Hydrocyclones Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432996 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Hydrocyclones Market Size

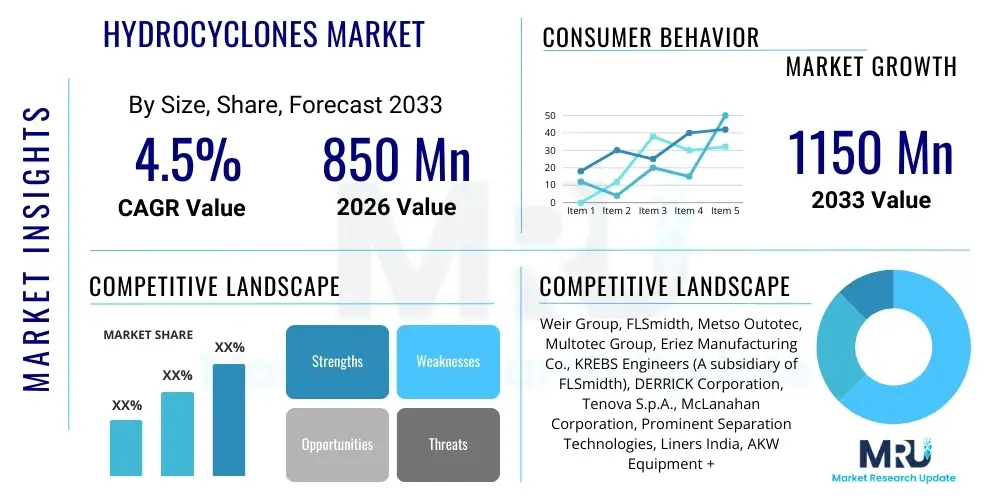

The Hydrocyclones Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at $850 million in 2026 and is projected to reach $1150 million by the end of the forecast period in 2033.

Hydrocyclones Market introduction

The Hydrocyclones Market encompasses the production, distribution, and utilization of separation equipment designed to classify, thicken, or separate solid particles from liquid slurries using centrifugal forces generated by tangential injection. Hydrocyclones are static devices known for their high throughput capacity, relatively low capital cost, and minimal moving parts, making them highly desirable in abrasive and demanding industrial environments. These devices operate by introducing the fluid mixture at high velocity into a conical vessel, forcing the denser solids outward toward the wall and down to the underflow, while the lighter fluid moves inward and exits via the overflow (vortex finder). Major applications span critical sectors, including mineral processing (classification and grinding circuits), chemical manufacturing, municipal and industrial wastewater treatment (dewatering and sludge thickening), and petroleum refining (catalyst recovery). The principal benefits derived from employing hydrocyclones include enhanced separation efficiency, significant reduction in footprint compared to traditional settling tanks, and robust operational resilience. The market expansion is primarily driven by continuous global infrastructure development, increasing demand for processed minerals, stricter environmental regulations necessitating advanced wastewater treatment, and the persistent industrial focus on improving operational efficiency and resource recovery.

Hydrocyclones Market Executive Summary

The global Hydrocyclones Market is characterized by robust technological advancements focusing on performance optimization and material science integration, largely driven by the increasing complexity of mined ores and the need for higher purity end-products. Current business trends indicate a strong shift towards modular and cluster hydrocyclone configurations, particularly in high-volume applications like iron ore, copper, and gold mining, facilitating scalability and reducing downtime. Geographically, the Asia Pacific region dominates market demand, fueled by large-scale mining activities, rapid industrialization in China and India, and significant infrastructure investments. Regional trends highlight growing adoption in developing economies seeking cost-effective separation technologies. Segment-wise, the mining and mineral processing application segment remains the largest revenue contributor, although the wastewater treatment sector is exhibiting the fastest growth due to stringent global environmental mandates regarding effluent quality and resource recovery. Furthermore, there is an accelerating trend in the implementation of computational fluid dynamics (CFD) modeling during the design phase to optimize flow patterns and separation performance, thereby extending the service life of wear components, which is a critical operational parameter for end-users.

AI Impact Analysis on Hydrocyclones Market

Common user questions regarding AI's impact on hydrocyclones center around automating operational control, predicting wear patterns in liners, and optimizing the critical parameters affecting separation efficiency, such as feed pressure and particle size distribution (PSD). Users are concerned with how AI integration can move beyond simple sensor monitoring to truly prescriptive maintenance and adaptive operational adjustments, especially in variable feed conditions characteristic of mineral processing plants. The key themes revolve around expectations for reduced energy consumption, minimized operator intervention, and achieving a consistently narrow particle size cut point. There is significant interest in using machine learning algorithms to correlate vibrational data, pressure differentials, and slurry properties in real-time to predict imminent failure of rubber or ceramic liners, shifting the maintenance paradigm from reactive to predictive. Integrating AI involves utilizing digital twins of hydrocyclone batteries, trained on historical data, to simulate various operating scenarios and recommend optimal adjustments to maximize throughput while maintaining the desired product quality. This level of optimization is crucial for high-value operations.

- AI-driven predictive maintenance forecasts liner and component wear based on sensor data, drastically reducing unplanned downtime.

- Machine learning algorithms optimize operational parameters (feed pressure, apex diameter) in real-time to maintain target classification efficiency despite fluctuating feed characteristics.

- Implementation of digital twins allows for simulation and remote tuning of hydrocyclone circuits, enhancing operational stability and energy efficiency.

- Automated control systems leverage AI to achieve tighter control over the cut point (d50), improving product quality and yield in mineral processing.

- Data analytics driven by AI identifies subtle correlations between slurry rheology, temperature, and separation performance for continuous process improvement.

DRO & Impact Forces Of Hydrocyclones Market

The Hydrocyclones Market expansion is significantly propelled by the increasing demand for efficient fine particle separation across various heavy industries, coupled with escalating global mining activities driven by the transition towards electric vehicles and renewable energy technologies requiring large quantities of base and critical metals. However, market growth faces restraints primarily stemming from the abrasive nature of slurries, leading to rapid wear of internal components, particularly liners and apexes, which necessitates frequent and costly maintenance. Furthermore, the operational complexity associated with achieving precise cut points for specific applications requires skilled labor and detailed process engineering, posing a barrier in developing regions. Opportunities lie in the development of advanced material sciences, specifically high-performance ceramics and specialized polymers, which offer superior abrasion and corrosion resistance, substantially extending component lifespan and reducing total cost of ownership. The impact forces driving market adoption include stringent governmental regulations concerning water conservation and efficient residue disposal, compelling industries to adopt highly efficient dewatering and classification technologies like hydrocyclones to recover process water and minimize environmental footprint. The increasing capital expenditure in both conventional mining and niche applications like lithium extraction further reinforces the positive market trajectory, emphasizing high-capacity, durable separation solutions.

Segmentation Analysis

The Hydrocyclones Market is rigorously segmented based on material, type, application, and end-use industry, reflecting the device's versatility across industrial environments. Segmentation by material is crucial as it directly impacts durability and cost, differentiating between rubber-lined units favored for high abrasion resistance and ceramic or polyurethane linings offering superior chemical resistance and lifespan in specific scenarios. Segmentation by type typically divides the market into standard hydrocyclones, dense medium cyclones (DMC), and specialized multi-stage or parallel cyclone clusters, each designed for distinct separation requirements. Application segmentation covers crucial industrial processes such as classification, dewatering, thickening, and scrubbing, reflecting the diverse functional roles these separators play. The primary end-use industries—Mining & Mineral Processing, Chemical, Oil & Gas, and Wastewater Treatment—represent the core demand drivers, each requiring unique design specifications tailored to their specific slurry characteristics and process goals.

- By Type: Standard Hydrocyclones, Dense Medium Cyclones (DMC), Multi-Stage Hydrocyclone Systems.

- By Material: Rubber Lined (Natural Rubber, Synthetic Rubber), Ceramic Lined (Alumina, Silicon Carbide), Polyurethane Lined, Metal Alloys.

- By Application: Classification and Sizing, Thickening and Dewatering, Separation and Concentration, Desanding and Desilting.

- By End-Use Industry: Mining and Mineral Processing, Chemical Processing, Oil and Gas (Drilling Mud and Sand Removal), Pulp and Paper, Municipal and Industrial Wastewater Treatment.

Value Chain Analysis For Hydrocyclones Market

The value chain for the Hydrocyclones Market begins with upstream activities focused on sourcing high-quality raw materials, primarily wear-resistant components such as specialized steel alloys for the shell structure and advanced materials like specialized natural rubber, high-density polyethylene (HDPE), and technical ceramics (e.g., silicon carbide or high-alumina) for internal linings. The complexity of the manufacturing phase involves precision casting and fabrication of the metal body, followed by expert lining application to ensure dimensional accuracy and resistance to abrasion and corrosion, which are critical performance indicators. Downstream analysis focuses heavily on the distribution and integration of the final product. Due to the high-capital nature and complexity of installation, direct sales and service provided by the original equipment manufacturer (OEM) often dominate the market, especially for large mining projects requiring customized hydrocyclone batteries and comprehensive after-sales support.

Distribution channels are categorized into direct and indirect routes. Direct distribution involves OEMs selling and servicing large, custom-engineered systems directly to major end-users (e.g., large mining corporations or national water utilities). This channel allows for maximum control over system design, installation, and maintenance contracts, fostering long-term relationships based on performance guarantees and technical expertise. Indirect channels include local distributors, agents, and system integrators who specialize in providing smaller, standard hydrocyclone units or components for localized chemical plants, smaller municipal treatment facilities, or offering integration services as part of a larger processing plant solution. System integrators play a vital role, especially in retrofit projects, providing expertise in matching the optimal hydrocyclone design parameters (vortex finder, apex size, feed pressure) to existing plant configurations and optimizing overall circuit efficiency.

The efficiency of the value chain is increasingly being enhanced by digital technologies. OEMs utilize sophisticated supply chain management tools to track material procurement and manage inventory of high-wear parts, minimizing lead times for critical replacements. The strong focus on aftermarket services, including performance monitoring, maintenance contracts, and rapid supply of high-abrasion components, constitutes a significant portion of the total market revenue and strengthens the competitive position of key manufacturers, effectively locking in customers through long-term service agreements and proprietary parts supply.

Hydrocyclones Market Potential Customers

The primary customers for hydrocyclones are large industrial entities that rely on continuous, high-volume solid-liquid separation processes where particle classification and thickening are essential steps for product quality, process water recovery, or waste management. The dominant end-users are concentrated within the Mining and Mineral Processing industry, where hydrocyclones form the backbone of grinding circuits, classification stages, and tailings dewatering operations for commodities like iron ore, copper, gold, bauxite, and potash. These customers require robust, high-throughput systems capable of handling extremely abrasive and corrosive slurries under intense operational stress.

Another significant segment comprises the Oil and Gas industry, particularly in upstream drilling operations where hydrocyclones are utilized for effective desanding and desilting of drilling fluids and produced water. Ensuring the cleanliness of drilling muds and managing sand ingress into production streams are critical functions that prevent equipment damage and maintain reservoir integrity. Furthermore, the chemical processing and industrial manufacturing sectors, especially those involved in pigment production, pharmaceuticals, and catalytic material recovery, utilize hydrocyclones for precise size classification and product recovery, valuing the high efficiency and customizable cut points achievable by these devices.

The fastest growing customer base lies within the Municipal and Industrial Wastewater Treatment sector. Public utilities and heavy industrial facilities (such as Pulp and Paper mills or power generation plants) employ hydrocyclones for sludge thickening, primary clarification, and grit removal. These applications are driven by increasingly strict environmental discharge regulations and the economic pressure to recover and reuse water, positioning hydrocyclones as indispensable tools for sustainable water resource management. Purchasing decisions in this sector are often influenced by total lifecycle cost, energy efficiency, and compliance with effluent quality standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $850 million |

| Market Forecast in 2033 | $1150 million |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Weir Group, FLSmidth, Metso Outotec, Multotec Group, Eriez Manufacturing Co., KREBS Engineers (A subsidiary of FLSmidth), DERRICK Corporation, Tenova S.p.A., McLanahan Corporation, Prominent Separation Technologies, Liners India, AKW Equipment + Process Design, Mineral Technologies Inc., Tega Industries Ltd., Linatex (Brand of Weir Group), Haver & Boecker Niagara, Russell Finex, Alfa Laval, Sepro Mineral Systems, MPE Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydrocyclones Market Key Technology Landscape

The technological landscape of the Hydrocyclones Market is rapidly evolving, driven primarily by the need to enhance separation efficiency, prolong operational life in highly corrosive and abrasive environments, and integrate digital controls for process optimization. A pivotal area of development involves materials science, particularly the utilization of advanced lining materials. While natural rubber remains the standard for high impact resistance, the use of specialized technical ceramics, such as high-purity alumina and reaction-bonded silicon carbide, is increasing dramatically. These ceramic linings offer significantly higher resistance to fine particle abrasion, leading to predictable wear rates and extended operational intervals, which is crucial for reducing the Total Cost of Ownership (TCO) in continuous processes like hard rock mining.

Computational Fluid Dynamics (CFD) modeling represents another core technological advancement. Manufacturers extensively utilize CFD simulations during the design phase to accurately map flow patterns, turbulence, and pressure drop within the hydrocyclone body. This sophisticated analysis allows engineers to optimize the geometry—specifically the feed chamber design, vortex finder diameter, and spigot (apex) dimensions—to achieve precise cut points (d50 separation size) and minimize localized erosion. This iterative design process has led to the development of specialized high-efficiency hydrocyclones capable of classifying ultra-fine particles below 10 micrometers, opening up new applications in high-purity material processing and tailings management.

Furthermore, the integration of smart technology, often termed 'Smart Hydrocyclones,' is reshaping market capabilities. These systems incorporate sensors (pressure transducers, flow meters, acoustic sensors) to monitor critical operating variables in real-time. This data is fed into Industrial Internet of Things (IIoT) platforms, enabling immediate detection of blockages (roping), apex wear, and feed fluctuations. This technological shift supports the adoption of automated control systems that adjust process parameters, such as dilution water addition or feed pump speed, ensuring consistent performance and maximizing operational output without constant manual calibration. Modular and cluster designs, which allow for parallel operation and easy maintenance access, also contribute significantly to the modern technological framework by providing flexible capacity solutions.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market region and exhibits the highest growth rate, primarily driven by massive infrastructure expansion and highly active mineral processing sectors in China, India, and Australia. The strong demand for base metals, coupled with increasing governmental focus on water treatment and environmental compliance in rapidly urbanizing areas, necessitates the adoption of large hydrocyclone batteries for both mining classification and municipal sludge thickening. Investments in new high-capacity mineral processing plants in countries like Indonesia and Vietnam further solidify APAC's leading position.

- North America: This region is characterized by high adoption rates of advanced, automated hydrocyclone systems, particularly within the Oil & Gas sector (desanding produced water) and high-value mining operations (e.g., gold and copper). The focus here is less on volume and more on efficiency, reliability, and low environmental impact, driving demand for premium products featuring ceramic liners and IIoT integration for predictive maintenance. Regulatory pressures regarding environmental cleanup also boost the wastewater segment.

- Europe: The European market demonstrates steady growth, concentrating on sophisticated applications in chemical processing, pharmaceuticals, and environmental engineering. Strict EU environmental directives push the development of highly efficient separation and dewatering technologies. Key market demand centers around high-quality, corrosion-resistant hydrocyclones, often integrated into complex closed-loop systems designed for maximum resource recovery and minimal waste generation, with a strong emphasis on CFD-optimized design and material longevity.

- Latin America (LATAM): This region is a vital hub due to the large-scale copper, iron ore, and lithium mining operations, particularly in Chile, Brazil, and Peru. Demand is high for robust, rubber-lined hydrocyclones capable of handling abrasive slurries in high-altitude environments. Market growth is closely tied to global commodity prices and foreign direct investment in resource extraction projects.

- Middle East and Africa (MEA): Growth in MEA is driven by the expansion of the regional mining sector (South Africa, Ghana) and investments in industrial wastewater treatment facilities and petroleum operations. While price sensitivity can be high, the need for reliable desanding technology in the oil and gas fields maintains steady demand for durable hydrocyclone solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydrocyclones Market.- Weir Group PLC

- FLSmidth & Co. A/S

- Metso Outotec Oyj

- Multotec Group

- Eriez Manufacturing Co.

- KREBS Engineers (A subsidiary of FLSmidth)

- DERRICK Corporation

- Tenova S.p.A.

- McLanahan Corporation

- Prominent Separation Technologies

- Liners India

- AKW Equipment + Process Design

- Mineral Technologies Inc. (MTi)

- Tega Industries Ltd.

- Linatex (Brand of Weir Group)

- Haver & Boecker Niagara

- Russell Finex Ltd.

- Alfa Laval AB

- Sepro Mineral Systems Corp.

- MPE Group

Frequently Asked Questions

Analyze common user questions about the Hydrocyclones market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a hydrocyclone in mineral processing?

The primary function is classification, which involves separating particles based on size and density, most commonly used in grinding circuits to return coarse material for further comminution while allowing fine material to advance for subsequent recovery processes like flotation or leaching. Hydrocyclones are essential for maximizing mill efficiency and optimizing particle size distribution (PSD).

How does the choice of lining material affect hydrocyclone performance and maintenance?

Lining material choice directly impacts the hydrocyclone's lifespan and maintenance costs. Rubber linings (e.g., natural or synthetic rubber) are standard for coarse, highly abrasive slurries due to their elasticity. In contrast, advanced ceramic linings (e.g., silicon carbide or high-alumina) offer superior resistance to fine particle abrasion and chemical attack, significantly extending operating life and reducing the frequency of component replacement.

What are the key operational parameters influencing hydrocyclone efficiency?

Key operational parameters include feed pressure, feed slurry concentration (solids percentage), and the geometry of the device, specifically the diameters of the vortex finder (overflow) and the spigot (underflow or apex). Maintaining optimal feed pressure is critical as it dictates the centrifugal force and, subsequently, the efficiency of the particle cut point (d50 separation size).

In which sector is the adoption of hydrocyclones growing fastest globally?

The adoption of hydrocyclones is currently growing fastest within the Municipal and Industrial Wastewater Treatment sector. This growth is driven by increasing regulatory scrutiny on effluent quality, the necessity for efficient sludge thickening before dewatering, and the global push toward water recovery and reuse in both municipal services and heavy industrial operations like pulp and paper mills.

What role does Computational Fluid Dynamics (CFD) modeling play in modern hydrocyclone design?

CFD modeling plays a critical role by allowing manufacturers to simulate the complex three-dimensional flow field, velocity profiles, and particle trajectories within the hydrocyclone before physical prototyping. This enables precise optimization of internal geometry to reduce turbulence, minimize energy loss, enhance classification sharpness, and accurately predict wear patterns, resulting in highly customized and efficient designs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager