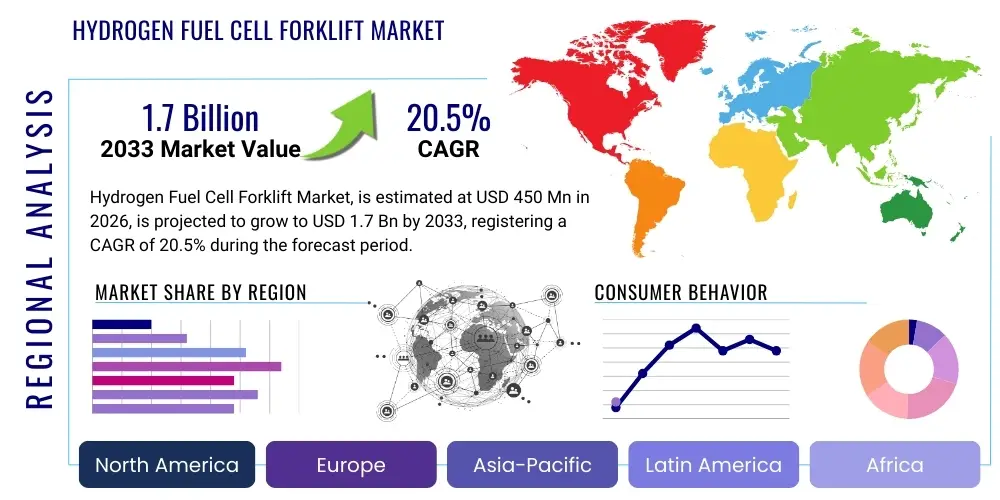

Hydrogen Fuel Cell Forklift Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439169 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Hydrogen Fuel Cell Forklift Market Size

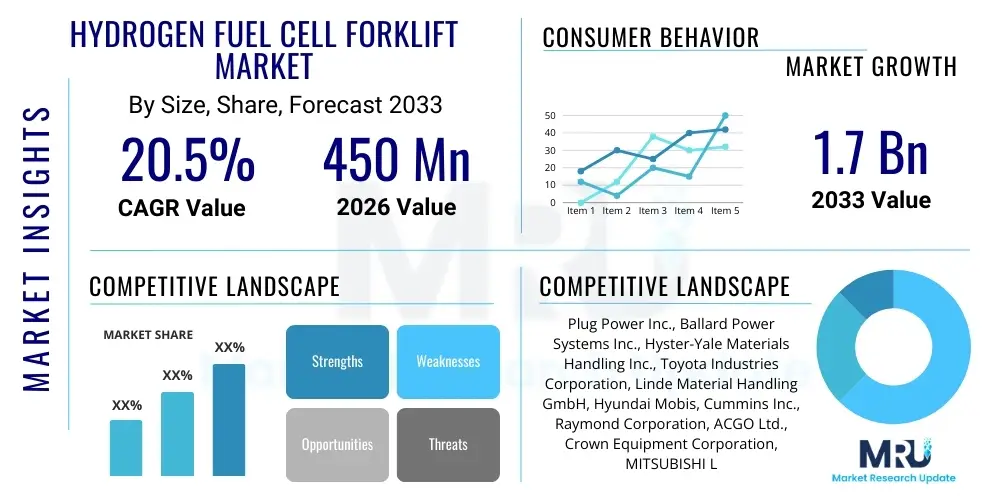

The Hydrogen Fuel Cell Forklift Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 20.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 1.7 Billion by the end of the forecast period in 2033.

Hydrogen Fuel Cell Forklift Market introduction

The Hydrogen Fuel Cell Forklift Market encompasses the manufacturing, distribution, and deployment of industrial trucks powered by proton-exchange membrane (PEM) fuel cells, which convert chemical energy from hydrogen into electricity to run the motor. These specialized forklifts are primarily used in high-intensity material handling environments, replacing traditional battery-electric or internal combustion engine (ICE) models. Fuel cell forklifts offer significant operational advantages, including rapid refueling times—typically under three minutes—and consistent power output throughout the operational shift, eliminating the performance degradation associated with traditional lead-acid batteries.

Major applications of hydrogen fuel cell forklifts are concentrated in sectors demanding high throughput and 24/7 operational capability, such as large-scale warehousing, third-party logistics (3PL) providers, manufacturing facilities, and refrigerated distribution centers. The appeal of these systems stems from their enhanced productivity; reduced operational footprint, as battery changing rooms are eliminated; and environmental benefits, producing only water and heat as byproducts, aligning with corporate sustainability mandates. The global push towards decarbonization and the establishment of robust hydrogen infrastructure are crucial external factors propelling market adoption.

The core benefits driving market growth include improved productivity, lower total cost of ownership (TCO) in large fleets compared to conventional batteries (when factoring in labor and infrastructure), and zero localized emissions. Key driving factors involve favorable government incentives for hydrogen adoption, expanding public-private partnerships focused on hydrogen fueling station development, and technological advancements improving the energy density and durability of fuel cell stacks. Furthermore, the increasing complexity of global supply chains necessitates reliable and continuous material handling equipment, solidifying the market position of hydrogen technology.

Hydrogen Fuel Cell Forklift Market Executive Summary

The Hydrogen Fuel Cell Forklift Market is poised for rapid expansion, driven by critical business trends focusing on operational efficiency and sustainable supply chain management. Major companies are prioritizing the integration of fuel cell technology to optimize multi-shift operations in logistics and manufacturing hubs, where downtime is prohibitively expensive. Technological advancements are continuously reducing the system size and cost of fuel cell power packs, making them increasingly competitive against lithium-ion alternatives. A significant business trend involves strategic partnerships between original equipment manufacturers (OEMs) and energy providers to establish comprehensive, turn-key hydrogen fueling solutions, thereby lowering the initial barriers to entry for end-users.

Regionally, North America leads the market due to early regulatory support, substantial private investment in logistics infrastructure, and the presence of large retail and e-commerce giants that have pioneered high-volume hydrogen forklift adoption. Europe is accelerating its transition, spurred by the European Green Deal and stringent emission standards, focusing heavily on green hydrogen production pathways to ensure sustainability. Asia Pacific, led by countries like Japan and South Korea, exhibits strong potential, fueled by aggressive national hydrogen strategies and significant investment in developing domestic fuel cell manufacturing capabilities and hydrogen distribution networks.

Segment trends highlight the dominance of the Class 3 pallet jack and Class 1 counterbalance forklift segments, reflecting their high utilization rates in fast-paced warehouse environments. The component segment is seeing rapid innovation, particularly in the hydrogen storage systems, focusing on lightweight, high-pressure tanks to maximize operational range and safety. Furthermore, the end-user landscape shows robust growth in the 3PL and food & beverage sectors, where consistent temperature maintenance and uninterrupted operation are paramount, underscoring the intrinsic reliability advantages offered by fuel cell technology over battery swapping procedures.

AI Impact Analysis on Hydrogen Fuel Cell Forklift Market

Users frequently inquire about how Artificial Intelligence (AI) can enhance the efficiency and predictive maintenance of hydrogen fuel cell fleets, specifically seeking data on optimizing hydrogen consumption, managing refueling schedules, and diagnosing stack health remotely. Key themes circulating in user queries revolve around integrating AI-driven predictive analytics with the physical fueling infrastructure (hydrogen dispensers and storage tanks) to ensure maximum utilization and prevent supply chain bottlenecks. There is a strong expectation that AI will move beyond simple telemetry to offer actionable insights regarding fuel cell degradation curves, cold start performance optimization, and autonomous route planning for greater energy efficiency, effectively reducing the TCO and justifying the initial capital investment in hydrogen technology.

- AI-Powered Predictive Maintenance: Utilizing machine learning algorithms to analyze real-time data from fuel cell stacks (voltage, temperature, pressure) and predict potential failures, significantly reducing unplanned downtime and maintenance costs.

- Hydrogen Consumption Optimization: AI systems analyze usage patterns, load profiles, and ambient temperatures to recommend optimal operational practices and hydrogen allocation across the fleet, maximizing efficiency per kilogram of hydrogen.

- Fleet Management and Refueling Logistics: Implementing algorithms for dynamic scheduling of refueling times, minimizing queueing at fueling stations, and ensuring continuous operational readiness, especially in high-density warehouse environments.

- Autonomous Operations Integration: AI enables the seamless integration of fuel cell power units into next-generation autonomous forklifts (AGVs), providing reliable, quick-refuel power necessary for continuous autonomous movement.

- Supply Chain Forecasting: Integrating AI with hydrogen supplier data to predict demand fluctuations and manage inventory levels at the facility's hydrogen storage buffer, ensuring a reliable supply chain.

- Digital Twin Modeling: Creating digital twins of fuel cell power packs to simulate various operational stressors and environments, accelerating R&D and improving the durability and lifespan of the technology.

DRO & Impact Forces Of Hydrogen Fuel Cell Forklift Market

The Hydrogen Fuel Cell Forklift Market is fundamentally shaped by powerful dynamics involving regulatory support, infrastructure development challenges, and the continuous drive for sustainable logistics solutions. Drivers primarily center on the mandated transition towards zero-emission vehicles in industrial settings, coupled with significant tax incentives and subsidies offered by governments globally to accelerate hydrogen adoption. Restraints largely stem from the high initial capital expenditure required for both the forklifts and the necessary on-site hydrogen infrastructure (compressors, storage tanks, dispensers), which poses a barrier for small and medium-sized enterprises. Opportunities exist primarily in exploiting the emerging green hydrogen value chain, which promises truly zero-carbon operations, and expanding applications into harsh environments, such as cold storage, where fuel cells excel over traditional batteries.

The key impact forces influencing the market are governmental regulations, which can mandate or heavily incentivize adoption; technological parity with alternatives, particularly lithium-ion batteries, which are becoming increasingly competitive in certain operational profiles; and the volatility of energy prices, specifically the cost and stable supply of hydrogen. The immediate and sustained impact of infrastructure development dictates the pace of market entry; without readily available, cost-effective hydrogen supply, adoption remains confined to large, localized fleets capable of justifying dedicated on-site infrastructure investment. Consequently, the market growth trajectory is highly correlated with the successful scaling of commercial hydrogen production and distribution networks.

The rapid evolution of battery technology, especially high-capacity lithium-ion cells, serves as a continuous restraint by offering lower initial costs and a more mature charging infrastructure. However, the superior performance profile of fuel cells in heavy-duty, multi-shift operations—where refueling speed minimizes labor costs and operational footprint—maintains its competitive edge. The overarching impact force remains the global commitment to achieving net-zero emissions, positioning hydrogen as a necessary long-term solution for decarbonizing heavy-duty material handling equipment, driving sustained R&D investment and supportive policy frameworks.

Segmentation Analysis

The Hydrogen Fuel Cell Forklift Market is meticulously segmented based on key structural and application criteria, allowing for targeted strategic planning and analysis of diverse end-user needs. Segmentation by Component provides insight into the technological value chain, focusing on the cost and innovation associated with the core fuel cell stack, hydrogen storage system, and auxiliary Balance of Plant (BOP). The segmentation by Forklift Type differentiates the market based on industrial classification (e.g., Class 1 Counterbalance vs. Class 3 Pallet Jacks), reflecting varying power requirements and duty cycles. The End-User segmentation identifies the primary economic sectors driving demand, quantifying adoption rates across logistics, manufacturing, and retail environments.

The analysis reveals that the Class 3 segment, comprising low lift pallet trucks and tow tractors, often sees quicker adoption due to lower power requirements and high volume use, making the rapid refueling benefit highly impactful. Conversely, Class 1 forklifts, used for heavy lifting and stacking, require more robust fuel cell systems and higher hydrogen throughput. Understanding these segments is crucial for manufacturers to tailor product specifications, such as system size, output power, and tank capacity, ensuring optimal performance that justifies the fuel cell premium. The logistics and e-commerce sectors remain the primary revenue generators due to their massive, centralized distribution centers operating 24/7.

Further granularity in segmentation helps stakeholders understand niche market requirements, such as those within the cold storage industry, which demands specialized fuel cell designs capable of reliable cold start performance. Geographical segmentation further divides the market, with North America representing a mature market characterized by early adopter fleet conversions, while Asia Pacific and Europe are rapidly emerging, driven by governmental policy support for hydrogen mobility. This multi-dimensional segmentation ensures a precise evaluation of market potential, identifying segments ripe for immediate investment and those requiring further infrastructural support.

- By Component:

- Fuel Cell Stack

- Hydrogen Storage System (Cylinder/Tank)

- Balance of Plant (BOP) (Compressors, Humidifiers, Air Management)

- By Forklift Type:

- Class 1 (Electric Motor Rider Trucks - Counterbalance)

- Class 2 (Electric Motor Narrow Aisle Trucks)

- Class 3 (Electric Motor Hand Trucks - Pallet Jacks and Stackers)

- By Power Output:

- < 5 kW

- 5 kW to 10 kW

- > 10 kW

- By End-User:

- Logistics and E-commerce

- Manufacturing (Automotive, Heavy Machinery)

- Food & Beverage (Including Cold Storage)

- Retail and Wholesale

- Other Industries (Pharmaceuticals, Chemicals)

Value Chain Analysis For Hydrogen Fuel Cell Forklift Market

The value chain for the Hydrogen Fuel Cell Forklift Market spans from upstream hydrogen production and component manufacturing to downstream fleet operation and maintenance. Upstream analysis focuses intensely on the secure and cost-effective supply of hydrogen, which involves production methods (gray, blue, or green), purification processes, and high-pressure storage and transportation logistics. Key upstream activities include the sourcing of critical materials for PEM stacks, such as platinum group metals (PGMs) and specialized membranes, which significantly influence the final cost and performance of the fuel cell power pack. Efficiency in this stage directly determines the operational fuel cost for end-users.

Midstream activities involve the design and integration of the fuel cell power unit itself. This includes manufacturing the proprietary fuel cell stack, integrating the necessary high-pressure carbon fiber wrapped storage tanks, and packaging the entire system to fit various forklift chassis types. OEMs either develop these power units internally or partner with specialized fuel cell manufacturers. The downstream segment encompasses the manufacturing and assembly of the forklift truck chassis, followed by the integration of the fuel cell system, marketing, sales, and comprehensive after-sales support, including maintenance and hydrogen supply contracts.

The distribution channel is predominantly direct or via specialized industrial material handling equipment dealers. Direct sales are common for large fleet conversions where the OEM provides a comprehensive, consultative package, including infrastructure planning and ongoing hydrogen supply management, often in collaboration with energy partners. Indirect channels involve authorized dealerships providing local sales, service, and maintenance support for smaller or regional fleet adoptions. The success of the downstream operation relies heavily on robust service networks capable of handling both traditional forklift mechanics and specialized fuel cell system diagnostics, ensuring high operational uptime for the customer.

Hydrogen Fuel Cell Forklift Market Potential Customers

The primary potential customers for hydrogen fuel cell forklifts are organizations engaged in high-throughput material handling operations that require continuous, multi-shift performance where vehicle downtime severely impacts profitability. These customers typically operate large fleets of 50 or more industrial trucks, making the economics of installing dedicated hydrogen infrastructure viable. Key decision-makers in these organizations prioritize Total Cost of Ownership (TCO) over initial capital expenditure, valuing labor savings from eliminated battery changes, consistent performance, and the long-term sustainability credentials offered by hydrogen.

Specifically, major e-commerce retailers and 3PL providers represent the largest and most receptive customer base. Companies managing enormous distribution centers, often exceeding one million square feet, find that the space-saving benefit of eliminating dedicated battery charging rooms and the productivity gain from rapid refueling significantly outweigh the cost of conversion. The demand for continuous operation, particularly during peak seasons, makes fuel cell technology a strategic necessity rather than a mere environmentally friendly upgrade. Moreover, organizations with strong ESG (Environmental, Social, and Governance) commitments are increasingly adopting hydrogen to meet corporate sustainability goals.

Furthermore, specialized industrial environments constitute a growing customer base. This includes large-scale automotive manufacturing plants, which often use Class 1 trucks in demanding environments, and cold storage warehouses. In cold storage, fuel cells maintain higher efficiency and performance compared to batteries, which suffer performance degradation in low temperatures. These segments are highly sensitive to operational resilience and continuous power delivery, solidifying their status as prime potential end-users for fuel cell technology in the material handling sector.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 1.7 Billion |

| Growth Rate | 20.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Plug Power Inc., Ballard Power Systems Inc., Hyster-Yale Materials Handling Inc., Toyota Industries Corporation, Linde Material Handling GmbH, Hyundai Mobis, Cummins Inc., Raymond Corporation, ACGO Ltd., Crown Equipment Corporation, MITSUBISHI LOGISNEXT Co. Ltd., Kion Group AG, Doosan Industrial Vehicle Co. Ltd., GenCell Ltd., Hydrogenics Corporation, Weichai Power Co., Ltd., Nuvera Fuel Cells, Inc., Horizon Fuel Cell Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydrogen Fuel Cell Forklift Market Key Technology Landscape

The technology landscape of the Hydrogen Fuel Cell Forklift Market is dominated by the advancement of Proton Exchange Membrane (PEM) fuel cell technology, which is favored for its high power density, quick start-up time, and efficiency at lower temperatures pertinent to warehouse operations. Continuous R&D efforts are focused on improving the durability and lifespan of the PEM stack, specifically by reducing reliance on costly Platinum Group Metal (PGM) catalysts and enhancing the tolerance of the membrane to contaminants. Furthermore, the integration technology is critical, requiring highly efficient DC/DC converters and advanced control systems to manage the power output to the electric motor seamlessly, ensuring peak performance regardless of the fuel level.

A secondary, yet equally vital, technological area is the development of robust and lightweight high-pressure hydrogen storage systems. Current industry standards utilize Type IV carbon fiber composite tanks operating at pressures typically around 350 bar (5,000 psi) to maximize the energy density and operating range of the forklift. Future technological progress is targeting 700 bar storage for even greater capacity, alongside standardized, modular fueling interfaces to simplify infrastructure deployment and refueling procedures. Safety technology, including advanced leak detection systems and pressure relief devices, is continuously being refined to meet stringent industrial safety codes.

The market is also witnessing the rise of advanced system integration and telemetry solutions. Modern fuel cell power units are equipped with sophisticated IoT sensors and connectivity capabilities that transmit real-time operational data, allowing fleet managers to monitor performance, manage maintenance schedules, and track hydrogen inventory remotely. This integration transforms the fuel cell power unit from a passive component into an intelligent, networked asset, crucial for optimizing large-scale logistics operations and paving the way for AI-driven predictive maintenance and autonomous fleet management systems.

Regional Highlights

Regional dynamics are critical to the global deployment of hydrogen fuel cell forklifts, with each major geographical area presenting unique drivers and infrastructure maturity levels. North America currently holds the largest market share, predominantly due to the early and aggressive adoption by major retail, e-commerce, and logistics players headquartered in the United States. This region benefits from established government support programs, such as investment tax credits, and a growing network of centralized, industrial-scale hydrogen generation and distribution hubs, particularly in high-density logistics corridors like the Northeast and the West Coast.

Europe represents a high-growth region, strongly influenced by ambitious decarbonization mandates articulated in the European Green Deal and associated national hydrogen strategies (e.g., Germany, France). While initial adoption rates were slower than in the U.S., the focus in Europe is heavily skewed toward utilizing green hydrogen (produced via electrolysis powered by renewables), ensuring a genuinely zero-emission solution. Investment is channeled into creating regional hydrogen valleys and standardized infrastructure across borders, aiming to make hydrogen refueling ubiquitous in major industrial zones.

Asia Pacific (APAC) is emerging as a significant market, driven by Japan and South Korea, which have positioned fuel cell technology as a national strategic priority. These countries are investing heavily in domestic manufacturing capacity for fuel cell components and are rapidly deploying hydrogen infrastructure for both transport and industrial applications. China, with its massive manufacturing and warehousing footprint, is expected to become a dominant force as provincial governments begin to introduce subsidies and pilot projects focused on hydrogen-powered material handling equipment, leveraging their extensive industrial base for large-scale adoption.

- North America: Market leader driven by large fleet operators (e-commerce, 3PL), mature infrastructure in key logistics hubs, and favorable government incentives (e.g., California’s zero-emission mandates). Focus on rapid TCO realization.

- Europe: High growth potential fueled by stringent EU emission standards and the European Hydrogen Strategy. Emphasis on establishing green hydrogen supply chains and developing cross-border refueling corridors.

- Asia Pacific (APAC): Rapidly emerging market led by South Korea and Japan's national hydrogen roadmaps. Significant investments in fuel cell manufacturing and deployment in large domestic logistics networks in China and India.

- Latin America: Nascent market focused on pilot projects, primarily in high-density industrial zones in Brazil and Mexico. Growth contingent on developing local, cost-competitive hydrogen production infrastructure.

- Middle East and Africa (MEA): Limited adoption currently, but strong long-term potential tied to large-scale green hydrogen production initiatives (e.g., NEOM in Saudi Arabia). Initial focus likely on port operations and heavy industrial complexes.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydrogen Fuel Cell Forklift Market.- Plug Power Inc.

- Ballard Power Systems Inc.

- Hyster-Yale Materials Handling Inc.

- Toyota Industries Corporation

- Linde Material Handling GmbH (Kion Group AG)

- Hyundai Mobis

- Cummins Inc. (through acquisitions like Hydrogenics)

- The Raymond Corporation

- Crown Equipment Corporation

- MITSUBISHI LOGISNEXT Co. Ltd.

- Doosan Industrial Vehicle Co. Ltd.

- GenCell Ltd.

- Nuvera Fuel Cells, Inc.

- Weichai Power Co., Ltd.

- Hydrogenics Corporation (now part of Cummins)

- Horizon Fuel Cell Technologies

- Intellipower

- ACGO Ltd.

- Enapter AG

- ITM Power PLC

Frequently Asked Questions

Analyze common user questions about the Hydrogen Fuel Cell Forklift market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the Total Cost of Ownership (TCO) comparison between fuel cell and lithium-ion forklifts?

The TCO for fuel cell forklifts becomes highly competitive, often lower, than lithium-ion or lead-acid batteries, especially in large fleet (50+ trucks) and high-throughput, multi-shift operations. Savings stem from eliminated battery swapping labor, reduced infrastructure footprint (no charging rooms needed), and consistent power delivery, maximizing productivity over the asset lifecycle.

How safe is the operation and storage of hydrogen fuel cell forklifts?

Hydrogen fuel cell forklifts are engineered with multiple safety redundancies, including specialized high-pressure tanks and automatic shut-off systems. Hydrogen is lighter than air, dissipating quickly in open environments. The safety record is strong, often matching or exceeding traditional battery systems, adhering to strict international safety standards like NFPA and ISO.

What are the primary operational benefits of hydrogen forklifts over battery-electric models?

The core benefits include extremely fast refueling (under three minutes, compared to hours for charging), 24/7 continuous operation without performance degradation (no "fuel sag"), elimination of dedicated battery maintenance rooms, and superior performance in cold storage environments where battery capacity diminishes significantly.

What is the current status of the hydrogen refueling infrastructure for industrial users?

The industrial hydrogen infrastructure is rapidly developing, characterized primarily by centralized, on-site fueling stations built for large, captive fleets. While public hydrogen fueling stations for industrial use are limited, leading OEMs and energy partners provide turnkey solutions for generating, storing, and dispensing hydrogen directly at the customer's warehouse or distribution center.

Which segments of the material handling market are adopting fuel cell technology most rapidly?

The segments exhibiting the fastest adoption are large-scale e-commerce and 3PL providers (third-party logistics) utilizing high volumes of Class 1 counterbalance trucks and Class 3 pallet jacks. These sectors prioritize minimizing downtime and maximizing throughput, making the rapid, consistent power delivery of fuel cells strategically advantageous.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager