Hydroxybutyl Vinyl Ether Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436159 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Hydroxybutyl Vinyl Ether Market Size

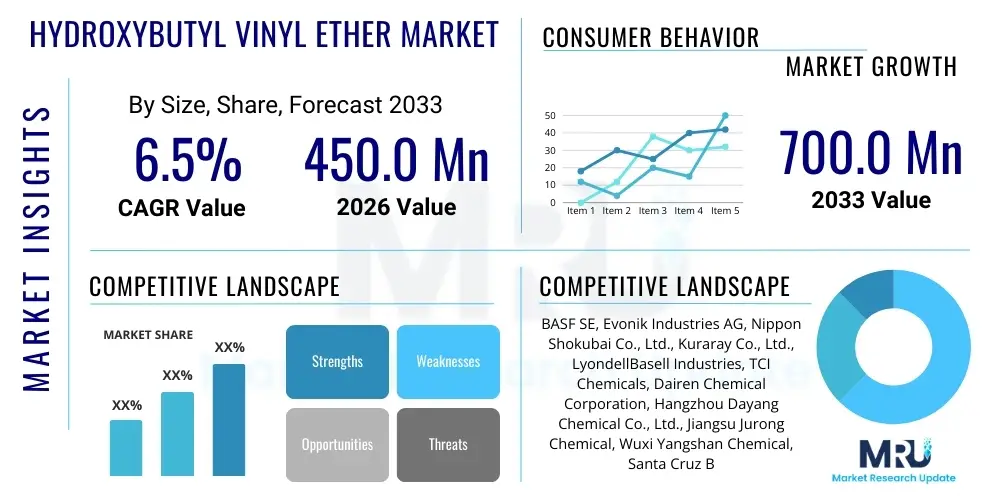

The Hydroxybutyl Vinyl Ether Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 450.0 Million in 2026 and is projected to reach USD 700.0 Million by the end of the forecast period in 2033.

Hydroxybutyl Vinyl Ether Market introduction

Hydroxybutyl Vinyl Ether (HBVE) is a highly reactive monomer characterized by its low viscosity, high compatibility with various polymer systems, and rapid curing capabilities, making it indispensable in modern high-performance material applications. Chemically, HBVE functions primarily as a reactive diluent and a crucial intermediate in the synthesis of specialty polymers, including poly(vinyl ether)s and various crosslinking agents. Its dual functionality—the hydroxy group allowing for polyurethane and polyester reactions, and the vinyl ether group enabling rapid radical or cationic polymerization—positions it uniquely within the chemical industry, particularly in sectors demanding stringent performance characteristics and environmental compliance.

The primary utility of HBVE is concentrated in sophisticated coating formulations, particularly those utilizing UV (Ultraviolet) or EB (Electron Beam) curing technologies. These technologies are favored across automotive, electronics, and graphic arts industries due to their zero or near-zero Volatile Organic Compound (VOC) emissions, rapid processing speeds, and superior physical properties of the cured films, such as enhanced scratch resistance and gloss retention. HBVE’s low toxicity and favorable handling characteristics further support its adoption as a preferred reactive diluent over traditional acrylate monomers in sensitive applications, contributing significantly to cleaner production processes and improved product longevity.

Key market driving factors include the escalating global demand for sustainable and solvent-free coating systems, driven by increasingly strict environmental regulations across North America and Europe, coupled with rapid industrialization in the Asia Pacific region. Furthermore, the expansion of high-tech manufacturing, specifically in the consumer electronics and photovoltaic sectors which require highly durable protective layers, continuously fuels the requirement for HBVE-based materials. The versatility of HBVE also allows its incorporation into advanced adhesive and sealant formulations, improving bond strength and curing speed, thereby cementing its role as a vital component in specialty chemical synthesis worldwide.

Hydroxybutyl Vinyl Ether Market Executive Summary

The Hydroxybutyl Vinyl Ether market is navigating a dynamic landscape characterized by robust demand originating from the UV curing and specialty coatings industries, paralleled by necessary adjustments in global supply chain resilience. Current business trends indicate a strong shift towards capacity expansion in Asia Pacific, particularly China and India, aiming to meet the burgeoning local demand from electronics and infrastructure projects, while Western manufacturers focus heavily on product purity enhancements and development of ultra-low VOC formulations. Pricing volatility in key raw materials, such as butanediol, poses a persistent challenge, compelling leading market players to integrate vertically or secure long-term supply agreements to ensure cost stability and competitive advantage in the highly specialized downstream segments.

Regional dynamics illustrate that Asia Pacific maintains its dominant market share, attributed to the massive scale of manufacturing operations in the coatings, automotive component production, and packaging industries, especially where high throughput and energy efficiency (enabled by UV curing) are paramount. North America and Europe, while slower in volume growth, are leaders in application innovation, particularly in medical adhesives and aerospace coatings, where regulatory compliance and extreme performance are non-negotiable. The focus in these mature markets is often on customizing HBVE derivatives for niche, high-value applications, ensuring compliance with strict environmental directives such as REACH in Europe and similar regulatory frameworks in the US, thereby maintaining a premium market positioning.

Segmentation analysis clearly highlights the application of UV Curing as the most lucrative segment, experiencing accelerated growth fueled by advancements in digital printing and flexible electronics protection. Furthermore, the high-purity (>99%) segment of HBVE is witnessing heightened demand, driven by sophisticated polymerization processes that require minimal impurities to achieve desired molecular weight distributions and physical properties in the final polymer. This trend underscores a market bifurcation: volume-driven demand for standard grades in general coatings, and high-value, quality-driven demand for ultra-pure grades in advanced polymer synthesis and sensitive electronics encapsulation, forcing suppliers to optimize their purification technologies and quality control protocols.

AI Impact Analysis on Hydroxybutyl Vinyl Ether Market

User inquiries regarding the impact of Artificial Intelligence on the Hydroxybutyl Vinyl Ether market predominantly center on how AI can accelerate material discovery, optimize complex production processes, and predict supply chain disruptions. Users are particularly interested in AI's capability to model the structure-property relationships of vinyl ether monomers and polymers, which typically involves intricate kinetic and thermal parameters difficult to assess manually. The core themes revolve around efficiency gains: minimizing batch-to-batch variability in synthesis, optimizing energy consumption in high-purity distillation steps, and using machine learning to predict the performance of HBVE-based formulations (e.g., curing speed, adhesion, lifespan) before expensive physical testing, thereby dramatically reducing R&D cycles and enhancing predictive maintenance across manufacturing assets.

- AI models accelerate the discovery and screening of novel HBVE derivative formulations by predicting reaction outcomes and optimal catalyst systems.

- Machine learning algorithms optimize polymerization kinetics and control systems, ensuring consistent high purity (>99.5%) yields necessary for electronics applications.

- Predictive maintenance analytics, powered by AI, minimize unexpected downtime in continuous flow reactors and distillation columns used for HBVE synthesis.

- Supply chain risk management utilizes AI to forecast raw material price fluctuations (e.g., butanediol) and model logistics disruptions, optimizing inventory levels globally.

- AI-driven quality control systems employ computer vision and spectroscopy data to rapidly detect and classify minor impurities, exceeding human detection capabilities in real-time.

DRO & Impact Forces Of Hydroxybutyl Vinyl Ether Market

The market for Hydroxybutyl Vinyl Ether is influenced by a powerful combination of systemic growth drivers, critical operational restraints, and substantial opportunities that collectively dictate its trajectory and profitability over the forecast period. The fundamental driver remains the accelerated shift towards energy-efficient and environmentally compliant coating technologies globally, particularly the preference for solvent-free, UV-curable systems where HBVE acts as an essential low-viscosity, high-reactivity crosslinker. Furthermore, the increasing complexity and miniaturization in electronics manufacturing necessitates highly precise and durable protective coatings, a requirement perfectly addressed by HBVE’s polymer capabilities, pushing volume and value growth simultaneously.

However, the market faces significant restraints, primarily revolving around the highly capital-intensive nature of synthesizing high-purity vinyl ethers, compounded by inherent volatility in key petrochemical feedstock prices, which directly impact manufacturing costs and final product margins. Regulatory challenges also impose constraints; while HBVE is favored for its low VOC nature, evolving chemical registration requirements in major jurisdictions, such as detailed toxicology data required under REACH, create regulatory barriers to entry and necessitate ongoing, costly compliance efforts for existing players. The long lead times and high energy consumption associated with achieving ultra-high purity levels required by specialty end-users further limit market responsiveness.

Conversely, significant opportunities exist in developing novel applications beyond traditional coatings, particularly in specialty elastomers, high-performance composites, and controlled drug release systems, leveraging HBVE's unique copolymerization properties. The burgeoning electric vehicle (EV) market presents a considerable untapped opportunity, as HBVE derivatives can be utilized in high-temperature stable adhesives and structural battery components, demanding materials with exceptional thermal and chemical resistance. Impact forces are strong, showing moderate bargaining power of buyers due to the specialized nature of the product, high bargaining power of suppliers due to oligopolistic raw material markets, and high threat of substitutes from specialized acrylates, although HBVE maintains an edge in certain adhesion and flexibility metrics.

Segmentation Analysis

The Hydroxybutyl Vinyl Ether market segmentation is comprehensively analyzed based on purity levels, which dictates suitability for specialized applications, and end-use applications, reflecting the monomer's diverse utility across industrial sectors. The purity segment, typically divided into >=99% and less than 99%, is crucial because ultra-high purity HBVE (>=99%) is mandatory for sensitive applications in optics, electronics encapsulation, and medical devices where even trace impurities can compromise performance, leading to higher price realization and stricter quality control protocols. Conversely, HBVE with purity less than 99% finds robust utility as a standard reactive diluent in less demanding industrial coatings and general adhesives where cost-efficiency is a primary concern.

Application segmentation reveals the dominance of the UV Curing sector, where HBVE serves as a fundamental building block for photopolymer formulations, ensuring low viscosity and fast cure speeds critical for high-volume manufacturing processes like rapid prototyping and protective film coating. The Coatings segment, including industrial maintenance coatings and protective primers, represents another substantial consumption area, driven by the need for enhanced durability and weather resistance in infrastructure and automotive finishes. The strategic importance of HBVE is also evident in the Adhesives & Sealants market, where its unique reactive properties contribute to strong, flexible bonds often required in structural applications and electronics assembly, offering superior moisture resistance compared to other traditional adhesive components.

Furthermore, the Chemical Intermediates segment, while smaller in volume, holds significant intellectual property value, as HBVE is utilized to synthesize advanced functional polymers, specialized surfactants, and unique crosslinking monomers required by high-end chemical manufacturers. The growth in this segment is driven by ongoing R&D efforts to develop new materials that can address emerging technological challenges, such as lightweighting in aerospace or improving thermal management in power electronics. The nuanced requirements across these varied segments necessitate suppliers to maintain flexible production capabilities and rigorous quality assurance systems tailored to the specific needs of each specialized end-user category, from bulk industrial consumers to highly technical material developers.

- By Purity:

- >=99% Purity

- Less than 99% Purity

- By Application:

- UV Curing Applications

- Coatings (Industrial and Protective)

- Adhesives & Sealants (Structural and Non-structural)

- Reactive Diluents (General Industrial Use)

- Chemical Intermediates (Polymer Synthesis)

- By End-Use Industry:

- Automotive and Transportation

- Electronics and Electrical

- Construction and Infrastructure

- Printing and Packaging

- Medical and Healthcare

Value Chain Analysis For Hydroxybutyl Vinyl Ether Market

The value chain for the Hydroxybutyl Vinyl Ether market begins with the upstream segment, focusing on the procurement and processing of fundamental petrochemical feedstocks. The primary raw materials typically include 1,4-Butanediol (BDO) and acetylene, often sourced from large commodity chemical producers. Stability and pricing of BDO are paramount, as its cost heavily influences the final pricing of HBVE. Manufacturers of HBVE engage in complex chemical synthesis processes, predominantly utilizing modified Reppe vinylation chemistry, which demands high levels of technical expertise, stringent safety protocols, and significant capital investment in specialized reaction and high-purity distillation equipment. Efficiency in this upstream stage is critical for maintaining competitive manufacturing costs against alternative reactive diluents.

The midstream phase involves the production, purification, and formulation of the HBVE monomer. Achieving the ultra-high purity required for electronics and advanced coating formulations is a significant value-adding step, often involving specialized distillation or chromatographic techniques. Following production, HBVE is distributed through well-established channel systems. Direct distribution is common for large-volume customers, particularly major UV resin manufacturers or large-scale automotive coating suppliers, allowing for direct technical support and customized supply agreements. Indirect channels, utilizing specialized chemical distributors and regional agents, facilitate market penetration into smaller formulators and niche application sectors, managing inventory and localized regulatory compliance.

The downstream segment encompasses the final conversion and application of HBVE into high-value end products. Major consumers are the formulators who blend HBVE into proprietary UV-curable inks, varnishes, protective topcoats, and structural adhesives. The value is significantly enhanced at this stage through formulation expertise, tailoring the HBVE concentration and co-monomers to achieve specific performance attributes, such as flexibility, hardness, and thermal resistance required by the end-use industry. This downstream processing and application knowledge ultimately determines the success of the product, where the performance benefits of HBVE—low viscosity and high reactivity—translate directly into improved manufacturing efficiency and superior product lifespan for end-users like automotive OEMs and consumer electronics brands.

Hydroxybutyl Vinyl Ether Market Potential Customers

The primary potential customers and buyers of Hydroxybutyl Vinyl Ether are specialized chemical formulators and large-scale industrial manufacturers operating in sectors reliant on high-performance, rapid-curing materials. Foremost among these are manufacturers of UV/EB curable coatings and inks, who utilize HBVE as a key reactive diluent to lower the viscosity of formulations without introducing volatile organic solvents, thereby meeting stringent environmental standards while maintaining rapid processing speeds essential for mass production in printing and packaging industries. These customers seek reliable, high-purity supply to ensure consistent curing performance and final product quality, making long-term procurement relationships with HBVE producers standard practice.

Another significant customer segment includes automotive and aerospace component manufacturers. These industries require highly durable, chemically resistant, and thermally stable adhesives and sealants for structural bonding and protective exterior finishes. Automotive OEMs, in particular, use HBVE derivatives in clearcoats and primers for enhanced scratch resistance and gloss retention. The demand from this sector is characterized by strict specification requirements and a strong emphasis on consistent batch quality, as failures can result in costly recalls or compliance issues, pushing these buyers toward premium-grade HBVE suppliers with robust quality assurance protocols and global certifications.

Furthermore, electronics and electrical encapsulation material providers represent a rapidly expanding customer base. With the continuous miniaturization of sensitive components and the rise of flexible electronics, there is an escalating need for protective coatings and potting compounds that offer excellent dielectric properties, moisture barrier performance, and low shrinkage upon curing. Buyers in this segment, including semiconductor manufacturers and display panel producers, procure HBVE for its ability to create stable, high-performance polymer matrices that protect sensitive circuits, prioritizing ultra-high purity grades to prevent ionic contamination and subsequent device failure. These customers often drive innovation in high-purity and specialty functionalized vinyl ether derivatives.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.0 Million |

| Market Forecast in 2033 | USD 700.0 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Evonik Industries AG, Nippon Shokubai Co., Ltd., Kuraray Co., Ltd., LyondellBasell Industries, TCI Chemicals, Dairen Chemical Corporation, Hangzhou Dayang Chemical Co., Ltd., Jiangsu Jurong Chemical, Wuxi Yangshan Chemical, Santa Cruz Biotechnology, Sigma-Aldrich (Merck KGaA), Tokyo Chemical Industry Co., Ltd., Gantrade Corporation, Maruzen Petrochemical Co., Ltd., Yancheng Jingxin Chemical, Sichuan Lutianhua Co., Ltd., Shanghai Chemdo Trading Co., Ltd., Shandong Jinxuan Chemical, and Arkema Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydroxybutyl Vinyl Ether Market Key Technology Landscape

The technological landscape of the Hydroxybutyl Vinyl Ether market is dominated by advancements in synthesis methods aimed at improving yield, reducing energy consumption, and crucially, enhancing product purity to meet the stringent demands of high-tech applications. The foundational chemistry for HBVE production often relies on variations of the Reppe process, involving the reaction of 1,4-Butanediol with acetylene, often under high pressure and specialized catalyst systems. Modern technological progress focuses on implementing continuous flow reactors and heterogeneous catalysts to achieve greater control over reaction kinetics, minimizing byproduct formation, which is essential for maximizing the conversion rate and reducing the subsequent burden on purification steps.

A significant area of technological focus involves sophisticated purification techniques. Since HBVE is used in applications like optical coatings and electronics, impurities (such as unreacted starting materials, catalyst residues, and low molecular weight byproducts) must be minimized to levels often below 100 parts per million. Advancements in multi-stage vacuum distillation, coupled with precision solvent extraction and chromatographic purification, are standard practices in leading manufacturers. Emerging technologies include the use of membrane separation and ion exchange resins specifically tailored to remove polar and ionic contaminants, ensuring the HBVE grade meets the ultra-high purity specifications required for sensitive photopolymerization processes and long-term material stability.

Furthermore, the key technology landscape is expanding into the development of functionalized vinyl ether derivatives beyond the basic HBVE structure. R&D efforts are concentrated on synthesizing oligomeric vinyl ethers and multi-functional HBVE analogs that can offer customized viscosity profiles, improved adhesion to challenging substrates (like low-energy plastics), and better compatibility with complex resin systems (e.g., epoxies and polyurethanes). These formulation technologies leverage HBVE’s inherent reactivity to create hybrid chemistries that address specific end-user performance gaps, driving innovation in areas such as high-temperature-resistant coatings for aerospace and flexible electronic display encapsulation materials, thereby sustaining the product's relevance in evolving materials science.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for Hydroxybutyl Vinyl Ether, primarily driven by massive manufacturing scale, especially in China, South Korea, and Japan. The region dominates global production of consumer electronics, automotive components, and protective packaging, all of which rely heavily on high-speed, solvent-free UV curing systems where HBVE is essential. Rapid infrastructural development and increasing investments in industrial coatings and infrastructure in emerging economies like India further solidify APAC's market leadership. The competitive landscape is intense, favoring local manufacturers who benefit from robust supply chain integration and lower operational costs.

- North America: North America represents a mature, high-value market characterized by stringent environmental regulations (mandating low-VOC solutions) and strong demand from specialty sectors like aerospace, medical devices, and high-performance architectural coatings. While volume growth is slower than in APAC, the focus is heavily on high-purity grades of HBVE used in advanced R&D and niche industrial applications requiring superior performance and adherence to complex regulatory frameworks such as TSCA. Key drivers include the ongoing adoption of UV-LED curing technologies and expansion in structural adhesive applications in automotive lightweighting.

- Europe: The European market is highly regulated, primarily influenced by REACH compliance, which favors HBVE as a lower-toxicity, low-VOC alternative to traditional solvents and reactive diluents. Demand is strong in the automotive refinish, industrial floor coatings, and printing industries. Germany, France, and Italy are key consuming nations, focusing on sustainability and high-quality durable goods manufacturing. European manufacturers tend to invest significantly in sustainable production processes and advanced derivative chemistry to maintain competitive differentiation within the global market.

- Latin America (LATAM) and Middle East & Africa (MEA): These regions are emerging markets showing significant potential, driven by infrastructure projects, expanding domestic automotive assembly sectors, and rising industrialization, particularly in Brazil, Mexico, Saudi Arabia, and the UAE. While currently reliant on imports for specialized chemical monomers like HBVE, local demand growth is steady, focusing mainly on general industrial coatings and construction chemicals. Market growth is closely tied to local economic stability and foreign direct investment in manufacturing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydroxybutyl Vinyl Ether Market.- BASF SE

- Evonik Industries AG

- Nippon Shokubai Co., Ltd.

- Kuraray Co., Ltd.

- LyondellBasell Industries

- TCI Chemicals

- Dairen Chemical Corporation

- Hangzhou Dayang Chemical Co., Ltd.

- Jiangsu Jurong Chemical

- Wuxi Yangshan Chemical

- Santa Cruz Biotechnology

- Sigma-Aldrich (Merck KGaA)

- Tokyo Chemical Industry Co., Ltd.

- Gantrade Corporation

- Maruzen Petrochemical Co., Ltd.

- Yancheng Jingxin Chemical

- Sichuan Lutianhua Co., Ltd.

- Shanghai Chemdo Trading Co., Ltd.

- Shandong Jinxuan Chemical

- Arkema Group

Frequently Asked Questions

Analyze common user questions about the Hydroxybutyl Vinyl Ether market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of Hydroxybutyl Vinyl Ether (HBVE) in industrial applications?

HBVE primarily functions as a high-performance reactive diluent and crosslinking monomer, vital in UV/EB curing systems to reduce viscosity, increase cure speed, and enable solvent-free (low-VOC) formulations in protective coatings, inks, and adhesives, offering superior flexibility and adhesion properties.

Which application segment holds the largest share in the HBVE market?

The UV Curing application segment holds the largest market share, driven by its utilization in rapidly expanding sectors such as consumer electronics protection, automotive clearcoats, and high-speed packaging printing due to the mandatory requirement for fast processing and environmentally compliant coating solutions.

How do raw material costs impact the pricing structure of HBVE?

Raw material costs, particularly the price of 1,4-Butanediol (BDO), are the most significant determinant of HBVE production cost. Volatility in petrochemical commodity markets directly affects the operational expenditures of HBVE manufacturers, leading to price fluctuations for downstream specialty chemical customers.

Which geographical region is leading the consumption and production of Hydroxybutyl Vinyl Ether?

The Asia Pacific (APAC) region is the global leader in both consumption and production of HBVE, fueled by large-scale manufacturing bases in China and South Korea, intensive industrialization, and strong regional demand from the electronics and general industrial coating sectors.

What are the purity requirements for HBVE used in electronics encapsulation?

HBVE used in sensitive electronics encapsulation requires ultra-high purity (typically >=99.5%) to prevent ionic contamination, which can cause circuit failure. Strict purification technologies like multi-stage distillation are employed to minimize impurities such as catalyst residues and unreacted feedstock.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Hydroxybutyl Vinyl Ether (HBVE) Market Size Report By Type (Normal Product, Customized Product), By Application (Fluroresin, Modifiers, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Hydroxybutyl Vinyl Ether Market Statistics 2025 Analysis By Application (Fluroresin, Modifiers), By Type (Normal Product, Customized Product), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager