Hydrogen Circulation Pump Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440664 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Hydrogen Circulation Pump Market Size

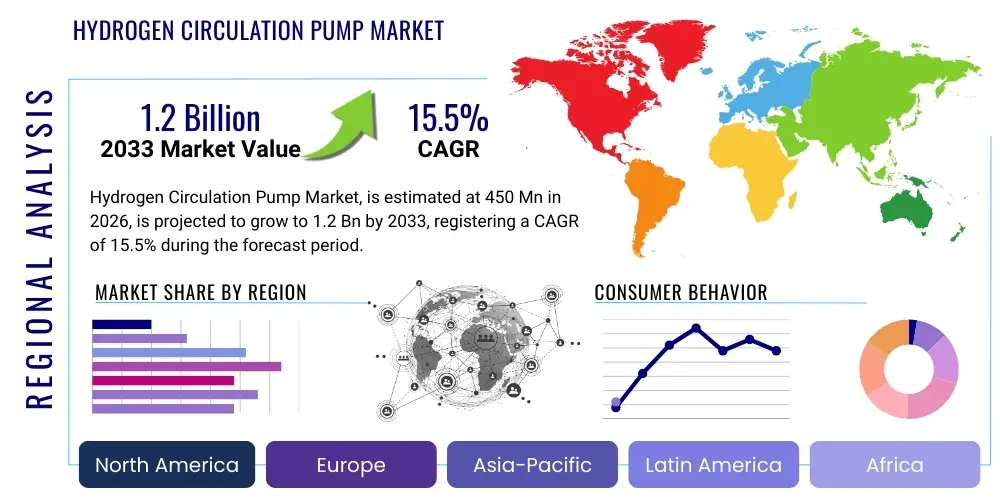

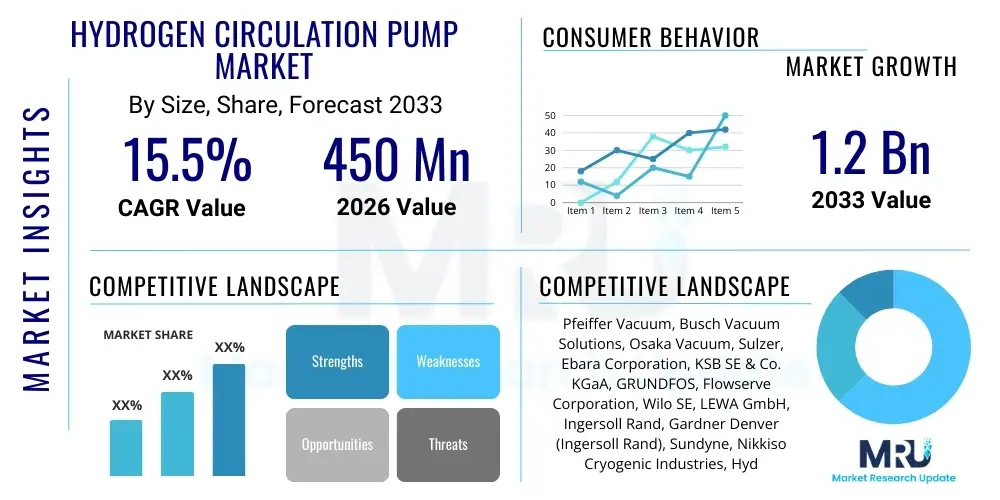

The Hydrogen Circulation Pump Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 15.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 1.2 Billion by the end of the forecast period in 2033.

Hydrogen Circulation Pump Market introduction

The Hydrogen Circulation Pump Market is experiencing robust growth, driven by the global imperative to transition towards sustainable energy sources and decarbonize various sectors, including transportation, industrial processes, and power generation. These specialized pumps are critical components in hydrogen systems, designed to safely and efficiently circulate hydrogen gas or liquid within fuel cells, hydrogen production facilities, refueling stations, and industrial applications. Their primary function is to maintain optimal hydrogen flow rates, manage pressure, and ensure thermal regulation, thereby enhancing the efficiency and longevity of hydrogen-powered technologies. The product range typically includes centrifugal, diaphragm, reciprocating, and regenerative pumps, each engineered to meet specific operational demands in terms of pressure, flow, and purity requirements. Major applications span from fuel cell electric vehicles (FCEVs) and hydrogen-powered industrial machinery to large-scale hydrogen production and storage infrastructure, including power-to-gas systems and green hydrogen electrolysis plants. The key benefits of advanced hydrogen circulation pumps include improved energy efficiency in fuel cell stacks, enhanced safety through precise gas management, reduced operational costs, and extended system lifespan due to optimized performance and minimized wear. The market's expansion is significantly propelled by several driving factors such as increasing governmental support for hydrogen economy initiatives, rapid advancements in fuel cell technology, the escalating demand for clean mobility solutions, and the growing industrial adoption of hydrogen as a feedstock and energy carrier, all contributing to a burgeoning ecosystem that relies heavily on efficient hydrogen handling components.

Hydrogen Circulation Pump Market Executive Summary

The Hydrogen Circulation Pump Market is poised for substantial growth, reflecting a global pivot towards hydrogen as a cornerstone of future energy systems. Business trends indicate a surge in partnerships and collaborations between pump manufacturers, fuel cell developers, and hydrogen infrastructure providers, aiming to create integrated solutions and accelerate market penetration. There is a strong emphasis on research and development to enhance pump efficiency, durability, and cost-effectiveness, particularly for high-pressure and high-temperature applications. Regional trends reveal North America and Europe leading in terms of policy support and initial infrastructure deployment, while Asia Pacific, particularly countries like Japan, South Korea, and China, are emerging as powerhouses in hydrogen technology manufacturing and adoption, fueled by ambitious national hydrogen strategies and significant investments in FCEVs and industrial hydrogen. The Middle East is also increasingly focusing on green hydrogen production, creating new demand centers. Segment trends highlight the automotive sector, especially FCEVs, as a primary driver for pump demand, with a growing emphasis on compact, high-performance pumps suitable for mobile applications. Concurrently, the industrial segment, encompassing chemical processes, refineries, and steel production, is demonstrating increasing demand for robust circulation pumps capable of handling large volumes of hydrogen in continuous operations. Furthermore, the burgeoning hydrogen refueling station (HRS) network and the expanding scope of power-to-gas projects are creating specialized demand for high-pressure, reliable pumps critical for efficient hydrogen compression and distribution, underscoring a diversified growth across multiple end-use sectors, each contributing uniquely to the market's upward trajectory.

AI Impact Analysis on Hydrogen Circulation Pump Market

User inquiries concerning AI's influence on the Hydrogen Circulation Pump Market frequently revolve around how artificial intelligence can enhance operational efficiency, predictive maintenance, and overall system optimization. Key themes include the potential for AI to improve pump performance and reliability, minimize downtime, and reduce energy consumption. Users are keen to understand if AI-driven diagnostics can preempt failures, optimize flow rates in real-time based on demand fluctuations, or even assist in the design of more efficient pump architectures. There is also interest in AI's role in managing complex hydrogen ecosystems, where pumps are just one component of a larger interconnected system involving production, storage, and distribution. Expectations are high that AI will lead to more autonomous and intelligent hydrogen infrastructure, ensuring safer and more cost-effective operations, directly impacting the selection, integration, and management of circulation pumps.

- AI-driven predictive maintenance: Algorithms analyze operational data from hydrogen circulation pumps (e.g., vibration, temperature, pressure, flow rate) to predict potential failures before they occur, enabling proactive maintenance, reducing unscheduled downtime, and extending pump lifespan.

- Real-time performance optimization: AI systems can dynamically adjust pump parameters (e.g., motor speed, valve positions) in response to varying hydrogen demand, system pressure, and temperature fluctuations, ensuring optimal efficiency, minimizing energy consumption, and improving overall system responsiveness in applications like fuel cell power plants or refueling stations.

- Enhanced safety and fault detection: AI can monitor for anomalies in pump operation that might indicate leaks, blockages, or other safety-critical issues, providing early warnings and facilitating rapid response mechanisms, which is crucial given the flammable nature of hydrogen.

- Intelligent control systems integration: AI serves as the brain for integrated hydrogen management systems, coordinating the operation of circulation pumps with other components such as compressors, electrolyzers, and storage tanks to achieve system-wide efficiency and stability.

- Design and simulation optimization: AI tools can be used in the design phase to simulate various pump geometries, material choices, and operating conditions, accelerating the development of more efficient, durable, and cost-effective hydrogen circulation pumps by identifying optimal configurations.

- Supply chain and demand forecasting: AI can contribute to better forecasting of demand for hydrogen circulation pumps by analyzing trends in FCEV adoption, hydrogen infrastructure development, and industrial project timelines, leading to optimized production and inventory management for manufacturers.

- Automated diagnostics and troubleshooting: AI-powered diagnostic tools can quickly pinpoint the root cause of pump malfunctions, reducing the time and expertise required for repairs, thereby lowering maintenance costs and improving operational continuity.

DRO & Impact Forces Of Hydrogen Circulation Pump Market

The Hydrogen Circulation Pump Market is significantly shaped by a confluence of drivers, restraints, opportunities, and the resulting impact forces. Key drivers include the aggressive global push for decarbonization and the urgent need to mitigate climate change, which positions hydrogen as a clean energy vector, thereby increasing demand for essential components like circulation pumps. Escalating investments in hydrogen infrastructure, particularly in the expansion of fuel cell electric vehicle (FCEV) fleets, the establishment of hydrogen refueling stations (HRS), and the development of large-scale green hydrogen production facilities through electrolysis, further propel market growth. Government incentives, subsidies, and supportive regulatory frameworks in major economies are playing a pivotal role in accelerating the adoption of hydrogen technologies across various sectors, creating a favorable environment for pump manufacturers. However, the market faces significant restraints such as the relatively high initial capital expenditure required for hydrogen infrastructure and associated equipment, including specialized pumps, which can hinder widespread adoption in price-sensitive markets. Challenges related to hydrogen storage and transportation, coupled with persistent safety concerns regarding hydrogen handling, also present barriers to market expansion, necessitating stringent safety protocols and robust equipment design. Furthermore, intense competition from established fossil fuel industries and the nascent stage of the overall hydrogen economy pose challenges, as alternative energy solutions are often more mature and cost-competitive. Despite these restraints, substantial opportunities abound, driven by technological advancements in fuel cell efficiency and durability, which in turn require more sophisticated and reliable circulation pumps. The expanding applications of hydrogen beyond mobility, into industrial processes like steel production, ammonia synthesis, and power generation, open up new revenue streams for pump manufacturers. Emerging markets in developing economies are also presenting fertile ground for future growth as they seek sustainable energy solutions. The collective impact forces reflect a transformative period for the energy sector, where the imperative for sustainability and the promise of a hydrogen economy are compelling innovation, investment, and policy support, while simultaneously demanding solutions that address cost, safety, and infrastructure development to unlock the full potential of this nascent yet rapidly evolving market.

Segmentation Analysis

The Hydrogen Circulation Pump Market is meticulously segmented to provide a granular understanding of its diverse applications and technological requirements. This segmentation allows for targeted market strategies, identifying specific demand patterns across various industries and operational environments. The market is primarily divided based on the pump type, which categorizes the mechanical design and operating principles; by application, detailing the end-use scenarios where these pumps are deployed; by pressure range, reflecting the operational demands for different hydrogen systems; and by end-use industry, showcasing the vertical markets that are adopting hydrogen technologies. Each segment presents unique characteristics, growth drivers, and challenges, making a detailed analysis crucial for stakeholders to identify lucrative avenues and tailor their product offerings effectively. For instance, the demand for high-pressure pumps differs significantly between refueling stations and industrial chemical processes, while the choice of pump type, such as centrifugal or diaphragm, is dictated by factors like flow rate, hydrogen purity requirements, and system pressure. Understanding these intricate layers of segmentation is essential for market participants to navigate the complex landscape of the emerging hydrogen economy and position themselves competitively.

- By Type

- Centrifugal Pumps: Suited for high flow rates and lower pressures, commonly used in large-scale hydrogen production and storage.

- Diaphragm Pumps: Ideal for high purity hydrogen and leak-free operation, often preferred in critical applications like fuel cells and laboratories.

- Reciprocating Pumps: Capable of achieving very high pressures, essential for hydrogen compression at refueling stations and industrial gas transfer.

- Gear Pumps: Used for controlled flow and pressure in various industrial hydrogen processes.

- Regenerative Pumps: Offer advantages in handling low flow rates against high differential pressures, finding niche applications in specific hydrogen systems.

- By Application

- Fuel Cell Electric Vehicles (FCEV): Circulation of hydrogen within the fuel cell stack to generate electricity.

- Industrial (Chemical, Refineries, Power Generation): Hydrogen circulation for chemical reactions, cooling, and power production in industrial plants.

- Hydrogen Refueling Stations (HRS): High-pressure transfer and recirculation of hydrogen during dispensing.

- Power-to-Gas Systems: Integration with electrolyzers for hydrogen production and subsequent distribution.

- Research & Development: Pumps used in laboratories and pilot projects for studying hydrogen behavior and system development.

- By Pressure Range

- Low Pressure: Typically < 10 bar, for certain storage and process applications.

- Medium Pressure: Ranging from 10-100 bar, for various industrial and medium-scale applications.

- High Pressure: Exceeding 100 bar, critical for FCEV refueling and high-density storage.

- By End-Use Industry

- Automotive: Primarily for FCEVs and hydrogen-powered buses/trucks.

- Energy & Power: For fuel cell power plants, hydrogen production, and grid balancing.

- Chemical & Petrochemical: For various industrial processes utilizing hydrogen as a reactant or coolant.

- Manufacturing: Hydrogen applications in metallurgy, glass production, and electronics.

- Others: Includes aerospace, marine, and specialized research applications.

Value Chain Analysis For Hydrogen Circulation Pump Market

The value chain for the Hydrogen Circulation Pump Market is a complex network involving various stages from raw material procurement to end-user application, highlighting the interdependencies and value addition at each step. Upstream analysis reveals a reliance on suppliers of specialized materials such as high-grade stainless steel, advanced polymers, and seals resistant to hydrogen embrittlement, along with precision components like motors, bearings, and control electronics. These suppliers are critical as the integrity and performance of hydrogen pumps are heavily dependent on the quality and chemical compatibility of their constituent materials, necessitating stringent quality control and innovation in material science. The manufacturing stage involves intricate design, precision machining, assembly, and rigorous testing processes to ensure pumps meet the demanding safety, efficiency, and durability standards required for hydrogen applications. This stage often incorporates advanced engineering techniques and automation to produce reliable and high-performance pumps. Moving downstream, the distribution channel is multifaceted, comprising direct sales to large industrial clients and OEMs (Original Equipment Manufacturers) in the automotive and energy sectors, as well as indirect channels through specialized distributors and integrators who provide turnkey hydrogen solutions. Direct sales are prevalent for custom-engineered, high-value pumps, allowing manufacturers to work closely with clients to meet specific requirements. Indirect channels, on the other hand, leverage established networks to reach a broader customer base, including smaller industrial users, research institutions, and emerging hydrogen project developers. The service and aftermarket segment, encompassing installation, maintenance, repair, and spare parts supply, also forms a crucial part of the downstream value chain, ensuring the long-term operational efficiency and safety of installed pumps. The strong emphasis on technical expertise and specialized support throughout the value chain underscores the sophisticated nature of the hydrogen technology market.

Hydrogen Circulation Pump Market Potential Customers

The Hydrogen Circulation Pump Market caters to a diverse range of end-users and buyers, each with specific requirements driven by their respective operational contexts within the burgeoning hydrogen economy. The automotive industry represents a significant customer segment, particularly manufacturers of Fuel Cell Electric Vehicles (FCEVs) such as passenger cars, buses, and heavy-duty trucks, who integrate these pumps into their fuel cell stacks to ensure efficient hydrogen circulation and optimal performance. These OEMs prioritize compact, durable, and energy-efficient pumps that can withstand dynamic operating conditions. Another critical customer group comprises developers and operators of Hydrogen Refueling Stations (HRS), which require high-pressure circulation pumps for efficient hydrogen compression, storage, and dispensing to vehicles. For HRS, reliability, safety, and rapid refueling capabilities are paramount. The industrial sector, encompassing chemical plants, oil refineries, and manufacturers of specialty gases, also forms a substantial customer base. In these settings, hydrogen is used as a feedstock, coolant, or for various catalytic processes, necessitating robust pumps capable of handling large volumes and continuous operation under demanding conditions. Furthermore, companies involved in power generation and energy storage, particularly those developing fuel cell power plants, power-to-gas systems, and grid-scale hydrogen energy solutions, are increasingly adopting hydrogen circulation pumps. These customers seek pumps that contribute to overall system efficiency, grid stability, and long-term operational integrity. Finally, research and development institutions, universities, and government laboratories constitute a segment of buyers focused on cutting-edge hydrogen technologies, prototype development, and testing, often requiring specialized, flexible, and high-precision pumping solutions. The common thread among all these potential customers is the need for reliable, safe, and efficient hydrogen circulation to unlock the full potential of hydrogen as a clean energy carrier and industrial resource.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 1.2 Billion |

| Growth Rate | 15.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pfeiffer Vacuum, Busch Vacuum Solutions, Osaka Vacuum, Sulzer, Ebara Corporation, KSB SE & Co. KGaA, GRUNDFOS, Flowserve Corporation, Wilo SE, LEWA GmbH, Ingersoll Rand, Gardner Denver (Ingersoll Rand), Sundyne, Nikkiso Cryogenic Industries, Hydro-Pac Inc., Chart Industries, Cryostar, Burckhardt Compression AG, Atlas Copco, HPC PUMPS. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydrogen Circulation Pump Market Key Technology Landscape

The Hydrogen Circulation Pump Market is characterized by a dynamic and evolving technological landscape, driven by the unique challenges associated with handling hydrogen, a highly flammable gas with small molecular size that requires specialized equipment to prevent leaks and ensure efficiency. Key technologies employed in this market focus on material science, sealing mechanisms, magnetic coupling, and intelligent control systems. Advanced materials such as specific grades of stainless steel (e.g., 316L, duplex steels) and specialized polymers are crucial for pump components to resist hydrogen embrittlement and corrosion, ensuring long-term durability and safety. The development of new alloys and composite materials capable of withstanding extreme pressures and temperatures, while maintaining chemical inertness to hydrogen, is an ongoing area of innovation. Sealing technologies are paramount, with innovations in mechanical seals, lip seals, and dynamic seals designed to achieve ultra-low leakage rates, which is critical for both safety and preventing hydrogen loss. Non-contact seals and magnetic couplings are increasingly being adopted to eliminate mechanical wear and significantly reduce the risk of leaks, particularly in high-pressure and high-speed applications. Furthermore, the integration of magnetic drive technology in pumps allows for hermetically sealed pump heads, isolating the motor from the fluid and eliminating shaft seals, thereby offering superior leak tightness. Beyond mechanical design, the technological landscape also encompasses advanced motor and drive systems, including variable speed drives and permanent magnet motors, which enhance energy efficiency and provide precise control over flow rates and pressures. Smart sensor technology and integrated monitoring systems are increasingly being incorporated to provide real-time data on pump performance, pressure, temperature, and potential anomalies. This data is often fed into sophisticated control algorithms, sometimes enhanced by AI, to optimize operational parameters, predict maintenance needs, and enhance overall system reliability and safety. The continuous pursuit of higher efficiency, extended operational life, and uncompromising safety standards remains at the forefront of technological advancements in the hydrogen circulation pump sector, enabling the broader adoption and reliability of hydrogen energy systems.

Regional Highlights

- North America: This region is demonstrating significant traction in the Hydrogen Circulation Pump Market, primarily driven by substantial government initiatives aimed at promoting hydrogen as a clean energy carrier, particularly within the transportation and industrial sectors. Countries like the United States and Canada are investing heavily in establishing robust hydrogen infrastructure, including the deployment of hydrogen refueling stations and the development of fuel cell electric vehicles. Regulatory incentives and funding programs from agencies such as the Department of Energy are fostering innovation and commercialization of hydrogen technologies. The presence of major automotive OEMs and a burgeoning industrial hydrogen demand from chemical and refining sectors further cements North America's position as a key growth region.

- Europe: Europe stands at the forefront of the hydrogen economy, with ambitious targets for decarbonization and extensive strategies like the European Green Deal and the EU Hydrogen Strategy. This has created a fertile ground for the Hydrogen Circulation Pump Market. Nations such as Germany, France, and the Netherlands are leading in green hydrogen production projects, fuel cell deployment, and establishing cross-border hydrogen pipelines. Strong political will, significant public and private investments in research and development, and a mature industrial base are driving the demand for high-performance circulation pumps across various applications, including industrial processes, grid balancing, and heavy-duty transport.

- Asia Pacific (APAC): The Asia Pacific region is rapidly emerging as a global leader in the hydrogen market, propelled by proactive government policies, substantial industrial investments, and a growing emphasis on energy security and clean air. Countries like Japan, South Korea, and China are at the vanguard of hydrogen technology adoption, particularly in the fuel cell electric vehicle segment and large-scale industrial hydrogen applications. China's enormous manufacturing capabilities and increasing focus on hydrogen infrastructure, coupled with Japan's long-term vision for a "hydrogen society" and South Korea's aggressive rollout of FCEVs and HRS, are creating immense demand for hydrogen circulation pumps, positioning APAC as the largest and fastest-growing market.

- Latin America: While currently a smaller market, Latin America presents significant long-term potential for the Hydrogen Circulation Pump Market, primarily due to its vast renewable energy resources, especially for green hydrogen production. Countries such as Chile, Brazil, and Argentina are actively exploring and developing projects to leverage their abundant solar and wind power for electrolysis, aiming to become major exporters of green hydrogen. As these nascent hydrogen economies mature and infrastructure develops, the demand for essential components like circulation pumps for production, storage, and local applications is expected to witness substantial growth.

- Middle East and Africa (MEA): The MEA region is strategically positioned to become a global hub for green hydrogen production, given its exceptional solar energy potential and access to vast land. Countries like Saudi Arabia, UAE, and Oman are investing billions in large-scale green hydrogen and ammonia projects, driven by diversification strategies away from fossil fuels. This monumental shift towards hydrogen production for domestic consumption and export is creating significant opportunities for hydrogen circulation pump manufacturers, particularly for large-scale industrial pumps required in electrolysis plants, storage facilities, and export terminals. The demand is poised for exponential growth as these mega-projects come online.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydrogen Circulation Pump Market.- Pfeiffer Vacuum

- Busch Vacuum Solutions

- Osaka Vacuum

- Sulzer

- Ebara Corporation

- KSB SE & Co. KGaA

- GRUNDFOS

- Flowserve Corporation

- Wilo SE

- LEWA GmbH

- Ingersoll Rand

- Gardner Denver (Ingersoll Rand)

- Sundyne

- Nikkiso Cryogenic Industries

- Hydro-Pac Inc.

- Chart Industries

- Cryostar

- Burckhardt Compression AG

- Atlas Copco

- HPC PUMPS

Frequently Asked Questions

Analyze common user questions about the Hydrogen Circulation Pump market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a hydrogen circulation pump and why is it important?

A hydrogen circulation pump is a specialized device designed to move hydrogen gas or liquid within various hydrogen systems, such as fuel cells, production plants, and refueling stations. It is crucial for maintaining optimal flow rates, pressure, and thermal conditions, which directly impacts the efficiency, safety, and longevity of hydrogen-powered technologies.

What are the primary applications driving the demand for hydrogen circulation pumps?

The demand for these pumps is primarily driven by Fuel Cell Electric Vehicles (FCEVs), hydrogen refueling stations (HRS), industrial hydrogen processes (e.g., in chemical and petrochemical plants, power generation), and power-to-gas systems involved in green hydrogen production and storage.

What technological advancements are key in the Hydrogen Circulation Pump Market?

Key advancements include the development of advanced materials resistant to hydrogen embrittlement, innovative leak-tight sealing mechanisms (like magnetic couplings), high-efficiency motor drives, and integrated smart control systems with sensors for real-time monitoring and predictive maintenance, all enhancing safety and performance.

What are the main challenges facing the growth of the Hydrogen Circulation Pump Market?

Major challenges include the high initial investment costs for hydrogen infrastructure, limitations in current hydrogen storage and distribution networks, ongoing safety concerns related to hydrogen handling, and the need for further standardization and cost reduction to compete with established energy sources.

Which regions are leading in the adoption and development of hydrogen circulation pump technologies?

The Asia Pacific region, particularly countries like Japan, South Korea, and China, along with Europe (Germany, France) and North America (USA, Canada), are at the forefront due to strong government support, significant investments in hydrogen infrastructure, and rapid technological advancements in fuel cell and green hydrogen production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager