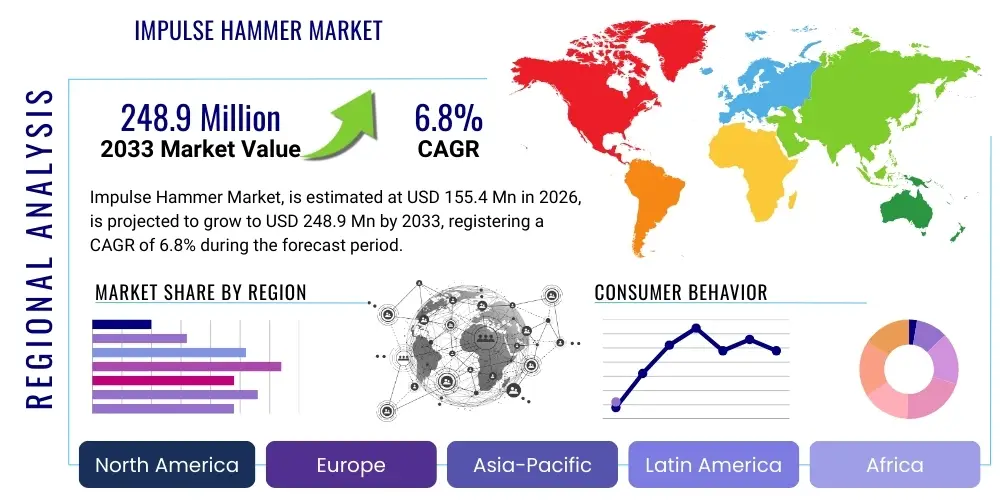

Impulse Hammer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437921 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Impulse Hammer Market Size

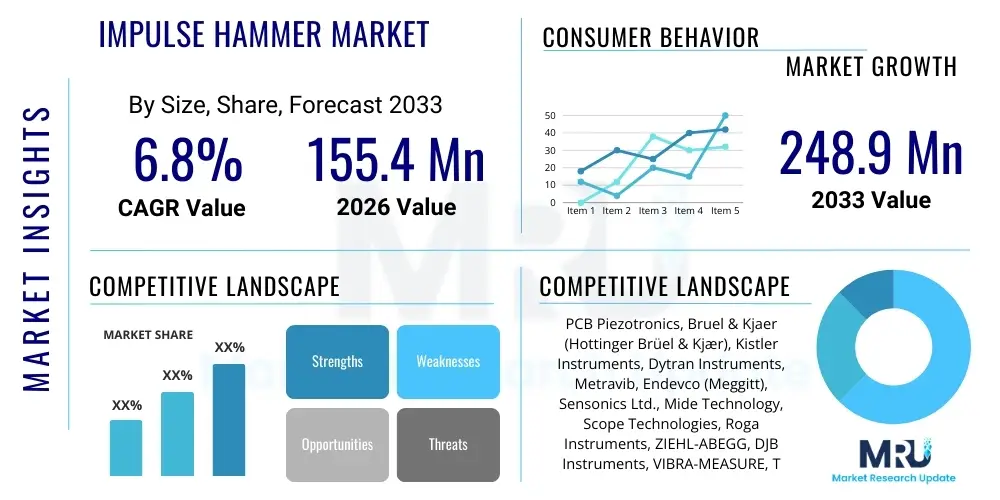

The Impulse Hammer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 155.4 million in 2026 and is projected to reach USD 248.9 million by the end of the forecast period in 2033.

Impulse Hammer Market introduction

The Impulse Hammer Market encompasses specialized electromechanical instruments designed to apply a quantifiable, short-duration force impulse to a structure or material for the purpose of dynamic testing, primarily modal analysis and structural integrity assessment. These precision tools integrate a force sensor, typically piezoelectric or piezoresistive, within the striking tip, allowing researchers and engineers to accurately measure the magnitude and temporal characteristics of the input force. The fundamental principle revolves around characterizing the dynamic response (e.g., acceleration or vibration) of a tested object when excited by this impulse, enabling the identification of natural frequencies, damping ratios, and mode shapes, which are critical parameters in fields ranging from aerospace engineering to civil infrastructure monitoring.

Impulse hammers are indispensable across diverse industries due to their versatility and non-destructive testing (NDT) capabilities. Major applications include quality control in manufacturing, where they verify the structural soundness of components like turbine blades and engine parts; predictive maintenance in industrial settings, where they help diagnose mechanical issues by analyzing changes in vibration signatures; and research and development for new material characterization. The benefits of using impulse hammers are manifold, providing highly accurate, repeatable excitation inputs necessary for complex frequency response function (FRF) measurements. Furthermore, they are highly portable and generally easier to set up than shaker systems, making them ideal for in-situ field testing and dynamic measurements on large structures such as bridges, buildings, and industrial machinery.

Driving factors for this specialized market include the increasing global emphasis on infrastructure safety and longevity, requiring regular NDT procedures on aging assets. Furthermore, the relentless pursuit of lighter yet stronger materials in the aerospace and automotive sectors necessitates advanced dynamic testing to ensure structural reliability under operational stress. The continuous advancement in sensor technology, signal conditioning electronics, and data acquisition systems that pair with impulse hammers enhances their accuracy and usability, fueling their broader adoption across academic research institutions and commercial testing laboratories worldwide. The integration of these tools with modern computerized analysis techniques is fundamentally changing how dynamic measurements are performed and interpreted.

Impulse Hammer Market Executive Summary

The Impulse Hammer Market is experiencing robust growth driven by the burgeoning demand for reliable structural health monitoring solutions and the pervasive integration of these testing methodologies into predictive maintenance schedules across critical industries. Business trends show a distinct movement toward wireless and miniaturized impulse hammers, allowing for easier access to complex testing points and reduced setup time, aligning perfectly with Industry 4.0 mandates for efficiency. Furthermore, strategic partnerships between impulse hammer manufacturers and specialized software providers are key, focusing on delivering integrated solutions that streamline data acquisition, processing, and advanced modal analysis, thereby increasing the value proposition for end-users seeking comprehensive diagnostic tools rather than just hardware components.

Regional trends indicate that the Asia Pacific (APAC) region is emerging as the fastest-growing market segment, primarily propelled by massive investments in new infrastructure projects, burgeoning manufacturing capabilities, particularly in China and India, and increased regulatory enforcement regarding structural safety standards. North America and Europe, while mature markets, continue to lead in terms of technological adoption and high-end specialized applications, particularly within aerospace, defense, and high-precision R&D sectors, focusing on ultra-low force and high-frequency measurements. These established regions also exhibit a strong demand for sophisticated calibration and maintenance services, contributing significantly to the aftermarket service segment of the market.

Segment trends highlight the dominance of medium-force impulse hammers due to their wide applicability across automotive and industrial machinery testing. However, the high-growth segments are micro and miniature hammers, which cater to the testing of small, lightweight, and sensitive electronic components and composite materials, crucial for modern electronics and specialized defense applications. The application segment is heavily skewed towards modal analysis, which remains the primary driver for impulse hammer utilization, although structural health monitoring (SHM) applications are rapidly gaining momentum, necessitating the development of more rugged, environmentally resistant hammer designs suitable for continuous field deployment and data collection.

AI Impact Analysis on Impulse Hammer Market

User queries regarding the intersection of Artificial Intelligence (AI) and the Impulse Hammer Market commonly focus on how AI can automate complex measurement protocols, interpret large volumes of dynamic response data, and enhance the predictive capabilities of structural health monitoring systems. Key concerns center around the reliability of AI-driven defect identification, the need for standardized training datasets for modal analysis interpretation, and the integration complexity of AI algorithms with existing proprietary data acquisition hardware. Users are highly expectant that AI will move the diagnostic process beyond simple frequency analysis, enabling sophisticated anomaly detection and life prediction based on subtle changes in the frequency response functions (FRFs) generated by impulse hammer tests.

AI's primary influence is manifesting in the post-processing phase, transforming raw dynamic measurements into actionable diagnostic insights. Traditional modal analysis requires significant expertise to correctly identify modes, separate noise, and adjust parameters. Machine learning algorithms are now being trained on extensive datasets of healthy and degraded structures to automatically perform mode shape extraction, parameter estimation, and comparative analysis against baseline data. This automation dramatically reduces the analysis time and decreases the dependency on highly specialized dynamic testing experts, thereby broadening the accessibility and applicability of impulse hammer diagnostics to general engineering teams.

Furthermore, AI facilitates predictive maintenance by identifying subtle shifts in a structure’s dynamic characteristics long before failure is imminent. By continuously analyzing the impact response signatures from periodic impulse hammer tests, deep learning models can track degradation progression in composites or metal structures with high precision. This capability transforms the impulse hammer from a snapshot diagnostic tool into a vital component of a comprehensive, real-time or near-real-time structural integrity management system, driving demand for smart, connected impulse hammers featuring integrated edge computing capabilities for rapid, localized AI-driven data processing.

- Automation of Modal Parameter Estimation: AI algorithms analyze FRFs to automatically identify natural frequencies, damping ratios, and mode shapes, minimizing manual interpretation errors.

- Predictive Anomaly Detection: Machine learning models track minor deviations in dynamic signatures over time to predict component fatigue or structural failure proactively.

- Optimized Test Procedures: AI recommends optimal impulse locations and data acquisition settings based on the geometry and material properties of the structure being tested.

- Enhanced Noise Filtering: AI-driven signal processing improves the signal-to-noise ratio in complex industrial environments, ensuring cleaner data inputs for analysis.

- Automated Reporting and Diagnosis: Integration of AI generates comprehensive structural health reports, summarizing conditions and recommending maintenance actions.

DRO & Impact Forces Of Impulse Hammer Market

The Impulse Hammer Market is shaped by a confluence of accelerating drivers, structural restraints, significant opportunities for technological expansion, and intense competitive forces that govern its growth trajectory. Key drivers include the escalating global investment in smart cities and critical infrastructure refurbishment, which mandates rigorous NDT and structural health monitoring (SHM) protocols. Furthermore, regulatory frameworks, particularly in highly engineered sectors such as aerospace, nuclear energy, and railway transport, are becoming stricter, compelling organizations to adopt high-precision dynamic testing equipment like impulse hammers to ensure compliance and operational safety.

Restraints impeding market potential primarily relate to the technical complexity associated with accurate impulse testing. Achieving precise, repeatable measurements requires specialized knowledge regarding sensor calibration, proper mounting techniques for accelerometers, and advanced signal processing skills. The initial cost of high-quality impulse hammers, particularly those with wide dynamic ranges and sophisticated data acquisition systems, remains substantial, posing a barrier to entry for smaller engineering firms or educational institutions. Moreover, competitive pressure from alternative testing methods, such as non-contact laser vibrometry or specialized ultrasonic testing, offers viable alternatives in specific niche applications, requiring impulse hammer manufacturers to continuously justify the cost-effectiveness and versatility of their products.

Opportunities for market expansion are significant, particularly through the development of fully integrated, wireless dynamic testing kits that simplify data capture and analysis through cloud connectivity. Miniaturization, coupled with enhanced sensor technology capable of operating reliably in harsh environments (extreme temperatures, high humidity), opens new avenues in in-situ monitoring within confined or difficult-to-access industrial environments. The emerging global focus on composite materials testing in the wind energy and defense sectors, where unique challenges exist in detecting internal delamination and subtle damage, presents a strong market niche requiring specialized impulse hammer tips and optimized force ranges. The increasing adoption of digital twins also necessitates highly accurate input data from physical tests, positioning impulse hammers as crucial data feeders for virtual structural models.

Segmentation Analysis

The Impulse Hammer Market is rigorously segmented based on crucial parameters, primarily defined by the characteristics of the impact force generated, the material of the striking tip, and the intended application area. Segmentation by force range (Low, Medium, High) is critical as it dictates the suitability of the hammer for testing structures ranging from small electronics components requiring sub-Newton forces to massive concrete beams needing kilo-Newton impacts. The design intricacies, sensor types, and necessary signal conditioning vary significantly across these force ranges, resulting in specialized product lines catering to distinct engineering requirements.

Segmentation by Tip Material (e.g., Plastic, Rubber, Steel, Aluminum, Nylon) determines the frequency content of the impulse—a harder tip (steel) generates a shorter pulse duration, resulting in higher frequency excitation, ideal for small, stiff structures. Conversely, softer tips (rubber/plastic) produce a longer pulse, concentrating energy at lower frequencies, suitable for testing large, flexible structures like building components. This segmentation allows end-users to precisely tune the excitation characteristics to the specific modal properties of the structure under investigation, ensuring the acquisition of meaningful and comprehensive frequency response data.

Further segmentation by application highlights the key industries driving demand, including Automotive R&D, Aerospace and Defense, Civil Engineering, and Industrial Machinery Monitoring. The distinct requirements of each sector—for instance, high-frequency, precision testing in aerospace versus low-frequency, rugged field testing in civil engineering—drive innovation in hammer design, leading to diversified product offerings and tailored measurement solutions. This detailed segmentation aids manufacturers in targeting specific customer needs and optimizing their product portfolios for maximum market penetration and technological relevance.

- By Force Range:

- Low Force Impulse Hammers (1 N to 500 N)

- Medium Force Impulse Hammers (500 N to 5 kN)

- High Force Impulse Hammers (5 kN and above)

- By Tip Material:

- Metal Tips (Steel, Aluminum)

- Polymer Tips (Plastic, Nylon, Teflon)

- Rubber Tips

- By Application:

- Modal Analysis

- Structural Health Monitoring (SHM)

- Acoustic & Noise Testing (NVH)

- Experimental Structural Dynamics (ESD)

- By End-User Industry:

- Aerospace & Defense

- Automotive

- Civil Infrastructure

- Industrial Machinery & Manufacturing

- Power Generation (Wind, Nuclear)

- Academia & Research

Value Chain Analysis For Impulse Hammer Market

The value chain for the Impulse Hammer Market is highly specialized, beginning with the meticulous upstream analysis involving the sourcing and processing of high-performance materials, particularly piezoelectric ceramics (like PZT) and precision alloys for hammer bodies and internal components. The quality and stability of the piezoelectric material are paramount as they directly influence the linearity, sensitivity, and temperature stability of the force sensor element, which is the core functional component. Manufacturing involves complex assembly processes, including micro-welding and high-precision calibration, followed by stringent quality control tests to ensure the measured impulse force corresponds exactly to the electrical output signal across the required dynamic range and frequency spectrum.

Midstream activities involve the integration of the impulse hammer with data acquisition (DAQ) systems and proprietary analysis software. Many manufacturers offer complete, bundled solutions that include signal conditioners, DAQ hardware, and dedicated modal analysis platforms. This integration requires significant software development expertise, ensuring seamless data transfer and compatibility with industry-standard analysis formats (e.g., Universal File Format). Branding, packaging, and technical documentation, which is crucial due to the highly technical nature of the product, also occur in this stage, preparing the specialized equipment for market entry.

Downstream analysis focuses on distribution channels, which are typically indirect through highly specialized technical distributors, representatives, and value-added resellers (VARs) who possess deep expertise in dynamic testing and vibration analysis. Direct sales are common for large volume customers, particularly major automotive or aerospace R&D centers. These distribution channels must be capable of providing localized technical support, calibration services, and post-sales maintenance, which are critical differentiators in this market. The final stage involves calibration services and repairs, forming a significant aftermarket segment that ensures the long-term accuracy and reliability of the high-precision equipment throughout its lifecycle, often managed directly by the original equipment manufacturer (OEM) or certified service centers.

Impulse Hammer Market Potential Customers

Potential customers and end-users of impulse hammers span a wide array of technical and engineering disciplines, all united by the need for non-destructive dynamic testing and structural integrity assessment. The primary target audience includes R&D departments in high-tech manufacturing sectors, particularly aerospace and automotive, where the validation of design models through experimental modal analysis is a mandatory step in product development. These customers utilize impulse hammers to determine the vibration characteristics of prototypes, ensuring they meet stringent performance and safety criteria under dynamic loading conditions, which is essential for components like engine mounts, chassis structures, and aircraft wings.

A rapidly expanding customer base is found within civil engineering and infrastructure maintenance organizations, including government transportation departments and private structural consulting firms. These groups employ high-force impulse hammers for assessing the health of large structures such as bridges, dams, and historic buildings, often as part of routine structural health monitoring programs. The results help engineers identify damage, measure structural flexibility, and predict remaining service life, ensuring public safety and optimizing repair schedules, thereby reducing unexpected failures and maintenance costs.

Furthermore, educational institutions (universities and technical colleges) constitute a consistent customer segment, purchasing impulse hammers for teaching experimental modal analysis and advanced vibration theory to future engineers and researchers. Industrial machinery operators, specifically in power generation (turbines, generators) and processing plants, represent another core group. They rely on impulse hammers for fast, preliminary diagnosis during predictive maintenance routines, identifying loose components or developing cracks through deviations in vibration signatures before resorting to more extensive diagnostic procedures. The demand for reliable, repeatable measurements across all these diverse sectors solidifies the customer base for specialized impulse hammer technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 155.4 Million |

| Market Forecast in 2033 | USD 248.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | PCB Piezotronics, Bruel & Kjaer (Hottinger Brüel & Kjær), Kistler Instruments, Dytran Instruments, Metravib, Endevco (Meggitt), Sensonics Ltd., Mide Technology, Scope Technologies, Roga Instruments, ZIEHL-ABEGG, DJB Instruments, VIBRA-MEASURE, TMI-Orion, GRAS Sound & Vibration, IMI Sensors, VIBRALIGN, VTS Sensor Technology, Ono Sokki, HIOKI E.E. CORPORATION |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Impulse Hammer Market Key Technology Landscape

The technological landscape of the Impulse Hammer Market is defined by continuous innovation in sensor design, signal conditioning, and integration capabilities, aimed at enhancing measurement accuracy, repeatability, and ease of use. A major focus is on optimizing the piezoelectric sensor element to achieve superior linearity across a wider dynamic range and minimize thermal drift, ensuring the fidelity of the force signal irrespective of ambient environmental conditions. Manufacturers are increasingly utilizing advanced material science, including specialized ceramics and quartz, to refine the sensing element, allowing hammers to accurately capture both extremely low-force impacts required for composite testing and high-force impacts for civil engineering structures, without compromising sensitivity or survivability.

Wireless technology integration represents a pivotal technological shift. Modern impulse hammers are moving away from traditional cabled connections to integrate Bluetooth Low Energy (BLE) or proprietary wireless protocols for communication with data acquisition systems. This eliminates the operational constraints imposed by cables, simplifying setup in complex industrial environments and enabling synchronized, distributed testing across large structures. Furthermore, the incorporation of smart electronics, including integrated TEDS (Transducer Electronic Data Sheet) chips, allows the hammer to self-identify to the connected DAQ system, automatically loading calibration data and eliminating manual setup errors, thereby accelerating the testing cycle significantly.

Another crucial technological development involves the sophistication of interchangeable tips and mass adaptors. Engineers require precise control over the impulse frequency spectrum, which is directly manipulated by the stiffness and mass of the striking tip. Advanced hammers now feature quick-change mechanisms and extensive tip kits made from engineered polymers and metal alloys, allowing users to precisely tailor the input energy to excite specific modes of interest in the structure. Coupled with advanced digital signal processing (DSP) embedded within the signal conditioner, these technological advancements ensure that impulse hammers remain at the forefront of experimental structural dynamics testing, offering high precision and adaptability necessary for complex, modern engineering challenges.

Regional Highlights

- North America (NA): Leading the market in high-value, R&D-intensive applications, particularly within aerospace, defense, and advanced automotive sectors. The region benefits from stringent regulatory requirements for NDT and a mature technological ecosystem supporting advanced dynamic testing and predictive maintenance adoption. Major growth is driven by demand for ultra-precision, low-force hammers for composite material analysis.

- Europe: Characterized by strong adoption in the industrial machinery, automotive manufacturing (NVH testing), and power generation sectors. European regulations regarding machinery safety and vibration exposure are among the strictest globally, necessitating continuous monitoring and detailed modal analysis, driving steady demand for high-quality impulse hammer systems, especially in Germany, France, and the UK.

- Asia Pacific (APAC): Expected to register the highest CAGR due to rapid urbanization, massive infrastructure development (bridges, high-speed rail, smart cities), and the expansion of domestic automotive and electronics manufacturing bases, particularly in China and India. The demand here is growing rapidly for both medium-force impulse hammers for general industry and high-force hammers for large civil engineering projects.

- Latin America (LATAM): A developing market focused primarily on mining, oil & gas, and basic infrastructure projects. Adoption is growing as industries move from reactive to predictive maintenance strategies, creating localized demand for rugged, reliable impulse hammers for monitoring large machinery and process equipment.

- Middle East and Africa (MEA): Growth is concentrated in the Gulf Cooperation Council (GCC) states, driven by large-scale construction projects, oil and gas infrastructure, and defense spending. Demand is focused on robust equipment capable of functioning reliably under extreme heat and dusty conditions for asset integrity management and structural assessments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Impulse Hammer Market.- PCB Piezotronics (A PCB Group Company)

- Bruel & Kjaer (HBK - Hottinger Brüel & Kjær)

- Kistler Instruments AG

- Dytran Instruments, Inc.

- Endevco (Meggitt PLC)

- Metravib SAS

- Sensors, Inc.

- IMI Sensors

- Roga Instruments GmbH

- DJB Instruments Ltd.

- VIBRA-MEASURE SAS

- Mide Technology Corporation

- GRAS Sound & Vibration A/S

- Ono Sokki Co., Ltd.

- TMI-Orion

- VTS Sensor Technology

- HIOKI E.E. CORPORATION

- The Modal Shop, Inc.

- Teledyne LeCroy (QuantumX)

- National Instruments (NI)

Frequently Asked Questions

Analyze common user questions about the Impulse Hammer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an impulse hammer in structural testing?

The primary function of an impulse hammer is to excite a structure with a short, quantifiable, mechanical force pulse, which is necessary for experimental modal analysis. The integrated force sensor measures the precise input force, allowing engineers to calculate the Frequency Response Function (FRF) when paired with an accelerometer measuring the structure’s resulting vibration. This data is essential for identifying natural frequencies, mode shapes, and damping characteristics crucial for structural integrity assessment and validation.

How does the choice of hammer tip material affect dynamic testing results?

The hammer tip material directly determines the duration of the impact pulse, which in turn defines the bandwidth or range of frequencies excited. Hard tips (e.g., steel or aluminum) create a very short pulse, exciting high frequencies, suitable for small, stiff structures like machine parts. Conversely, soft tips (e.g., rubber or polymer) produce a longer pulse, concentrating energy at lower frequencies, which is ideal for large, flexible structures such as bridges or building sections. Selecting the correct tip is vital for capturing meaningful modal data within the required frequency range.

What is the significance of the Impulse Hammer Market's growth in the Asia Pacific region?

The rapid growth of the Impulse Hammer Market in the Asia Pacific (APAC) region is driven primarily by extensive government investment in new infrastructure projects, including high-speed railways, large-scale construction, and modernization of manufacturing facilities. Increased regulatory pressure for structural safety and the swift adoption of predictive maintenance techniques in industrial sectors mandate the use of advanced NDT tools like impulse hammers for quality control and structural health monitoring (SHM), positioning APAC as the highest growth area.

How is AI specifically impacting the operational efficiency of impulse hammer testing?

AI significantly enhances the operational efficiency of impulse hammer testing primarily by automating complex data analysis. Machine learning algorithms are used for automated modal parameter estimation, instantaneously identifying natural frequencies and mode shapes from acquired FRF data. This reduces reliance on highly specialized expertise, accelerates the post-processing phase, and improves the reliability of predictive anomaly detection by comparing current structural responses against historical and baseline models.

What are the main technical challenges restraining broader adoption of impulse hammers?

The main technical challenges restraining broader adoption include the high initial equipment cost associated with precision sensor technology and the necessary, sophisticated data acquisition systems. Furthermore, achieving highly accurate and repeatable results demands specialized expertise in sensor mounting, environmental compensation, and signal processing. Maintaining calibration accuracy over time and in harsh field environments also presents a significant logistical and technical hurdle for many potential end-users.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager