Hydrogen Peroxide Disinfection System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440136 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Hydrogen Peroxide Disinfection System Market Size

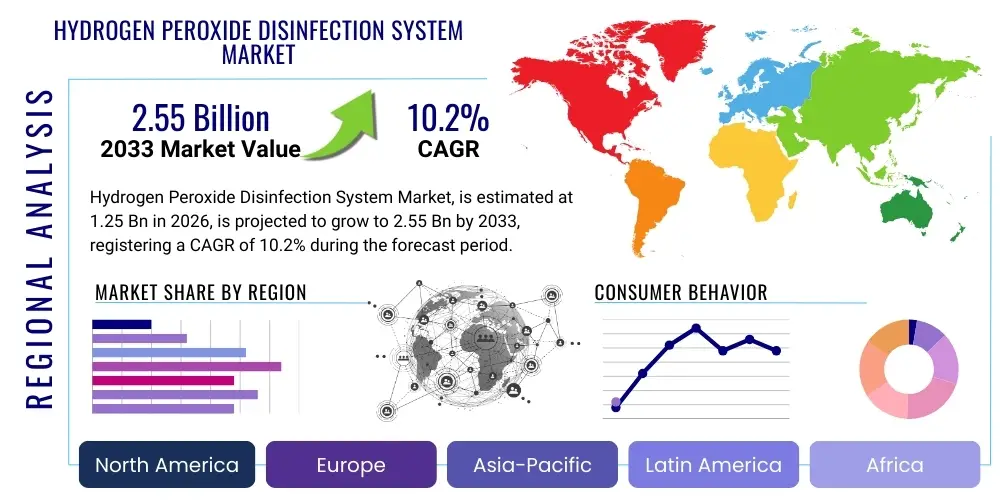

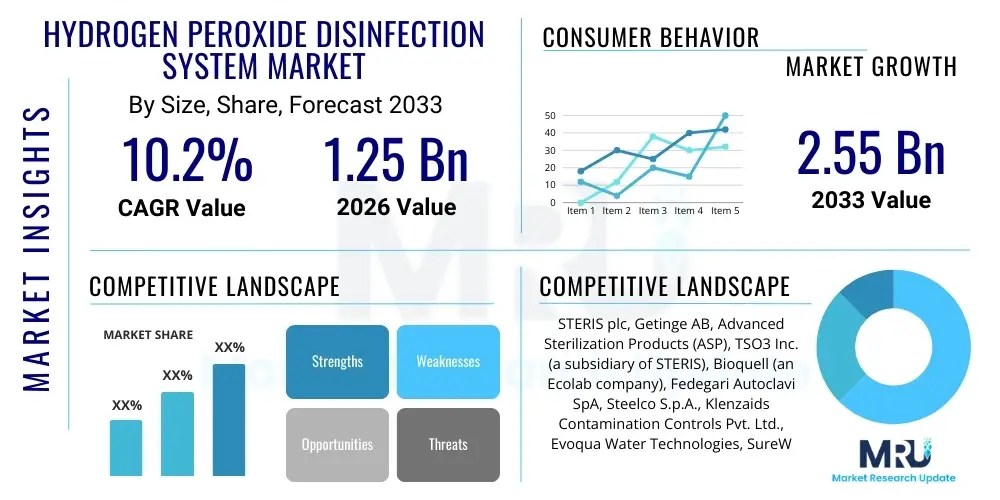

The Hydrogen Peroxide Disinfection System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.2% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 2.55 Billion by the end of the forecast period in 2033.

Hydrogen Peroxide Disinfection System Market introduction

The Hydrogen Peroxide Disinfection System Market encompasses a range of advanced technologies designed for high-level disinfection and sterilization, primarily utilizing hydrogen peroxide as the active agent. These systems are pivotal in environments requiring stringent contamination control, such as healthcare facilities, pharmaceutical manufacturing, biotechnological research, and food processing. Hydrogen peroxide, known for its potent oxidizing properties, effectively destroys a broad spectrum of microorganisms, including bacteria, viruses, fungi, and spores, making it an ideal choice for critical applications where conventional methods may fall short or leave residues.

Product descriptions within this market vary, ranging from vaporized hydrogen peroxide (VHP) systems, which deploy H2O2 as a gas to penetrate intricate spaces and surfaces, to aerosolized and plasma-based systems that offer different operational profiles and material compatibility. Major applications extend across sterile processing departments in hospitals for surgical instruments, decontamination of isolation rooms, sterilization of sensitive medical devices, and ensuring aseptic conditions in cleanrooms for drug production. Furthermore, the technology finds utility in the food and beverage industry for packaging sterilization and in research laboratories for equipment and facility disinfection.

The benefits of hydrogen peroxide disinfection systems are manifold, including their broad-spectrum efficacy, residue-free decomposition into water and oxygen, environmental friendliness compared to some traditional disinfectants, and relatively low material compatibility issues. These systems often offer automated cycles, reducing human error and ensuring consistent disinfection levels. Key driving factors for market growth include the escalating concerns over healthcare-associated infections (HAIs), the increasing demand for advanced sterilization techniques in the burgeoning pharmaceutical and biotechnology sectors, the growing number of surgical procedures globally, and the stringent regulatory frameworks mandating high standards of hygiene and safety across various industries. Additionally, the continuous advancements in system design, automation, and cycle efficiency further bolster market expansion.

Hydrogen Peroxide Disinfection System Market Executive Summary

The Hydrogen Peroxide Disinfection System Market is experiencing robust growth, driven by an intensified global focus on infection control and patient safety across various sectors. Business trends indicate a strong move towards integrated solutions, where manufacturers offer not just standalone disinfection units but also comprehensive service packages, including installation, validation, maintenance, and training. There is a notable industry shift towards developing more portable, energy-efficient, and user-friendly systems that can be rapidly deployed in diverse settings. Strategic partnerships between technology providers and healthcare systems, as well as pharmaceutical companies, are becoming increasingly common to facilitate wider adoption and tailor solutions to specific operational needs. Furthermore, the market is witnessing increased investment in research and development to enhance the speed and efficacy of disinfection cycles, reduce cycle times, and improve material compatibility for a broader range of medical devices and laboratory equipment.

Regionally, North America and Europe currently dominate the market, primarily due to established healthcare infrastructures, stringent regulatory mandates for infection control, and high adoption rates of advanced medical technologies. However, the Asia Pacific region is projected to exhibit the highest growth rate during the forecast period. This surge is attributed to the rapidly expanding healthcare expenditure, increasing awareness regarding HAIs, the burgeoning pharmaceutical and biotechnology industries, and the growing number of hospitals and clinics in countries like China, India, and Japan. Latin America, the Middle East, and Africa are also emerging as significant markets, driven by improving healthcare access, modernization of facilities, and a rising imperative to meet international health and safety standards. Government initiatives and funding aimed at upgrading public health infrastructure are playing a crucial role in accelerating market penetration in these developing regions.

Segmentation trends highlight the increasing prominence of vaporized hydrogen peroxide (VHP) systems due to their superior penetration capabilities and efficacy in decontaminating complex spaces and sensitive equipment. In terms of applications, the healthcare sector remains the largest segment, with hospitals and pharmaceutical companies being major end-users. Within healthcare, the demand for hydrogen peroxide disinfection systems in operating rooms, intensive care units, and sterile processing departments is particularly high. The biopharmaceutical and research sectors are also showing significant growth, spurred by the need for aseptic environments for drug discovery, development, and manufacturing. Material compatibility and the need for validated processes in these highly regulated industries further drive the adoption of H2O2 systems. Innovation in system design, focusing on automation and integration with existing facility management systems, is a key trend shaping future market dynamics across all segments.

AI Impact Analysis on Hydrogen Peroxide Disinfection System Market

Common user questions regarding AI's impact on the Hydrogen Peroxide Disinfection System Market often revolve around how artificial intelligence can enhance system efficiency, predictive maintenance, and overall disinfection efficacy, while also addressing concerns about data privacy and the potential for job displacement. Users are keen to understand if AI can optimize disinfection cycles based on environmental factors, predict equipment failures before they occur, and provide real-time efficacy monitoring. There is a strong expectation that AI will lead to more intelligent, autonomous, and adaptive disinfection solutions, ultimately improving patient safety and operational cost-effectiveness. The underlying theme is a desire for smarter, more reliable, and less human-dependent systems that can demonstrate verifiable performance improvements.

- AI integration for predictive maintenance, anticipating equipment malfunctions before they occur, thus minimizing downtime and extending asset lifespan.

- Optimization of disinfection cycles through machine learning algorithms that analyze environmental data, microbial load, and room characteristics, leading to reduced cycle times and improved energy efficiency.

- Real-time efficacy monitoring and validation, utilizing AI-powered sensors and analytics to confirm successful disinfection and generate comprehensive compliance reports.

- Enhanced user training and support through AI-driven simulations and virtual assistants, improving operational proficiency and reducing human error.

- Automated decision-making for chemical dosage and dispersion patterns, ensuring optimal H2O2 distribution and minimizing chemical waste.

- Data analytics for identifying infection hotspots and patterns, enabling targeted disinfection strategies and proactive intervention in healthcare settings.

- Development of autonomous disinfection robots capable of navigating complex environments and executing programmed disinfection routines with minimal human oversight.

DRO & Impact Forces Of Hydrogen Peroxide Disinfection System Market

The Hydrogen Peroxide Disinfection System Market is significantly influenced by a confluence of driving forces, restraining factors, and emerging opportunities. A primary driver is the global escalation in healthcare-associated infections (HAIs), which pose a severe threat to patient safety and place an immense financial burden on healthcare systems. This has spurred a heightened demand for advanced, effective, and reliable disinfection methods like hydrogen peroxide systems. Alongside this, the increasing number of surgical procedures worldwide and the consequent need for sterile environments and instruments further propel market growth. The rapid expansion and modernization of healthcare infrastructure, particularly in developing economies, coupled with stringent regulatory guidelines from bodies such as the FDA and EPA mandating high standards of sterilization and disinfection, reinforce the market's upward trajectory. The continuous growth of the pharmaceutical and biotechnology industries, requiring aseptic conditions for manufacturing and research, also acts as a powerful catalyst for adoption.

Despite the strong growth drivers, several restraints temper the market's potential. The high initial capital investment required for purchasing and installing advanced hydrogen peroxide disinfection systems can be a significant barrier for smaller healthcare facilities or those with limited budgets. Operational complexities, including the need for specialized training for personnel and strict adherence to safety protocols due to the corrosive and irritating nature of hydrogen peroxide, can also deter potential adopters. Furthermore, the presence of alternative disinfection methods, such as ethylene oxide, steam sterilization, and UV-C light, though often with different application profiles, presents competitive pressures. Concerns regarding potential material incompatibility with certain sensitive medical devices and the necessity for specific room preparation for vaporized hydrogen peroxide (VHP) applications are additional factors that require careful consideration by end-users.

However, the market is ripe with opportunities that promise future expansion. Emerging economies in Asia Pacific, Latin America, and the Middle East and Africa represent largely untapped markets with rapidly developing healthcare sectors and increasing awareness about infection control, presenting significant growth prospects. Technological advancements, including the integration of automation, IoT, and AI for improved system monitoring, efficiency, and data analytics, are creating new avenues for product differentiation and enhanced user experience. The growing focus on environmentally friendly and residue-free disinfection solutions positions hydrogen peroxide systems favorably, aligning with global sustainability trends. Moreover, the potential for expanding applications beyond traditional healthcare into areas such as commercial spaces, public transport, and veterinary clinics, especially in the wake of global pandemics, offers substantial long-term growth opportunities. These impact forces collectively shape the competitive landscape and strategic direction of the Hydrogen Peroxide Disinfection System Market.

Segmentation Analysis

The Hydrogen Peroxide Disinfection System market is meticulously segmented to provide a detailed understanding of its diverse components, applications, and end-user profiles. This comprehensive segmentation allows for a precise analysis of market dynamics, identifying key growth areas and competitive landscapes. The market can be broadly categorized by product type, application, and end-use, each with distinct characteristics and drivers. Understanding these segments is crucial for stakeholders to develop targeted strategies, optimize product offerings, and capitalize on emerging trends within specific niches of the disinfection industry.

- By Product Type

- Vaporized Hydrogen Peroxide (VHP) Systems

- Aerosolized Hydrogen Peroxide Systems

- Plasma Hydrogen Peroxide Systems

- Liquid Hydrogen Peroxide Disinfection Systems

- By Application

- Healthcare Facilities

- Hospitals

- Clinics & Ambulatory Surgical Centers

- Dental Clinics

- Laboratories

- Pharmaceutical & Biotechnology Companies

- Medical Device Manufacturing

- Food & Beverage Industry

- Industrial Cleanrooms

- Research Institutions

- Others (e.g., Veterinary Clinics, Commercial Spaces)

- Healthcare Facilities

- By End-Use

- Sterilization

- High-Level Disinfection

- Decontamination

Value Chain Analysis For Hydrogen Peroxide Disinfection System Market

The value chain for the Hydrogen Peroxide Disinfection System Market is intricate, beginning with the raw material suppliers and extending through to the end-users, encompassing several critical stages that add value to the final product and service. The upstream segment primarily involves the sourcing and processing of chemical raw materials, most notably hydrogen peroxide, which is produced by specialized chemical manufacturers. These companies focus on ensuring purity, concentration, and stable supply of the active disinfecting agent. Additionally, upstream activities include the manufacturing of electronic components, sensors, pumps, and specialized engineering materials required for constructing the sophisticated disinfection systems. Suppliers at this stage play a crucial role in maintaining quality standards and ensuring the availability of components that meet stringent industry specifications.

Moving further down the value chain, the core manufacturing stage involves the design, assembly, and integration of these components into complete hydrogen peroxide disinfection systems. This includes the development of system hardware, software for cycle control and monitoring, and safety features. Manufacturers invest heavily in research and development to innovate new technologies, improve system efficiency, reduce cycle times, and enhance material compatibility. After manufacturing, the distribution channel plays a pivotal role in reaching the end-users. This involves a mix of direct sales, where manufacturers sell directly to large institutional clients like hospital networks or pharmaceutical giants, and indirect distribution through a network of distributors, wholesalers, and specialized medical equipment suppliers. These intermediaries often provide localized sales support, logistics, and initial technical assistance, extending the market reach of manufacturers.

The downstream segment of the value chain focuses on post-sale activities, including installation, validation, maintenance, and ongoing technical support for the installed systems. This critical phase ensures that the systems operate optimally and meet regulatory compliance throughout their lifecycle. Direct channels facilitate closer relationships between manufacturers and end-users, allowing for customized solutions and rapid feedback loops, which are vital for product improvement and customer satisfaction. Indirect channels leverage the established networks and regional expertise of distributors, which can be particularly effective in fragmented markets or for reaching smaller clients. Ultimately, the effectiveness of the entire value chain hinges on seamless coordination, quality assurance at each stage, and a strong focus on customer service to ensure the safe, efficient, and reliable deployment of hydrogen peroxide disinfection systems in critical environments.

Hydrogen Peroxide Disinfection System Market Potential Customers

The potential customers for Hydrogen Peroxide Disinfection Systems are diverse and span across various industries that demand high levels of cleanliness, sterility, and decontamination to ensure safety, regulatory compliance, and product integrity. The primary and most significant segment of end-users are healthcare facilities. This category includes a broad range of institutions such as large multi-specialty hospitals, small and medium-sized clinics, specialized surgical centers, intensive care units, emergency rooms, dental clinics, and pathology laboratories. Within these settings, the systems are crucial for sterilizing surgical instruments, decontaminating patient rooms, operating theaters, and medical equipment, thereby preventing the spread of healthcare-associated infections (HAIs) and ensuring patient safety. Pharmaceutical and biotechnology companies represent another major customer base, where these systems are indispensable for maintaining aseptic conditions in cleanrooms, isolators, and fill-finish areas during drug manufacturing, compounding, and research and development activities. The stringent regulatory requirements for product purity and safety in these industries necessitate reliable and validated disinfection solutions.

Beyond healthcare and pharma, the medical device manufacturing industry is a significant consumer, utilizing hydrogen peroxide disinfection systems for sterilizing sensitive medical instruments and implantable devices that cannot withstand high temperatures or harsh chemical treatments. The food and beverage industry also represents a growing segment, employing these systems for sterilizing packaging materials, processing equipment, and production environments to prevent microbial contamination and extend product shelf life. This is particularly relevant for aseptic packaging applications. Industrial cleanrooms, found in sectors such as electronics, aerospace, and optics, which require ultra-clean environments to prevent particle and microbial contamination from affecting sensitive manufacturing processes, also constitute an important customer group. Research institutions and universities with biomedical laboratories and animal research facilities similarly rely on these systems for equipment and facility decontamination.

Additionally, other emerging potential customers include veterinary clinics and animal hospitals, which require effective disinfection for preventing disease transmission among animals. Commercial spaces, public transport sectors, and government facilities, especially in the context of pandemic preparedness and response, are increasingly considering these advanced disinfection technologies for broader environmental decontamination. These diverse end-users are united by a common need for highly effective, safe, and often automated disinfection solutions that can meet rigorous hygiene standards and contribute to a safer, healthier, and more productive environment. Understanding the specific needs, regulatory landscapes, and operational challenges of each customer segment is crucial for market players to tailor their offerings and maximize market penetration.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 2.55 Billion |

| Growth Rate | 10.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces | >|

| Segments Covered | >|

| Key Companies Covered | STERIS plc, Getinge AB, Advanced Sterilization Products (ASP), TSO3 Inc. (a subsidiary of STERIS), Bioquell (an Ecolab company), Fedegari Autoclavi SpA, Steelco S.p.A., Klenzaids Contamination Controls Pvt. Ltd., Evoqua Water Technologies, SureWash (Hygieia Group), Daicel Corporation, Solvay S.A., Arkema S.A., Evonik Industries AG, Merck KGaA, DuPont de Nemours, Inc., Clorox Healthcare, 3M Company, Cantel Medical (now a STERIS company), Ecolab Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydrogen Peroxide Disinfection System Market Key Technology Landscape

The Hydrogen Peroxide Disinfection System Market is characterized by a dynamic and evolving technology landscape, continuously driven by the demand for enhanced efficacy, safety, and operational efficiency. The cornerstone technology is the precise generation and dispersion of hydrogen peroxide in various forms to achieve microbial inactivation. Vaporized Hydrogen Peroxide (VHP) systems are prominent, utilizing a generator to convert liquid hydrogen peroxide into a dry gas, which then circulates throughout an enclosed space, penetrating complex geometries and porous materials. The key technological challenge here involves controlling humidity, temperature, and H2O2 concentration to ensure optimal sporicidal activity without condensation, which can lead to material degradation. Advanced VHP systems incorporate sophisticated aeration cycles to rapidly break down residual H2O2 into water and oxygen, ensuring safe re-entry into treated areas.

Beyond VHP, other significant technologies include aerosolized hydrogen peroxide systems, which typically use nebulizers or atomizers to produce a fine mist of hydrogen peroxide. While often simpler and more portable, their efficacy can be limited by particle size and distribution consistency. Plasma hydrogen peroxide systems, primarily used for sterilizing heat and moisture-sensitive medical devices, operate by generating a low-temperature plasma field within a vacuum chamber, which then converts hydrogen peroxide into reactive free radicals. These radicals effectively destroy microorganisms at lower temperatures, preserving the integrity of delicate instruments. Innovations in this area focus on optimizing plasma generation, reducing cycle times, and improving chamber design for larger capacities.

Current technological advancements are concentrating on integrating smart features such as IoT connectivity for remote monitoring and control, AI-driven algorithms for predictive maintenance and cycle optimization, and advanced sensor technology for real-time validation of H2O2 concentration and efficacy. Development efforts are also focused on improving material compatibility, reducing energy consumption, and designing more compact and portable units. There is also a push towards developing systems that offer faster decontamination cycles and more environmentally benign operations. Furthermore, research into novel formulations of hydrogen peroxide, often combined with other synergistic agents, aims to broaden the spectrum of activity and improve stability, ensuring the market continues to provide cutting-edge solutions for infection control and sterilization needs.

Regional Highlights

- North America: This region holds a significant market share, driven by a well-established healthcare infrastructure, high healthcare expenditure, stringent regulatory standards set by bodies like the FDA and CDC for infection control, and a strong presence of key market players. The U.S. and Canada are leaders in adopting advanced disinfection technologies due to high awareness of HAIs and continuous investment in patient safety initiatives.

- Europe: Europe represents another dominant market, characterized by advanced medical facilities, robust pharmaceutical and biotechnology industries, and strict adherence to European Union directives and national health regulations concerning sterilization and disinfection. Germany, the UK, France, and Italy are key contributors, driven by technological innovation and a proactive approach to public health challenges.

- Asia Pacific (APAC): Expected to exhibit the highest growth rate during the forecast period, APAC's market expansion is fueled by rapidly developing healthcare infrastructure, increasing healthcare expenditure, a growing burden of infectious diseases, and rising awareness about hygiene. Countries like China, India, Japan, and South Korea are witnessing significant investments in hospitals and pharmaceutical manufacturing facilities, driving demand.

- Latin America: This region is an emerging market, driven by improving economic conditions, increasing access to healthcare, and a growing focus on modernizing medical facilities. Brazil and Mexico are leading the adoption of advanced disinfection systems, supported by efforts to combat HAIs and comply with international health standards.

- Middle East and Africa (MEA): The MEA market is gradually expanding, propelled by increasing government investments in healthcare infrastructure, growing medical tourism, and a rising imperative for advanced infection control solutions. The UAE, Saudi Arabia, and South Africa are at the forefront of adopting these technologies, spurred by efforts to elevate healthcare quality to global standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydrogen Peroxide Disinfection System Market.- STERIS plc

- Getinge AB

- Advanced Sterilization Products (ASP)

- TSO3 Inc. (a subsidiary of STERIS)

- Bioquell (an Ecolab company)

- Fedegari Autoclavi SpA

- Steelco S.p.A.

- Klenzaids Contamination Controls Pvt. Ltd.

- Evoqua Water Technologies

- SureWash (Hygieia Group)

- Daicel Corporation

- Solvay S.A.

- Arkema S.A.

- Evonik Industries AG

- Merck KGaA

- DuPont de Nemours, Inc.

- Clorox Healthcare

- 3M Company

- Cantel Medical (now a STERIS company)

- Ecolab Inc.

Frequently Asked Questions

Analyze common user questions about the Hydrogen Peroxide Disinfection System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using a Hydrogen Peroxide Disinfection System?

Hydrogen Peroxide Disinfection Systems offer broad-spectrum efficacy against bacteria, viruses, fungi, and spores, providing high-level disinfection and sterilization. They decompose into water and oxygen, leaving no harmful residues, making them environmentally friendly and safe for sensitive equipment. These systems often feature automated cycles, ensuring consistent results and reducing the risk of human error.

How do Hydrogen Peroxide Disinfection Systems compare to traditional disinfection methods?

Compared to traditional methods like chemical wipes or UV-C light, hydrogen peroxide systems, especially vaporized (VHP) types, offer superior penetration into hard-to-reach areas and microscopic crevices, ensuring comprehensive decontamination. Unlike some harsh chemicals, H2O2 systems are generally compatible with a wider range of materials and leave no toxic residues, enhancing safety and material longevity.

What industries are the main adopters of Hydrogen Peroxide Disinfection Systems?

The primary adopters are healthcare facilities (hospitals, clinics, labs) for sterilizing medical devices and decontaminating patient environments. Pharmaceutical and biotechnology companies utilize them for aseptic cleanroom conditions. Additionally, medical device manufacturers, the food and beverage industry for packaging sterilization, and industrial cleanrooms are significant users.

What are the safety considerations when operating Hydrogen Peroxide Disinfection Systems?

Operating these systems requires adherence to strict safety protocols, including proper training, use of personal protective equipment (PPE), and ensuring adequate ventilation. Hydrogen peroxide can be an irritant to skin, eyes, and respiratory tracts, necessitating sealed environments during operation and proper aeration cycles before re-entry into treated areas. System design often incorporates advanced monitoring for H2O2 levels to ensure safety.

How is AI impacting the future of Hydrogen Peroxide Disinfection Systems?

AI is set to revolutionize these systems by enabling predictive maintenance to prevent failures, optimizing disinfection cycles based on real-time data for efficiency, and enhancing validation through continuous monitoring and reporting. AI can also facilitate autonomous operation, smart dosage adjustments, and improved training simulations, leading to more intelligent, reliable, and cost-effective disinfection solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager