Hypromellose Acetate Succinate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439566 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Hypromellose Acetate Succinate Market Size

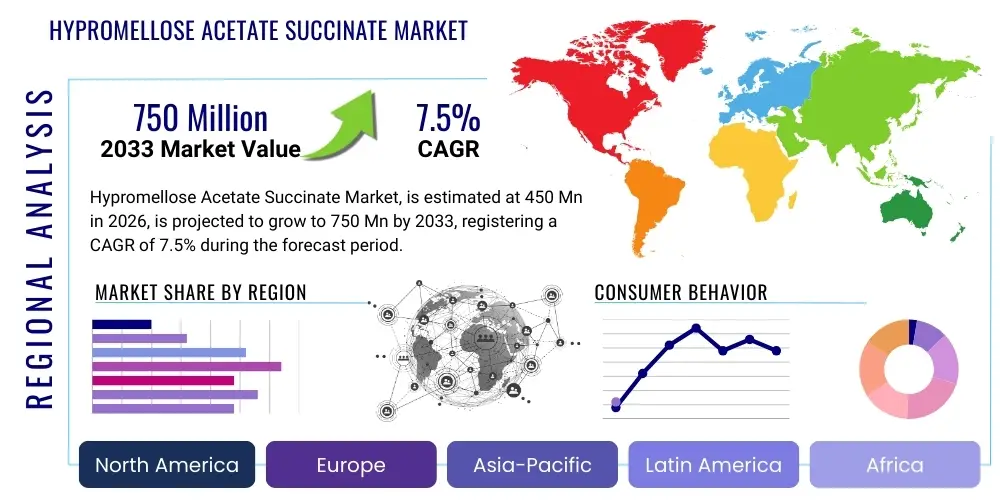

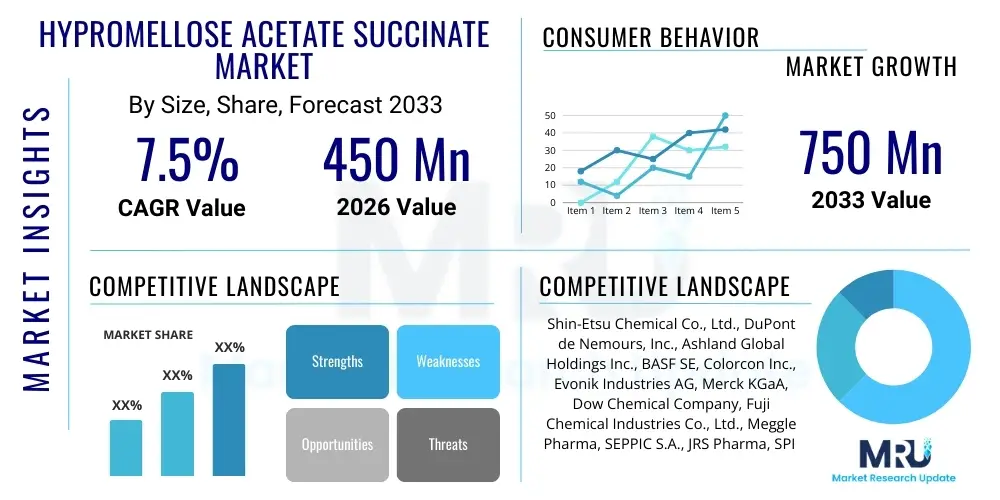

The Hypromellose Acetate Succinate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 750 Million by the end of the forecast period in 2033.

Hypromellose Acetate Succinate Market introduction

Hypromellose Acetate Succinate (HPMCAS) is a widely recognized and utilized enteric polymer in the pharmaceutical industry, specifically valued for its exceptional properties in drug formulation. It is a derivative of cellulose, chemically modified to possess pH-dependent solubility, making it ideal for protecting active pharmaceutical ingredients (APIs) from the acidic environment of the stomach and ensuring their release in the higher pH environment of the intestine. This characteristic is crucial for drugs that are sensitive to gastric acid, those that cause gastric irritation, or those intended for localized action in the small intestine, thereby enhancing patient compliance and therapeutic efficacy. The versatility of HPMCAS extends beyond enteric coating, as it is also a cornerstone excipient for improving the solubility and bioavailability of poorly water-soluble drugs through various advanced formulation techniques.

The product finds major applications across a spectrum of pharmaceutical dosage forms, including oral solid dosages such as tablets and capsules. In these applications, HPMCAS functions primarily as an enteric coating agent, preventing premature drug release in the stomach and facilitating targeted delivery. Beyond its role in enteric protection, it is increasingly employed in the preparation of amorphous solid dispersions (ASDs), a sophisticated technique designed to overcome the dissolution limitations of poorly soluble APIs. By forming an amorphous blend with the drug, HPMCAS helps maintain the drug in a supersaturated state upon dissolution, significantly enhancing its absorption and overall bioavailability. This dual utility makes HPMCAS an indispensable material in modern pharmaceutical development, addressing critical challenges in drug delivery and formulation.

The benefits derived from the use of HPMCAS are manifold, driving its sustained demand within the global pharmaceutical market. These benefits include improved drug stability, enhanced patient safety by reducing gastric irritation, and optimization of drug absorption profiles, which collectively contribute to superior therapeutic outcomes. Key driving factors for the market's expansion include the escalating global prevalence of chronic diseases, which necessitates the development of more effective and patient-friendly drug delivery systems. Additionally, the continuous innovation in pharmaceutical research and development, particularly in the realm of advanced drug formulation technologies aimed at addressing solubility and bioavailability issues, further fuels the adoption of HPMCAS. The expanding pipeline of new chemical entities (NCEs) with challenging physicochemical properties also ensures a persistent demand for high-performance excipients like HPMCAS.

Hypromellose Acetate Succinate Market Executive Summary

The Hypromellose Acetate Succinate (HPMCAS) market is experiencing robust growth, primarily propelled by dynamic business trends centered around pharmaceutical innovation and strategic partnerships. A significant trend involves increasing investments in research and development by pharmaceutical companies to overcome drug solubility and bioavailability challenges, positioning HPMCAS as a preferred excipient for amorphous solid dispersions and enteric coatings. The market is also characterized by a heightened focus on contract manufacturing and development organizations (CDMOs) that specialize in complex formulations, leading to increased outsourcing of HPMCAS-based drug product development and manufacturing. Furthermore, there is a growing emphasis on sustainable and cost-effective production methods for pharmaceutical excipients, influencing supply chain strategies and material sourcing within the HPMCAS market. This ecosystem of innovation, collaboration, and efficiency is shaping competitive landscapes and fostering new avenues for market penetration.

Regionally, the market exhibits diverse growth patterns influenced by healthcare expenditure, regulatory frameworks, and pharmaceutical manufacturing capacities. North America and Europe continue to dominate the HPMCAS market, attributed to their well-established pharmaceutical industries, robust R&D infrastructure, and stringent regulatory standards that favor high-quality excipients. However, the Asia Pacific region is emerging as the fastest-growing market, driven by increasing healthcare access, a burgeoning generic drug industry, and expanding pharmaceutical manufacturing bases, particularly in countries like China and India. Latin America, the Middle East, and Africa are also showing promising growth, albeit at a slower pace, as these regions invest more in healthcare infrastructure and pharmaceutical production capabilities, thereby expanding the potential customer base for HPMCAS-containing formulations.

Segment-wise, the HPMCAS market demonstrates clear trends reflecting its varied applications. The enteric coating segment remains a foundational driver, catering to the need for targeted drug delivery and gastric protection for a wide range of oral medications. Simultaneously, the solubility enhancement segment, particularly through amorphous solid dispersions, is experiencing accelerated growth due to the rising number of poorly soluble drug candidates in pharmaceutical pipelines. The specific grades of HPMCAS, differentiated by their acetyl and succinoyl content and molecular weight, are seeing tailored demand based on the desired dissolution profile and mechanical properties required for different drug formulations. These segmentation trends underscore the versatility of HPMCAS and its critical role in addressing diverse pharmaceutical formulation challenges, driving innovation and specialization across the industry.

AI Impact Analysis on Hypromellose Acetate Succinate Market

The integration of Artificial Intelligence (AI) and machine learning (ML) technologies is poised to significantly transform various facets of the Hypromellose Acetate Succinate (HPMCAS) market, influencing everything from excipient design and drug formulation to manufacturing optimization and supply chain management. Users frequently inquire about how AI can accelerate the discovery of optimal HPMCAS grades for specific APIs, predict their performance in complex solid dispersions, and enhance the efficiency of development processes. There is keen interest in AI's potential to reduce formulation timelines, minimize material waste, and ensure consistent product quality, ultimately leading to faster market entry for new drugs and more cost-effective production. Concerns often revolve around data privacy, the need for robust validation protocols for AI-driven insights, and the potential displacement of traditional formulation expertise, alongside the significant initial investment required for AI infrastructure. The overarching expectation is that AI will introduce a new era of precision and efficiency, enabling formulators to better leverage the unique properties of HPMCAS for challenging drug candidates and complex delivery systems.

- AI-driven predictive modeling can optimize HPMCAS grade selection for specific APIs, forecasting solubility enhancement and stability in amorphous solid dispersions (ASDs) with greater accuracy.

- Machine learning algorithms can analyze vast datasets of formulation parameters, patient demographics, and clinical outcomes to identify optimal HPMCAS concentrations and processing conditions for targeted drug release profiles.

- AI can facilitate automated quality control and process monitoring in HPMCAS manufacturing, detecting anomalies and ensuring consistency in polymer properties, thereby reducing batch-to-batch variability.

- Enhanced supply chain management through AI allows for real-time tracking of HPMCAS raw material sourcing, production, and distribution, improving efficiency and resilience against disruptions.

- Computational chemistry and AI simulations can explore novel HPMCAS co-processing strategies or modifications, leading to the development of next-generation functional excipients with tailored properties.

- AI-powered virtual screening can rapidly assess the compatibility of HPMCAS with various active pharmaceutical ingredients (APIs), significantly reducing experimental trial-and-error in early-stage formulation development.

- Robotics and automation, guided by AI, can streamline the high-throughput screening of HPMCAS-based formulations, accelerating the identification of promising drug candidates.

DRO & Impact Forces Of Hypromellose Acetate Succinate Market

The Hypromellose Acetate Succinate (HPMCAS) market is shaped by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces that dictate its growth trajectory. Among the primary drivers is the escalating demand for advanced drug delivery systems, particularly those addressing the solubility and bioavailability challenges of an increasing number of poorly water-soluble drug candidates in pharmaceutical pipelines. The pharmaceutical industry's continuous investment in research and development to create novel formulations, coupled with the rising prevalence of chronic diseases globally, further fuels the adoption of HPMCAS for enteric coatings and amorphous solid dispersions. The polymer’s proven efficacy in protecting APIs from gastric acid and enhancing drug absorption underpins its sustained and growing demand, cementing its role as a critical excipient in modern medicine. This strong functional benefit drives continuous innovation in its application.

Conversely, several restraints impede the market's full potential. The high cost associated with the research and development of new drug formulations utilizing advanced excipients like HPMCAS can be a significant barrier for smaller pharmaceutical companies. Stringent regulatory approval processes in key markets such as North America and Europe require extensive testing and documentation, adding to the time and cost burden for product commercialization. Furthermore, the availability of alternative enteric polymers and solubility enhancers, while sometimes less effective for specific applications, can present competitive pressure. Economic fluctuations, geopolitical instability, and disruptions in the global supply chain for raw materials also pose risks, potentially leading to increased production costs and supply shortages for HPMCAS manufacturers and end-users, thereby impacting market stability and growth.

Despite these challenges, substantial opportunities exist for market expansion. The burgeoning pharmaceutical markets in emerging economies, particularly in Asia Pacific, Latin America, and Africa, present significant untapped potential as healthcare infrastructure and pharmaceutical manufacturing capabilities grow. Technological advancements in excipient manufacturing and formulation science offer avenues for developing novel HPMCAS grades with enhanced functionalities or more cost-effective production methods. The increasing focus on personalized medicine and biopharmaceutical advancements, which often involve complex drug delivery challenges, creates new niches for HPMCAS applications. Strategic collaborations between excipient manufacturers, pharmaceutical companies, and academic institutions to explore innovative uses and optimize HPMCAS properties are also expected to unlock new growth trajectories and reinforce the polymer’s market position.

Segmentation Analysis

The Hypromellose Acetate Succinate (HPMCAS) market is strategically segmented to reflect the diverse applications, specific grades, and end-user requirements within the pharmaceutical industry. This comprehensive segmentation allows for a granular understanding of market dynamics, identifying key growth areas and specialized demands for this versatile excipient. The primary segmentation often revolves around its functional application, differentiating between its use for enteric coating, which protects drugs from gastric acid and ensures targeted release in the intestine, and its increasingly critical role in solubility enhancement, particularly through the formation of amorphous solid dispersions for poorly water-soluble APIs. Further segmentation considers various HPMCAS grades based on their unique chemical compositions, such as variations in acetyl and succinoyl content, which dictate their pH-dependent solubility profiles and mechanical properties, making them suitable for different formulation challenges. This detailed breakdown highlights the polymer's adaptability and its importance across the drug development lifecycle.

- By Application:

- Enteric Coating: Use of HPMCAS to protect acid-labile drugs from gastric fluid and ensure drug release in the small intestine.

- Solubility Enhancement (Amorphous Solid Dispersions): Utilization of HPMCAS as a polymeric carrier to improve the dissolution rate and bioavailability of poorly water-soluble drugs.

- Controlled Release: Application in formulations designed to release the drug over an extended period.

- Taste Masking: Use to mask the unpleasant taste of certain active pharmaceutical ingredients.

- By Grade/Type:

- Fine Grade (e.g., L, MF): Typically lower molecular weight and higher acetyl content, suitable for aqueous enteric coating and solid dispersions.

- Standard Grade (e.g., M): Medium molecular weight, offering balanced properties for various applications.

- Coarse Grade (e.g., H, HF): Higher molecular weight and succinoyl content, often used for solvent-based enteric coating and specific sustained-release formulations.

- Customized Grades: Tailored HPMCAS grades developed for specific drug candidates or unique formulation requirements.

- By End-Use Industry:

- Pharmaceuticals: Dominant end-user, encompassing ethical drugs, generic drugs, and over-the-counter (OTC) medications.

- Nutraceuticals: Use in dietary supplements requiring enteric protection or enhanced bioavailability.

- By Regional Market:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Hypromellose Acetate Succinate Market

The value chain for the Hypromellose Acetate Succinate (HPMCAS) market commences with upstream activities focused on the sourcing and processing of essential raw materials. The primary raw material for HPMCAS is cellulose, typically derived from wood pulp or cotton linter. Key upstream suppliers include forestry companies and chemical manufacturers providing purified cellulose, acetic anhydride, and succinic anhydride, which are crucial for the chemical modification process. Quality control at this stage is paramount, as the purity and consistency of these raw materials directly impact the final properties and performance of HPMCAS. Strong relationships with reliable raw material suppliers are vital to ensure a stable supply, maintain product quality, and manage cost efficiencies within the manufacturing process. Innovation in sustainable sourcing and green chemistry for precursor production also plays a role in enhancing upstream value.

Midstream activities involve the actual synthesis and purification of HPMCAS. Specialized chemical manufacturers undertake a multi-step chemical process, including esterification and purification, to produce various grades of HPMCAS with specific acetyl and succinoyl content and molecular weights, tailored for different pharmaceutical applications. This stage requires significant technical expertise, advanced manufacturing facilities, and adherence to stringent Good Manufacturing Practices (GMP) to ensure the excipient meets pharmaceutical-grade standards for purity, safety, and functionality. Companies often invest heavily in R&D to optimize synthesis processes, develop new HPMCAS grades, and enhance manufacturing scalability and cost-effectiveness. The output from this stage includes the refined HPMCAS product, ready for distribution to pharmaceutical formulators.

Downstream activities involve the distribution channel and the subsequent utilization of HPMCAS by end-users. Distribution can occur through direct sales channels, where HPMCAS manufacturers supply directly to large pharmaceutical companies, or through indirect channels involving specialized distributors and agents who cater to a broader range of pharmaceutical and nutraceutical manufacturers. These distributors often provide technical support and smaller batch sizes, making HPMCAS accessible to diverse market players. At the end-user stage, pharmaceutical companies integrate HPMCAS into their drug formulation processes, utilizing it for enteric coating of tablets and capsules, or as a critical component in amorphous solid dispersions to enhance drug solubility and bioavailability. The efficiency and reliability of these distribution networks are crucial for ensuring timely access to this essential excipient, supporting the uninterrupted production of various medicinal products.

Hypromellose Acetate Succinate Market Potential Customers

The primary potential customers for Hypromellose Acetate Succinate (HPMCAS) are entities within the pharmaceutical industry, ranging from large multinational pharmaceutical corporations to mid-sized biotech firms and contract development and manufacturing organizations (CDMOs). These companies rely on HPMCAS for its critical functional properties in drug formulation, specifically its ability to act as an effective enteric coating material and a powerful polymer for solubility enhancement through amorphous solid dispersions. Pharmaceutical manufacturers developing oral solid dosage forms are constant buyers, seeking HPMCAS to protect acid-sensitive drugs, prevent gastric irritation, and ensure targeted drug release in the intestines. Given the increasing complexity of new chemical entities (NCEs) entering development pipelines, particularly those with poor aqueous solubility, the demand from companies focused on bioavailability improvement technologies is particularly strong. Generic drug manufacturers also represent a significant customer segment, as they often seek to replicate existing drug formulations using cost-effective and proven excipients like HPMCAS.

Beyond traditional pharmaceutical companies, the nutraceutical industry is an emerging and increasingly important customer segment for HPMCAS. Nutraceutical manufacturers utilize HPMCAS for similar reasons as pharmaceutical companies: to protect sensitive dietary supplements from stomach acid, improve the absorption of poorly soluble vitamins or botanical extracts, and provide controlled release properties for enhanced efficacy. Companies specializing in advanced drug delivery systems, drug encapsulation technologies, and specialized functional ingredients also constitute key potential customers. Furthermore, academic and industrial research institutions engaged in drug discovery and formulation development frequently purchase HPMCAS for experimental purposes, piloting new drug candidates, and optimizing their delivery mechanisms. The versatility of HPMCAS, coupled with its established safety profile and regulatory acceptance, makes it an attractive excipient across a broad spectrum of health-related product developers, all aiming to improve product performance and consumer benefits.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 750 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Shin-Etsu Chemical Co., Ltd., DuPont de Nemours, Inc., Ashland Global Holdings Inc., BASF SE, Colorcon Inc., Evonik Industries AG, Merck KGaA, Dow Chemical Company, Fuji Chemical Industries Co., Ltd., Meggle Pharma, SEPPIC S.A., JRS Pharma, SPI Pharma, ABITEC Corporation, Pharmatrans SANAQ AG, Ideal Cures Pvt. Ltd., Roquette Freres, Wacker Chemie AG, Avebe U.A., Croda International Plc |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hypromellose Acetate Succinate Market Key Technology Landscape

The technology landscape surrounding the Hypromellose Acetate Succinate (HPMCAS) market is characterized by continuous innovation aimed at optimizing its production, enhancing its functional properties, and broadening its application spectrum within pharmaceutical formulations. Core manufacturing technologies involve advanced esterification processes to ensure precise control over the degree of substitution of acetyl and succinoyl groups, which directly influences the polymer's pH-dependent solubility and mechanical strength. Manufacturers are increasingly employing sophisticated purification techniques to achieve high purity HPMCAS, free from residual solvents and impurities, thus meeting stringent pharmaceutical regulatory requirements. Furthermore, particle engineering technologies, such as spray drying, co-precipitation, and micronization, are crucial for producing HPMCAS powders with specific particle size distributions and morphologies, which are essential for uniform coating applications and effective amorphous solid dispersion formation, directly impacting drug dissolution and stability.

Beyond its inherent manufacturing, the application technologies utilizing HPMCAS are also evolving rapidly. In enteric coating, advancements in film coating equipment and processes, including continuous coating techniques and controlled humidity environments, enable more efficient and consistent application of HPMCAS-based coatings, reducing processing times and material waste. For solubility enhancement, particularly in amorphous solid dispersions (ASDs), hot melt extrusion (HME) and spray drying technologies are paramount. These processes efficiently create homogeneous solid dispersions of poorly soluble drugs with HPMCAS, which then maintain the drug in an amorphous, supersaturated state upon dissolution, significantly improving bioavailability. Research into novel co-processing excipient strategies and the development of specialized analytical techniques for characterizing HPMCAS in complex drug formulations are also key technological advancements. These innovations collectively drive the versatility and utility of HPMCAS, supporting the development of next-generation drug products with enhanced performance.

Regional Highlights

- North America: This region consistently leads the HPMCAS market, primarily due to the presence of a robust and innovative pharmaceutical industry, significant investments in drug discovery and development, and a high concentration of key players. Stringent regulatory frameworks and a strong focus on advanced drug delivery systems drive demand for high-quality excipients.

- Europe: A mature pharmaceutical market, Europe is a major consumer of HPMCAS, fueled by a strong emphasis on research into novel drug formulations, a high prevalence of chronic diseases, and an aging population. Countries like Germany, Switzerland, and the UK are at the forefront of pharmaceutical innovation.

- Asia Pacific (APAC): Expected to be the fastest-growing region, APAC benefits from expanding healthcare infrastructure, a burgeoning generic drug industry, and increasing investments in pharmaceutical manufacturing, especially in China, India, and Japan. Rising disposable incomes and greater access to healthcare are driving market expansion.

- Latin America: This region is experiencing steady growth in the HPMCAS market, supported by improving healthcare access, increasing pharmaceutical production capabilities, and growing government initiatives to enhance public health. Brazil and Mexico are key contributors to regional demand.

- Middle East and Africa (MEA): While currently a smaller market, MEA shows promising growth potential due to increasing healthcare expenditure, efforts to diversify economies beyond oil, and a rising focus on local pharmaceutical manufacturing. Investments in healthcare infrastructure are gradually expanding the market for excipients like HPMCAS.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hypromellose Acetate Succinate Market.- Shin-Etsu Chemical Co., Ltd.

- DuPont de Nemours, Inc.

- Ashland Global Holdings Inc.

- BASF SE

- Colorcon Inc.

- Evonik Industries AG

- Merck KGaA

- Dow Chemical Company

- Fuji Chemical Industries Co., Ltd.

- Meggle Pharma

- SEPPIC S.A.

- JRS Pharma

- SPI Pharma

- ABITEC Corporation

- Pharmatrans SANAQ AG

- Ideal Cures Pvt. Ltd.

- Roquette Freres

- Wacker Chemie AG

- Avebe U.A.

- Croda International Plc

Frequently Asked Questions

Analyze common user questions about the Hypromellose Acetate Succinate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Hypromellose Acetate Succinate (HPMCAS) and what are its primary uses?

HPMCAS is a pH-sensitive cellulosic polymer widely used in pharmaceuticals. Its primary uses are as an enteric coating agent to protect acid-sensitive drugs from gastric degradation and ensure targeted release in the intestine, and as a polymer for amorphous solid dispersions to enhance the solubility and bioavailability of poorly water-soluble active pharmaceutical ingredients (APIs).

How does HPMCAS contribute to improving drug bioavailability?

HPMCAS improves drug bioavailability primarily by forming amorphous solid dispersions (ASDs) with poorly soluble drugs. In ASDs, HPMCAS maintains the drug in an amorphous state, preventing crystallization and leading to a supersaturated drug solution upon dissolution, which significantly enhances the rate and extent of absorption in the gastrointestinal tract.

What are the key drivers for the growth of the HPMCAS market?

Key drivers include the increasing global prevalence of chronic diseases necessitating advanced drug delivery systems, the growing number of poorly water-soluble drug candidates in pharmaceutical pipelines requiring solubility enhancement, and continuous innovation in drug formulation technologies aimed at improving therapeutic efficacy and patient compliance.

Which regions are leading in the consumption of HPMCAS?

North America and Europe are currently leading in HPMCAS consumption due to their well-established pharmaceutical industries, significant R&D investments, and stringent regulatory environments. However, the Asia Pacific region is rapidly emerging as a major growth market, driven by expanding pharmaceutical manufacturing and healthcare investments.

What impact does AI have on the HPMCAS market and drug formulation?

AI is set to revolutionize the HPMCAS market by enabling predictive modeling for optimal HPMCAS grade selection, accelerating formulation development, optimizing manufacturing processes for efficiency and quality, and enhancing supply chain management. This leads to more precise, cost-effective, and faster development of HPMCAS-based drug products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager