Ice Crusher Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435781 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Ice Crusher Machine Market Size

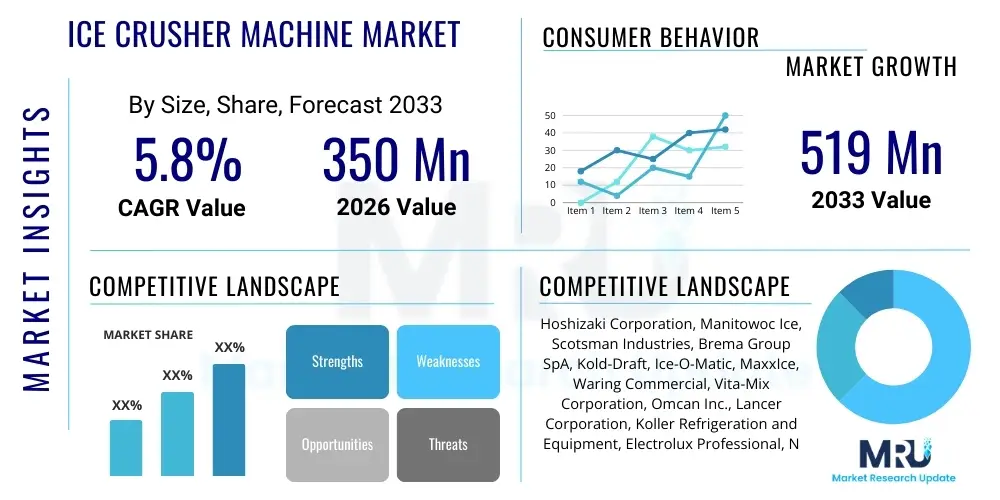

The Ice Crusher Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $350 Million USD in 2026 and is projected to reach $519 Million USD by the end of the forecast period in 2033.

Ice Crusher Machine Market introduction

The Ice Crusher Machine Market encompasses various mechanical or electromechanical devices designed to break down large cubes of ice into smaller, manageable fragments, granular ice, or finely shaved ice, suitable for consumption and storage. These machines range from manual, hand-cranked models to high-capacity, automated commercial units utilized heavily in the hospitality sector. The primary function is to facilitate the rapid preparation of beverages, chilled food displays, and therapeutic cold applications, thereby improving operational efficiency in high-demand environments.

The product description spans across several types, including block ice shavers, cube ice crushers, and multi-functional models that integrate crushing and dispensing capabilities. Key differentiating factors include crushing capacity (measured in kg/hour or lbs/minute), material construction (often food-grade stainless steel for durability and hygiene), and motor power. These machines are essential tools for ensuring the consistency and quality of crushed ice, which is critical for maintaining the flavor profile and temperature integrity of cocktails, smoothies, snow cones, and specialized cold presentations.

Major applications of ice crusher machines are concentrated in the Food Service Industry, including restaurants, bars, and cafes; the Healthcare Sector for cold packs and patient care; and the Retail and Entertainment industries, such as convenience stores, theme parks, and mass-market beverage producers. Driving factors propelling market growth include the rising global consumption of cold beverages, increasing urbanization leading to expansion of the HoReCa (Hotel, Restaurant, Catering) sector, and continuous innovation focused on energy efficiency and enhanced crushing mechanisms that minimize noise and vibration.

Ice Crusher Machine Market Executive Summary

The Ice Crusher Machine Market is characterized by robust growth driven by the sustained expansion of the global food and beverage industry and the increasing demand for customized ice textures in premium mixology and food presentation. Business trends indicate a strong shift towards automated, high-volume commercial crushers equipped with advanced safety features and smart sensors for load management. Manufacturers are increasingly focusing on durable, corrosion-resistant components and modular designs to simplify maintenance and replacement, catering specifically to the intensive usage patterns observed in commercial kitchens and high-traffic bar environments.

Regional trends highlight the Asia Pacific (APAC) region as the fastest-growing market, primarily due to burgeoning tourism, rapid expansion of quick-service restaurants (QSRs), and cultural preferences for iced desserts and chilled refreshments, particularly in densely populated economies like China and India. North America and Europe maintain significant market shares, characterized by high adoption rates of sophisticated, energy-efficient machines mandated by stringent environmental and operational efficiency regulations. Investment in Latin America and the Middle East & Africa (MEA) is accelerating, spurred by infrastructural development in the hospitality and entertainment sectors.

In terms of segmentation, the Automatic Ice Crusher segment dominates the market due to its superior efficiency and reduced labor requirements, positioning it favorably within the professional foodservice segment. Furthermore, the stainless steel material segment is experiencing increased demand due to its longevity and compliance with stringent sanitation standards. The market structure remains competitive, with key players focusing on strategic mergers, acquisitions, and the introduction of versatile, multi-texture crushing devices to capture niche market demands, such as fine powder ice for specific culinary applications.

AI Impact Analysis on Ice Crusher Machine Market

Common user questions regarding AI’s impact on the Ice Crusher Machine Market revolve around concerns about maintenance predictability, optimization of operational workflow, and the integration of automated quality control. Users often inquire whether AI can predict mechanical failure based on vibration patterns or motor strain, thereby minimizing costly downtime in critical commercial settings. Another major theme is the potential for AI-driven inventory management, connecting ice production and crushing rates directly to real-time consumption data to reduce energy waste and optimize scheduling for staff. The expectation is that AI integration will shift the ice crushing machinery from simple mechanical devices to smart appliances capable of self-diagnosis and operational optimization.

The integration of Artificial Intelligence and Machine Learning (ML) algorithms is primarily impacting the operational efficiency and predictive maintenance cycles of commercial ice crusher machines. By utilizing embedded sensors to monitor variables such as motor temperature, blade wear, noise levels, and load input variability, AI systems can process this complex dataset to forecast potential mechanical failures hours or days before they occur. This transition from reactive to predictive maintenance significantly enhances asset utilization and reduces the total cost of ownership (TCO) for large-scale foodservice operators, positioning advanced AI-enabled units as a premium, high-value investment.

Beyond maintenance, AI is also crucial in optimizing energy consumption. Smart ice crushers can learn peak operational hours and adjust motor speeds and crushing cycles dynamically, ensuring that ice is crushed and ready just in time for peak demand periods, rather than running inefficiently during lulls. This fine-tuning capability, driven by historical data analysis and real-time demand signals (potentially integrated with Point-of-Sale systems), addresses major concerns about environmental sustainability and rising energy costs, further solidifying the necessity for intelligent automation in the competitive hospitality environment.

- AI-driven Predictive Maintenance: Utilizing ML models to analyze sensor data (vibration, temperature) to forecast mechanical failure, maximizing uptime.

- Optimized Energy Consumption: Smart algorithms regulate motor speed and operation cycles based on real-time consumption patterns and historical demand data.

- Automated Quality Control: AI vision systems inspect crushed ice consistency, ensuring adherence to pre-set granular size specifications for different beverage applications.

- Inventory Integration: Connecting ice crushing output rates directly to kitchen or bar inventory management systems to prevent stockouts or overproduction.

- Remote Diagnostics and Troubleshooting: Enabling manufacturers to remotely access machine operational data for rapid diagnostics and firmware updates, improving service response times.

DRO & Impact Forces Of Ice Crusher Machine Market

The market dynamics for ice crusher machines are shaped by a complex interplay of increasing demand from the HoReCa sector (Drivers), stringent health and energy efficiency regulations (Opportunities), and persistent issues related to initial investment cost and maintenance complexity (Restraints). Impact forces are primarily governed by the shifting landscape of consumer beverage preferences, the drive towards automation in foodservice, and the need for durable, high-hygiene machinery. Understanding these forces is crucial for manufacturers developing next-generation products that balance power, efficiency, and cost effectiveness.

Key drivers center on the global rise in consumption of iced and blended beverages, particularly in emerging economies where disposable income is increasing. The relentless expansion of global coffee chains and fast-casual dining formats, which rely heavily on consistent ice supply, directly fuels demand for high-capacity crushers. Furthermore, the growing sophistication of cocktail culture, demanding specific ice types (e.g., pebble, snow, or clear crushed ice), compels commercial establishments to invest in versatile, precision-engineered crushing equipment. Technological advancements in motor efficiency and noise reduction also serve as internal drivers, encouraging replacement cycles for older, less efficient units.

However, the market faces restraints, chiefly the high initial capital expenditure associated with advanced commercial models, especially those built from high-grade stainless steel and incorporating advanced electronic controls. Furthermore, the lack of skilled technicians in certain developing regions poses a challenge to the maintenance and repair of complex automated crushers. Opportunities abound in the development of modular, multi-functional machines that can produce varying ice textures with minimal adjustment, catering to versatile menu demands. Additionally, leveraging sustainable manufacturing processes and incorporating low-energy motors presents a significant opportunity to attract environmentally conscious buyers and comply with global energy standards.

- Drivers:

- Rapid growth of the global foodservice and hospitality sector (HoReCa).

- Increasing consumer preference for iced beverages, smoothies, and specialty cocktails requiring varied ice textures.

- Focus on operational efficiency and speed in high-volume commercial environments.

- Technological advancements leading to quieter, more energy-efficient, and durable machines.

- Restraints:

- High initial investment and operational cost of commercial-grade, automated equipment.

- Challenges related to frequent maintenance and potential mechanical wear of blades and motors under heavy usage.

- Availability of specialized parts and technical service in remote or less developed markets.

- Opportunity:

- Integration of IoT and smart features for predictive maintenance and remote monitoring.

- Development of eco-friendly, energy-star certified models addressing sustainability concerns.

- Expansion into niche markets such as specialized medical cold therapy and upscale home entertainment systems.

- Impact Forces:

- Supplier Power: Moderate to High, driven by specialized component manufacturers (motors, food-grade steel).

- Buyer Power: High, due to product standardization and competitive pricing among numerous manufacturers.

- Threat of New Entrants: Moderate, mitigated by high R&D costs for specialized commercial machinery.

- Threat of Substitutes: Low, as high-volume ice crushing cannot be efficiently replaced by manual methods or other cooling technologies.

Segmentation Analysis

The Ice Crusher Machine Market is comprehensively segmented based on parameters critical to both commercial usability and operational scale, including machine type, operational mode, material construction, and end-user application. Analyzing these segments provides a clear understanding of market preferences and where specialized investment is concentrated. The delineation between manual and automatic operational modes remains the most fundamental distinction, dictating the target market—manual crushers serve smaller, non-professional settings, while automatic machines dominate high-throughput commercial and industrial applications.

Segmentation by material is becoming increasingly crucial, driven by regulatory demands for sanitation and long-term durability. Stainless steel machines consistently outperform plastic or hybrid models in terms of longevity, resistance to corrosion from melted ice and cleaning chemicals, and compliance with global health standards like NSF certification. This premium material segment commands higher pricing but delivers a significantly reduced replacement frequency, appealing to risk-averse commercial buyers prioritizing hygiene and robustness.

Furthermore, end-user segmentation reveals concentrated demand from the HoReCa sector (restaurants, hotels, bars) which requires heavy-duty, continuous operation capacity. Conversely, the retail segment (convenience stores, small vendors) often opts for compact, cost-effective machines. This detailed segmentation allows manufacturers to tailor product specifications—from throughput capacity and motor cooling systems to footprint size and noise characteristics—to meet the precise operational demands of specific vertical markets, ensuring maximum market penetration and optimized product portfolios.

- By Type:

- Cube Ice Crusher (Standard commercial application)

- Block Ice Shaver (Used primarily for snow cones and fine, fluffy ice desserts)

- Multi-functional Crusher/Dispenser

- By Operational Mode:

- Manual/Hand Cranked

- Automatic/Electric

- By Material:

- Stainless Steel

- Plastic/ABS

- Hybrid (Combination of metal and food-grade plastic components)

- By Application/End-User:

- Hotels, Restaurants, and Catering (HoReCa)

- Bars and Nightclubs

- Healthcare Facilities (Hospitals, Clinics)

- Retail Outlets (Convenience Stores, Food Kiosks)

- Industrial Food Processing

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Ice Crusher Machine Market

The value chain for the Ice Crusher Machine Market starts with the Upstream activities involving the sourcing of raw materials, primarily high-grade stainless steel (304 or 316 for food contact surfaces), specialized industrial motors, and electronic control components (PCBs, sensors). Strong supplier relationships in the stainless steel sector are crucial, as material quality directly impacts the hygiene rating and longevity of the final product. Component manufacturers, particularly those supplying high-torque, energy-efficient motors, exert significant influence over the cost and performance metrics of the crusher machines.

Midstream activities encompass the core manufacturing processes: precision casting, metal fabrication, blade sharpening, motor integration, and final assembly. Efficient manufacturing logistics and stringent quality control are vital here, especially for ensuring the geometric precision of the crushing mechanisms (blades, drums, hammers) to deliver consistent ice particle size. Companies that invest in advanced robotics and automation for assembly often achieve better cost efficiencies and higher product consistency than those relying on manual labor, leading to competitive advantages.

Downstream analysis focuses on distribution and end-user sales. Distribution channels are typically a mix of Direct sales (for large institutional buyers like hotel chains or industrial food processors) and Indirect sales, utilizing specialized commercial kitchen equipment distributors, foodservice supply wholesalers, and, increasingly, e-commerce platforms specializing in restaurant supplies. Indirect channels provide broader reach and local service support, which is critical for bulky, maintenance-intensive equipment. Effective post-sale support, including spare parts availability and on-site servicing, plays a significant role in maintaining customer satisfaction and driving repeat purchases in the professional market.

Ice Crusher Machine Market Potential Customers

Potential customers for ice crusher machines span a diverse range of commercial and institutional entities that require reliable, high-volume production of crushed ice for operational or therapeutic purposes. The largest end-user segment is the global HoReCa sector, including luxury hotels needing sophisticated ice for premium beverage service, high-turnover restaurants requiring large quantities for cooling beverages and food ingredients, and specialized bars focusing on mixology that necessitate precise ice textures (e.g., pellet ice for specific cocktails like mojitos).

Beyond the primary foodservice segment, the institutional and healthcare sectors represent substantial and growing clientele. Hospitals and rehabilitation centers utilize ice crushers for creating fine ice for patient consumption, cold compresses, and post-operative care, prioritizing hygiene, reliability, and quiet operation. Furthermore, large industrial operations, such as seafood processing plants, meat packers, and beverage bottling companies, require high-capacity, heavy-duty industrial crushers to rapidly cool products during processing or transportation, where continuous operation under harsh conditions is the key requirement.

Finally, the retail and leisure industries form another key demographic. Convenience stores, gas stations offering self-serve fountain drinks, and major entertainment venues (stadiums, theme parks) purchase robust, user-friendly dispensing crushers. The emerging market for high-end residential kitchen appliance integration also presents a niche potential customer base, comprising affluent homeowners seeking professional-grade amenities for entertaining, although this segment typically demands smaller, aesthetically pleasing units.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $350 Million USD |

| Market Forecast in 2033 | $519 Million USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hoshizaki Corporation, Manitowoc Ice, Scotsman Industries, Brema Group SpA, Kold-Draft, Ice-O-Matic, MaxxIce, Waring Commercial, Vita-Mix Corporation, Omcan Inc., Lancer Corporation, Koller Refrigeration and Equipment, Electrolux Professional, New Air, Ziegra Eismaschinen GmbH, Everest Refrigeration, Snowie LLC, Wilbilt Inc., SHAVATRONICS, CBC Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ice Crusher Machine Market Key Technology Landscape

The technological landscape of the Ice Crusher Machine Market is focused primarily on improving crushing efficiency, enhancing hygiene standards, and integrating smart operational features. Key advancements revolve around blade and rotor technology. Manufacturers are increasingly utilizing precision-engineered, hardened alloy steel blades with specialized coatings to maintain sharpness longer and reduce friction, thereby minimizing heat generation during high-speed crushing. This not only extends the machine's lifespan but also ensures that the ice quality (texture and temperature) remains optimal for end-use, reducing the rate of premature melting.

Another major technological area is motor and transmission design. There is a clear trend toward high-efficiency brushless DC motors (BLDC) which offer higher torque at lower energy consumption compared to traditional AC motors. These advanced motors also allow for variable speed control, enabling users to fine-tune the crushing process to achieve different granularity levels—from coarse chipped ice to fine powder snow—without needing mechanical component swaps. The integration of advanced noise and vibration dampening technology (using specialized polymer mounts and acoustic baffling) is crucial for machines deployed in front-of-house or quiet healthcare settings, driving premium pricing for quieter models.

The move toward digitalization, enabled by IoT (Internet of Things) connectivity, represents the cutting edge of the market. Modern commercial crushers are equipped with sensors that track operational metrics (run time, load cycles, maintenance alerts) and transmit this data wirelessly to cloud platforms. This allows operators to monitor fleet performance remotely and facilitates proactive intervention, optimizing deployment schedules and minimizing downtime. Furthermore, advanced self-cleaning cycles and material coatings with antimicrobial properties (like certain types of silver ion coatings) are becoming standard, addressing the paramount concern of food safety and hygiene in professional environments.

Regional Highlights

- North America: This region holds a significant market share, characterized by high adoption rates of automated, high-capacity crushers due to the mature and highly capitalized foodservice industry. Strict sanitation regulations (e.g., NSF standards) drive demand for premium stainless steel and advanced cleaning features. The region is a leader in implementing smart, IoT-enabled crushing solutions for streamlined operational management, especially within major hotel and restaurant chains.

- Europe: The European market is mature and distinguished by a strong emphasis on energy efficiency and sustainability. Demand is high for crushers complying with stringent EU energy directives. The market is driven by the robust tourism sector and the increasing sophistication of European cafe and bar culture. Germany, the UK, and France are key contributors, favoring durable, high-quality, long-life machinery.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market, fueled by explosive growth in urbanization, rising disposable incomes, and the massive expansion of the HoReCa sector. Countries like China, India, and Southeast Asian nations show massive demand for machines suitable for local culinary traditions (e.g., shaved ice desserts). Market growth is currently driven by both entry-level cost-effective models and premium units purchased by international luxury hotel chains.

- Latin America (LATAM): This region is experiencing steady growth, linked to increasing investment in hospitality infrastructure and international tourism development, particularly in Brazil and Mexico. Demand focuses on robust, easy-to-maintain crushers that can withstand fluctuating power supplies and operate reliably in high ambient temperatures. Price sensitivity remains a factor, driving demand for locally assembled or mid-range imported models.

- Middle East and Africa (MEA): Growth is primarily concentrated in the Gulf Cooperation Council (GCC) countries, driven by mega-projects in tourism, luxury hospitality, and entertainment complexes (e.g., Saudi Arabia’s Vision 2030 and UAE’s tourism expansion). The intense heat necessitates high-efficiency ice production and crushing capabilities. The African market remains nascent but offers long-term growth potential spurred by increasing urbanization and the emergence of modern foodservice chains.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ice Crusher Machine Market.- Hoshizaki Corporation

- Manitowoc Ice (A Welbilt Brand)

- Scotsman Industries (A Middleby Company)

- Brema Group SpA

- Kold-Draft

- Ice-O-Matic

- MaxxIce

- Waring Commercial

- Vita-Mix Corporation

- Omcan Inc.

- Lancer Corporation

- Koller Refrigeration and Equipment

- Electrolux Professional

- New Air

- Ziegra Eismaschinen GmbH

- Everest Refrigeration

- Snowie LLC

- Wilbilt Inc.

- SHAVATRONICS

- CBC Co. Ltd.

Frequently Asked Questions

Analyze common user questions about the Ice Crusher Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Ice Crusher Machine Market?

The Ice Crusher Machine Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033, driven largely by the expansion of the global hospitality and foodservice sectors.

Which segmentation dominates the commercial Ice Crusher Machine Market?

The Automatic/Electric operational mode segment, particularly those utilizing stainless steel components, dominates the commercial market due to their high throughput capacity, operational consistency, and adherence to stringent food safety and hygiene standards required in HoReCa environments.

How is AI technology influencing modern Ice Crusher machines?

AI is primarily integrated for predictive maintenance, using embedded sensors to monitor machine health and forecast mechanical failures, significantly reducing downtime and optimizing energy consumption based on real-time operational demand and historical usage patterns.

Which geographical region shows the highest growth potential for Ice Crusher Machines?

The Asia Pacific (APAC) region is forecasted to show the highest growth rate, fueled by rapid urbanization, substantial investment in tourism infrastructure, and the cultural popularity of chilled and iced beverages across key economies like China and India.

What are the primary restraints affecting market expansion?

The primary restraints include the relatively high initial capital expenditure required for sophisticated, commercial-grade automated crushers and the challenges associated with complex maintenance schedules, particularly in regions lacking specialized technical expertise.

The ongoing modernization of commercial kitchens globally, coupled with consumer preference for customizable cold beverages, ensures sustained demand for efficient ice crushing solutions. Key industry participants are continually investing in research and development to enhance motor longevity, reduce acoustic output, and integrate IoT capabilities, positioning the market for steady, technologically driven growth over the forecast period.

Detailed analysis confirms that achieving market differentiation relies heavily on superior material quality (stainless steel being preferred for longevity and hygiene), advanced crushing mechanisms that offer variable granularity, and smart features that support remote monitoring and predictive diagnostics, catering to the exacting standards of the modern foodservice supply chain.

Furthermore, sustainability mandates are compelling manufacturers to prioritize energy-efficient designs and components, ensuring that future products meet stringent global standards while delivering maximum performance. This strategic alignment of technology, quality, and environmental responsibility will define competitive success within the Ice Crusher Machine Market moving toward 2033.

The competitive intensity is expected to rise as regional players gain technological parity with established global leaders. Strategic partnerships, focusing on localized distribution networks and customized service contracts, will be crucial for maintaining market share, particularly in high-growth areas like Southeast Asia and Latin America. The capacity to offer comprehensive product portfolios, ranging from compact bar crushers to heavy-duty industrial units, will be instrumental in capturing the entire spectrum of potential end-users.

Specific attention must be paid to the evolving needs of the healthcare sector, which increasingly demands ultra-hygienic, easy-to-sanitize machines capable of producing fine, easily digestible ice for patient care, thereby opening up specialized revenue streams distinct from the traditional hospitality sector. Investment in antimicrobial surface technology and sealed operational compartments is critical for addressing this niche yet vital market requirement.

In conclusion, the Ice Crusher Machine Market remains fundamentally tethered to the health of the global foodservice industry. While facing short-term pressures related to material costs and supply chain complexities, the long-term outlook is robust, supported by demographic trends favoring cold beverage consumption and continuous innovation enhancing machine performance and operational intelligence.

Advanced sensor technology, now commonly embedded in premium models, allows for real-time adjustments to blade speed and feed rate, ensuring that the crushing action is optimized regardless of the incoming ice size or density. This level of precise control minimizes motor strain and prevents potential jamming, thereby prolonging the operational life of the equipment in demanding commercial environments where consistent output is non-negotiable. Such operational intelligence significantly enhances the perceived value proposition for large institutional buyers.

Material science innovation also extends to specialized polymers used in gaskets, seals, and non-contact internal components, designed to resist thermal shock and chemical degradation from cleaning agents. The durability of these minor components is often overlooked but proves critical in high-usage scenarios, impacting overall machine longevity and reducing the frequency of maintenance intervention, which is a major factor in calculating the TCO for commercial operators.

The rising tide of customized beverage preparation means that machines capable of producing three or more distinct ice textures (e.g., snow, coarse crush, pellet) are increasingly favored. This versatility allows businesses, particularly high-end bars and specialty dessert shops, to streamline their equipment footprint while maximizing their menu offerings. Manufacturers who successfully integrate this multi-texture capability into a single, reliable unit gain a substantial competitive edge.

Furthermore, the ecological impact is becoming a non-negotiable factor. Buyers, especially in North America and Europe, actively seek out crushers that carry third-party certifications related to energy consumption. Manufacturers are responding by engineering superior insulation and cooling systems for the motor unit, ensuring that energy is efficiently translated into crushing power rather than wasted as heat, supporting the broader corporate sustainability goals of major purchasers.

In the regional context, regulatory environments are key determinants of product design. For instance, in parts of the Middle East, crushers must be engineered to handle significantly higher ambient temperatures without compromising cooling integrity or mechanical performance. This mandates the use of specialized cooling fans and high-temperature-rated electrical components, showcasing how geographical climate conditions directly influence technological specifications and procurement decisions.

The market also witnesses considerable activity in the aftermarket services segment. As machines become more sophisticated, the provision of comprehensive service contracts, rapid spare parts availability, and remote diagnostic services becomes a critical component of the overall purchase decision. Companies offering robust service ecosystems are better positioned to secure long-term contracts with major hotel chains and restaurant franchises, ensuring recurring revenue streams beyond initial equipment sales.

The competition is not solely based on price or capacity but increasingly on user interface and ease of cleaning. Intuitive digital control panels, often touch-screen enabled, simplify operation and allow staff to quickly select desired ice textures or cleaning cycles. Additionally, designs that facilitate easy, tool-free disassembly of ice contact components are highly valued, as they reduce the time and effort required for daily sanitation procedures, directly addressing labor efficiency challenges in the foodservice sector.

Future R&D efforts are expected to focus on integrating advanced material coatings that actively prevent microbial growth on crushing surfaces, moving beyond simple stainless steel to composite materials or ceramic-coated components. Such innovations would raise the benchmark for hygiene and product safety, creating a new premium tier within the commercial market based purely on unparalleled sanitary assurance.

Finally, the proliferation of specialized events and mobile food service (food trucks, outdoor catering) drives demand for compact, portable, yet powerful ice crushers. These units must balance durability with a lighter footprint and reliance on standard power inputs, representing a distinct sub-segment requiring tailored product specifications and optimized battery or generator compatibility for remote operation.

These detailed market insights confirm the dynamic nature of the Ice Crusher Machine Market, driven equally by technological advancement and evolving end-user operational demands across diverse global regions.

The report confirms that while foundational mechanical engineering remains crucial, future market leadership will be contingent upon successful integration of smart technology, superior hygienic design, and alignment with global energy efficiency standards, transforming the ice crusher from a simple utility appliance into an interconnected, high-performance operational asset.

The current market landscape emphasizes the importance of robust security features in connected devices. With IoT-enabled ice crushers transmitting operational data, manufacturers must guarantee cybersecurity to protect proprietary business data and prevent unauthorized access or tampering. This necessitates compliance with industrial IoT security protocols and encryption standards, adding another layer of complexity and cost to the R&D process but building trust among large corporate clients.

Furthermore, miniaturization technology is opening doors to more efficient internal designs. Compact gearboxes and high-density motors allow manufacturers to build high-capacity crushers with a smaller physical footprint, addressing the perpetual space constraints faced by commercial kitchens, especially in urban areas where real estate is expensive. This optimized physical design contributes significantly to improved workflow and kitchen layout flexibility.

The role of customizability is also expanding, especially for large institutional buyers. Some manufacturers now offer modular systems where the ice crusher can be integrated directly with existing ice makers, storage bins, and specialized dispensing nozzles. This tailor-made approach allows clients to build bespoke ice handling solutions that perfectly match their specific throughput requirements and spatial limitations, moving beyond off-the-shelf standardized units.

In emerging markets, the focus remains on affordability and ruggedness. Machines designed for these regions often prioritize simpler mechanical structures that are easier to repair using readily available parts, even if they sacrifice some of the advanced features found in premium models destined for North American or European markets. This localized design approach is essential for achieving broad market penetration in developing economies where maintenance infrastructure is less centralized.

Finally, social commerce and direct-to-consumer (D2C) channels are influencing the visibility and purchase patterns for smaller, high-quality residential and light commercial crushers. Digital marketing strategies focusing on visual appeal, recipe integration, and influencer partnerships are increasingly relevant for capturing the attention of small business owners and high-end residential consumers who prioritize both aesthetics and functionality.

The successful navigation of the Ice Crusher Machine Market requires a multi-faceted strategy that addresses operational efficiency, technological sophistication, regional customization, and strict compliance with global health and safety protocols. The convergence of these factors will dictate which firms achieve sustainable growth in the years leading up to 2033.

The complexity of ice crushing mechanisms requires specialized material knowledge to ensure long-term functionality. For instance, the stress placed on internal components by continuous crushing cycles necessitates the use of anti-fatigue materials, often requiring advanced metal treatments such as cryogenic processing or specialized surface hardening techniques to prevent microscopic cracking and premature failure, especially for components that interface directly with the ice at high speeds and low temperatures.

Market analysts are keenly observing the impact of sustainability certifications beyond just energy usage. Buyers are beginning to favor crushers manufactured using recycled or sustainably sourced materials, and those adhering to 'circular economy' principles, which prioritize end-of-life recycling and minimizing waste. Manufacturers that can transparently demonstrate a lower carbon footprint throughout the product lifecycle gain a competitive edge with environmentally conscious large corporations.

Moreover, the rise of specialized cold chain logistics and the increased global demand for crushed ice in transportation (e.g., maintaining the freshness of vaccines or perishables) introduces a B2B demand sector distinct from the HoReCa industry. This sector requires ultra-reliable, high-capacity crushers designed for continuous, industrial-scale output, often demanding specific certifications related to handling temperature-sensitive goods and large volumes.

The evolution of sensory technology within crushers also aids in ensuring food safety. Certain high-end models now incorporate sensors that detect impurities or inconsistencies in the incoming ice supply (e.g., non-water contaminants), automatically halting the crushing process and issuing an alert. This pre-emptive quality control protects the integrity of the finished product and prevents potential contamination of beverages or food items, adding significant value in the eyes of institutional buyers with zero-tolerance policies for food safety breaches.

In summary, the market is moving towards highly integrated, smart, and durable machinery. Success for market participants will hinge on their ability to offer comprehensive solutions that minimize operational friction, maximize hygienic safety, and consistently deliver high-quality crushed ice tailored to specific application needs, backed by robust global service and support infrastructure.

The transition toward integrated ice-making and crushing systems is becoming a defining feature in the premium segment. Instead of separate units, combined systems offer a single, sterilized pathway from water input to crushed ice output, dramatically reducing potential points of contamination and simplifying maintenance protocols. These advanced integrated machines represent the peak of efficiency and hygiene in high-demand settings.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager