration enables advanced process control features such as force-stroke curve monitoring, automatic tonnage control, and multi-point cushioning systems, which are essential for achieving consistent quality when working with variable material thicknesses or complex geometries. Furthermore, the incorporation of IoT (Internet of Things) capabilities allows these machines to communicate production status and diagnostic data to centralized manufacturing execution systems (MES), facilitating remote monitoring and contributing to overall operational transparency.

Material handling and tooling technologies also represent a vital part of the landscape. Automated quick-die change (QDC) systems are increasingly being integrated, significantly reducing setup times and improving overall equipment effectiveness (OEE), particularly in high-mix, low-volume production environments. Moreover, the hydraulic press industry is investing in specialized hydraulic fluid formulations that offer improved thermal stability, reduced wear, and enhanced environmental compatibility, addressing both performance requirements and environmental regulatory pressures. The combination of efficient power units, precision controls, and smart connectivity defines the current state-of-the-art in hydraulic press technology, moving the market towards higher levels of automation and sustainability.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand patterns and technological adoption rates within the Hydraulic (Oil) Press Market. Asia Pacific (APAC) stands out as the global powerhouse, accounting for the largest market share and exhibiting the highest growth trajectory. This dominance is primarily attributable to extensive industrialization, massive government spending on infrastructure, and the region's status as the global hub for automotive and electronics manufacturing. Countries such as China, which is undergoing massive industrial modernization, and India, with its rapidly expanding domestic manufacturing capabilities (under initiatives like 'Make in India'), drive significant demand for both standard and high-tonnage forming machinery. The region also benefits from a competitive manufacturing cost structure, attracting global press manufacturers to establish local production and service facilities.

Europe represents a mature yet highly specialized market, characterized by stringent quality standards and a strong focus on advanced, high-precision applications, particularly in the premium automotive, aerospace, and specialized machinery sectors (e.g., tooling and defense). Western European countries, including Germany, Italy, and France, prioritize the adoption of high-efficiency servo-hydraulic presses and automated systems to maintain competitiveness against lower-cost regions. The market growth here is steady, driven by technological upgrades (replacing older mechanical presses) and the push towards sustainable manufacturing practices requiring energy-optimized equipment.

North America, led by the United States, exhibits steady demand driven primarily by the aerospace & defense sector and the revitalization of the domestic automotive industry, heavily focusing on electric vehicle (EV) production. The region shows a high propensity for adopting cutting-edge technologies, including AI integration for predictive maintenance and highly customized press solutions. Latin America and the Middle East & Africa (MEA) are emerging markets. Latin America’s growth is cyclical, tied to commodity prices and automotive investment in countries like Brazil and Mexico. MEA’s demand, particularly in Saudi Arabia and the UAE, is linked to diversification away from oil, focusing on local heavy industry and infrastructure projects, creating niche demand for robust, reliable hydraulic forming equipment suited for demanding operating conditions.

- Asia Pacific (APAC): Dominant market share; highest CAGR driven by automotive, electronics manufacturing, and infrastructure growth in China, India, and ASEAN nations. Focus on volume manufacturing and modernization.

- North America: Mature market; strong demand from Aerospace & Defense and high-precision EV component manufacturing; high adoption rate of smart technologies and automation.

- Europe: Stable, high-value market; emphasis on servo-hydraulic technology, sustainability, and high-precision forming for premium automotive and specialized machinery industries (Germany, Italy).

- Latin America (LATAM): Emerging market, growth driven by automotive assembly and cyclical industrial investment in Brazil and Mexico; focus on cost-effective, durable machinery.

- Middle East & Africa (MEA): Growing demand linked to industrial diversification projects, mining, and localized heavy equipment production, requiring reliable and robust machinery.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydraulic (Oil) Press Market.- Schuler Group

- Siempelkamp Maschinen- und Anlagenbau GmbH

- SMS Group

- VOGEL Manufacturing

- Beckwood Press Co.

- Phoenix Press International

- Nidec Minster Corporation

- Dake

- Macrodyne Technologies Inc.

- Qingdao Hefei Machinery

- Santec Group

- Stamtec

- Komatsu Ltd.

- Pama S.P.A.

- Fagor Arrasate

- Mitsubishi Heavy Industries

- Hare Press

- Enerpac Tool Group

- RK Machinery

- Gasbarre Products Inc.

Frequently Asked Questions

Analyze common user questions about the Hydraulic (Oil) Press market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between hydraulic presses and mechanical presses?

Hydraulic presses utilize fluid pressure to generate force, allowing for full tonnage capacity throughout the entire stroke and offering superior control over ram speed and pressure profile, making them ideal for deep drawing and complex forming. Mechanical presses use a flywheel and crank mechanism, achieving peak force only at the bottom of the stroke, and are generally preferred for high-speed, shallow stamping operations where maximum tonnage consistency is not required throughout the full travel.

How is the growth of Electric Vehicles (EVs) influencing the Hydraulic Press Market?

The EV transition drives demand for specialized hydraulic presses, particularly large-tonnage models and hydroforming equipment, required for forming lighter, high-strength materials (like aluminum and advanced steels) used in battery casings, structural components, and chassis frames. These applications necessitate the precise force control and deep drawing capabilities inherent in modern hydraulic systems to ensure component integrity and lightweight design compliance.

What are servo-hydraulic presses and why are they considered a key technological trend?

Servo-hydraulic presses integrate a variable-speed servo motor to drive the hydraulic pump, allowing the system to modulate flow and pressure instantly and precisely. This technology is a key trend because it significantly improves energy efficiency (consuming less power during idle and non-pressing segments), offers enhanced process control (ram speed and position), and reduces heat generation, making them essential for high-precision and sustainable manufacturing operations.

Which end-use industry is the largest consumer of hydraulic presses globally?

The automotive industry is the largest end-user segment for hydraulic presses globally. This sector relies heavily on hydraulic presses for large-scale metal forming, stamping of body panels, and assembly operations, particularly as manufacturers increasingly adopt complex processes for lightweight vehicle component production and the specialized forming required for EV battery enclosures.

What is the role of Industry 4.0 in modern hydraulic press operations?

Industry 4.0 integrates hydraulic presses through advanced IoT sensors, real-time data analytics, and connectivity (MES/ERP systems). This integration facilitates crucial capabilities such as AI-driven predictive maintenance, remote diagnostics, automated process optimization, and digital twin simulations, fundamentally improving operational efficiency, reducing downtime, and ensuring consistent output quality across the manufacturing plant.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager