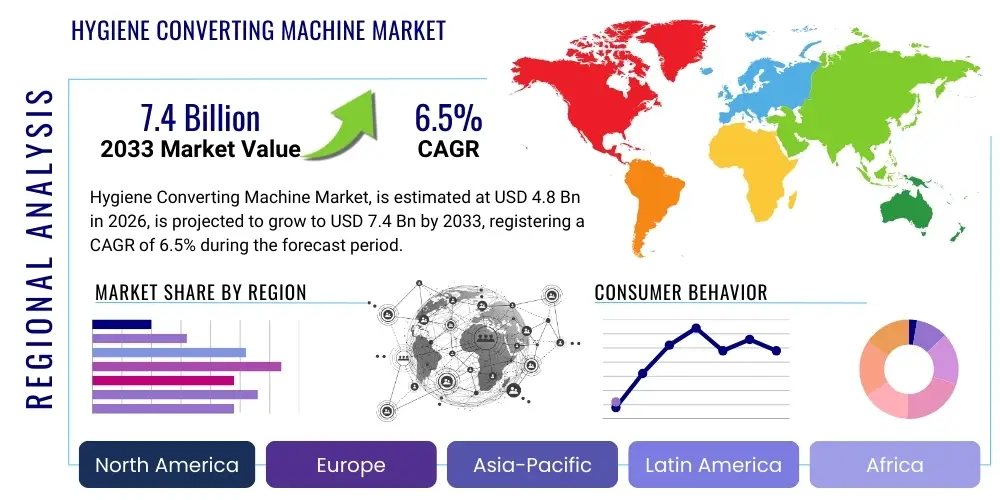

Hygiene Converting Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439062 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Hygiene Converting Machine Market Size

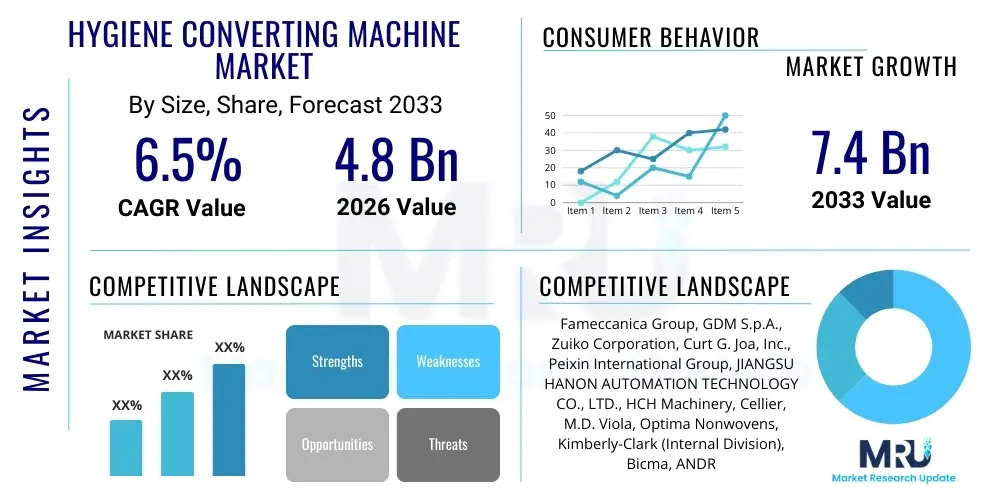

The Hygiene Converting Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.4 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily driven by the escalating global demand for disposable hygiene products, particularly in emerging economies where rapid urbanization and increasing consumer awareness regarding health and sanitation are major catalysts. Manufacturers are investing heavily in high-speed, fully automated converting lines to maximize throughput and reduce operational costs, thereby fueling market expansion.

The valuation reflects robust investment across key end-user sectors, including baby care, feminine hygiene, and adult incontinence. While developed markets focus on incorporating advanced features like biodegradability and material efficiency into their product lines, thus requiring sophisticated machinery upgrades, developing regions are focused on establishing foundational manufacturing capacities. The shift towards sustainable production methods and the integration of highly sensitive monitoring systems for quality control are elevating the average unit cost of hygiene converting machinery, contributing significantly to the market size growth.

Hygiene Converting Machine Market introduction

The Hygiene Converting Machine Market encompasses specialized industrial equipment designed for the high-volume, automated production of disposable hygiene articles, including baby diapers, adult incontinence products, sanitary napkins, panty liners, and related absorbent goods. These machines execute complex processes such as nonwoven material unwinding and lamination, absorbent core formation (using fluff pulp and super absorbent polymers or SAP), high-precision cutting, adhesive application, elastic strand placement, and final product folding and packaging. The efficiency and reliability of these converting lines are critical determinants of profitability and quality in the highly competitive disposable hygiene industry.

The primary applications of these sophisticated machines lie within the consumer goods manufacturing sector, serving major multinational corporations and specialized private label producers. Key benefits derived from utilizing modern hygiene converting technology include drastically improved production speeds, enhanced product consistency through automated quality inspection, and the capability to handle a diverse range of complex material combinations required for next-generation absorbent products. Furthermore, these machines enable flexibility in product design, allowing manufacturers to quickly adapt to evolving consumer preferences, such as thinner core structures, improved fit, and skin-friendly materials.

Driving factors for this market include global demographic trends such as an aging population (boosting demand for adult incontinence products), rising birth rates in specific regions, and increasing disposable income leading to higher consumption of premium hygiene items. Technological advancements, particularly in servo motor controls, ultrasonic welding, and advanced sensor technology for defect detection, further accelerate market growth by enhancing the speed, precision, and efficiency of the converting process, reducing material waste, and improving overall operational uptime.

Hygiene Converting Machine Market Executive Summary

The Hygiene Converting Machine Market is characterized by intense technological competition and strategic consolidation, driven primarily by the need for higher speeds and greater flexibility in production. Business trends show a strong pivot towards digitalization, predictive maintenance (Industry 4.0 integration), and machinery capable of processing sustainable and bio-based raw materials. The market leaders are focusing on modular machine designs that allow for quick changeovers between product sizes and types, minimizing downtime and catering to varied regional demands. Mergers and acquisitions are common as larger entities seek to acquire niche technological expertise, especially in adhesive application or advanced core formation techniques.

Regionally, Asia Pacific (APAC) stands as the dominant market, fueled by massive population bases, expanding middle classes, and escalating awareness regarding hygiene practices, particularly in China and India. Europe and North America, while mature, exhibit growth through replacement cycles and the adoption of ultra-high-speed machinery coupled with highly specialized features for premium segments like leak guards and superior absorbent distribution. Segment trends indicate that the machines for Adult Incontinence products are experiencing the fastest growth, primarily due to the global aging population demographic, followed closely by technologically advanced baby diaper machinery focusing on complexity and material savings.

Overall, the market remains capital-intensive, favoring established machinery manufacturers that can offer comprehensive service contracts and high levels of automation. The imperative for hygiene product manufacturers is reducing Total Cost of Ownership (TCO), making energy efficiency, waste reduction capabilities, and exceptional operational reliability crucial selling points for new converting lines. The integration of advanced human-machine interfaces (HMIs) and remote diagnostics capabilities represents the strategic direction for future product development across all key machine types.

AI Impact Analysis on Hygiene Converting Machine Market

User inquiries regarding AI's influence in the Hygiene Converting Machine Market predominantly revolve around optimizing production lines, enhancing quality control accuracy, and implementing predictive maintenance schedules. Users are keen to understand how AI algorithms can interpret massive datasets generated by high-speed sensors (vision systems, tension controls, adhesive application monitors) to preemptively identify minute defects or potential mechanical failures, thus maximizing uptime and reducing material wastage. A major theme is the expectation that AI will transition current quality assurance systems from reactive inspection to proactive, real-time process adjustment, leading to significant cost savings and improved product consistency. Concerns often center on the complexity of integrating these advanced systems into legacy machinery and the need for specialized training for technical staff to manage sophisticated AI-driven analytics platforms.

- Real-time quality inspection and defect classification using deep learning algorithms analyzing high-speed camera feeds.

- Predictive maintenance schedules determined by machine learning models analyzing vibration, temperature, and current consumption data from servo systems.

- Optimized material usage and waste reduction through AI-driven control loop adjustments based on historical performance and material variability.

- Enhanced throughput and speed optimization by using reinforcement learning to fine-tune complex machine synchronization parameters.

- Automated recipe management and quick changeover optimization minimizing human intervention and error during product transitions.

- Improved supply chain management and inventory forecasting for raw materials based on projected machine utilization derived from AI models.

DRO & Impact Forces Of Hygiene Converting Machine Market

The Hygiene Converting Machine Market is primarily driven by sustained global demand for disposable hygiene products, catalyzed by population growth, urbanization, and heightened sanitation awareness, especially in APAC and Latin America. Key technological drivers include the continuous pursuit of higher operational speeds and the integration of highly precise servo-driven systems that offer flexibility and material savings. However, the market faces significant restraints, chiefly the high initial capital investment required for state-of-the-art converting lines and the inherent complexity of integrating diverse raw materials (nonwovens, pulp, SAP, elastomers) efficiently. Opportunities abound in developing localized, cost-effective machinery solutions for emerging markets, and focusing R&D on lines specifically designed for processing sustainable and recyclable materials, which aligns with growing global regulatory pressures and consumer preference shifts towards ecological products. These factors collectively exert substantial impact force, propelling rapid innovation in automation and material handling while creating barriers to entry for smaller manufacturers.

The impact forces also include the volatility in raw material pricing, particularly for fluff pulp and polymers, which directly affects the profitability of end-product manufacturers, thereby influencing their investment timelines for new machinery. Secondly, stringent product quality standards imposed by regulatory bodies and consumer expectation demand highly reliable inspection and control systems, compelling machinery manufacturers to invest heavily in advanced sensing and vision technologies. The force of competitive dynamics compels manufacturers to shorten development cycles for new machine models, prioritizing energy efficiency and reduced footprint alongside peak performance. Furthermore, the availability of skilled labor capable of operating and maintaining these increasingly complex, highly digitized machines remains a persistent challenge, acting as a frictional force against rapid adoption in certain developing regions.

Segmentation Analysis

The Hygiene Converting Machine Market is comprehensively segmented based on the product manufactured, the degree of automation, and the technology employed. By product type, the market is highly diversified, encompassing specialized lines for baby diapers (further broken down into open-style and pant-style), adult incontinence products (pads, briefs, and protective underwear), and feminine hygiene items (sanitary napkins and panty liners). Segmentation by degree of automation differentiates between semi-automatic and fully automatic high-speed lines, with the latter dominating due to industry demands for scale and efficiency. Analyzing the market through segmentation allows stakeholders to target specific growth vectors, such as the rapidly expanding market for adult pant-style products or the continuous technological updates required in the premium baby diaper segment, ensuring focused strategic investment and development efforts.

- By Product Type:

- Baby Diaper Converting Machines (Open Diapers, Pant Diapers)

- Adult Incontinence Product Converting Machines (Pads, Briefs, Protective Underwear)

- Feminine Hygiene Product Converting Machines (Sanitary Napkins, Panty Liners)

- Other Hygiene Products (e.g., Medical Pads, Underpads)

- By Operation Speed:

- Low Speed (Below 400 Products/Minute)

- Medium Speed (400 – 800 Products/Minute)

- High Speed (Above 800 Products/Minute)

- By Automation Level:

- Semi-Automatic

- Fully Automatic

- By Technology:

- Mechanical Drive Systems

- Full Servo Drive Systems

Value Chain Analysis For Hygiene Converting Machine Market

The value chain for the Hygiene Converting Machine Market begins with upstream activities, primarily involving the suppliers of crucial high-precision components. This includes manufacturers of highly specialized servo motors, advanced controllers, precision bearings, ultrasonic bonding equipment, high-speed vision inspection systems, and sophisticated adhesive dispensing nozzles. The relationship between machinery manufacturers and component suppliers is symbiotic, driving innovation as components must meet exacting standards for speed, durability, and synchronization required for modern converting lines operating at speeds exceeding 1000 pieces per minute. Quality and reliability of these components are paramount, directly influencing the overall performance and maintenance profile of the final converting machine.

Midstream, the value chain centers on the machinery manufacturers who design, assemble, and test the integrated converting lines. This phase involves extensive engineering R&D focused on modularity, quick-change capabilities, and software integration (HMI, PLC programming). Distribution channels play a critical role, largely characterized by direct sales models, given the complexity and high cost of the equipment. Direct distribution allows manufacturers to offer specialized technical consultation, installation supervision, and comprehensive after-sales support, which is essential for maximizing customer satisfaction and operational efficiency. Agents or indirect distributors are occasionally used in niche or geographically distant markets to facilitate initial contact and local support.

Downstream, the key focus is on the end-users—the hygiene product manufacturers (HPMs). HPMs require extensive training and technical support to operate and maintain the complex machinery. The service component of the downstream segment, including spare parts supply, maintenance contracts, and operational software updates, constitutes a significant long-term revenue stream for the machine manufacturers. The ultimate downstream buyers are consumers of disposable hygiene products, whose demand dictates the production volume and technological specifications required from the converting machinery, completing the feedback loop that drives continuous innovation within the market.

Hygiene Converting Machine Market Potential Customers

The primary potential customers and end-users of hygiene converting machines are large-scale multinational Consumer Packaged Goods (CPG) companies that dominate the disposable hygiene sector, such as Procter & Gamble, Kimberly-Clark, and Unicharm. These global players require massive, ultra-high-speed production lines capable of producing billions of units annually across various regions. Their purchasing decisions are driven by the need for peak efficiency, lowest cost per unit, superior quality assurance features, and flexibility to adapt to innovative product designs.

A second major segment comprises specialized regional and local manufacturers, often operating under private label contracts or serving specific domestic markets. These customers frequently seek machinery that balances moderate speed with cost-effectiveness, prioritizing robust design and ease of maintenance suitable for local technical capabilities. Growth in this segment is particularly robust in emerging economies where local brands are rapidly gaining market share against established international players, necessitating investment in mid-speed, reliable converting equipment to support their expansion.

Furthermore, medical device manufacturers and specialized producers focusing on niche absorbent products, such as wound care dressings or advanced medical underpads, represent another important, albeit smaller, customer base. These entities require converting lines with exceptionally high precision and compliance capabilities, often adhering to strict pharmaceutical or medical standards. The purchase rationale for all customer types is intrinsically linked to enhancing operational scale, achieving material efficiency, and maintaining a competitive edge through superior product quality and design innovation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.4 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fameccanica Group, GDM S.p.A., Zuiko Corporation, Curt G. Joa, Inc., Peixin International Group, JIANGSU HANON AUTOMATION TECHNOLOGY CO., LTD., HCH Machinery, Cellier, M.D. Viola, Optima Nonwovens, Kimberly-Clark (Internal Division), Bicma, ANDRITZ Nonwoven, Delta Converting, TIEJI. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hygiene Converting Machine Market Key Technology Landscape

The technological landscape of the Hygiene Converting Machine Market is dominated by the transition from traditional mechanical line shafts to full servo drive systems. Full servo technology offers unparalleled precision, synchronization, and flexibility, allowing manufacturers to achieve operational speeds far exceeding 1200 products per minute while minimizing material waste and noise. These systems enable highly complex product designs, such as multi-layer cores or asymmetrical elastic placement, that are essential for premium product differentiation. Furthermore, the modular nature of servo-driven units allows for faster product changeovers and easier integration of future technological upgrades, significantly enhancing the machine's longevity and adaptability.

Another crucial technological area involves advanced material handling and bonding techniques. Ultrasonic welding and bonding systems are increasingly replacing traditional heat and adhesive methods in certain applications, offering cleaner, faster, and more energy-efficient means of securing nonwoven layers. Concurrently, adhesive dispensing systems have become highly sophisticated, featuring slot coating, melt blowing, and precise pattern application technologies to optimize glue usage and integrity, particularly for high-stress areas like waistbands and leak guards. The accurate dosing and placement of Super Absorbent Polymers (SAP) and fluff pulp through controlled air-laying and forming technologies are also continuously evolving to allow for thinner, more efficient absorbent cores, a key driver for material cost reduction.

The integration of Industry 4.0 principles is fundamentally reshaping machine intelligence and connectivity. This includes the widespread implementation of advanced sensors, high-resolution vision inspection systems (cameras and laser scanners) for 100% quality check assurance, and sophisticated Human-Machine Interfaces (HMIs) for real-time monitoring and diagnostic capabilities. Remote access and secure cloud connectivity facilitate predictive maintenance using AI/ML algorithms, reducing unplanned downtime significantly. The focus is shifting towards creating a digital twin of the converting line, allowing for simulation and optimization before physical changes are implemented, streamlining complex processes and accelerating time-to-market for new hygiene product designs.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for hygiene converting machines, primarily driven by demographic factors. Countries like China and India have massive, expanding consumer bases combined with rising disposable incomes, translating directly into increased demand for both baby diapers and sanitary napkins. The market dynamic here is characterized by high investment in brand-new, high-capacity production lines to meet escalating domestic consumption and serve as regional export hubs. Local machinery manufacturers are rapidly improving their technological capabilities to compete with established Western and Japanese players, focusing particularly on offering cost-effective, reliable machinery tailored for regional material sourcing and specific local product requirements. The emphasis remains on scale and efficiency to serve the highly price-sensitive mid-range segment. This region sees continuous investment, often subsidized or encouraged by government initiatives focused on improving sanitation and domestic manufacturing capabilities. The market is also heavily influenced by the adoption of pant-style diapers, demanding specialized and complex converting machinery.

- North America: North America is characterized as a mature market dominated by large, established CPG companies. Growth in this region is less about building new capacity and more focused on replacement cycles, technological upgrades, and the adoption of ultra-high-speed, specialized machinery designed for premium products. Key regional trends include the demand for converting lines capable of handling eco-friendly, biodegradable, and sustainable materials (such as bio-plastics and TCF fluff pulp), aligning with strong consumer preferences for sustainability. Manufacturers prioritize maximum automation, superior energy efficiency, and the integration of advanced diagnostic software (AI-driven monitoring) to maintain highly competitive operational costs and product quality integrity across their sophisticated supply chains. The adult incontinence segment, driven by the aging demographic, remains a significant investment area for specialized converting machinery.

- Europe: Similar to North America, the European market is mature but highly sophisticated, marked by stringent quality control standards and a powerful regulatory push toward environmental sustainability. European demand is driven by the need for converting machines that offer ultimate flexibility for quick changeovers between diverse SKUs (Stock Keeping Units) and varying material specifications, often catering to numerous smaller, diverse national markets. Investment flows heavily into advanced full-servo lines and equipment suitable for high-end absorbent products, including medical and surgical hygiene items. Furthermore, European manufacturers lead in adopting innovative heating, bonding, and waste management technologies integrated into their converting lines. Research and development in machinery design often centers around reducing the environmental footprint of the manufacturing process itself, including energy recovery systems and minimizing trim waste.

- Latin America (LATAM): The LATAM market, while facing economic volatility in certain areas, exhibits strong potential growth, largely driven by expanding middle classes and increased hygiene penetration rates in populous nations like Brazil, Mexico, and Argentina. The demand pattern is often cyclical, favoring reliable, mid-to-high speed machinery that provides a favorable return on investment (ROI). Local production is critical due to import duties and logistical challenges, meaning there is steady demand for establishing local converting facilities. Manufacturers often seek machinery capable of handling regionally available raw materials and producing products tailored to local fit preferences and pricing tiers. The competitive landscape necessitates localized sales support and readily available spare parts, influencing machinery procurement decisions significantly.

- Middle East and Africa (MEA): The MEA region is fragmented but shows robust growth in specific, resource-rich Gulf Cooperation Council (GCC) countries and high-population African nations. The market is primarily driven by the need to build local production capacity to reduce reliance on imports and serve rapidly growing consumer bases. Infrastructure development, rising urbanization, and government focus on healthcare expenditure boost the establishment of new converting facilities. Machinery demand spans the spectrum, from refurbished mid-speed lines sought for initial entry into the African market, to state-of-the-art high-speed lines in technologically advanced Middle Eastern hubs. The challenging operating environment often places a premium on robust, easy-to-maintain equipment and comprehensive technical training packages offered by machinery vendors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hygiene Converting Machine Market.- Fameccanica Group (Angelini Industries)

- GDM S.p.A. (Coesia Group)

- Zuiko Corporation

- Curt G. Joa, Inc.

- Peixin International Group

- JIANGSU HANON AUTOMATION TECHNOLOGY CO., LTD.

- HCH Machinery

- M.D. Viola Machine S.R.L.

- Optima Nonwovens (Optima Group)

- Bicma Hygiene Technology GmbH

- Andritz Nonwoven (Andritz Group)

- Cellier Group

- Delta Converting Srl

- TIEJI Group

- Qingdao Jierui Machine & Technology Co., Ltd.

- Fujian Nanxiang Machinery Co., Ltd.

- W+D (Winkler+Dünnebier)

- A.Celli Nonwovens S.p.A.

- E.A.C. Converting Equipment S.R.L.

- YuanJi Converting Equipment Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Hygiene Converting Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the demand for high-speed hygiene converting machines?

Demand is primarily driven by the escalating global consumption of disposable hygiene products, particularly in emerging markets, coupled with manufacturers' efforts to reduce production costs per unit. The pursuit of operational excellence and lower Total Cost of Ownership (TCO) necessitates continuous investment in faster, more automated, and material-efficient full servo-driven lines.

How is the focus on sustainability impacting the design and technology of converting machinery?

Sustainability mandates are compelling machine manufacturers to develop systems capable of processing novel, bio-based, or recyclable nonwoven materials and films. This requires advanced bonding technologies (e.g., ultrasonic welding) and sophisticated material feeding systems designed to handle the often more sensitive nature of eco-friendly raw materials without compromising high-speed operation or product integrity.

Which segment of the hygiene converting machine market is expected to exhibit the fastest growth?

The Adult Incontinence Product Converting Machine segment is projected to show the fastest growth rate. This accelerated expansion is directly attributable to the demographic shift towards an aging global population, particularly in mature economies, leading to consistently higher demand for adult diapers and protective underwear solutions.

What role does Industry 4.0 play in modern hygiene converting machine operations?

Industry 4.0 integration involves implementing AI/ML for predictive maintenance, advanced sensor suites for real-time quality control (vision systems), and secure remote diagnostics. This digitization maximizes machine uptime, optimizes complex production parameters, and minimizes material wastage, thereby significantly enhancing overall manufacturing efficiency.

What are the main technological differences between baby diaper and sanitary napkin converting machines?

Baby diaper machines, especially pant-style lines, are significantly more complex due to the intricate 3D shaping, elastic strand placement, and required application of high-precision materials like Super Absorbent Polymers (SAP). Sanitary napkin machines are generally flatter, less complex in core formation, but require extreme precision in wing folding and packaging, focusing on high speed and minimal adhesive application.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager