Hydrogen Peroxide Vapor (HPV) Decontamination System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437160 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Hydrogen Peroxide Vapor (HPV) Decontamination System Market Size

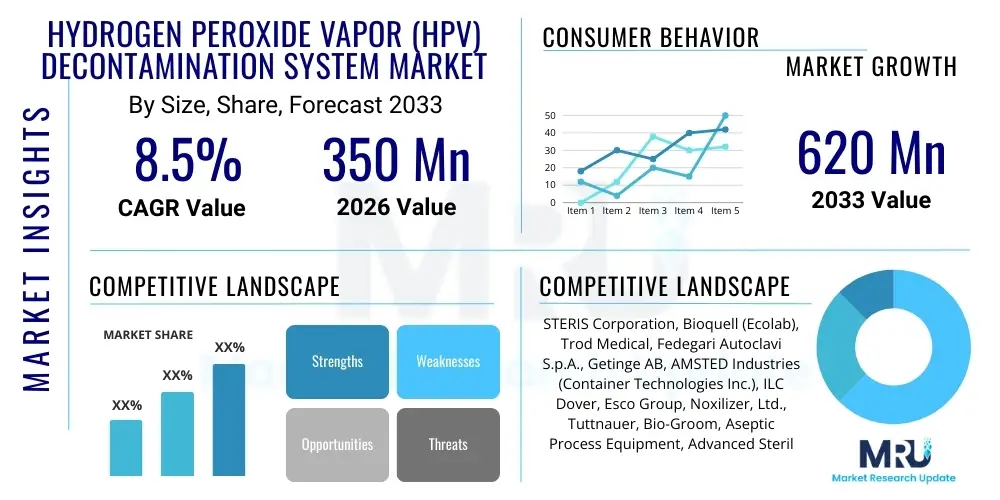

The Hydrogen Peroxide Vapor (HPV) Decontamination System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 350 million in 2026 and is projected to reach USD 620 million by the end of the forecast period in 2033.

Hydrogen Peroxide Vapor (HPV) Decontamination System Market introduction

The Hydrogen Peroxide Vapor (HPV) Decontamination System Market encompasses specialized equipment and services used for the bio-decontamination of enclosed spaces, equipment, and sensitive materials. HPV systems utilize a vaporized solution of hydrogen peroxide, which acts as a powerful broad-spectrum biocide, effectively inactivating bacteria, viruses, fungi, and spores. This non-toxic, residue-free sterilization process is critical for maintaining aseptic conditions in highly regulated environments. Major applications include room and facility decontamination, sterilization of laboratory equipment, transfer chambers, isolators, and ensuring biosafety level (BSL) protocols are met across various industries. The primary advantage of HPV is its ability to achieve a high Sterility Assurance Level (SAL) without causing damage to electronic equipment or sensitive surfaces, unlike traditional methods like formaldehyde.

The core product within this market involves portable or fixed generators that precisely control the temperature, concentration, and humidity required to vaporize the hydrogen peroxide solution and distribute the HPV throughout the target area. The efficacy of these systems is derived from the high oxidative potential of hydrogen peroxide, which disrupts the cell membranes and internal structures of microorganisms. System operational procedures typically include conditioning, gassing, dwell time, and aeration phases, all monitored by sophisticated sensors and validation tools, such as biological and chemical indicators. The market is increasingly driven by the need for validated, repeatable, and automated decontamination processes, especially in sectors where cross-contamination poses significant risks to human health or product integrity.

A primary benefit driving market adoption is the enhanced safety profile for both operators and the environment, as HPV breaks down into harmless water and oxygen after the cycle completion, eliminating the need for complex waste disposal protocols associated with harsher chemicals. Furthermore, the rising incidence of Healthcare-Associated Infections (HAIs) and the global expansion of pharmaceutical manufacturing, particularly aseptic filling and biologics production, solidify the demand for high-performance decontamination solutions. Regulatory bodies, including the FDA and EMA, mandate strict environmental control and validated cleaning procedures in Good Manufacturing Practice (GMP) facilities, thereby reinforcing the essential role of HPV systems in maintaining compliance and product quality.

Hydrogen Peroxide Vapor (HPV) Decontamination System Market Executive Summary

The Hydrogen Peroxide Vapor (HPV) Decontamination System Market is exhibiting strong growth momentum, primarily fueled by the accelerating global focus on infection prevention and control (IPC) across healthcare and life sciences sectors. Business trends indicate a shift towards fully integrated and automated HPV systems that offer quicker cycle times, remote monitoring capabilities, and enhanced data logging features, addressing the industry's demand for operational efficiency and stringent validation. Key market players are investing heavily in R&D to develop compact, mobile systems suitable for diverse applications, ranging from routine equipment sterilization to emergency whole-room bio-decontamination. The market is also seeing robust demand for ancillary services, including specialized training, validation services, and consumables (hydrogen peroxide solutions, biological indicators), contributing significantly to the overall revenue streams.

Regionally, North America and Europe maintain their dominance due to established regulatory frameworks (FDA, EU GMP) mandating high levels of environmental decontamination in pharmaceutical and medical device manufacturing. However, the Asia Pacific (APAC) region is projected to register the highest CAGR, driven by rapid urbanization, substantial investments in R&D infrastructure, and the expansion of domestic biotechnology and pharmaceutical production capabilities, particularly in China and India. The increasing establishment of modern hospital infrastructure in developing economies further accelerates the adoption of advanced infection control technologies like HPV, positioning APAC as a crucial growth engine over the forecast period.

In terms of segmentation, the Equipment segment, particularly portable HPV generators, holds the largest market share due to their flexibility and broad applicability across various room sizes and equipment types. Concurrently, the Services segment is anticipated to grow at a faster pace, reflecting the increasing outsourcing of complex decontamination validation and routine cycle maintenance by end-users seeking specialized expertise and minimizing capital expenditure. The Pharmaceutical and Biotechnology application segment remains the primary revenue driver, given the critical requirement for aseptic processing environments, though the growing utilization in clinical laboratories and hospitals for terminal disinfection cycles is also contributing substantial growth.

AI Impact Analysis on Hydrogen Peroxide Vapor (HPV) Decontamination System Market

User queries regarding AI's influence on the HPV market commonly center around cycle optimization, predictive maintenance, and validation accuracy. Users seek to understand if AI and Machine Learning (ML) can shorten the typically long HPV cycle times while ensuring sterilization efficacy, how AI tools can prevent costly equipment failures, and whether generative engines can assist in real-time regulatory documentation and compliance reporting. The core expectation is that AI will transform HPV from a standard, rule-based process into an intelligent, adaptive system that adjusts parameters dynamically based on environmental data and historical performance, significantly enhancing throughput and reliability in critical manufacturing environments.

AI is projected to revolutionize the HPV decontamination process by introducing predictive modeling for bioburden reduction kinetics. By integrating advanced sensors (temperature, humidity, peroxide concentration, particle counts) with ML algorithms, systems can learn the optimal gassing profiles for specific room geometries and equipment loads, drastically reducing the overall cycle time without compromising the Sterility Assurance Level (SAL). This shift from static, validated cycles to dynamic, optimized cycles addresses a primary constraint of HPV technology, making decontamination faster and more predictable, which is crucial for maintaining continuous production schedules in GMP environments.

Furthermore, AI-driven analytics are being utilized to optimize the maintenance and longevity of HPV equipment. ML algorithms analyze operational data, identifying anomalies in component performance (e.g., vaporizers, pumps, filters) before they lead to catastrophic failure. This transition to predictive maintenance minimizes unplanned downtime—a significant cost driver in pharmaceutical manufacturing—and ensures that the decontamination systems are consistently operating within validated parameters. AI also aids in post-cycle analysis by automatically correlating sensor data with biological indicator results, generating detailed, auditable reports that streamline regulatory compliance and quality assurance documentation.

- AI optimizes HPV cycle times by dynamically adjusting vapor delivery based on real-time environmental sensor data and room size specifications.

- Machine Learning models predict maintenance needs for HPV generators (e.g., vaporizer coil lifespan), ensuring maximum uptime and reducing unexpected system failures.

- Generative AI assists in automated regulatory reporting and validation documentation by processing vast quantities of cycle data and ensuring compliance standards are met.

- Advanced image processing and sensor fusion, enhanced by AI, can detect potential surface coverage gaps, ensuring comprehensive spore eradication across complex geometries.

- AI integration supports remote diagnostics and troubleshooting, allowing vendors to address system issues quickly, minimizing disruption to end-user operations.

DRO & Impact Forces Of Hydrogen Peroxide Vapor (HPV) Decontamination System Market

The HPV Decontamination System Market is profoundly shaped by a confluence of accelerating drivers and constraining factors, balanced by significant opportunities emerging from technological evolution and geographical expansion. The paramount driver is the escalating global focus on combating Hospital-Acquired Infections (HAIs) and the heightened regulatory stringency imposed by agencies like the FDA, necessitating validated, reproducible sterilization methods in healthcare and pharmaceutical settings. However, the market faces restraints, primarily related to the high initial capital investment required for purchasing advanced HPV generators and the need for specialized, continuous operator training and meticulous maintenance protocols to ensure effective system performance. Successfully navigating these forces defines competitive success in this specialized sector.

Key drivers include the burgeoning growth of the biopharmaceuticals sector, which relies heavily on barrier isolation technologies and controlled aseptic environments where HPV is the preferred method of sterilization for isolators and RABS (Restricted Access Barrier Systems). The effectiveness of HPV against multi-drug resistant organisms (MDROs) also solidifies its adoption in healthcare. Conversely, a significant restraint is the relatively long cycle time required for full room decontamination compared to traditional fogging methods, although this is rapidly being addressed by newer, optimized technology incorporating better aeration and catalytic breakdown processes. Furthermore, the perceived complexity of the validation process (e.g., mapping spore strip placement, interpreting sensor data) can deter smaller facilities, favoring outsourcing instead.

Opportunities for expansion lie significantly within emerging economies in the APAC and Latin America regions, where rapid modernization of hospital infrastructure and increasing foreign direct investment in local pharmaceutical manufacturing plants are creating robust demand. Technological advancements present another key opportunity, particularly the integration of Internet of Things (IoT) sensors and cloud connectivity for real-time monitoring and remote validation. Developing specialized, high-throughput HPV systems tailored for specific niche applications, such as large-scale animal research facilities or unique cleanroom configurations, also represents fertile ground for market penetration and differentiation among leading vendors.

Segmentation Analysis

The HPV Decontamination System market is segmented across several critical dimensions, including the nature of the offering (Product vs. Service), the type of system (Portable vs. Fixed), the concentration of hydrogen peroxide used, and the primary end-user applications. Understanding these segments is vital for stakeholders to tailor product development and market strategies. The segmentation highlights the intrinsic value of both the physical equipment—the specialized generators—and the essential support services, such as validation, maintenance, and training, that ensure the systems operate effectively and remain compliant with stringent global regulatory standards.

The segmentation by Product Type often differentiates between HPV generators and related consumables, with generator sales driving initial capital expenditure and consumables (peroxide solutions, indicators) providing recurring revenue streams. End-user segmentation clearly defines the primary demand landscape, dominated by pharmaceutical and biotechnology companies requiring guaranteed sterile environments for drug production, followed closely by hospitals and academic research institutions focused on biosafety and infection control. Geographical segmentation remains crucial, showing the mature, regulation-heavy markets of North America and Europe contrasting with the high-growth potential of emerging regions like Asia Pacific, which is rapidly building GMP-compliant facilities.

- By Product Type:

- HPV Generators (Portable Systems, Fixed/Integrated Systems)

- Consumables (Hydrogen Peroxide Solutions, Biological Indicators, Chemical Indicators)

- By End User:

- Pharmaceutical and Biotechnology Companies

- Hospitals and Healthcare Facilities

- Medical Device Manufacturers

- Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs)

- Academic and Research Institutes (BSL Laboratories)

- By Application:

- Room/Area Decontamination (Terminal Cleaning)

- Isolation Chamber Sterilization (Isolators, RABS)

- Equipment and Instrument Sterilization

- Transfer Chamber Decontamination

- By Service:

- Maintenance and Calibration

- Validation and Documentation

- Training and Consulting

Value Chain Analysis For Hydrogen Peroxide Vapor (HPV) Decontamination System Market

The value chain for the HPV Decontamination System Market begins with the upstream sourcing and manufacturing of high-purity hydrogen peroxide solution, the core raw material, and specialized components such as high-precision vaporization systems, sensor technology, and aeration units. Manufacturing involves intricate engineering to produce reliable, validated generators capable of stable vapor delivery across varying environmental conditions. Key upstream challenges include ensuring a stable supply of high-grade peroxide and integrating proprietary sensor technology that accurately measures sub-parts-per-million concentrations, critical for process control and validation in highly sensitive environments.

The midstream of the value chain is characterized by complex distribution channels, which are generally segmented into direct sales models for large pharmaceutical companies requiring specialized installation and custom integration, and indirect models utilizing specialized distributors for hospitals and smaller research institutions. Direct engagement is often preferred due to the necessity of comprehensive pre-sales consultation, site surveys, and specialized technical support required during installation and initial validation. The distribution also includes specialized logistics for the delivery of the hydrogen peroxide liquid and biological indicators, requiring specific safety and handling protocols.

Downstream activities are dominated by specialized service provision, which often constitutes a recurring revenue stream far exceeding the initial system sale. This includes complex validation services (IQ/OQ/PQ protocols), routine preventive maintenance, and expert training necessary to ensure end-users maintain regulatory compliance (e.g., GxP standards). The direct interaction between the manufacturer/service provider and the end-user is critical in the post-sales phase, as successful market penetration hinges not just on the efficacy of the system but on the reliability and responsiveness of the validation and repair support provided throughout the system’s lifecycle. The shift towards connected, IoT-enabled systems further integrates the service provider into the end-user’s operational workflow.

Hydrogen Peroxide Vapor (HPV) Decontamination System Market Potential Customers

The potential customer base for HPV Decontamination Systems is heavily concentrated in sectors requiring absolute microbial control and highly validated sterilization processes. The primary end-users are pharmaceutical and biotechnology companies, which utilize these systems extensively for the sterilization of aseptic processing areas, filling lines, cleanrooms, and, most crucially, barrier isolation technology (isolators and RABS). These customers prioritize reliability, validated cycle performance, and rapid turnaround times to minimize production pauses. The increasing production of sensitive biologics and cell therapies, which demand ultra-clean environments, is continually expanding this customer segment.

Hospitals and other acute healthcare facilities represent a rapidly growing customer segment, driven by the imperative to reduce the incidence of highly publicized Healthcare-Associated Infections (HAIs), particularly those resistant to standard chemical cleaning. HPV systems are deployed in hospitals for terminal decontamination of operating rooms, patient isolation rooms, and high-risk areas like Intensive Care Units (ICUs) and neonatal wards. While hospital budgets are often tighter than pharmaceutical budgets, the demonstrable reduction in infection rates provides a compelling return on investment, particularly as regulatory focus on HAI reporting intensifies globally.

Furthermore, institutions involved in advanced research, including academic laboratories, Contract Research Organizations (CROs), and animal testing facilities (vivaria), constitute significant buyers. BSL-3 and BSL-4 laboratories require stringent and easily validated decontamination methods for ensuring biosafety protocols are strictly followed after handling high-hazard biological agents. For CROs and CMOs, adopting state-of-the-art HPV systems is essential for attracting and retaining clients who demand GMP compliance and the highest level of sterility assurance for their outsourced projects, positioning these systems as critical competitive differentiators.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 620 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | STERIS Corporation, Bioquell (Ecolab), Trod Medical, Fedegari Autoclavi S.p.A., Getinge AB, AMSTED Industries (Container Technologies Inc.), ILC Dover, Esco Group, Noxilizer, Ltd., Tuttnauer, Bio-Groom, Aseptic Process Equipment, Advanced Sterilization Products (ASP), Shinva Medical Instrument Co., Ltd., Wenzhou Fanyat Machinery Co., Ltd., Zhejiang Tailin Bioengineering Co., Ltd., JCE Biotechnology, LSP Technologie GmbH, MBRAUN, SagiCofam S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydrogen Peroxide Vapor (HPV) Decontamination System Market Key Technology Landscape

The technological landscape of the HPV Decontamination System market is focused on enhancing efficacy, reducing cycle times, and improving data integrity and connectivity. Current advancements are heavily concentrated on refined vaporization and aeration technologies. Modern HPV generators increasingly incorporate advanced catalytic converters and sophisticated internal control systems to ensure precise control over the hydrogen peroxide concentration (parts per million—ppm) and the dew point within the treated area. This precision is essential for achieving optimal "micro-condensation" required for effective sporicidal action without damaging sensitive equipment. Furthermore, integrated sensor technology, including specialized VHP sensors and biological indicators utilizing fluorescent technology, provides real-time feedback and instantaneous cycle validation status, moving away from post-cycle verification.

A major technological trend is the development of fully integrated, fixed HPV systems designed to be incorporated directly into the HVAC and building management systems (BMS) of pharmaceutical cleanrooms and BSL facilities. These integrated solutions allow for continuous environmental monitoring and automatic, pre-programmed decontamination cycles, reducing human intervention and minimizing procedural variability, thereby guaranteeing repeatable results required by GMP standards. This integration often includes sophisticated air handling controls that manage air pressure differentials and ensure the safe containment and breakdown of the vapor post-cycle, optimizing the rapid return of the space to operational status, which is a key determinant of system efficiency.

Digital transformation, particularly the application of IoT and cloud computing, is critical. Newer systems are equipped with robust data logging and remote connectivity features, enabling predictive maintenance, remote diagnostics, and secure, cloud-based storage of validation records. This digital overlay facilitates compliance tracking and operational analysis across multiple sites for global pharmaceutical manufacturers. The move towards low-temperature vaporization and improved liquid formulation stability also broadens the applicability of HPV systems to temperature-sensitive materials and complex medical devices, reinforcing HPV's position as the gold standard for robust, residue-free bio-decontamination.

Regional Highlights

The global HPV Decontamination System market demonstrates distinct regional dynamics, influenced by regulatory maturity, healthcare spending, and industrialization rates.

- North America (U.S. and Canada): Dominates the market share due to stringent FDA regulations governing pharmaceutical manufacturing, robust expenditure on infection control in hospitals, and the high concentration of major biotechnology and medical device companies. The early adoption of advanced barrier isolation technologies (RABS and isolators) ensures consistent high demand for HPV systems and related consumables and services.

- Europe (Germany, UK, France): Represents the second largest market, driven by strict EU GMP requirements and significant investment in clinical research infrastructure. Demand is stable and focuses on fixed, integrated HPV systems for optimizing complex cleanroom facilities and adhering to centralized safety standards.

- Asia Pacific (APAC) (China, India, Japan): Projected to be the fastest-growing region. Growth is fueled by rapid expansion of domestic pharmaceutical industries (generic and biologics), massive investments in modern hospital construction, and increasing adoption of Western standards for infection control and aseptic processing, particularly in contract manufacturing organizations (CMOs).

- Latin America (LATAM): Exhibits moderate growth, primarily centered in Brazil and Mexico, driven by efforts to modernize healthcare infrastructure and increasing foreign investment in localized pharmaceutical production, leading to greater demand for validated decontamination solutions.

- Middle East & Africa (MEA): Emerging market characterized by selective adoption in high-income Gulf Cooperation Council (GCC) countries investing in state-of-the-art specialized hospitals and sophisticated research centers. Regulatory compliance is gradually strengthening, which will further unlock market potential over the forecast period.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydrogen Peroxide Vapor (HPV) Decontamination System Market.- STERIS Corporation

- Bioquell (Ecolab)

- Trod Medical

- Fedegari Autoclavi S.p.A.

- Getinge AB

- AMSTED Industries (Container Technologies Inc.)

- ILC Dover

- Esco Group

- Noxilizer, Ltd.

- Tuttnauer

- Bio-Groom

- Aseptic Process Equipment

- Advanced Sterilization Products (ASP)

- Shinva Medical Instrument Co., Ltd.

- Wenzhou Fanyat Machinery Co., Ltd.

- Zhejiang Tailin Bioengineering Co., Ltd.

- JCE Biotechnology

- LSP Technologie GmbH

- MBRAUN

- SagiCofam S.p.A.

Frequently Asked Questions

Analyze common user questions about the Hydrogen Peroxide Vapor (HPV) Decontamination System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driving factor for the growth of the HPV Decontamination System Market?

The primary factor driving market growth is the global imperative to reduce Healthcare-Associated Infections (HAIs) and the increasingly stringent regulatory requirements (e.g., FDA, EMA) mandating validated, highly effective sterilization methods in pharmaceutical, biotechnology, and healthcare environments.

How does Hydrogen Peroxide Vapor (HPV) differ from traditional sterilization methods like formaldehyde?

HPV offers significant advantages over older methods like formaldehyde, primarily because it is non-carcinogenic, leaves no toxic residue (breaking down into water and oxygen), and is compatible with sensitive electronic equipment, offering rapid aeration and return-to-service times while achieving high Sterility Assurance Levels (SAL).

Which end-user segment dominates the HPV Decontamination System market demand?

The Pharmaceutical and Biotechnology segment holds the largest market share. This dominance is due to the critical need for validated aseptic processing environments for drug manufacturing, particularly involving isolators, RABS, and cleanroom areas governed by strict GxP regulations.

What is the role of IoT and AI in modern HPV systems?

IoT and AI are crucial for enhancing operational efficiency. IoT enables real-time remote monitoring and secure data logging, while AI algorithms are used to optimize decontamination cycle parameters, shorten cycle times, and implement predictive maintenance schedules, ensuring maximum system uptime and compliance.

What are the key challenges facing the adoption of HPV technology in emerging markets?

Key challenges include the high initial capital expenditure required for purchasing and installing the systems, coupled with the need for specialized technical expertise and comprehensive training to ensure correct operation and validation protocols are consistently followed in less established regulatory environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager