Immobilized Trypsin Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431871 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Immobilized Trypsin Market Size

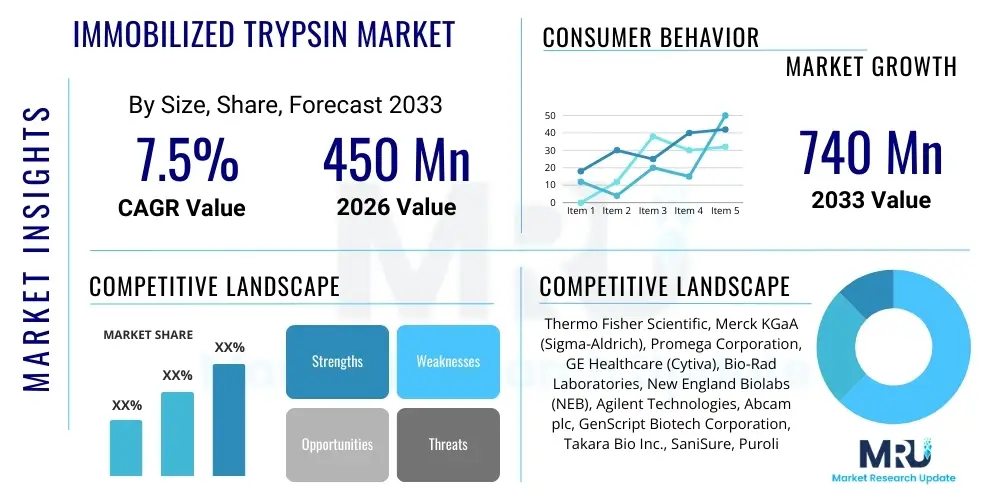

The Immobilized Trypsin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 740 Million by the end of the forecast period in 2033.

Immobilized Trypsin Market introduction

Immobilized trypsin represents a critical advancement in enzyme technology, transforming standard proteomics workflows. Trypsin, a serine protease, is traditionally used to cleave proteins into smaller peptides for mass spectrometry analysis. Immobilization involves covalently attaching the trypsin enzyme to an inert, insoluble support matrix, such as agarose beads, magnetic particles, or porous polymers. This functional modification significantly enhances the enzyme's stability, reusability, and operational temperature range, while preventing self-digestion (autolysis). The resultant immobilized format is highly sought after in high-throughput applications, offering superior purification and separation efficiency compared to its free-solution counterpart.

The primary applications of immobilized trypsin are concentrated within the biopharmaceutical and clinical research sectors, predominantly in peptide mapping, protein sequencing, and large-scale synthesis of specific peptide fragments. Its efficiency and ease of removal from reaction mixtures—a simple filtration or magnetic separation step—streamline complex analytical processes, reducing preparation time and minimizing potential sample contamination. Furthermore, the enhanced stability allows for continuous flow reactor designs, facilitating industrial-scale protein digestion that is pivotal for quality control in therapeutic protein manufacturing, including monoclonal antibodies (mAbs) and biosimilars.

Market growth is substantially driven by the accelerating demand for advanced proteomics research globally, especially in personalized medicine and biomarker discovery. The increasing investment in bioprocess optimization and the rising complexity of therapeutic protein analysis necessitate robust, reliable, and scalable enzyme platforms. Regulatory mandates concerning the structural characterization of biopharmaceuticals also contribute significantly, positioning immobilized trypsin as an indispensable tool for ensuring product safety and efficacy. These factors collectively establish a strong foundation for sustained market expansion throughout the forecast period.

- Product Description: Trypsin enzyme covalently linked to a solid support matrix (e.g., agarose, silica, magnetic beads) to enhance stability and reusability.

- Major Applications: Proteomics (peptide mapping, protein identification), Biopharmaceutical quality control, Continuous flow biocatalysis, and High-throughput screening.

- Benefits: Increased enzyme half-life, prevention of autolysis, easy separation from reaction mixture, reduced cost per reaction, and suitability for automation.

- Driving Factors: Growth in personalized medicine, rising global investment in protein research, and expansion of biopharmaceutical manufacturing capabilities.

Immobilized Trypsin Market Executive Summary

The Immobilized Trypsin Market is characterized by intense technological innovation focused on improving matrix compatibility and linkage chemistries to maximize enzyme loading and performance repeatability. Business trends indicate a strong move toward strategic collaborations between enzyme manufacturers and core proteomics technology providers (such as mass spectrometry instrument vendors) to offer integrated workflow solutions. Key players are investing heavily in developing novel magnetic bead-based immobilization systems, which significantly accelerate sample preparation in clinical diagnostics and drug screening. Furthermore, the shift towards continuous manufacturing processes in biologics production is necessitating large-scale, industrial-grade immobilized enzyme columns, driving demand for high-capacity, robust matrices capable of sustaining prolonged operational cycles.

Regionally, North America maintains market dominance due to robust funding for life sciences, the presence of major pharmaceutical and biotechnology hubs, and advanced research infrastructure focused on precision medicine and disease pathogenesis. However, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by substantial government initiatives promoting domestic biopharma R&D, coupled with increasing investments from multinational corporations establishing manufacturing and research centers in countries like China, India, and South Korea. These developing markets are rapidly adopting high-throughput analytical techniques, favoring the efficiency and cost-effectiveness offered by immobilized enzyme preparations.

Segment-wise, the application of immobilized trypsin in mass spectrometry sample preparation holds the largest market share, driven by the indispensable role of proteomics in drug development pipelines. Within the matrix type segmentation, porous polymers and magnetic particles are experiencing rapid adoption, particularly the latter due to their suitability for automated, high-volume processing. End-user trends show hospitals and clinical diagnostic labs emerging as key growth areas, moving beyond traditional academic and industrial research settings, as biomarker identification and therapeutic monitoring become standard practice, thereby diversifying the customer base and ensuring stable, long-term market demand.

AI Impact Analysis on Immobilized Trypsin Market

User inquiries frequently center on how Artificial Intelligence (AI) can optimize the typically time-consuming and variable steps associated with proteolytic digestion using immobilized trypsin. Specific questions often relate to the potential for AI algorithms to predict optimal digestion parameters—such as incubation time, temperature, and enzyme-to-substrate ratio—based on the physicochemical properties of the target protein and the specific matrix characteristics. Users are keenly interested in AI’s capability to analyze high-volume, multi-omics data generated post-digestion, expecting AI-driven platforms to rapidly identify peptide fragments, quantify post-translational modifications (PTMs), and filter out digestion artifacts, thereby enhancing data quality and accelerating the pace of discovery in complex proteomics studies.

AI's primary influence is manifested through its integration into high-throughput robotic platforms where immobilized trypsin is utilized for automated sample preparation. Machine learning models are being employed to monitor and control continuous flow reactors, ensuring maximum enzyme efficiency and preventing matrix fouling or degradation, crucial factors for maintaining reproducibility in industrial bioprocessing. By analyzing kinetic data in real-time, AI systems can dynamically adjust flow rates or buffer conditions, moving away from static, predefined protocols toward adaptive digestion strategies. This level of optimization significantly reduces reagent consumption, lowers operational costs, and minimizes the variability inherent in traditional manual protocols, addressing a major concern in large-scale proteomics.

Furthermore, AI and deep learning are revolutionizing the interpretation of mass spectrometry outputs derived from immobilized trypsin digestion. These advanced analytical tools can handle the complexity of identifying peptides derived from multiple, closely related protein variants or highly modified proteins, areas where manual or traditional software analysis struggles. The ability of AI to accurately classify and quantify thousands of peptides simultaneously dramatically shortens the time required for protein characterization, acting as a profound accelerator for drug target validation and quality control processes in biopharmaceutical manufacturing. This transformative impact positions AI as an essential component in maximizing the utility and data output derived from immobilized trypsin technologies.

- AI optimizes digestion protocols by predicting ideal conditions (time, temperature, ratio) based on substrate profile.

- Machine learning algorithms enhance quality control in continuous bioprocessing, monitoring enzyme stability and minimizing autolysis.

- AI facilitates high-throughput data analysis post-mass spectrometry, accelerating peptide identification and PTM quantification.

- Integration of AI into robotic platforms enables adaptive automation, improving the reproducibility and efficiency of sample preparation using magnetic immobilized trypsin.

- Deep learning models aid in distinguishing signal from noise, reducing artifacts and improving the accuracy of complex proteome mapping studies.

DRO & Impact Forces Of Immobilized Trypsin Market

The Immobilized Trypsin Market is fundamentally shaped by a convergence of technological drivers and infrastructural opportunities, counterbalanced by cost and regulatory restraints. Key drivers include the exponential growth in demand for high-resolution structural biology studies and the mandatory requirements for detailed characterization of biotherapeutic agents, propelling the adoption of robust enzymatic tools. The core opportunity lies in developing novel, application-specific matrices, such as thermally stable ceramic or silica-based carriers, that can further broaden the operational window of the enzyme, allowing its use in more extreme industrial environments or novel microfluidic systems. The efficiency gain—reusability and high throughput—is the dominant pull factor for end-users transitioning from traditional free trypsin.

Conversely, significant restraints exist, primarily revolving around the initial high capital investment required for adopting advanced immobilization platforms and continuous flow reactors. Furthermore, the stability and functional capacity of the immobilized enzyme can be sensitive to complex biological matrices (samples high in lipids or detergents), leading to concerns regarding long-term storage stability and consistency across different batches of immobilized product. Regulatory hurdles, although generally supportive of advanced characterization, sometimes require extensive validation studies for new immobilized enzyme systems before they are approved for use in GxP-compliant biomanufacturing environments, slowing market penetration for smaller innovators.

The Impact Forces analysis reveals that technological advancements are the primary accelerators, particularly those improving covalent linkage chemistries (e.g., highly selective click chemistry), resulting in more stable and active immobilized preparations. The substitute threat remains moderate; while alternative proteases (e.g., Lys-C, Glu-C) exist, trypsin’s cleavage specificity remains the gold standard for mainstream proteomics. Supplier power is concentrated among a few specialized chemical and life science suppliers who provide the high-purity matrices and specialty linkers, slightly increasing raw material costs. Buyer power is moderate, influenced heavily by price sensitivity in academic and governmental research sectors, but offset by the necessity of the tool in high-value biopharma R&D.

Segmentation Analysis

The Immobilized Trypsin Market is systematically segmented based on matrix type, application, and end-user, providing a clear framework for understanding market dynamics and targeted strategic development. The matrix type segmentation is crucial as the performance characteristics—such as flow rate, binding capacity, and chemical stability—are highly dependent on the support material. Agarose beads remain a historically stable segment due to their biocompatibility and low non-specific binding, while synthetic polymers and magnetic particles are rapidly expanding their share driven by needs for faster separation and automation capability, respectively.

Application analysis highlights the market's dependence on complex analytical needs. Proteomics and peptide mapping constitute the core revenue streams, given that virtually all protein characterization relies on efficient and reproducible cleavage. However, the bioprocess engineering segment, focused on large-scale peptide synthesis and continuous purification processes, is poised for significant future growth as the industry adopts continuous manufacturing methodologies to improve efficiency and reduce manufacturing footprint. This shift emphasizes the demand for industrial-grade, robust, and regenerable immobilized enzyme columns.

End-user segmentation clearly defines the market's customer base, dominated currently by biotechnology and pharmaceutical companies that utilize immobilized trypsin for mandatory quality control (QC) testing and drug discovery. Academic and research institutes represent the second largest segment, driven by fundamental research and grant-based funding. Crucially, the fastest growing segment is Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs), as biopharma companies increasingly outsource complex analytical tasks, requiring high-throughput, standardized protocols that immobilized trypsin efficiently provides.

- By Matrix Type:

- Agarose Beads

- Magnetic Particles

- Silica/Glass Beads

- Polymeric Supports (e.g., Polyethylene Glycol, Polystyrene)

- Hydrogel Matrices

- By Application:

- Mass Spectrometry Sample Preparation (Peptide Mapping and Protein Identification)

- Bioprocess Engineering (Continuous flow synthesis and purification)

- High-Throughput Screening (HTS)

- Clinical Diagnostics and Biomarker Discovery

- By End-User:

- Biotechnology and Pharmaceutical Companies

- Academic and Research Institutes

- Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs)

- Clinical Laboratories and Hospitals

Value Chain Analysis For Immobilized Trypsin Market

The value chain for the Immobilized Trypsin Market begins with the upstream segment, which encompasses the sourcing and purification of high-quality, recombinant or porcine trypsin and the specialized support matrices (e.g., high-purity agarose, functionalized magnetic beads). Suppliers in this stage focus on stringent quality control to ensure low trace protease contamination and consistent batch-to-batch properties of the matrix material. Key challenges upstream include managing the cost fluctuations of highly purified enzyme feedstock and optimizing the large-scale synthesis of uniform, porous polymeric supports necessary for high-performance immobilization. The quality and purity of these raw materials directly dictate the performance and longevity of the final immobilized product, emphasizing the importance of robust supplier relationships and internal purification capabilities.

The core immobilization process, located mid-chain, involves advanced chemical functionalization, where manufacturers utilize various linkage chemistries (such as carbodiimide, epoxy, or Schiff base reactions) to covalently attach the trypsin to the activated matrix. This stage is proprietary and highly knowledge-intensive, as efficiency and stability are maximized by optimizing coupling density and ensuring minimal disruption to the enzyme's active site. Following successful immobilization, the product undergoes rigorous washing, testing for leakage, residual activity, and batch consistency before formulation and packaging. This manufacturing sophistication creates a high barrier to entry for new competitors and differentiates established market leaders based on product reliability and technical superiority.

Downstream analysis focuses on the distribution channels and end-user integration. Products are primarily distributed through direct sales channels to large biopharmaceutical companies and CROs requiring technical support and bulk ordering, and through specialized life science distributors who cater to academic institutions and smaller laboratories globally. The final step involves end-users integrating the immobilized trypsin into automated workflows, such as robotic sample preparation systems or packed chromatography columns. The growing preference for pre-packed columns and customized kits suitable for specific mass spectrometry platforms highlights a critical downstream requirement for user-friendly, plug-and-play solutions, driving manufacturers to focus on indirect sales via specialized platform partnerships.

Immobilized Trypsin Market Potential Customers

The primary end-users and potential buyers of immobilized trypsin are large pharmaceutical and biotechnology companies involved in the development and manufacturing of complex protein therapeutics, including monoclonal antibodies (mAbs), fusion proteins, and biosimilars. These organizations require reliable, highly reproducible, and scalable digestion systems for comprehensive protein characterization mandated by regulatory agencies like the FDA and EMA. Their usage spans across R&D (target identification), process development (optimization of expression and purification), and quality control (release testing of final therapeutic products), demanding immobilized trypsin preparations that can withstand industrial throughput and GxP standards.

Academic and governmental research institutes, particularly those focusing on fundamental proteomics, structural biology, and disease mechanisms, represent a consistently robust customer segment. These laboratories utilize immobilized trypsin extensively in large-scale projects aiming at mapping entire proteomes, identifying novel biomarkers, and studying protein-protein interactions. While often more price-sensitive than industry players, this segment drives demand for specialized, smaller-scale preparations and innovative matrix types that facilitate complex, experimental workflows. Grant funding levels and institutional research budgets directly influence purchasing power within this sector, necessitating diverse product offerings from vendors.

A rapidly expanding customer base includes Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs), which leverage immobilized trypsin to provide high-volume, standardized analytical services to the global biopharma industry. Their business model relies on maximizing efficiency and minimizing cost per sample, making the reusability and automation compatibility of immobilized enzymes highly attractive. Clinical diagnostic laboratories are also emerging as significant buyers, utilizing these stabilized enzymes for sample preparation in advanced clinical proteomics, particularly for mass spectrometry-based diagnostic tests aimed at personalized treatment stratification and monitoring chronic diseases.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 740 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Merck KGaA (Sigma-Aldrich), Promega Corporation, GE Healthcare (Cytiva), Bio-Rad Laboratories, New England Biolabs (NEB), Agilent Technologies, Abcam plc, GenScript Biotech Corporation, Takara Bio Inc., SaniSure, Purolite Corporation, Danaher Corporation (Pall/Beckman Coulter), Novozymes A/S, Roche Diagnostics, Biocon Ltd., Lonza Group AG, BBI Solutions, OriGene Technologies, Creative Enzymes. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Immobilized Trypsin Market Key Technology Landscape

The technological landscape of the Immobilized Trypsin Market is dominated by advancements in matrix functionalization and reactor design, aimed at maximizing enzyme activity and minimizing leaching. Covalent bonding chemistry remains the cornerstone, with techniques such as glutaraldehyde cross-linking, carbodiimide activation (EDC/NHS), and epoxy functionalization being widely employed to create stable linkages between the trypsin and the support material. The shift towards milder, highly specific linkage chemistries, such as metal chelation or bioorthogonal click chemistry, is a major trend, reducing denaturation during the immobilization process and leading to preparations with significantly higher retained activity and greater operational stability, addressing critical limitations of older methodologies.

A notable technological focus is on optimizing the physical properties of the support matrices themselves. Manufacturers are developing novel porous polymer resins and nano-structured silica particles that offer increased surface area-to-volume ratio, thereby boosting the enzyme loading capacity and improving mass transfer characteristics essential for rapid digestion kinetics. The integration of magnetic nanoparticles is arguably the most disruptive technological advancement, enabling the use of immobilized trypsin in rapid magnetic separation protocols. This technology is particularly valuable in high-throughput automated systems and clinical diagnostics where rapid, contamination-free separation is paramount. Magnetic immobilization allows for robust agitation during digestion, followed by instantaneous magnetic removal, streamlining complex, multi-step sample preparation.

Furthermore, microfluidic and continuous flow technologies are increasingly defining the application landscape. Utilizing immobilized trypsin within microreactor chips allows for highly controlled digestion environments, significantly reducing sample volumes and reaction times. This approach is instrumental in analytical chemistry and clinical sample processing where sample availability is limited. Manufacturers are developing pre-packed, disposable micro-columns containing highly stable immobilized trypsin, designed specifically for integration with advanced chromatography systems and next-generation mass spectrometers, thus offering truly integrated, high-resolution proteomic platforms that enhance both reproducibility and overall analytical throughput.

Regional Highlights

North America is the global leader in the Immobilized Trypsin Market, underpinned by the world's largest concentration of leading biopharmaceutical companies and advanced academic research centers, particularly in the U.S. and Canada. The region benefits from substantial private and governmental investments in genomics and proteomics, coupled with a well-established infrastructure for clinical trials and novel drug development. High adoption rates of cutting-edge technologies like high-resolution mass spectrometry and automated liquid handling systems further solidify North America's position, ensuring continuous demand for high-performance immobilized enzyme products used in mandated regulatory characterization.

Europe represents the second largest market, driven primarily by the strong presence of major pharmaceutical innovators (e.g., in Germany, Switzerland, and the UK) and robust public funding programs like Horizon Europe, which prioritize advanced life science research and bioprocess optimization. Regulatory agencies within Europe have stringent requirements for biotherapeutic characterization, compelling manufacturers to adopt standardized, highly reliable sample preparation tools. The market is also heavily influenced by the adoption of continuous biomanufacturing techniques, wherein immobilized trypsin columns are essential for in-line product quality monitoring and large-scale peptide production.

The Asia Pacific (APAC) region is forecasted to be the fastest-growing market, propelled by rapid economic expansion, increasing healthcare expenditure, and governmental policies supporting domestic biotechnology development in countries such as China, Japan, and India. The outsourcing of biopharma manufacturing and research activities to APAC countries, particularly to large CMOs and CROs, significantly boosts the demand for high-throughput, cost-effective immobilized enzymes. While currently lagging in total market size, the rapid establishment of advanced research facilities and the growing patient population requiring complex diagnostics ensure that APAC will be the primary engine of market growth throughout the forecast period.

- North America (U.S., Canada): Market leader due to high R&D spending, established biopharma industry, and early adoption of automated proteomics workflows.

- Europe (Germany, UK, France): Strong second market, driven by advanced biomanufacturing adoption and strict regulatory requirements for biotherapeutic characterization.

- Asia Pacific (China, Japan, India, South Korea): Fastest growth region, characterized by increasing outsourcing activities, expanding domestic biotech sector, and rising government investment in life sciences.

- Latin America & MEA: Emerging markets focusing on local diagnostic and clinical applications, gradually improving research infrastructure, and slowly increasing adoption of established proteomics tools.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Immobilized Trypsin Market.- Thermo Fisher Scientific

- Merck KGaA (Sigma-Aldrich)

- Promega Corporation

- GE Healthcare (Cytiva)

- Bio-Rad Laboratories

- New England Biolabs (NEB)

- Agilent Technologies

- Abcam plc

- GenScript Biotech Corporation

- Takara Bio Inc.

- SaniSure

- Purolite Corporation

- Danaher Corporation (Pall/Beckman Coulter)

- Novozymes A/S

- Roche Diagnostics

- Biocon Ltd.

- Lonza Group AG

- BBI Solutions

- OriGene Technologies

- Creative Enzymes

Frequently Asked Questions

Analyze common user questions about the Immobilized Trypsin market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using immobilized trypsin over native, free trypsin in proteomics?

Immobilized trypsin offers significant advantages in efficiency and reproducibility, primarily through increased thermal and chemical stability, prevention of enzyme autolysis (self-digestion), and ease of separation (simplifying downstream analysis). Its reusability drastically reduces the cost per reaction and makes it ideal for automated, high-throughput workflows necessary for advanced proteomics research and biopharma quality control.

Which matrix type is experiencing the fastest growth in the immobilized trypsin market?

Magnetic particles are the fastest-growing matrix segment. Their suitability for automation, combined with the rapid magnetic separation capabilities, dramatically speeds up sample preparation time, making them highly desirable for high-throughput screening (HTS), clinical diagnostics, and robotic proteomics platforms where speed and scalability are crucial performance indicators.

How does the immobilization process affect the operational life and stability of the enzyme?

Covalent immobilization significantly extends the operational life of trypsin by physically restricting its movement and preventing the intermolecular interactions that lead to autolytic degradation. The enzyme's resistance to thermal and pH variations is enhanced, allowing it to maintain catalytic activity over repeated cycles and broader operational parameters essential for continuous bioprocessing applications.

What key technological innovations are currently driving the immobilized trypsin market?

Key technological advancements include the development of novel, highly specific linkage chemistries (like click chemistry) to ensure minimal active site disruption during coupling. Additionally, advancements in microfluidic reactor design and the integration of highly porous, custom polymeric supports are improving mass transfer and enzyme loading capacity for highly efficient, small-volume digestions.

Which end-user segment contributes the most to the overall revenue of the immobilized trypsin market?

Biotechnology and Pharmaceutical companies constitute the largest revenue segment. This is driven by their critical and non-negotiable need for reproducible protein characterization, peptide mapping, and quality control (QC) testing of biotherapeutic products, necessitating robust and standardized immobilized enzyme systems for GxP compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager