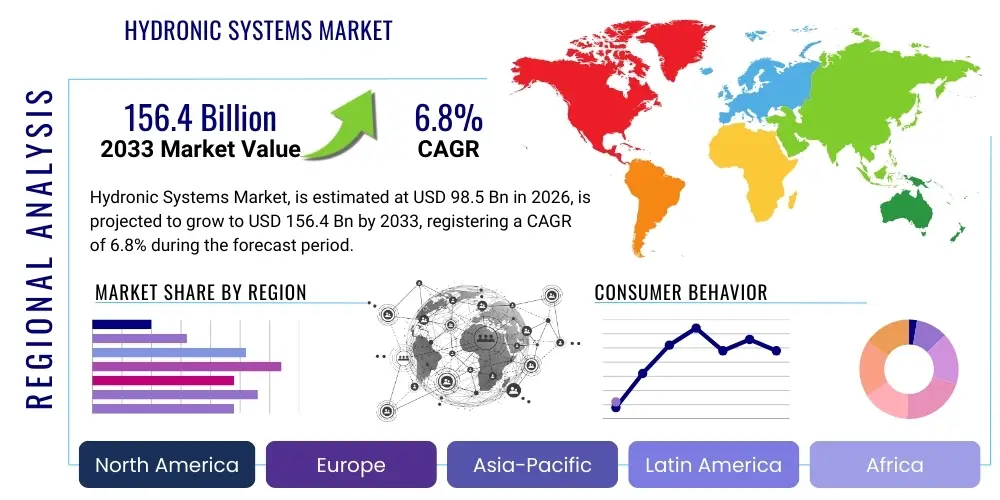

Hydronic Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436742 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Hydronic Systems Market Size

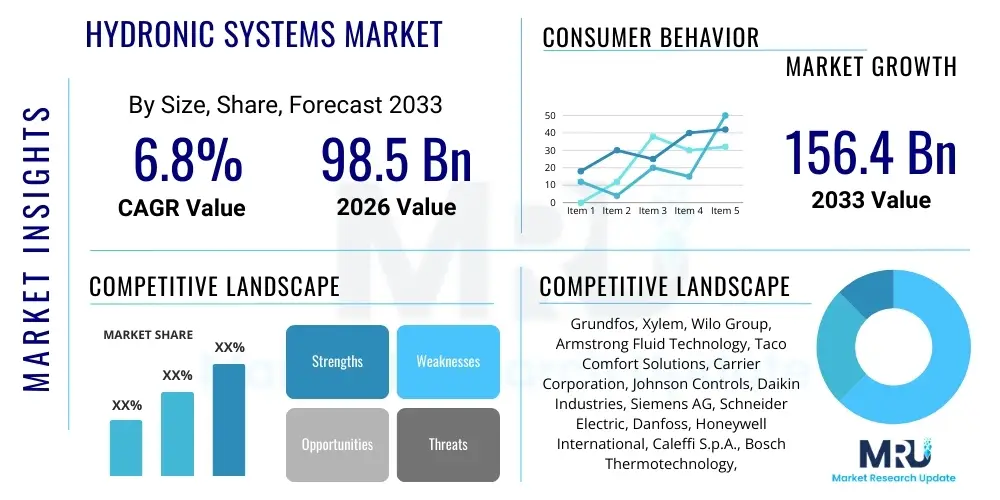

The Hydronic Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 98.5 Billion in 2026 and is projected to reach USD 156.4 Billion by the end of the forecast period in 2033.

Hydronic Systems Market introduction

Hydronic systems represent sophisticated fluid-based infrastructure designed for heating, cooling, and ventilation (HVAC) applications within various building types. These systems utilize water or a water-glycol mixture (the working fluid) circulated through a closed loop using pumps, distributing thermal energy efficiently from a central plant (like a boiler, chiller, or heat pump) to terminal units (such as radiant panels, fan coil units, or radiators). The core product components include specialized pumps, control valves, piping networks, heat exchangers, and intelligent control systems that manage flow rates and temperatures precisely. Hydronic solutions are critically important for large-scale commercial, institutional, and industrial facilities where zonal temperature control and high energy efficiency are paramount requirements for operational sustainability and occupant comfort.

Major applications of hydronic systems span across residential, commercial, and industrial sectors. In residential buildings, they are commonly utilized for radiant floor heating and snow melting, offering superior comfort compared to forced-air systems. The commercial segment, encompassing offices, hospitals, data centers, and educational institutions, relies heavily on large-scale hydronic cooling (chilled water systems) and heating (boiler systems) due to their inherent scalability, efficiency, and ability to handle diverse load profiles simultaneously. Industrial applications primarily involve process cooling or precise temperature maintenance critical for manufacturing operations, utilizing specialized fluids and components tailored for harsh environments and high-capacity heat transfer.

The primary benefits driving the adoption of hydronic systems include exceptional energy efficiency, superior zone control, quiet operation, and system longevity. Driving factors for market growth include stringent global building energy codes aimed at reducing carbon emissions, the increasing necessity for sustainable HVAC solutions in green building certifications (like LEED), and the robust growth in commercial construction, particularly in high-density urban areas. Furthermore, the integration of hydronic systems with renewable energy sources, such as geothermal heat pumps and solar thermal collectors, enhances their appeal as future-proof heating and cooling solutions, providing significant long-term operational cost savings despite higher initial capital expenditure.

Hydronic Systems Market Executive Summary

The Hydronic Systems Market is experiencing robust growth driven by the global imperative toward energy conservation and sustainable infrastructure development. Current business trends indicate a significant shift towards smart hydronic systems featuring variable speed drives (VSDs) for pumps and intelligent control valves integrated with Building Management Systems (BMS). Manufacturers are focused on developing modular and prefabricated hydronic solutions that simplify installation, reduce on-site labor costs, and improve system commissioning accuracy. Furthermore, there is a clear trend in the adoption of low-temperature heating systems, catalyzed by the deployment of high-efficiency heat pumps, demanding specialized components designed for optimized performance at lower supply water temperatures, thus enhancing overall system efficiency.

Regionally, the market dynamics are highly influenced by climate and regulatory landscapes. North America and Europe remain mature markets, characterized by high replacement demand and strong regulatory frameworks mandating high-efficiency components in new constructions and renovations. Europe, in particular, is a leader in adopting district heating networks, which fundamentally rely on large-scale hydronic distribution, propelling growth in specialized heat exchangers and high-pressure pumps. The Asia Pacific region, led by rapidly expanding economies like China and India, presents the highest growth potential, fueled by massive urbanization, large-scale infrastructure projects, and increasing consumer awareness regarding energy-efficient cooling solutions, particularly in the booming commercial real estate and data center sectors.

Segment trends reveal that the Control Systems segment, including sensors, actuators, and advanced thermostats, is anticipated to witness the fastest growth, primarily due to the digitalization of building management and the necessity for predictive maintenance capabilities. By application, the Commercial sector maintains the largest market share due to the sheer scale and complexity of HVAC requirements in large institutional and corporate buildings. Within the component category, the focus is shifting from standard constant-speed pumps to highly efficient, electronically commutated motor (ECM) circulators and smart valves capable of dynamic balancing, ensuring precise flow control and minimizing energy waste across varying load conditions throughout the building envelope.

AI Impact Analysis on Hydronic Systems Market

User queries regarding the intersection of Artificial Intelligence (AI) and Hydronic Systems primarily revolve around optimization capabilities, predictive maintenance, and energy savings potential. Common questions include how AI algorithms can predict fluctuating building loads accurately, whether AI-driven control systems can outperform traditional proportional-integral-derivative (PID) controllers, and what the financial return on investment (ROI) is for implementing machine learning in existing hydronic infrastructure. Users are concerned about data security, the required complexity of sensor networks, and the integration challenges when retrofitting older systems with advanced AI modules. The key themes emerging are the expectation for substantial energy cost reductions, the desire for automated fault detection before major failures occur, and the seamless harmonization of hydronic operations with overall smart building platforms.

The impact of AI is transforming hydronic system management from reactive maintenance to highly proactive and adaptive operation. AI allows for the continuous analysis of vast datasets generated by sensors monitoring water flow, temperature, pressure, and pump energy consumption. Machine learning models can identify subtle inefficiencies, such as minor valve leakage or suboptimal pump staging, that human operators or standard BMS protocols might miss. This analytical capability translates into dynamic system adjustments—modulating chiller sequencing, optimizing pump VSD speeds based on real-time occupancy data, and adjusting setpoints to maintain comfort while minimizing energy input. For example, AI can forecast cooling needs an hour in advance based on weather predictions and historical system performance, initiating pre-cooling cycles strategically.

The long-term influence of AI extends into system design and lifecycle management. AI tools are being developed to optimize the initial sizing and placement of hydronic components, minimizing pressure drop and maximizing thermal distribution efficiency before construction even begins. In operational phases, AI significantly enhances maintenance strategies by predicting component failure probability, allowing facilities managers to schedule repairs precisely when needed, rather than relying on time-based preventative schedules. This shift minimizes unplanned downtime, extends the lifespan of expensive equipment like boilers and chillers, and fundamentally alters the labor requirements for system upkeep, promoting specialized expertise in data science and integration.

- Enhanced Predictive Maintenance: AI algorithms analyze vibration, temperature, and flow data to predict pump or valve failure, reducing unexpected downtime.

- Dynamic System Optimization: Real-time adjustment of flow rates, differential pressure setpoints, and staging logic based on occupancy and load forecasting via machine learning.

- Automated Fault Detection and Diagnostics (FDD): Rapid identification of system anomalies, such as fouling in heat exchangers or sensor drift, improving operational resilience.

- Energy Consumption Reduction: Optimization of chiller and boiler sequencing and modulation to achieve peak efficiency based on predicted thermal demand.

- Improved Commissioning Efficiency: AI-assisted tools streamline the system balancing and commissioning process by identifying optimal calibration parameters quickly.

- Integration with Smart Grids: AI allows hydronic systems, especially those using thermal storage, to participate in demand response programs by adjusting operation based on grid pricing signals.

DRO & Impact Forces Of Hydronic Systems Market

The Hydronic Systems Market is principally influenced by a confluence of powerful drivers, structural restraints, and emerging opportunities, all mediated by significant impact forces such as regulatory mandates and technological evolution. A primary driver is the accelerating global focus on reducing energy consumption in buildings, supported by stringent governmental policies promoting high-efficiency HVAC solutions, such as the EU's Energy Performance of Buildings Directive (EPBD) and various national efficiency standards in North America. These mandates favor hydronic systems over traditional air-based systems due to water's superior thermal transfer capabilities and the inherent efficiency gains achieved through variable flow systems. Furthermore, the robust expansion of the construction sector globally, especially the growth of large, complex commercial buildings and data centers requiring high-capacity cooling, significantly bolsters demand for advanced chilled water systems.

However, market growth faces notable restraints, chiefly concerning the high initial capital investment required for hydronic system installation compared to simpler, direct-expansion (DX) systems. The complexity of design, which involves detailed hydraulic balancing, pump selection, and sophisticated piping networks, necessitates highly skilled labor, leading to increased installation costs and potential project delays if expertise is lacking. Another constraint involves the perception of high maintenance difficulty associated with water quality management (corrosion, scaling) and the potential for leaks, which often requires specialized chemical treatment and ongoing monitoring. Addressing these challenges requires better training programs for installers and end-users, alongside the introduction of more standardized, modular component designs.

Opportunities for market expansion are abundant, particularly through the ongoing integration of Internet of Things (IoT) technologies and the rise of smart building automation. IoT sensors and connected controls facilitate remote monitoring, predictive maintenance, and granular optimization previously unavailable, transforming system reliability and efficiency. A key technological opportunity lies in the expanding adoption of district energy systems (heating and cooling), which necessitate vast networks of high-performance hydronic infrastructure. Furthermore, the continued development of high-efficiency components like magnetic bearing chillers, advanced heat pumps utilizing natural refrigerants, and intelligent proportional balancing valves are opening new niches for energy savings, making hydronics a competitive solution even in historically air-dominant markets. These opportunities are supported by market impact forces emphasizing sustainability, life-cycle cost analysis, and digitalization across the building services industry.

Segmentation Analysis

The Hydronic Systems Market is comprehensively segmented across several dimensions, including System Type (Heating, Cooling, Combined), Component (Pumps, Valves, Heat Exchangers, Controls), and Application (Residential, Commercial, Industrial). This granular segmentation helps in understanding the diverse demands placed on manufacturers and service providers. The transition toward integrated systems capable of both heating and cooling, often driven by reversible heat pumps, is redefining the Type segment. Meanwhile, the Component segment is witnessing rapid innovation focused on increasing component intelligence and energy efficiency, particularly in the critical areas of fluid circulation and flow management, which directly impact overall system performance and operational costs across all application settings.

- System Type:

- Heating Systems (Boilers, Radiant Panels, Radiators)

- Cooling Systems (Chillers, Cooling Towers, Fan Coil Units)

- Combined Heating and Cooling Systems (Heat Pumps, Four-Pipe Systems)

- Component:

- Pumps and Circulators (Standard Pumps, ECM Pumps, Variable Speed Drives)

- Valves and Actuators (Control Valves, Balancing Valves, Isolation Valves)

- Heat Exchangers (Plate, Shell and Tube, Brazed)

- Piping and Fittings (Copper, Steel, PEX, CPVC)

- Terminal Units (Fan Coil Units, Radiant Panels, Air Handling Units)

- Control Systems (Thermostats, Sensors, BMS Integration Modules)

- Application:

- Residential (Single-family homes, Multi-family buildings)

- Commercial (Office Buildings, Retail, Data Centers, Hospitality, Healthcare)

- Industrial (Manufacturing Plants, Process Cooling, Power Generation)

Value Chain Analysis For Hydronic Systems Market

The value chain for the Hydronic Systems Market begins with upstream activities focused on the sourcing and processing of raw materials, primarily specialized metals (steel, copper, aluminum) and plastics used for pumps, valves, piping, and heat exchangers. Key upstream suppliers include specialized material producers and component manufacturers who provide core technologies such as motors for pumps (e.g., ECM motors) and precision manufacturing for complex valve bodies. Cost optimization at this stage is crucial, as the performance and longevity of the final system are highly dependent on the quality of these base components. Strategic partnerships with reliable component suppliers ensure material compliance with relevant industry standards, such as pressure ratings and corrosion resistance.

The core midstream activity involves the manufacturing, assembly, and testing of complete hydronic systems and sub-assemblies (e.g., packaged pump stations, modular chillers). Major equipment manufacturers integrate components from upstream suppliers, applying rigorous quality control and often incorporating proprietary intellectual property related to efficiency optimization and control logic. Distribution channels play a vital role in connecting manufacturers to the final installation site. Direct channels involve large manufacturers selling directly to major contractors or specialized energy services companies (ESCOs) for massive commercial or district heating projects. Indirect channels, which dominate the smaller commercial and residential segments, rely heavily on a network of wholesale distributors, specialized mechanical supply houses, and local dealers who provide inventory, logistics, and localized technical support.

Downstream activities center on installation, system commissioning, maintenance, and eventual replacement or retrofit. Installation is typically performed by highly skilled mechanical, electrical, and plumbing (MEP) contractors who must accurately size, install, and balance the complex fluid dynamics of the system. System commissioning—the process of verifying that the system operates according to the design specifications—is essential for achieving efficiency targets and relies on specialized technical expertise. Post-installation, the value chain shifts towards long-term service agreements, where maintenance providers utilize increasingly digital tools for predictive monitoring, ensuring operational efficiency and maximizing the system's lifespan. The effectiveness of the distribution and service network is a critical determinant of market penetration and customer satisfaction.

Hydronic Systems Market Potential Customers

The potential customer base for hydronic systems is broad, encompassing three primary end-user categories: residential owners, commercial building developers and owners, and industrial facility operators. In the residential sector, the primary buyers are custom home builders and renovation contractors seeking high-end heating solutions, particularly radiant floor heating, which offers exceptional comfort and energy efficiency. These customers prioritize system aesthetics (invisibility of heating elements) and long-term operating cost savings, often choosing premium, durable components that integrate seamlessly with smart home technology.

The largest and most lucrative segment consists of commercial end-users, including real estate developers, facility management companies, hospital administrators, university systems, and data center operators. These customers typically purchase large-scale, complex hydronic systems for central heating and cooling. For commercial entities, purchasing decisions are driven by total cost of ownership (TCO), stringent redundancy requirements (especially in data centers and hospitals), regulatory compliance, and the need to achieve specific indoor climate quality standards crucial for employee productivity or patient recovery. Data centers, in particular, represent a high-growth customer segment requiring massive, efficient chilled water systems to handle high thermal loads.

Industrial end-users, encompassing manufacturers (e.g., automotive, chemical, pharmaceutical) and utility companies, require hydronic systems primarily for precise process cooling and temperature control. These applications often involve non-standard fluid compositions, high pressures, and extreme temperatures. Industrial buyers prioritize reliability, durability against corrosion and operational stress, and adherence to specialized safety and environmental regulations. Their purchasing cycle often involves extensive engineering consultation, focusing on customized solutions and components designed for continuous, heavy-duty operation rather than standard commercial off-the-shelf products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 98.5 Billion |

| Market Forecast in 2033 | USD 156.4 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Grundfos, Xylem, Wilo Group, Armstrong Fluid Technology, Taco Comfort Solutions, Carrier Corporation, Johnson Controls, Daikin Industries, Siemens AG, Schneider Electric, Danfoss, Honeywell International, Caleffi S.p.A., Bosch Thermotechnology, Mueller Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydronic Systems Market Key Technology Landscape

The technological landscape of the Hydronic Systems Market is undergoing a rapid evolution, primarily driven by the need for greater energy efficiency, precision control, and seamless integration into digital building ecosystems. A pivotal technological shift involves the widespread adoption of Electronically Commutated Motor (ECM) circulators and pumps, which significantly reduce electricity consumption compared to older constant-speed induction motors. These ECM pumps incorporate internal variable speed drives (VSDs), allowing them to adjust their performance curve instantaneously to match the real-time demands of the system, minimizing excess flow and associated energy waste. Furthermore, advanced hydraulic balancing methodologies, facilitated by differential pressure controls and intelligent motorized control valves, ensure optimal thermal distribution across vast networks, crucial for maintaining comfort and maximizing boiler/chiller efficiency.

The integration of digital technologies represents another major trend. Modern hydronic control systems utilize sophisticated sensors—including ultrasonic flow meters and high-accuracy temperature sensors—to provide Building Management Systems (BMS) with precise operational data. This data forms the backbone of digital twin modeling and predictive maintenance protocols. The shift towards IoT connectivity enables remote system access, diagnostics, and over-the-air firmware updates, significantly reducing the maintenance burden and improving responsiveness. Advanced algorithms are now employed for optimal start/stop sequencing of central plant equipment, minimizing transient losses and extending equipment lifespan through managed operation cycles.

Material science and thermal efficiency improvements are also key differentiators. The use of high-performance materials in heat exchangers, particularly advanced plate heat exchanger designs, maximizes the surface area for heat transfer while minimizing the component footprint. In heating applications, the proliferation of low-temperature hydronic systems, driven by high-efficiency condensing boilers and renewable heat sources like geothermal heat pumps, requires specialized PEX piping and low-mass radiant panels designed for optimal performance below 120°F (49°C). These technological advancements collectively enhance the sustainability profile of hydronic systems, positioning them favorably against competing HVAC technologies in the push towards net-zero energy buildings.

Regional Highlights

The geographical analysis of the Hydronic Systems Market reveals distinct growth trajectories and technological preferences shaped by climate, regulatory environment, and construction activity. The regional dynamics are crucial for manufacturers planning market entry or expansion strategies, focusing not only on raw demand volume but also on the specific component needs driven by local energy sources and thermal requirements.

- North America (United States, Canada): This region is characterized by a strong emphasis on commercial retrofits and high-efficiency upgrades, particularly in the dense urban cores of the Northeast and Mid-Atlantic. Growth is driven by energy code updates (e.g., ASHRAE 90.1) mandating high-efficiency pumps and controls. The US market shows high adoption of chilled water systems in commercial buildings and a growing residential interest in radiant floor heating coupled with geothermal heat pumps, focusing on minimizing operational costs and maximizing system longevity.

- Europe (Germany, UK, France, Scandinavia): Europe is the global leader in district heating and low-temperature hydronic solutions. Regulatory pressures, especially the European Green Deal and national efforts to phase out fossil fuel boilers, are accelerating the transition to high-efficiency heat pumps (air-source and ground-source) and sophisticated control valves. Scandinavia leads in high-density district energy networks, demanding durable, large-scale heat exchangers and high-pressure piping systems. Germany and the UK show high demand for smart metering and highly integrated control systems for zonal temperature management.

- Asia Pacific (China, India, Japan, South Korea): APAC is the fastest-growing region, fueled by massive infrastructure investment, rapid urbanization, and a soaring demand for cooling solutions, particularly in tropical and subtropical climates. China and India are major hubs for commercial construction (data centers, skyscrapers), creating immense opportunities for large-scale chiller plants and associated hydronic networks. The focus is often on initial cost-effectiveness alongside increasing requirements for basic energy efficiency, leading to high-volume sales of pumps and standardized component packages.

- Latin America (Brazil, Mexico): Market growth here is moderate, concentrated primarily in new commercial and industrial developments. The market often follows global trends but is sensitive to economic fluctuations. There is increasing interest in energy-saving technologies, particularly in industrial process cooling applications, driving demand for robust and reliable components suitable for fluctuating power supply conditions.

- Middle East and Africa (MEA): This region is dominated by extreme cooling requirements, leading to high demand for high-capacity chilled water systems and reliable cooling towers, particularly in the Gulf Cooperation Council (GCC) countries. Major drivers include large hospitality projects, residential towers, and massive industrial expansion. Energy efficiency is becoming increasingly important due to high air conditioning loads, promoting the use of VSDs and advanced flow measurement controls to manage peak demand effectively.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydronic Systems Market.- Grundfos

- Xylem

- Wilo Group

- Armstrong Fluid Technology

- Taco Comfort Solutions

- Carrier Corporation

- Johnson Controls

- Daikin Industries

- Siemens AG

- Schneider Electric

- Danfoss

- Honeywell International

- Caleffi S.p.A.

- Bosch Thermotechnology

- Mueller Industries

- Victaulic Company

- Flowserve Corporation

- Uponor Corporation

- Uponor Corporation

- Pentair plc

Frequently Asked Questions

Analyze common user questions about the Hydronic Systems market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Hydronic Systems Market?

The primary driver is the global emphasis on building energy efficiency and sustainability mandates. Hydronic systems, particularly those integrated with variable speed technology and renewable heat sources (like heat pumps), offer significantly lower operational energy consumption compared to traditional forced-air HVAC systems, aligning with stringent international energy codes and green building certifications (e.g., LEED).

How are smart controls and IoT affecting the efficiency of installed hydronic systems?

Smart controls and IoT are fundamentally transforming hydronic system efficiency by enabling dynamic, real-time optimization. IoT sensors provide continuous data on flow, pressure, and temperature, allowing AI-driven Building Management Systems (BMS) to modulate pump speeds and valve positions precisely. This capability minimizes unnecessary flow and pump head, resulting in substantial energy savings, often exceeding 20%, and facilitating proactive, predictive maintenance schedules.

Which geographical region exhibits the highest growth potential for new hydronic installations?

The Asia Pacific (APAC) region, specifically emerging economies such as China and India, demonstrates the highest growth potential. This growth is directly linked to rapid commercial and residential construction booms, massive infrastructure projects (like new data centers and hospitals), and increasing adoption of central air conditioning and heating systems in dense urban centers across the region.

What are the main financial disadvantages associated with implementing hydronic systems?

The main financial disadvantage is the high initial capital expenditure (CapEx). Hydronic systems require complex, specialized components, extensive piping networks, and highly skilled installation labor for accurate hydraulic balancing and commissioning. While they offer superior energy savings (lower OpEx) over their lifespan, the upfront investment is significantly higher compared to simpler, decentralized HVAC alternatives.

What is the role of variable speed drive (VSD) technology in modern hydronic systems?

VSD technology is critical for optimizing pump and chiller efficiency. By allowing pumps to adjust motor speed according to the actual thermal load requirement, VSDs prevent over-pumping, reduce pressure differential fluctuations, and significantly lower electrical energy consumption. This optimization ensures that only the necessary fluid flow is delivered, enhancing both system performance and minimizing wear and tear on mechanical components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager